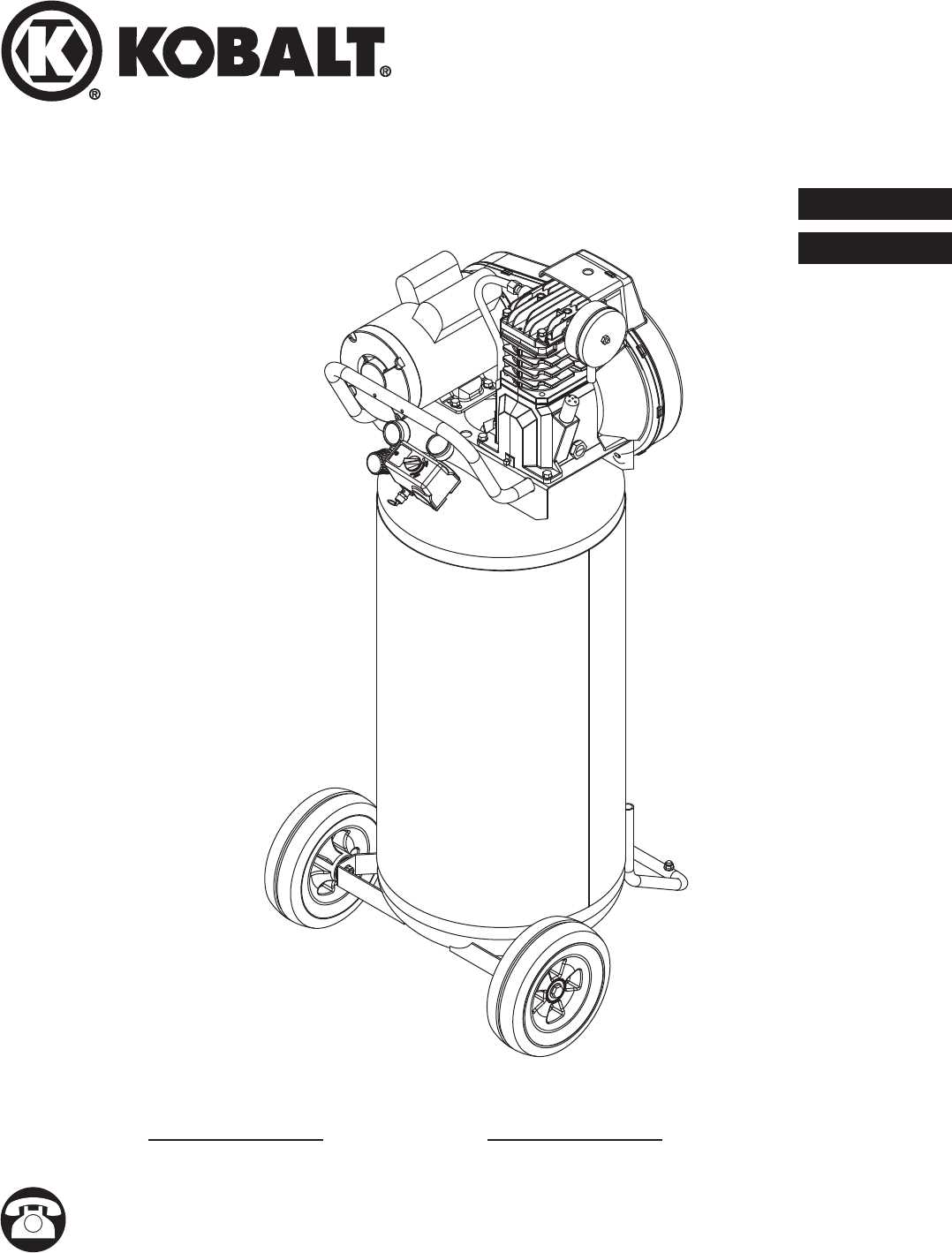

When working with powerful machinery designed for various tasks, grasping the intricacies of its components is essential. This section delves into the structure and functionality of a 20-gallon unit, providing insight into how each element contributes to its overall efficiency. Whether you’re a novice or a seasoned user, comprehending these components can significantly enhance your operational knowledge.

Each element within the system plays a vital role in ensuring optimal performance. From the motor to the various connectors, every piece is meticulously designed to work in harmony. Understanding these relationships not only aids in effective usage but also empowers you to maintain the equipment properly, ensuring longevity and reliability.

