The inner workings of a vehicle’s power system are a marvel of engineering, intricately designed to convert fuel into motion. Each element plays a crucial role, working in harmony to ensure optimal performance and efficiency. Gaining insight into these components provides a deeper appreciation for the technology that drives us forward.

In this exploration, we will delve into the various sections that contribute to the overall functionality of the mechanism. By examining their individual roles and interactions, we can better understand the ultimate objective: seamless operation and reliability on the road.

From the initial intake of fuel to the expulsion of exhaust, each segment is vital to the entire process. Understanding these intricate relationships allows enthusiasts and everyday drivers alike to grasp how their vehicles truly function.

Understanding Car Engine Components

Gaining insight into the intricate mechanisms that drive a vehicle reveals the harmony of various elements working together. Each unit plays a critical role in ensuring optimal performance and efficiency. A deeper comprehension of these vital components is essential for enthusiasts and professionals alike.

| Component | Description |

|---|---|

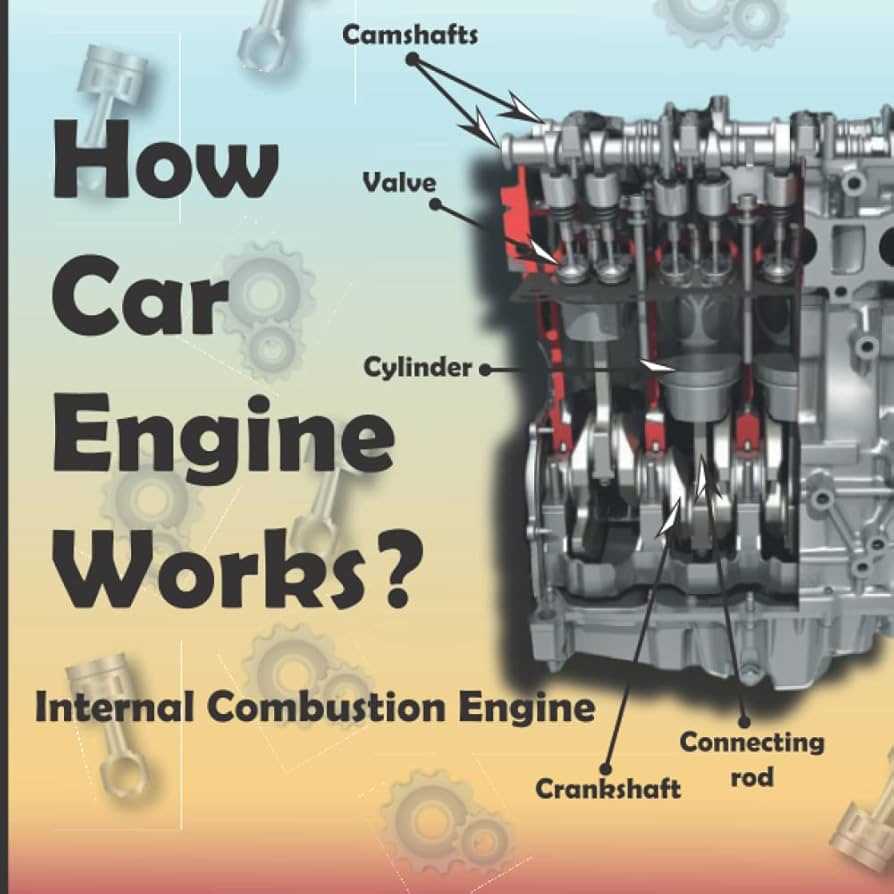

| Piston | Translates the force from combustion into mechanical energy. |

| Crankshaft | Converts the linear motion of pistons into rotational motion. |

| Camshaft | Regulates the opening and closing of valves for air and fuel intake. |

| Valves | Control the flow of air and fuel into the combustion chamber. |

| Ignition System | Initiates the combustion process to generate power. |

Overview of Engine Functionality

This section explores the fundamental operations that drive mechanical systems, focusing on how energy is transformed into motion. Understanding these processes is crucial for appreciating how these complex machines work efficiently and reliably.

