Maintaining a pristine lawn requires reliable equipment designed for efficiency and durability. A particular model, well-known among garden enthusiasts, offers remarkable features that facilitate easy operation and effective grass cutting. Understanding the various elements that make up this machine can greatly enhance your user experience and ensure optimal performance.

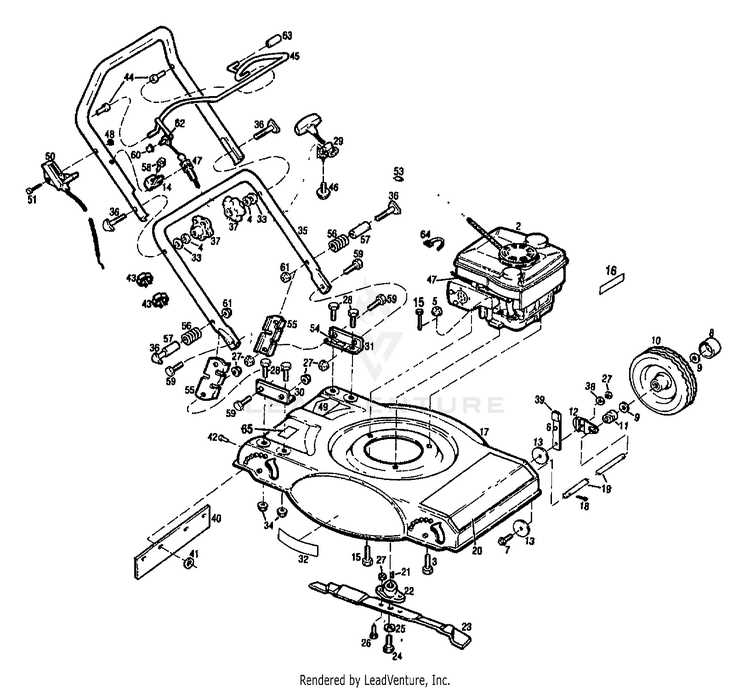

The intricate structure of this lawn care device is essential for its operation. Each component plays a significant role in its functionality, contributing to a seamless mowing process. By familiarizing yourself with these individual elements, you can easily troubleshoot any issues that may arise and keep your equipment running smoothly.

In this section, we will explore the different components that constitute this garden essential. From the engine to the wheels, each part has its specific function, working in harmony to deliver exceptional results. Grasping the layout of these elements not only aids in maintenance but also empowers users to make informed decisions regarding repairs or replacements.

Troy Bilt 21 Self Propelled Mower Overview

This section provides a comprehensive examination of a popular lawn maintenance tool known for its efficiency and ease of use. Designed to simplify the task of grass cutting, it combines innovative technology with user-friendly features to enhance the overall mowing experience. The model stands out due to its robust construction and reliable performance, making it a preferred choice among homeowners.

Equipped with a powerful engine, this device offers impressive cutting power, allowing users to tackle various types of terrain with ease. Its ergonomic design ensures comfort during operation, while the adjustable settings cater to different grass lengths and preferences. The equipment’s maneuverability is enhanced, enabling users to navigate around obstacles without hassle.

Maintenance is straightforward, ensuring longevity and optimal functioning. Regular care and attention to key components guarantee that this equipment remains in top shape throughout the mowing season. Overall, this model represents a perfect blend of functionality, durability, and convenience, making it an essential addition to any lawn care arsenal.

Essential Components of the Mower

The functionality and efficiency of a lawn care device rely on its critical elements. Understanding these key components can greatly enhance the user’s experience and maintenance knowledge. Each part serves a specific role, contributing to the overall performance and reliability of the equipment.

Key Features

Various features work together to ensure optimal operation. Familiarizing oneself with these aspects can aid in troubleshooting and effective usage.