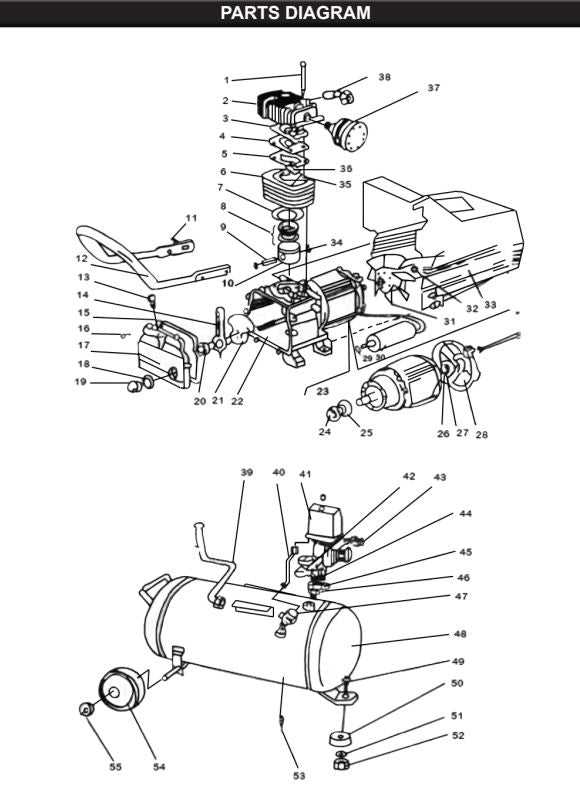

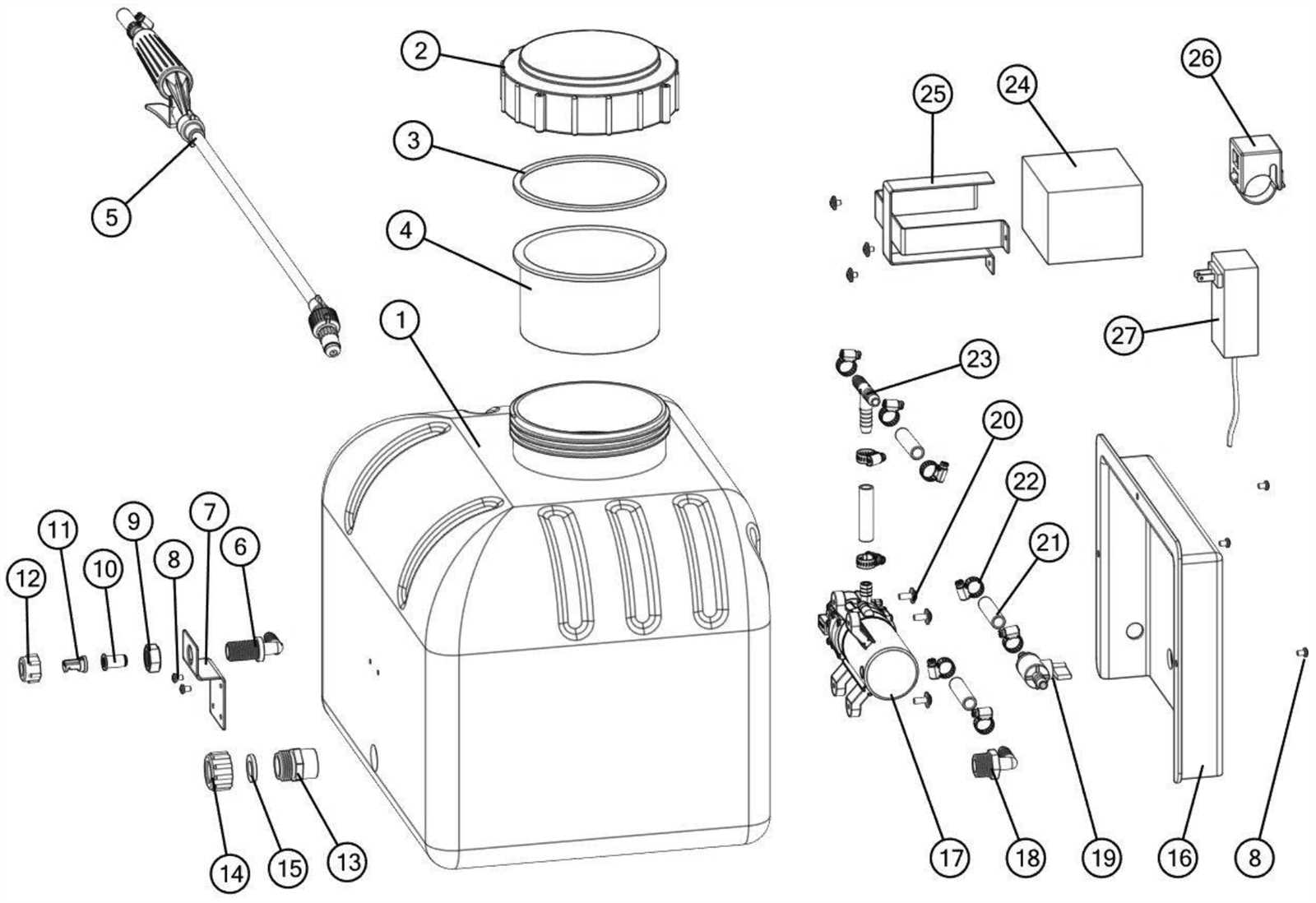

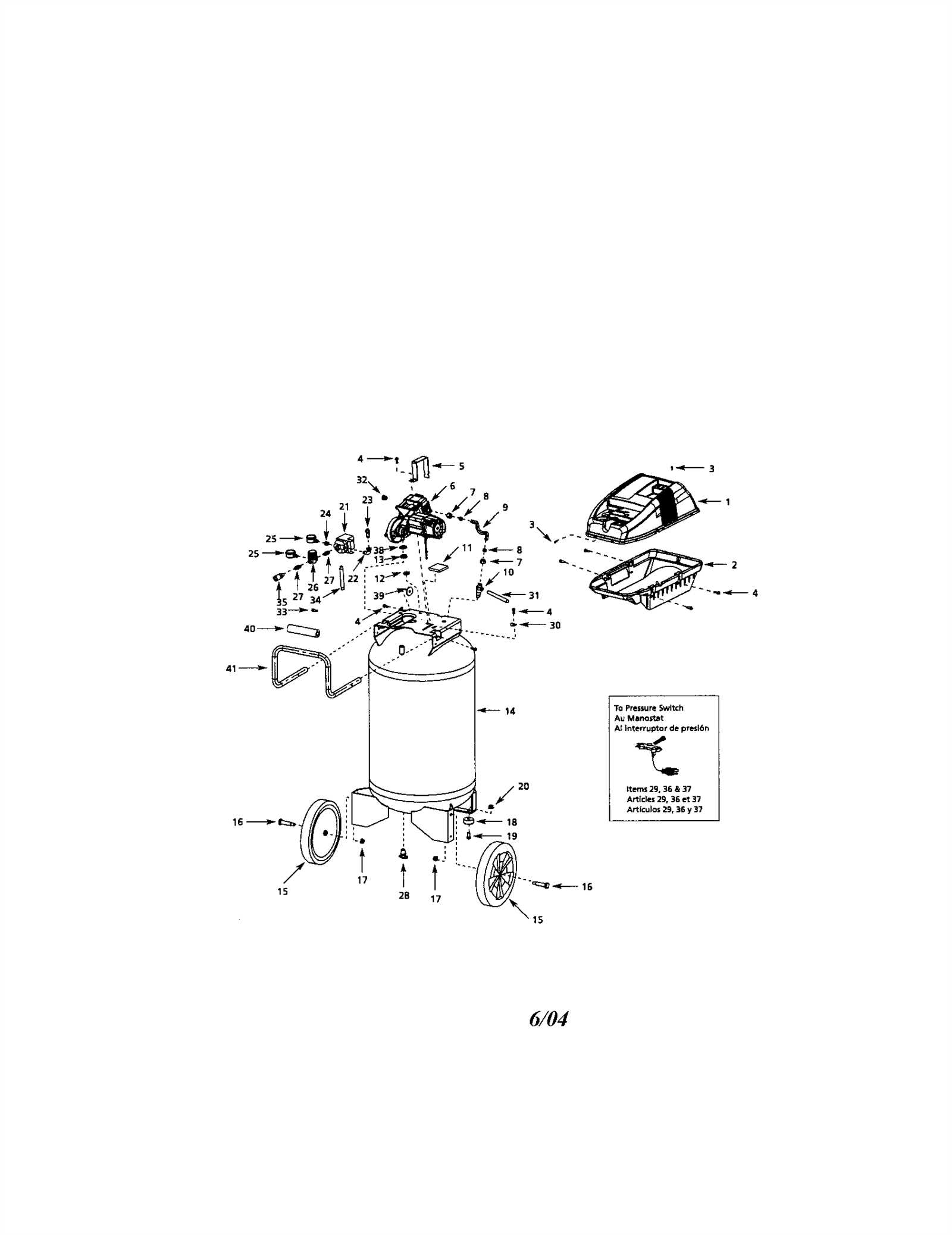

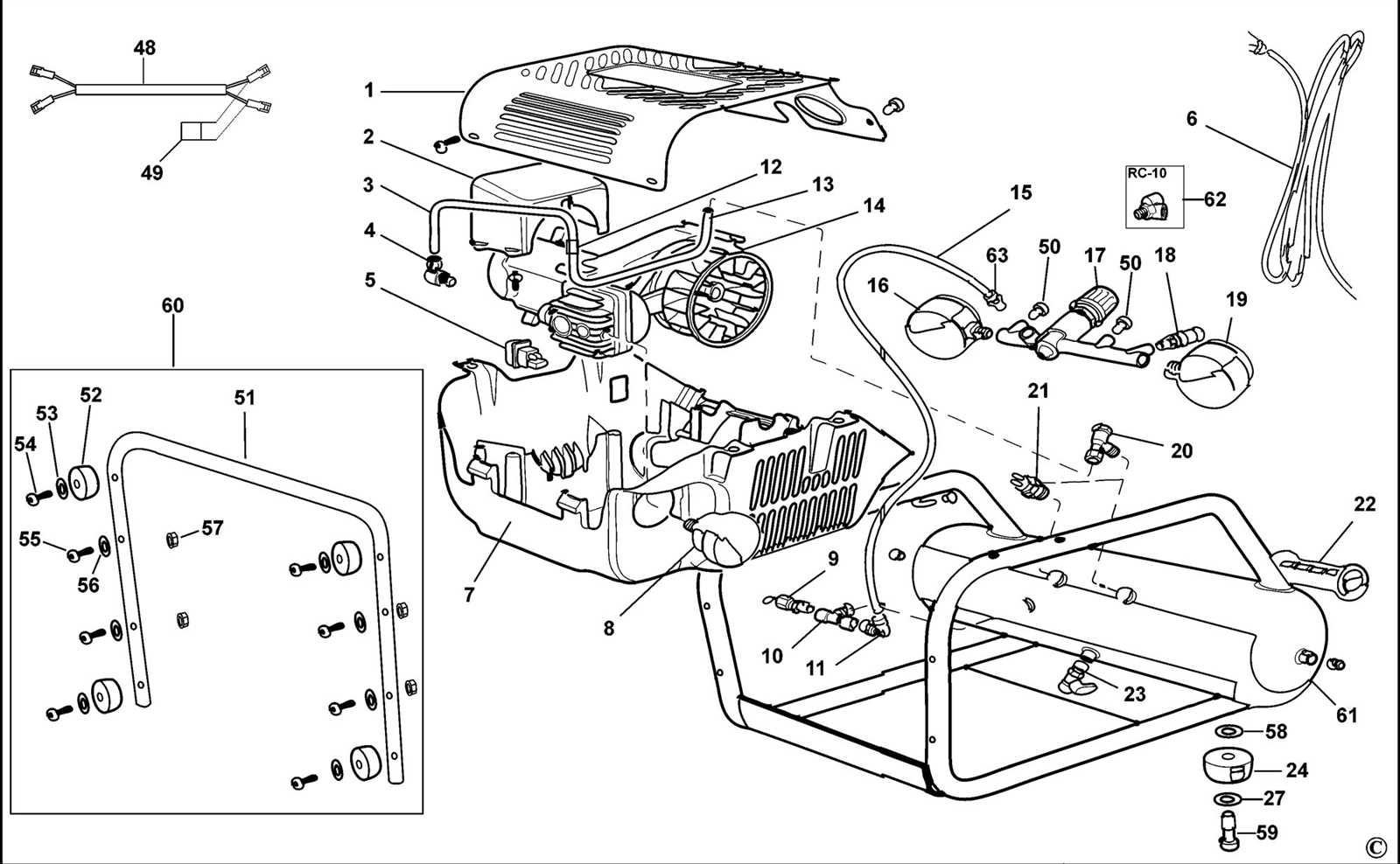

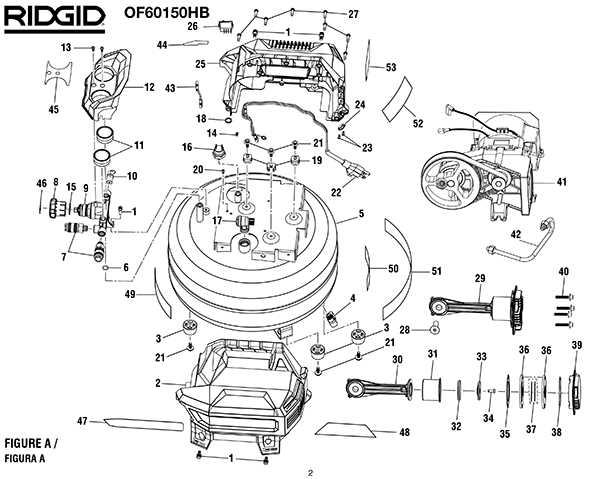

Visual representations of the internal architecture serve as valuable tools for troubleshooting and repair. By familiarizing yourself with the layout and