In the realm of mechanical systems, comprehending the intricate assembly of various elements is essential for effective maintenance and troubleshooting. This knowledge empowers users to identify and replace malfunctioning segments, ensuring optimal performance and longevity of their machinery.

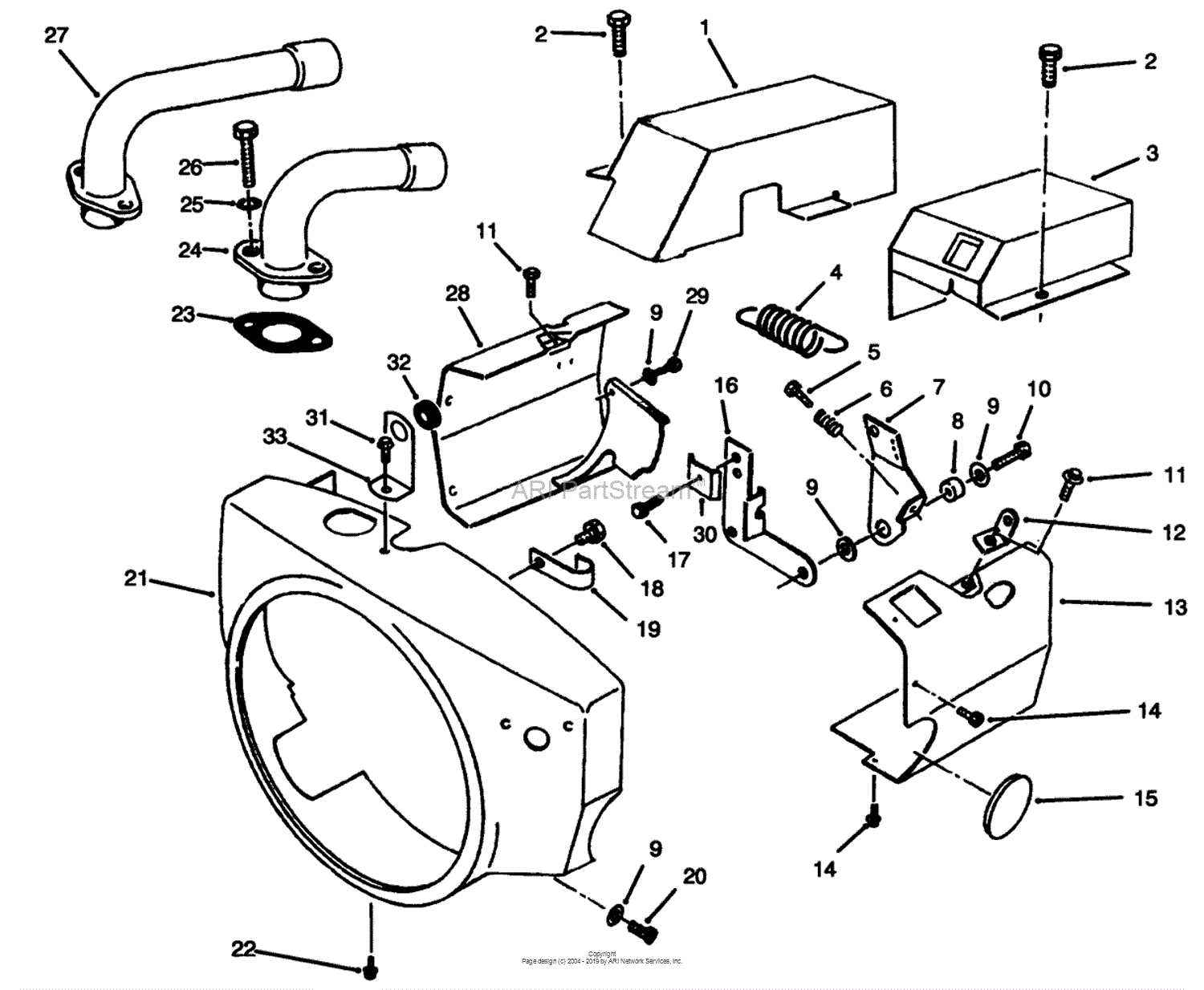

The following discussion delves into a detailed visual representation that highlights each component’s function and placement. Such an illustration serves as a valuable resource for both seasoned technicians and enthusiastic hobbyists alike, providing clarity on how the unit operates as a cohesive whole.

By familiarizing oneself with the layout and interrelationships of these crucial components, one can significantly enhance repair efficiency and reduce downtime. Whether for routine servicing or unexpected repairs, this understanding is vital for anyone looking to keep their equipment running smoothly.