| Component | Description |

|---|---|

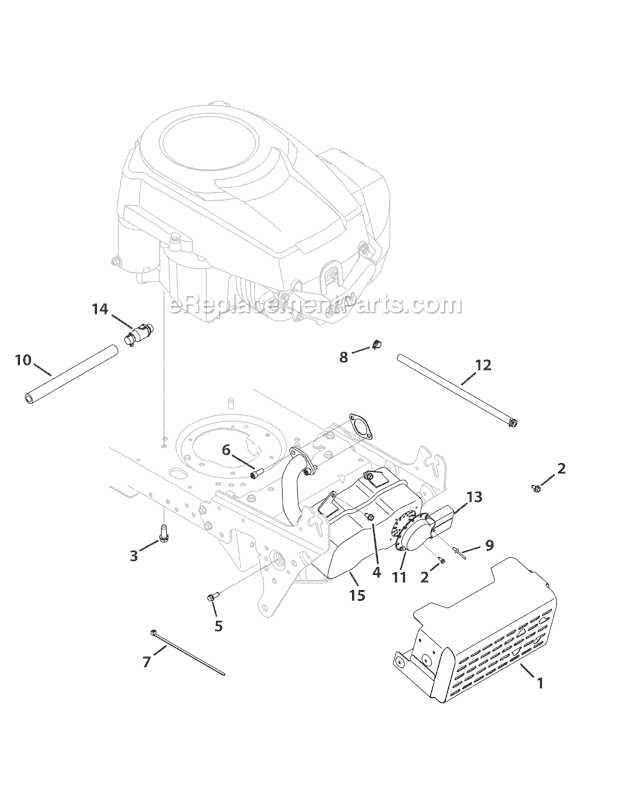

| Engine | Power source that drives the entire mechanism. |

| Blade | Cuts grass with precision, crucial for a clean finish. |

| Chassis | The frame that supports all components and provides stability. |

| Wheels | Facilitate movement across different terrains. |

| Handle | Provides control and maneuverability during operation. |

Importance of Each Component

Every feature plays a vital role in ensuring effective lawn maintenance. Regular inspection and understanding of these elements can lead to improved longevity and performance of the device.