interconnections, you can navigate any issues that may arise with greater confidence. This knowledge transforms potential challenges into manageable tasks, enhancing your overall experience with the equipment.

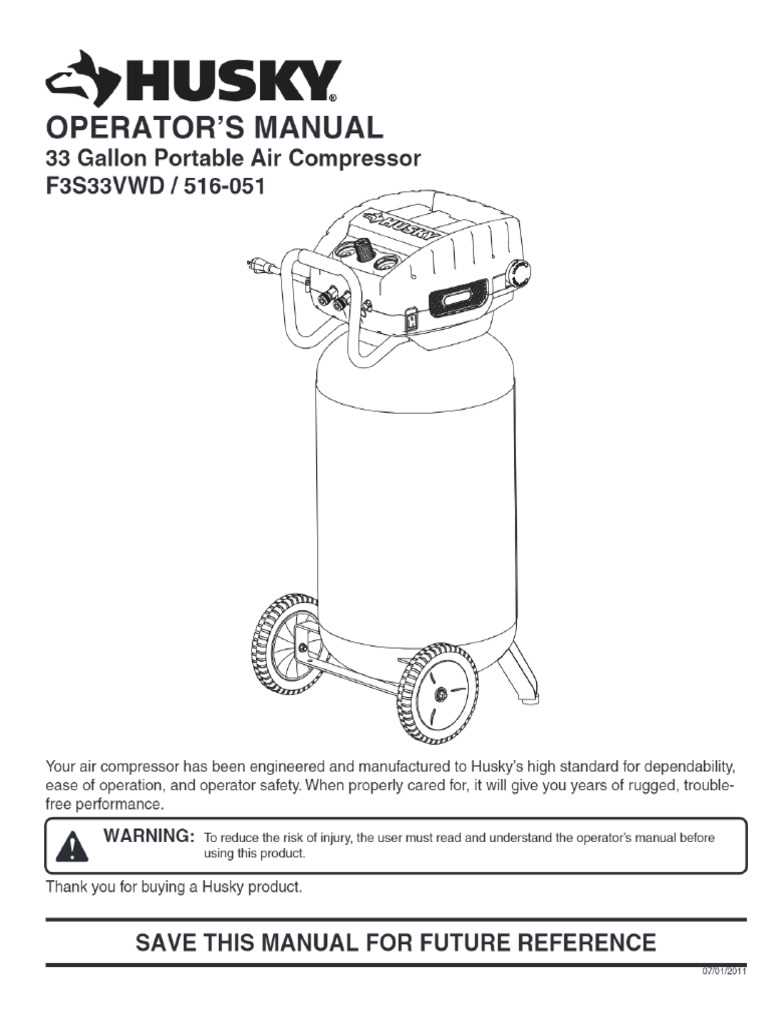

Understanding Husky 20 Gallon Air Compressor

This section delves into the essential features and functionality of a popular portable pressure device designed for various tasks. Recognizing its components and how they interact can greatly enhance user experience and efficiency. By grasping the key aspects of this machinery, individuals can maximize its potential in both professional and personal settings.

Key Features and Specifications

At the core of this model lies a robust design that ensures durability and reliability. The unit typically boasts a significant storage capacity, allowing for prolonged use without the need for frequent refills. Additionally, it often includes an efficient motor that provides consistent performance, making it suitable for a wide range of applications, from inflating tires to powering tools.