Understanding the Onan P220 Engine

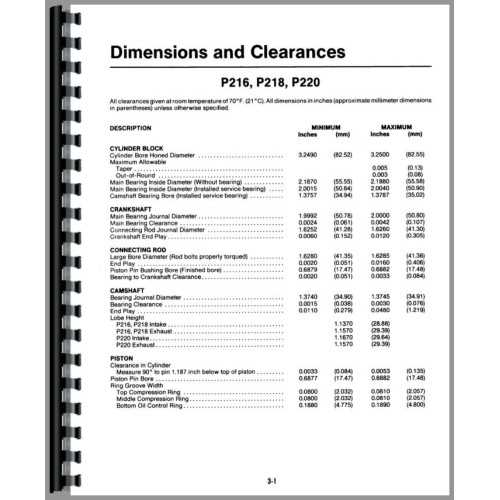

The mechanical unit in question is a robust piece of machinery widely utilized in various applications, known for its reliability and efficiency. This model has been designed to deliver optimal performance, making it a popular choice among users seeking dependable operation. A thorough comprehension of its components and functionality is essential for effective maintenance and troubleshooting.

At the heart of this system lies a complex arrangement of elements that work in unison to generate power. Each segment plays a vital role, contributing to the overall efficiency and durability of the unit. Familiarity with these individual components enhances one’s ability to diagnose issues and ensure smooth operation over time.

In essence, understanding this machinery involves more than just recognizing its parts; it requires a deeper insight into how each element interacts within the assembly. By grasping the fundamentals of its design and function, users can make informed decisions regarding care and usage, ultimately extending the life of the unit and maximizing its potential.

Key Components of the Onan P220

This section delves into the essential elements that make up a specific power unit, focusing on their functionality and interrelation. Understanding these vital components is crucial for effective maintenance and operation, ensuring optimal performance and longevity.

Major Elements

Each vital part plays a significant role in the overall efficiency and reliability of the system. From the combustion mechanism to the cooling system, every element is designed to work harmoniously.

Component Overview

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, converting fuel into mechanical energy. |

| Piston | Moves up and down within the cylinder, creating pressure for energy production. |

| Crankshaft | Transforms linear motion from the piston into rotational motion, powering external applications. |

| Ignition System | Initiates combustion by providing a spark at the appropriate moment. |

| Cooling System | Regulates temperature to prevent overheating during operation. |

| Fuel System | Delivers the necessary fuel to the combustion chamber efficiently. |

Understanding these core components enhances troubleshooting abilities and promotes more informed decisions regarding maintenance practices, ensuring a reliable power source for various applications.

Importance of Engine Diagrams

Understanding the intricate layout of a mechanical unit is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling technicians and enthusiasts alike to grasp complex systems quickly. These illustrations facilitate not only troubleshooting but also enhance the learning experience for those new to the field.

Enhanced Troubleshooting

When a malfunction occurs, having a clear visual reference can significantly expedite the diagnostic process. By pinpointing components and their interconnections, individuals can identify issues more efficiently. This clarity reduces the time spent guessing, ultimately leading to quicker resolutions and less downtime.

Facilitating Learning and Knowledge Sharing

Visual aids play a vital role in education, allowing learners to visualize abstract concepts. Whether for training purposes or collaborative projects, these resources foster a deeper understanding of mechanical systems. Additionally, they promote effective communication among team members, ensuring everyone is on the same page.

In conclusion, the value of visual representations in the realm of mechanics cannot be overstated. They are indispensable for both immediate problem-solving and long-term educational growth.

How to Read Engine Diagrams

Understanding technical illustrations can significantly enhance your ability to work with mechanical systems. These visual aids serve as guides, offering insights into the structure and functionality of various components. By familiarizing yourself with the conventions and symbols used in these visuals, you can streamline your repair or maintenance tasks.

First, identify the key elements present in the illustration. Components are often labeled with letters or numbers, which correspond to a legend or key that explains their function. This reference is crucial for deciphering the relationships and roles of different parts.

Next, pay attention to the orientation and layout. Most visuals follow a specific flow, typically depicting the sequence of assembly or operation. Recognizing the arrangement can help you understand how various elements interact within the system.

Additionally, familiarize yourself with common symbols used in these visuals. Icons may represent electrical connections, fluid pathways, or mechanical movements. A solid grasp of these representations will aid in troubleshooting and assembly processes.