Basic Principles of Operation

The core function revolves around the conversion of fuel into kinetic energy, enabling the overall system to perform tasks. This transformation occurs through a series of coordinated actions, where various components interact seamlessly to maintain performance.

Key Processes

| Process | Description |

|---|---|

| Intake | Air and fuel mixture enters the chamber, setting the stage for combustion. |

| Compression | The mixture is compressed, increasing temperature and pressure for efficient ignition. |

| Power Stroke | Combustion occurs, forcing components to move and generate work. |

| Exhaust | Byproducts are expelled, allowing for the next cycle to begin. |

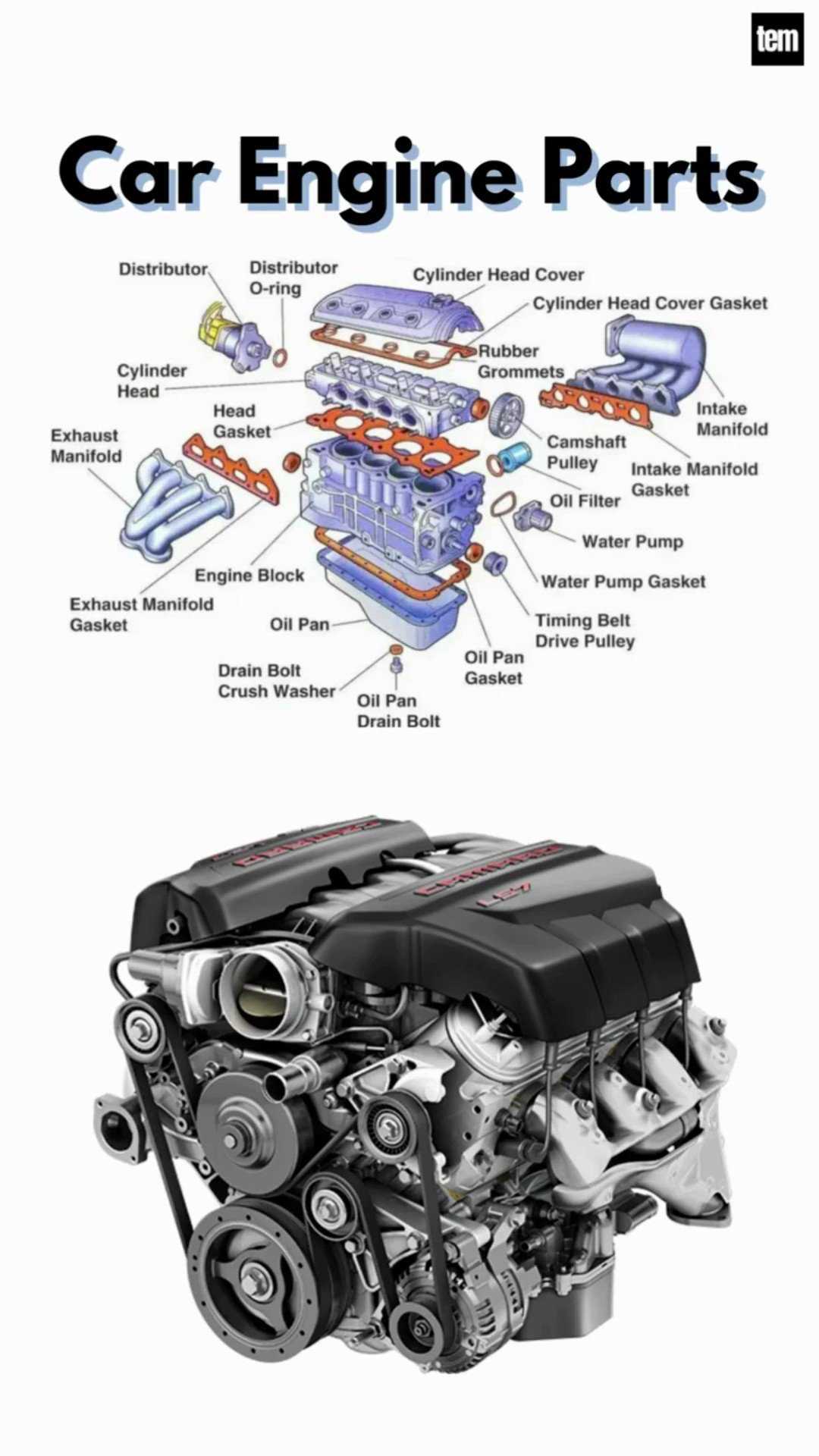

Key Parts of Internal Combustion Engines

Understanding the essential components of internal combustion systems is crucial for grasping how they operate efficiently. Each element plays a significant role in the conversion of fuel into kinetic energy, contributing to the overall functionality and performance of the mechanism.

Main Components

- Cylinder

- Piston

- Crankshaft

- Fuel Injector

- Camshaft

Supporting Elements

- Spark Plug

- Valves

- Exhaust System

- Cooling System

- Lubrication System

Fuel System and Its Role

The fuel system serves a critical function in the operation of a vehicle, ensuring that the right mixture of fuel and air is delivered efficiently to the combustion chamber. This intricate network plays a vital role in maintaining performance, optimizing efficiency, and reducing emissions, ultimately contributing to a smooth and powerful ride.

Key Components of the Fuel System

At the heart of this system lies the fuel pump, responsible for transporting fuel from the tank to the combustion area. Once there, the fuel is metered and atomized by the injectors, creating a fine mist that allows for complete combustion. Filters are also essential, as they remove impurities, safeguarding both the injectors and the overall functionality.

Importance of Proper Functioning

A well-maintained fuel system is crucial for optimal vehicle performance. Malfunctions can lead to issues such as misfires, poor fuel economy, and increased emissions. Regular inspections and timely replacements of components like filters and pumps help ensure that the system operates effectively, promoting longevity and reliability.

Ignition System Explained

The ignition mechanism is crucial for initiating the combustion process within the internal combustion process. It ensures that the fuel-air mixture ignites at the precise moment, maximizing efficiency and power output while minimizing emissions.

