Understanding the different elements that make up a pool cleaning system is essential for maintaining its smooth operation. Each element plays a key role in ensuring that the equipment functions properly, providing optimal performance and long-lasting durability. By familiarizing yourself with the various components, you can quickly identify issues and address them effectively, ensuring your cleaning system remains reliable.

In this section, we will explore the structure and essential elements that form the foundation of a well-functioning pool cleaning device. Knowing how each piece works together will not only help in regular upkeep but also in preventing potential issues from escalating into costly repairs. Let’s delve into the intricacies of the system and discover how these elements combine to create an efficient solution for keeping your pool pristine.

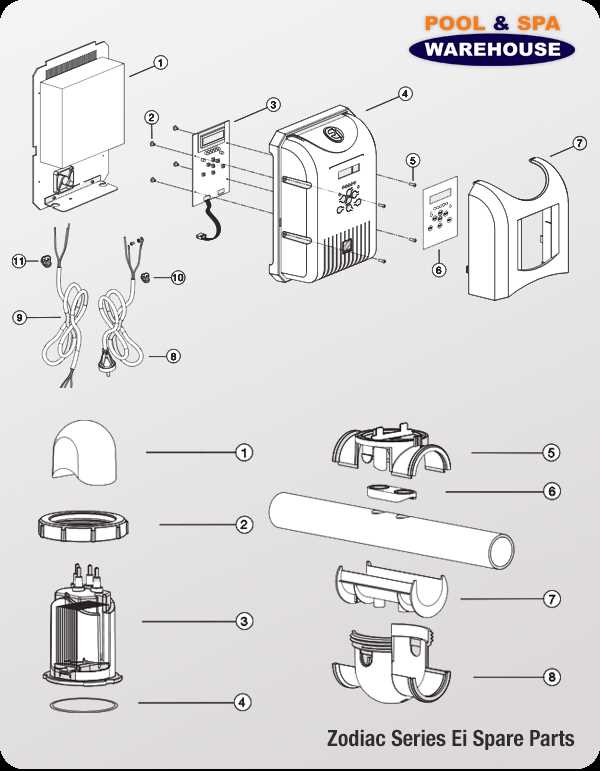

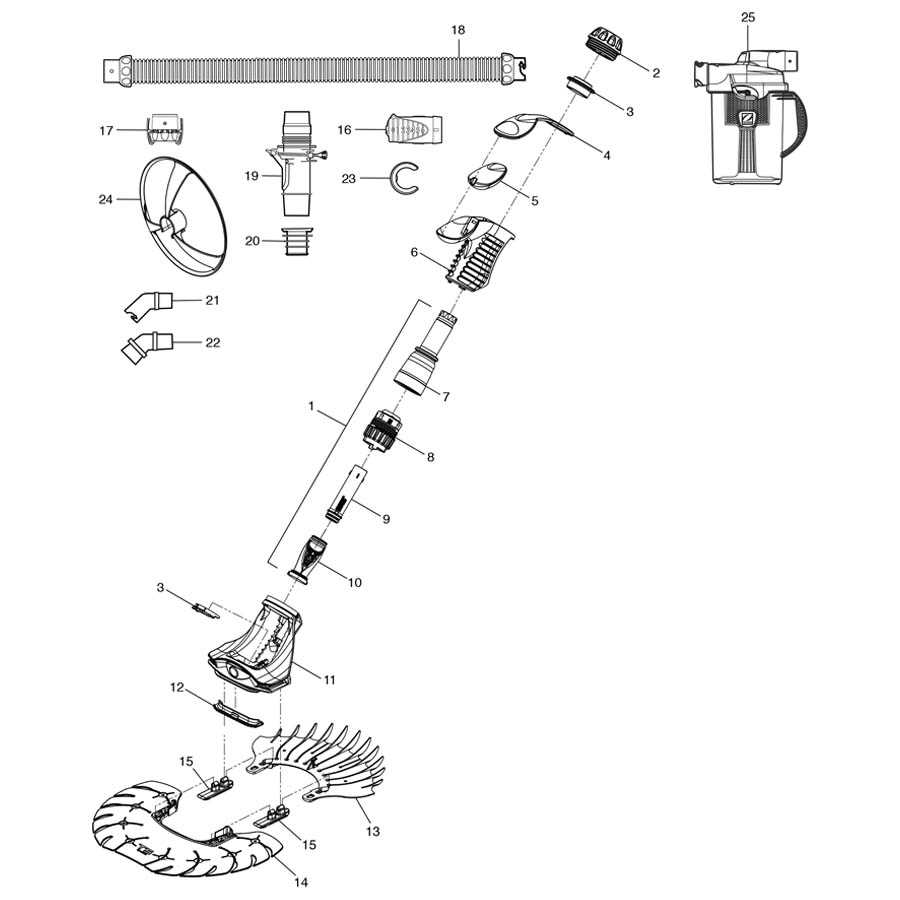

G2 Overview and Components

The G2 model is designed to provide efficient cleaning for various surfaces. This system operates with precision, utilizing multiple features that ensure effective performance. In this section, we will explore the main elements that contribute to its reliable functionality and how each part plays a crucial role in maintaining optimal operation.

Main Functional Features

Understanding the core components is essential for grasping how this system operates. Below are key elements that enhance its performance:

- Flexible body structure that adapts to different surface contours.

- Innovative valve mechanism regulating water flow for consistent operation.

- Enhanced footpad for stability and smooth navigation.

Supporting Elements

Main Body Construction and Features