Finally, practice makes perfect. Regularly consulting and analyzing different illustrations will enhance your confidence and efficiency in interpreting them. Over time, you’ll find that reading these visual guides becomes second nature.

Common Issues with Onan P220

Mechanical systems often face a range of challenges that can affect their performance and longevity. Understanding these common problems can help users identify symptoms early and address them effectively. This section will explore typical complications encountered with this type of machinery, providing insights into their causes and potential solutions.

One frequent concern is overheating, which can stem from inadequate cooling or blocked airflow. Users should regularly check coolant levels and ensure that vents are free from debris to prevent this issue. Another prevalent problem is fuel supply inconsistency, which can lead to stalling or poor performance. It’s crucial to inspect fuel lines and filters regularly for clogs or leaks.

Electrical malfunctions are also common, particularly related to the ignition system. Faulty spark plugs or weak batteries can cause starting difficulties. Regular maintenance of electrical components can help avoid such issues. Lastly, abnormal noises during operation might indicate internal wear or damage, warranting immediate inspection to prevent further complications.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring optimal performance and extending the lifespan of machinery. Implementing a routine maintenance schedule can prevent unexpected breakdowns and enhance efficiency. Here are some effective strategies to keep your equipment in peak condition.

Regular Inspections

Conducting frequent checks is vital. Look for signs of wear and tear, leaks, or unusual noises. Early detection can save you time and resources.

- Inspect belts and hoses for cracks or fraying.

- Check fluid levels and top off as necessary.

- Examine filters and replace them regularly.

Cleaning Procedures

Keeping your machinery clean can significantly improve its performance. Dirt and debris can lead to overheating and other issues.

- Clear away dust and grime from air intakes and vents.

- Wash exterior surfaces to prevent corrosion.

- Use appropriate cleaning agents that do not damage components.

By following these maintenance tips, you can enhance reliability and ensure your machinery remains functional for years to come.