Key Components

This system comprises several vital elements that work in harmony to create a spark. Each component plays a significant role in ensuring reliable performance.

| Component | Function |

|---|---|

| Spark Plug | Generates the spark for ignition. |

| Ignition Coil | Transforms low voltage to high voltage. |

| Distributor | Distributes the electrical charge to the correct cylinder. |

Operation Process

During operation, the ignition coil receives current, which it amplifies and sends to the distributor. This component directs the charge to the appropriate spark plug, resulting in ignition and initiating the power stroke within the cycle.

Cooling Mechanisms in Engines

The efficiency and longevity of mechanical systems largely depend on their ability to manage heat. Excessive temperatures can lead to failure, making effective thermal regulation essential. Various strategies are employed to ensure optimal functioning by dissipating heat generated during operation.

Liquid cooling is one of the most common approaches, utilizing a coolant that circulates through passages to absorb heat and release it via a radiator. This method provides consistent temperature control, preventing overheating.

Air cooling, on the other hand, relies on airflow to dissipate heat. This technique is often found in smaller, less complex machinery, where simplicity and lightweight design are priorities. While effective, it may not offer the same level of temperature regulation as liquid systems.

Another innovative method involves thermoelectric coolers, which use electric currents to transfer heat. These devices are compact and can provide targeted cooling, making them suitable for specific applications where traditional methods may fall short.

Ultimately, understanding these cooling strategies allows for better maintenance and enhances performance, ensuring that the systems operate smoothly over extended periods.

Lubrication Systems Importance

The effective functioning of mechanical systems relies heavily on the management of friction and heat. Proper lubrication plays a crucial role in minimizing wear and tear, ensuring longevity and performance.

Lubrication not only reduces friction between moving components but also aids in the removal of heat generated during operation. This process enhances efficiency, leading to optimal performance and reduced energy consumption.

Moreover, a well-maintained lubrication system helps in preventing corrosion and contamination, thereby safeguarding the integrity of vital components. Regular monitoring and timely servicing are essential to ensure that this system functions at its ultimate capacity.