The core structure of the device is designed to ensure durability and efficiency during operation. It combines streamlined form with essential components that work together to deliver reliable performance in various conditions. The body is engineered for ease of use and seamless maintenance, while its materials are selected to withstand wear and tear over time.

Key Components

The central construction consists of several interconnected elements that contribute to the overall function. These components are arranged to optimize movement and ensure consistent flow, reducing strain on the system.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Casing | Protects internal mechanisms and provides structural support. |

| Aspect | Importance |

|---|---|

| Flow Control | Prevents damage and optimizes performance |

| Pressure Regulation | Maintains stability and efficiency |

| Energy Consumption | Reduces costs through efficient operation |

| Maintenance | Ensures longevity and reliability of the system |

Wear and Maintenance of the Foot Pad

The foot pad is a crucial component that significantly impacts performance and comfort during use. Proper care and timely maintenance ensure longevity and optimal functionality. Regular inspection and attention to wear can prevent more extensive damage, contributing to a smoother experience.

Signs of Wear

Identifying the signs of wear is essential for effective maintenance. Look for visible cracks, abrasions, or thinning areas that indicate deterioration. Regularly checking for these indicators helps in assessing the condition and determining if replacement is necessary.

Maintenance Tips

To maintain the foot pad in good condition, clean it regularly with a mild detergent and water, ensuring all debris is removed. Avoid harsh chemicals that could degrade the material. Additionally, store the equipment in a dry place away from direct sunlight to prevent premature wear. Implementing these practices will prolong the life of the foot pad and enhance overall performance.