Maintenance and Troubleshooting

Regular upkeep is crucial for maintaining optimal performance. Users should routinely check for wear and tear on components to prevent any operational issues. Understanding common challenges and their solutions can save time and enhance the longevity of the equipment. For instance, addressing air leaks or ensuring proper lubrication can significantly improve functionality.

In summary, familiarizing oneself with this versatile device can lead to improved outcomes in various projects. A thorough understanding of its mechanics and proper care practices empowers users to tackle tasks efficiently.

Key Components of the Compressor

Understanding the essential elements of a pressure system is crucial for effective operation and maintenance. Each part plays a significant role in ensuring optimal functionality, contributing to the overall performance and longevity of the equipment.

Motor: The motor is the powerhouse of the unit, responsible for converting electrical energy into mechanical energy. It drives the pump, enabling the creation of compressed gas.

Pump: The pump is where the compression process occurs. It compresses the gas and builds up pressure, making it available for various applications.

Tank: The storage vessel holds the compressed gas for later use. Its capacity affects the duration of operation before needing to refill.

Pressure Switch: This component regulates the pressure levels within the system. It automatically turns the motor on and off based on preset pressure thresholds, ensuring safety and efficiency.

Regulator: The regulator controls the output pressure, allowing users to adjust the pressure level according to specific requirements.

Drain Valve: This part is essential for maintaining the system by allowing moisture buildup to be released. Regular drainage helps prevent corrosion and damage.

Each of these components is integral to the system’s effectiveness, and understanding their functions can significantly enhance user experience and equipment maintenance.

Importance of Maintenance for Longevity

Regular upkeep is essential for extending the lifespan of any mechanical device. Consistent attention to maintenance not only ensures optimal performance but also prevents unexpected failures that can lead to costly repairs. Establishing a routine for checking and servicing equipment can significantly enhance its reliability and efficiency over time.

Key Benefits of Regular Maintenance

There are several advantages to adhering to a structured maintenance schedule. These include:

| Benefit | Description |

|---|---|

| Enhanced Performance | Regular servicing helps maintain peak functionality, allowing the device to operate smoothly. |

| Increased Lifespan | Consistent care reduces wear and tear, extending the overall life of the equipment. |

| Cost Savings | Preventative maintenance can minimize the risk of major breakdowns, saving money on repairs. |

| Safety Assurance | Routine checks can identify potential hazards, ensuring a safer operating environment. |

Maintenance Tips for Optimal Performance

To achieve the best results, consider these maintenance strategies:

- Regularly inspect components for wear and damage.

- Keep the operating area clean and free of debris.

- Follow the manufacturer’s guidelines for service intervals.

- Use quality replacement parts when necessary.

How to Identify Replacement Parts

Identifying components that need replacement is crucial for maintaining the efficiency and longevity of your equipment. Understanding how to accurately locate and recognize these elements can save time and prevent costly repairs.

Follow these steps to effectively identify what you need:

- Consult the Manual: Begin by reviewing the user guide that accompanied your machine. It often contains valuable information about each component and their specifications.

- Look for Model Numbers: Check the device for any labels or tags that display the model number. This information can be critical in sourcing the correct items.

- Visual Inspection: Conduct a thorough examination of the unit. Note any parts that appear worn, damaged, or malfunctioning. Take photos for reference.

- Use Online Resources: Utilize manufacturer websites or online forums dedicated to your equipment. They can provide diagrams and lists of compatible components.

- Contact Support: If you’re unsure, reach out to customer service. They can guide you in identifying the necessary replacements based on your observations.

By following these guidelines, you can confidently pinpoint the elements that require attention, ensuring optimal performance and reliability of your machinery.

Common Issues and Troubleshooting Tips

In the realm of machinery, various challenges may arise during operation. Understanding these common problems and their solutions can enhance efficiency and prolong the lifespan of equipment. Below are some frequent concerns and actionable tips to address them effectively.

Frequent Challenges

| Issue | Description | Solution |

|---|---|---|

| Low Pressure | Insufficient output pressure for tasks. | Check for leaks and ensure proper settings. |

| Noisy Operation | Excessive noise during use. | Inspect for loose components and lubricate moving parts. |

| Overheating | Unit becomes excessively hot. | Allow cooling time and ensure adequate ventilation. |

Preventive Measures

Regular maintenance plays a crucial role in preventing issues. Schedule routine checks to clean filters and inspect connections, ensuring that the unit operates at its ultimate potential. This proactive approach can save time and resources in the long run.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for tackling common issues with your equipment. Follow these structured steps to ensure a smooth repair process, allowing you to efficiently restore functionality.