Exhaust Systems and Emissions Control

The management of gases produced during fuel combustion is crucial for maintaining environmental standards and enhancing performance. This system is designed to channel harmful byproducts away from the combustion chamber while minimizing their impact on the atmosphere.

At the core of this mechanism is a network of components that work in harmony to filter and reduce pollutants. From the manifold to the muffler, each segment plays a vital role in ensuring that exhaust emissions are treated before they are released into the air. Advanced technologies, including catalytic converters and particulate filters, have been integrated to further enhance efficiency and compliance with regulations.

In addition to environmental considerations, optimizing these systems can lead to improved fuel economy and power output. By reducing backpressure and enhancing the flow of gases, vehicles can achieve better performance while adhering to stringent emission standards. As regulations evolve, continuous innovations in design and materials will be necessary to meet the growing demands for cleaner and more efficient transport solutions.

Electrical Systems in Modern Engines

In contemporary powertrains, the integration of electrical systems plays a crucial role in enhancing performance and efficiency. These systems encompass various components that work synergistically to optimize functionality and ensure seamless operation.

Control Units serve as the brain of the setup, processing data from numerous sensors and making real-time adjustments to improve efficiency and responsiveness. This level of sophistication allows for better fuel management and emission control, contributing to a more eco-friendly performance.

Another vital element is the ignition system, which initiates the combustion process. Advances in this area have led to improved reliability and reduced energy consumption. Modern vehicles often utilize coil-on-plug technology, enhancing spark delivery and overall power output.

Battery systems have also evolved, providing the necessary energy to support various functions, from starting the powertrain to powering auxiliary components. The introduction of advanced batteries, including lithium-ion variants, has significantly increased energy efficiency and longevity.

Additionally, charging systems are designed to maintain optimal power levels, ensuring that all electrical components operate smoothly. Regenerative braking technologies have further contributed to energy conservation by harnessing kinetic energy during deceleration.

Overall, the advancements in electrical systems have revolutionized how power is generated and managed, leading to enhanced performance, lower emissions, and improved user experience in modern vehicles.