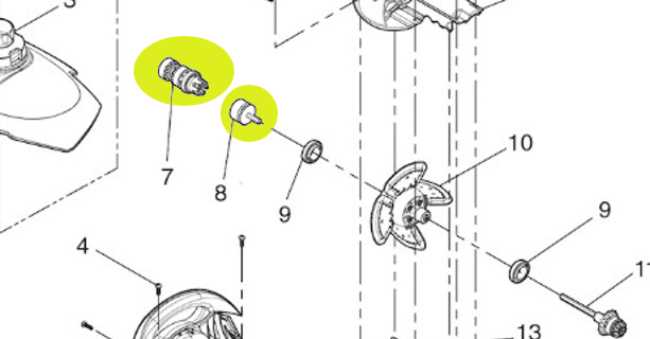

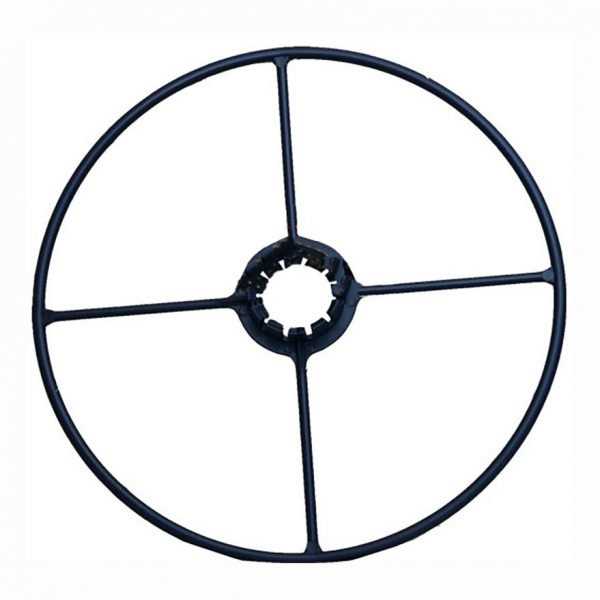

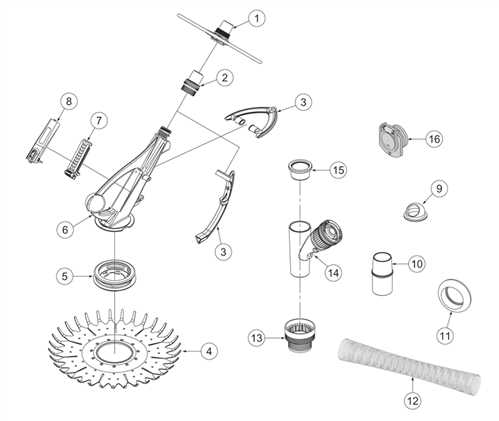

Guide to Replacing the Disc Assembly

Replacing the disc assembly is an essential maintenance task that ensures optimal performance of your equipment. This guide will provide you with a clear and concise approach to successfully carry out this procedure, helping you maintain efficiency and prolong the lifespan of your device.

Before beginning, it is crucial to gather all necessary tools and components. Ensure that your workspace is clean and well-organized to facilitate a smooth replacement process. Carefully consult the user manual for specific instructions related to your model, as there may be slight variations in the assembly procedure.

Start by turning off the device and disconnecting it from any power source to ensure safety. Once you have accessed the assembly area, inspect the components for any visible signs of wear or damage. If the disc is worn out or shows signs of malfunction, it is time to replace it.

To remove the old assembly, follow the manufacturer’s guidelines carefully. Typically, this involves loosening screws or clips that secure the disc in place. Once removed, take a moment to clean the area, removing any debris that may hinder the installation of the new component.

Next, position the new disc assembly into place, ensuring it fits snugly within the designated area. Secure it by tightening the screws or clips, being cautious not to overtighten and cause damage. After ensuring everything is properly secured, reconnect the power and conduct a test run to verify that the assembly functions correctly.

Regularly replacing components like the disc assembly not only enhances performance but also prevents potential issues that could arise from prolonged use of worn parts. By following this guide, you can confidently perform this maintenance task, ensuring your equipment remains in excellent condition.