Tools Required

- Screwdriver set

- Wrench set

- Replacement components

- Safety goggles

Repair Steps

- Turn off the power source and disconnect from any electrical outlets.

- Remove the outer casing to access internal mechanisms.

- Identify the faulty component using the troubleshooting guide.

- Carefully replace the damaged part with a new one.

- Reassemble the unit and ensure all screws and fittings are secure.

- Reconnect the power source and conduct a test run.

Accessories for Enhanced Performance

To maximize efficiency and functionality, incorporating the right enhancements can significantly improve your setup. Various tools and attachments are designed to optimize performance, ensuring that tasks are completed swiftly and effectively. Understanding these accessories allows users to tailor their systems to meet specific needs.

Essential Add-ons

Investing in quality attachments such as hoses and regulators can elevate your operational experience. These components facilitate better airflow and pressure control, enhancing the overall effectiveness of your equipment.

Specialized Tools

Incorporating quick-connect fittings and filters can further refine performance. Quick-connect fittings allow for seamless transitions between tools, while filters maintain the integrity of the system by preventing contaminants from affecting functionality.

Safety Precautions During Operation

Ensuring a safe working environment is crucial when using machinery. Proper precautions can prevent accidents and injuries, creating a more effective and enjoyable experience.

- Always wear appropriate personal protective equipment, such as goggles and gloves.

- Ensure that the workspace is well-ventilated to avoid the buildup of harmful fumes.

- Keep the area clear of obstructions to prevent tripping hazards.

Before operation, it’s essential to:

- Inspect the equipment for any signs of damage or wear.

- Read and understand the manufacturer’s instructions thoroughly.

- Check that all safety features are functional.

During use, maintain awareness of surroundings and avoid distractions to ensure maximum focus and safety.

Comparing Husky with Other Brands

When evaluating different options in the market, it’s essential to consider various attributes that set each brand apart. This analysis delves into how specific manufacturers distinguish themselves through performance, durability, and features, ultimately helping consumers make informed decisions.

Performance and Efficiency

Some brands focus on delivering superior performance and energy efficiency, which can be crucial for users needing reliable power. While one might excel in speed, another could shine in long-lasting operation. Understanding these differences can lead to better choices based on individual needs.

Durability and Build Quality

Durability is another critical factor. Certain manufacturers emphasize robust construction, while others may prioritize lightweight designs. Evaluating materials and user reviews can reveal which options stand up to rigorous tasks and provide ultimate longevity.

Upgrading Your Compressor: What to Consider

Enhancing your equipment can significantly improve performance and efficiency. When contemplating an upgrade, it’s essential to evaluate various aspects to ensure that the new model aligns with your needs and applications.

Key Factors to Evaluate

- Capacity: Determine the volume required for your tasks. An upgrade should meet or exceed your current demands.

- Power Source: Consider whether a different power option–electric, gasoline, or hybrid–might suit your usage better.

- Portability: Assess if you need a more mobile solution or if a stationary model would suffice.

- Noise Level: Examine how sound levels impact your working environment and whether a quieter model is necessary.

- Durability: Look for robust construction and quality materials to ensure longevity and reduce maintenance costs.

Performance Enhancements

- Pressure Rating: Higher pressure can allow for a wider range of tools and applications.

- Recovery Time: Faster recovery rates can improve workflow efficiency.

- Technological Features: Modern models may offer advanced controls or connectivity options that enhance usability.

By carefully considering these factors, you can make a well-informed decision that enhances your operational capabilities and fits your specific requirements.

Finding Parts: Online vs. Local Stores

When it comes to sourcing components for your equipment, choosing between digital platforms and brick-and-mortar shops can significantly influence your experience. Each option presents unique benefits and challenges that can affect your decision-making process.

Advantages of Online Shopping

Shopping online provides a vast selection and convenience. You can explore multiple vendors from the comfort of your home, often finding the ultimate deals. Moreover, detailed descriptions and customer reviews help you make informed choices.

Benefits of Local Retailers

Local stores offer immediate access to items, allowing for quick repairs. You can examine components firsthand, ensuring compatibility. Additionally, engaging with knowledgeable staff can provide valuable insights and recommendations.