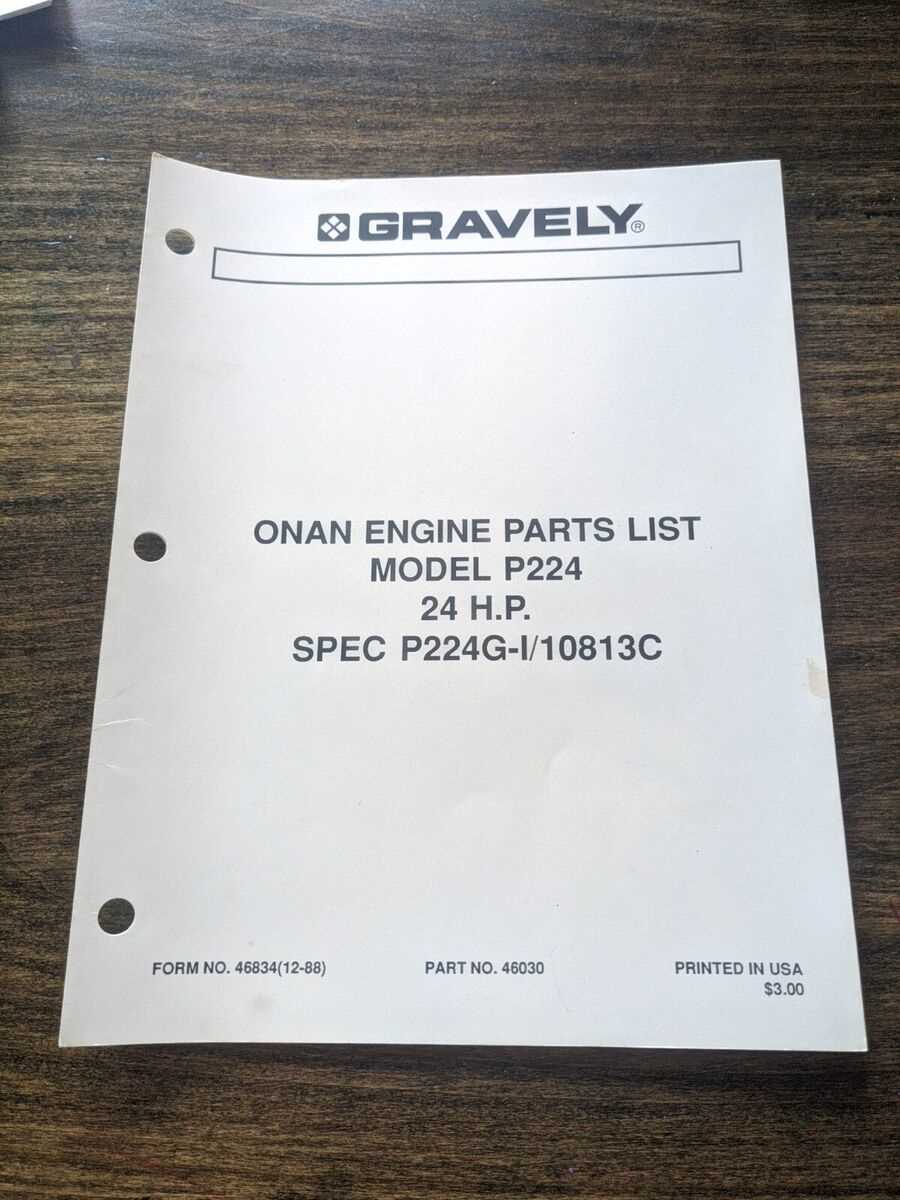

Replacement Parts Availability

Access to suitable components is essential for maintaining the optimal functionality of any machinery. A reliable supply of these items ensures that users can easily source what they need to keep their equipment in peak condition. Understanding the options available for procurement can significantly enhance operational efficiency.

Where to Find Components

Several avenues exist for locating necessary replacements:

- Authorized dealers and distributors

- Online marketplaces

- Local repair shops

- Specialty retailers

Factors Influencing Availability

Several factors may affect the accessibility of these crucial items:

- Demand and supply fluctuations

- Geographic location

- Model popularity and production status

- Lead time for special orders

Being aware of these elements can help users make informed decisions when seeking replacements, ultimately supporting uninterrupted performance of their machinery.

Identifying Genuine Onan Parts

When it comes to maintaining your machinery, ensuring that you use authentic components is crucial for optimal performance and longevity. Recognizing the difference between original and counterfeit items can save you from costly repairs and inefficiencies. In this section, we will explore key indicators that help distinguish genuine components from imitations.

Key Features to Look For

One of the most effective ways to verify authenticity is by examining the labeling and packaging. Authentic items often feature clear branding and high-quality materials. Check for any inconsistencies in logos, fonts, or colors that might indicate a fake. Additionally, original components typically come with detailed product information, including serial numbers and warranty details, which can often be verified through official channels.

Where to Purchase

Buying from authorized dealers is another vital step in ensuring you receive genuine components. Reputable suppliers often have a solid return policy and customer support, providing peace of mind. Be cautious of overly discounted items from unofficial sources, as these may be red flags for counterfeit goods.

Investing time in identifying authentic components not only enhances the performance of your machinery but also protects your investment in the long run.

Assembly and Disassembly Guidelines

This section provides essential instructions for the careful assembly and disassembly of mechanical units. Proper procedures ensure the longevity and functionality of components while minimizing the risk of damage. Following these guidelines will help maintain optimal performance and reliability.

Before beginning the process, it is crucial to gather all necessary tools and equipment. Ensure that the workspace is clean and organized to facilitate smooth operation. Additionally, consult the relevant documentation for specific instructions related to the model in use.

| Step | Description |

|---|---|

| 1 | Prepare the workspace and gather all required tools. |

| 2 | Carefully label and organize components for easier reassembly. |

| 3 | Follow the reverse order of assembly for disassembly. |

| 4 | Use appropriate force and techniques to avoid damaging parts. |

| 5 | Inspect all components for wear or damage before reassembly. |

| 6 | Reassemble by following the manufacturer’s specified sequence. |

By adhering to these guidelines, the risks associated with disassembling and reassembling mechanical units can be significantly reduced. Always prioritize safety and precision throughout the process.

Resources for Troubleshooting Problems

Identifying and resolving issues with machinery can be challenging, but having access to the right resources can simplify the process significantly. By utilizing manuals, forums, and diagnostic tools, users can efficiently navigate through common malfunctions and ensure optimal performance of their equipment.

User Manuals and Technical Guides

Comprehensive user manuals and technical guides provide essential information about the functionality and maintenance of your device. These resources often include troubleshooting sections that outline common issues and step-by-step solutions. Consulting these documents can help in diagnosing problems quickly and accurately.

Online Forums and Communities

Engaging with online forums and communities dedicated to machinery can be invaluable. Experienced users often share insights, troubleshooting tips, and solutions to similar problems. Participating in these discussions can broaden your understanding and provide practical advice that may not be available in traditional manuals.