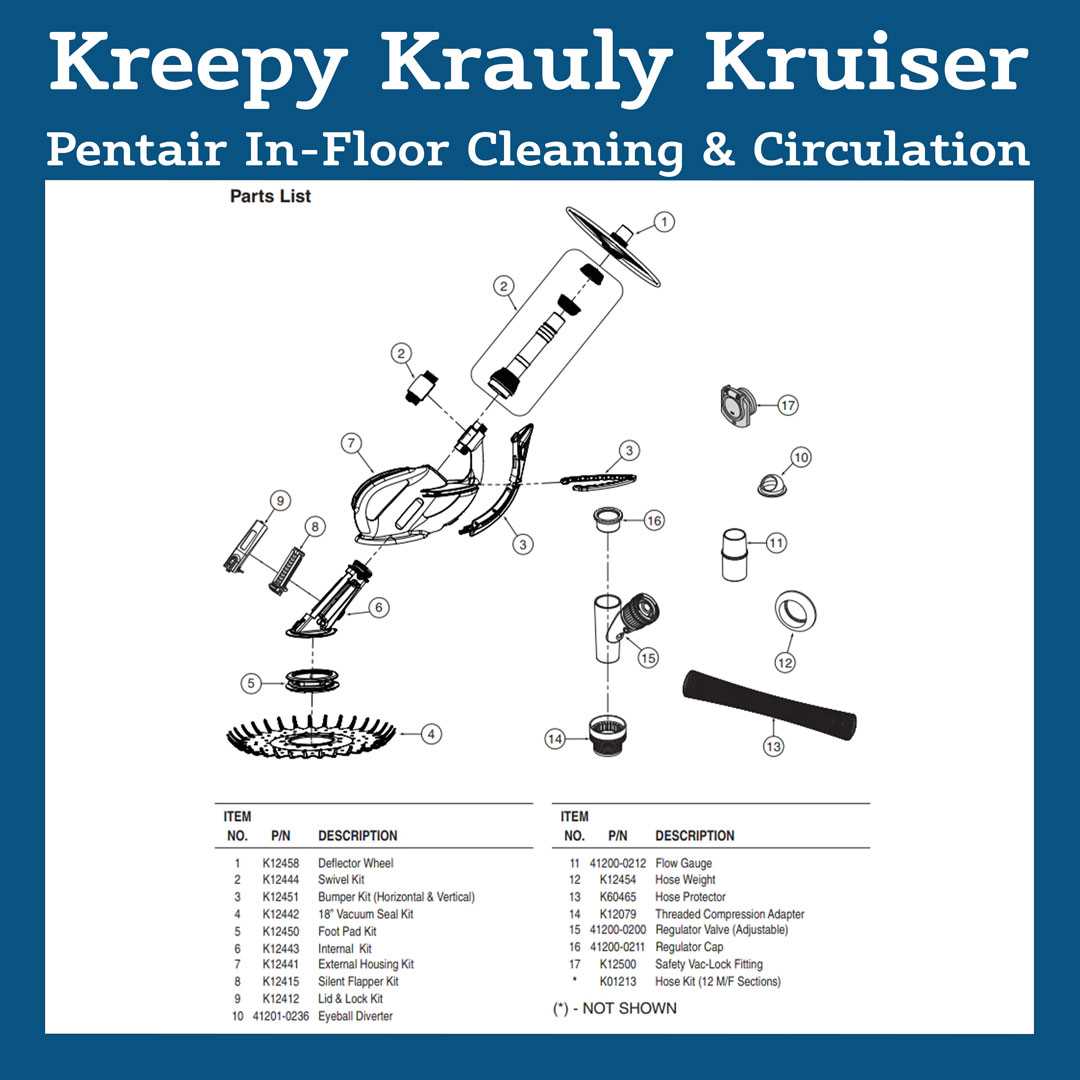

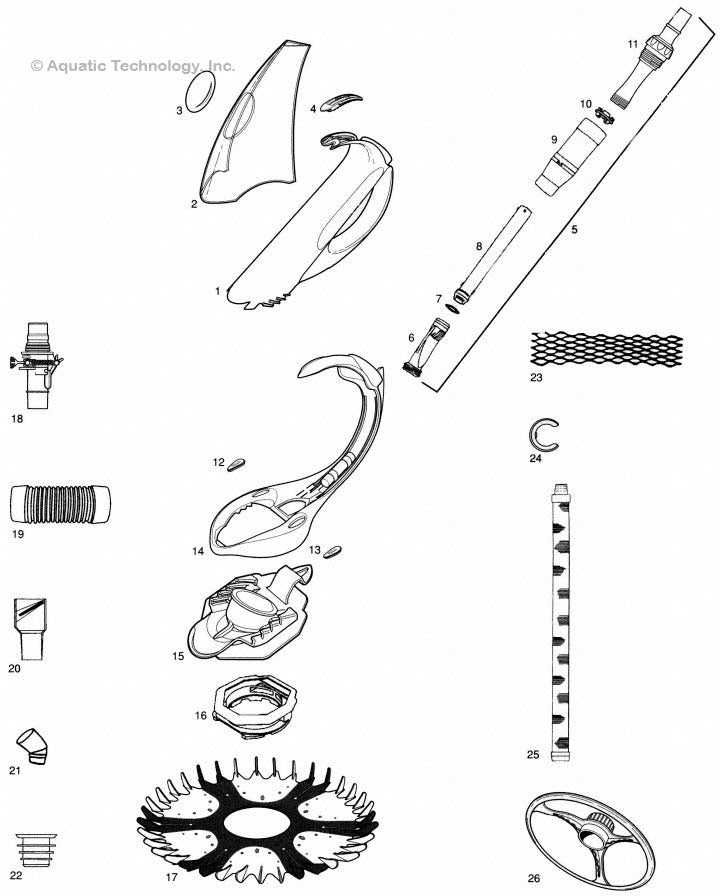

How the Pool Cleaner Weight System Works

The weight mechanism of a swimming pool cleaning device is essential for its efficient operation. This system plays a crucial role in maintaining the proper balance and stability of the cleaner while it moves through the water. Understanding how this feature functions can greatly enhance the cleaning performance of the equipment.

Here’s a closer look at the main components and their roles:

- Weights: The primary elements that provide the necessary heft to keep the cleaner submerged and prevent it from floating.

- Adjustment Mechanism: Many devices come with an option to modify the weight distribution, allowing users to tailor the balance according to specific pool conditions.

- Placement: Proper positioning of weights is crucial; it ensures that the cleaner navigates efficiently without getting stuck or missing spots.

The effectiveness of the weight system is influenced by various factors:

- Water Type: The density of the water can affect how the cleaner operates, necessitating adjustments to the weight.

- Pool Shape: Irregularly shaped pools may require different weight configurations to ensure thorough cleaning.

- Surface Material: The texture of the pool surface impacts how the cleaner moves, which can be managed through the weight system.