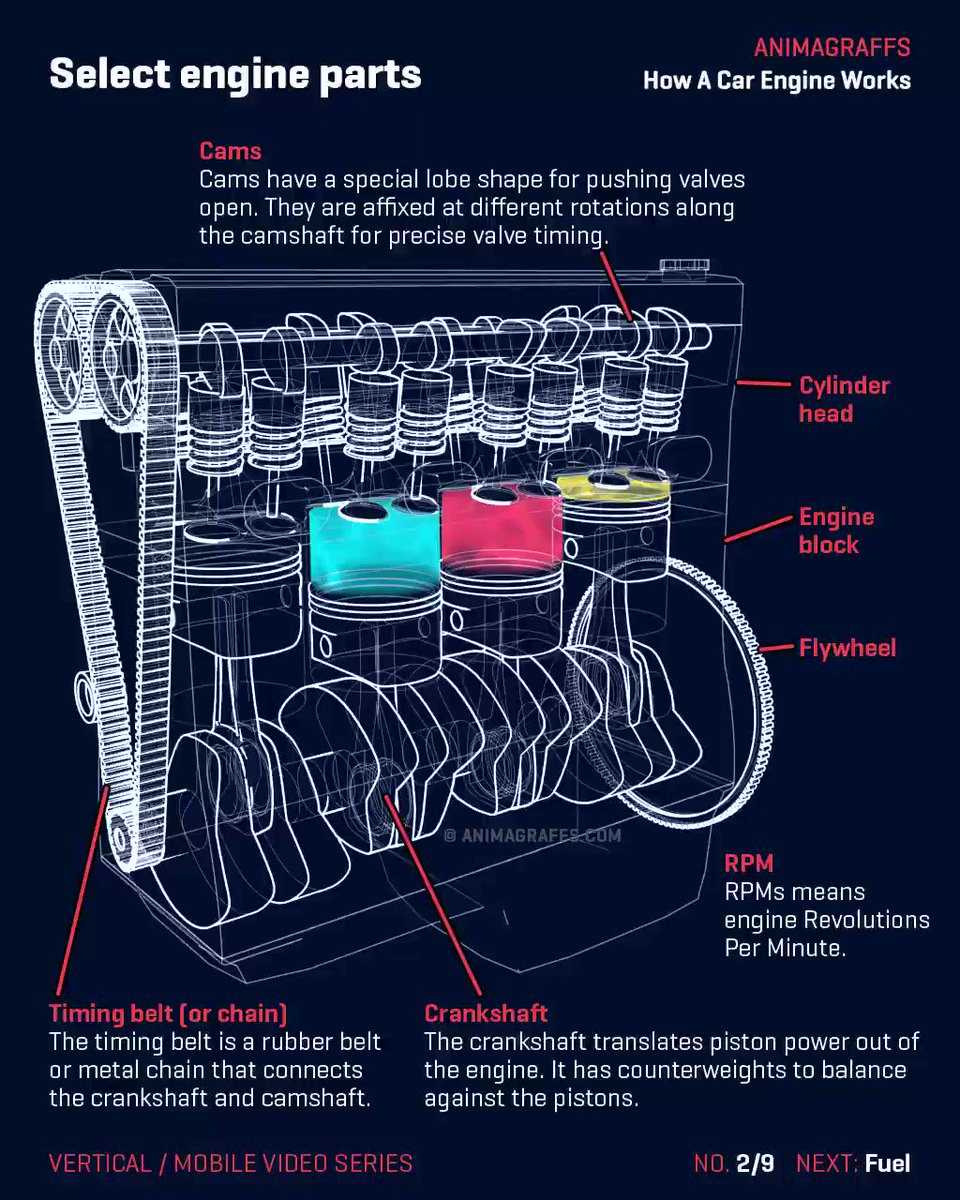

Mechanical Systems and Timing Belts

The interplay of various mechanical components is essential for optimal performance and reliability in any complex machinery. Among these elements, the synchronization of movement plays a crucial role in ensuring that all parts operate seamlessly together. This synchronization is often achieved through the use of specific belts designed to facilitate precise timing and coordination.

Timing belts serve as vital links within these intricate systems, allowing for the transfer of power and motion between critical components. Their design, typically featuring teeth for improved grip, enables them to maintain accuracy in timing, which is fundamental for the smooth operation of the entire mechanism. Proper maintenance and timely replacement of these belts are imperative, as their failure can lead to significant operational issues.

In summary, understanding the function and significance of timing belts within mechanical systems enhances our appreciation for the engineering behind reliable machinery. Their role is not merely functional; it embodies the precision and innovation that drive modern technology.

Engine Block: The Core Structure

The heart of a mechanical power unit lies in its foundational assembly, which serves as the main structure supporting various components. This robust framework is designed to withstand intense pressures and temperatures, ensuring optimal performance and durability.

Functions of the Core Assembly

This central unit fulfills several essential roles, including housing critical elements and facilitating efficient fluid movement. Its design is pivotal for maintaining balance and stability throughout the operational cycle.

Materials Used

The construction of this core structure typically involves high-strength alloys and advanced composites, providing the necessary resilience and thermal management capabilities.

| Material | Properties |

|---|---|

| Cast Iron | Durable, heat-resistant |

| Aluminum Alloy | Lightweight, excellent conductivity |

| Composite Materials | Corrosion-resistant, strong |

Turbochargers and Performance Enhancements

Turbochargers serve as a pivotal technology for boosting power and efficiency in modern vehicles. By harnessing exhaust gases, they significantly increase the intake of air, allowing for a more potent combustion process. This results in enhanced output without the need for larger displacement, offering a compact solution for performance enthusiasts.

The integration of these devices leads to remarkable improvements in acceleration and overall driving experience. Additionally, advancements in materials and design have made modern turbochargers more reliable and responsive, further enhancing their appeal. When paired with other modifications, such as upgraded fuel systems and intercoolers, they can elevate performance to ultimate levels, satisfying the demands of speed and power.

Beyond sheer power gains, turbochargers contribute to better fuel efficiency, making them an attractive option for those looking to balance performance with economy. This dual benefit underscores their importance in contemporary automotive engineering, shaping the future of high-performance vehicles.