In summary, a well-designed weight system is integral to the optimal functioning of a swimming pool cleaning device. By understanding its components and the factors influencing its performance, users can ensure that their equipment operates efficiently, providing a cleaner and more enjoyable swimming experience.

Inspecting and Maintaining the Float Valve

The float valve is a crucial component that regulates water flow and ensures proper functioning. Regular inspection and maintenance of this element are essential for optimal performance and longevity. This section will provide guidance on how to effectively assess and care for the float valve.

Inspection Process

Conducting a thorough inspection is vital to identify any potential issues. Follow these steps to perform an effective evaluation:

- Ensure the system is powered off to prevent any accidents.

- Remove any coverings or access panels to gain visibility of the float valve.

- Examine the float for any signs of damage, such as cracks or corrosion.

- Check the attachment points and seals for wear and tear.

- Test the float’s movement to ensure it rises and falls freely.

Maintenance Tips

Maintaining the float valve will help prolong its life and ensure consistent operation. Consider the following practices:

- Clean the float and surrounding areas regularly to remove debris and buildup.

- Lubricate moving parts with an appropriate lubricant to ensure smooth operation.

- Replace any worn or damaged components promptly to prevent leaks.

- Perform routine checks every few months to catch issues early.

- Keep an eye on water levels and functionality to spot irregularities.