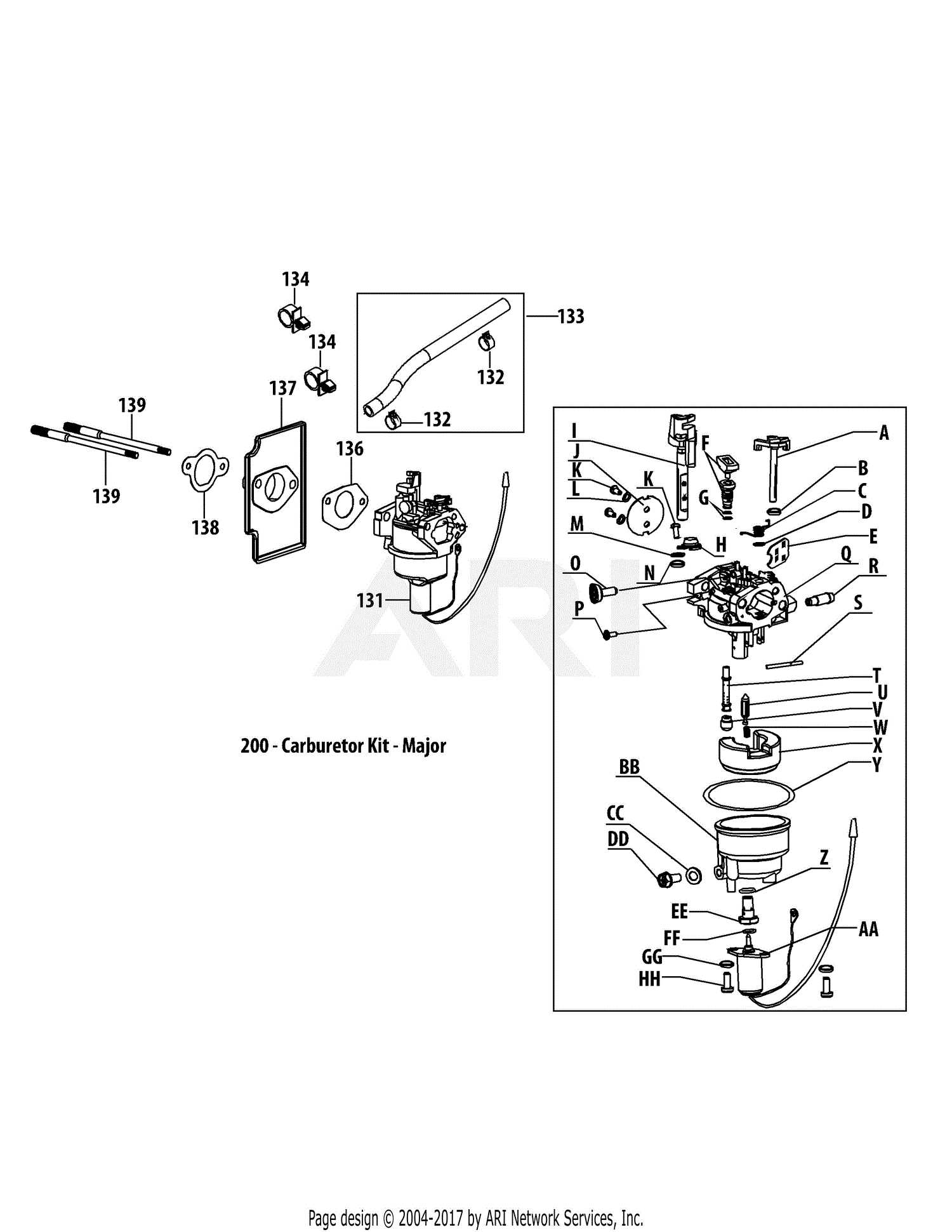

Identifying Common Replacement Parts

Understanding the essential components of a lawn maintenance machine is crucial for efficient upkeep and repair. Various elements may require attention over time due to wear and tear, and recognizing these can significantly enhance the longevity and performance of the equipment.

Among the frequently replaced components are the blades, which are vital for achieving a clean cut. Dull or damaged blades can hinder performance, making regular checks important. Another key item is the drive belt, responsible for transferring power from the engine to the wheels. A frayed or broken belt can lead to operational issues.

Additionally, the spark plug plays a significant role in the ignition process. A faulty spark plug can cause starting problems and reduce efficiency. Regular replacement ensures optimal performance. Lastly, the air filter is essential for maintaining clean airflow to the engine. Clogged filters can lead to decreased performance and increased fuel consumption.

Being aware of these common elements helps in effective maintenance, ensuring your equipment remains in top shape for any landscaping tasks.

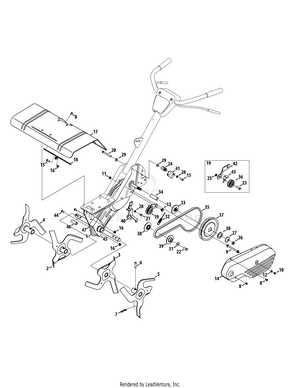

Understanding the Mower Assembly Process

The assembly of a lawn care machine involves several critical steps that ensure its effective operation and longevity. A comprehensive understanding of the process allows users to effectively maintain and troubleshoot their equipment, enhancing its performance over time.

Initially, it is essential to gather all necessary components, as well as tools required for the assembly. Each component plays a vital role in the functionality of the entire machine, and having a clear layout of these elements can streamline the assembly process. The next step involves following a systematic approach to connect various sections, ensuring that each component aligns correctly and securely.

Attention to detail is crucial during this stage, as even minor misalignments can lead to operational issues. Once the main assembly is complete, it is advisable to perform a thorough inspection of all connections and fastenings. This not only guarantees safety but also prevents future mechanical failures.

Finally, conducting a test run of the equipment can reveal any inconsistencies or problems that may not have been apparent during assembly. Regular maintenance and checks are recommended to keep the machinery in optimal working condition, thus extending its lifespan and enhancing user satisfaction.

Maintenance Tips for Optimal Performance

To ensure the long-lasting efficiency and smooth operation of your equipment, regular upkeep is crucial. Following a consistent maintenance routine will help prevent potential issues and keep everything running at its best, minimizing downtime and costly repairs.

Clean After Each Use: After finishing your work, make sure to remove any debris, grass, or dirt buildup. This prevents blockages and ensures the machine operates without resistance.

Check the Blades: Regular inspection of the blades is necessary. Sharpen or replace them when they become dull, as sharp blades are essential for a clean cut and reduce strain on the machine.

Inspect the Air Filter: Keeping the air filter clean helps maintain optimal engine performance. Replace it if it’s clogged to ensure proper airflow and efficient fuel use.

Monitor Oil Levels: Regularly check and change the oil according to the manufacturer’s recommendations. Clean oil helps lubricate moving

How to Troubleshoot Common Issues

Regular maintenance and addressing technical problems can extend the lifespan of outdoor equipment. Understanding how to diagnose and resolve frequent malfunctions helps to keep the machine running smoothly and prevent costly repairs.

Engine Problems

If the engine fails to start or runs poorly, there are several common causes to investigate. Checking the following components can often resolve the issue:

- Fuel supply: Ensure the fuel tank is filled and the fuel is fresh.

- Spark plug: Inspect for dirt or wear, and replace if necessary.

- Air filter: Clean or replace the air filter to allow proper airflow.

Drive Mechanism Issues

When the unit has difficulty moving or slows down unexpectedly, the following steps can help pinpoint the cause:

- Examine the belts and pulleys for signs of wear or tension problems.

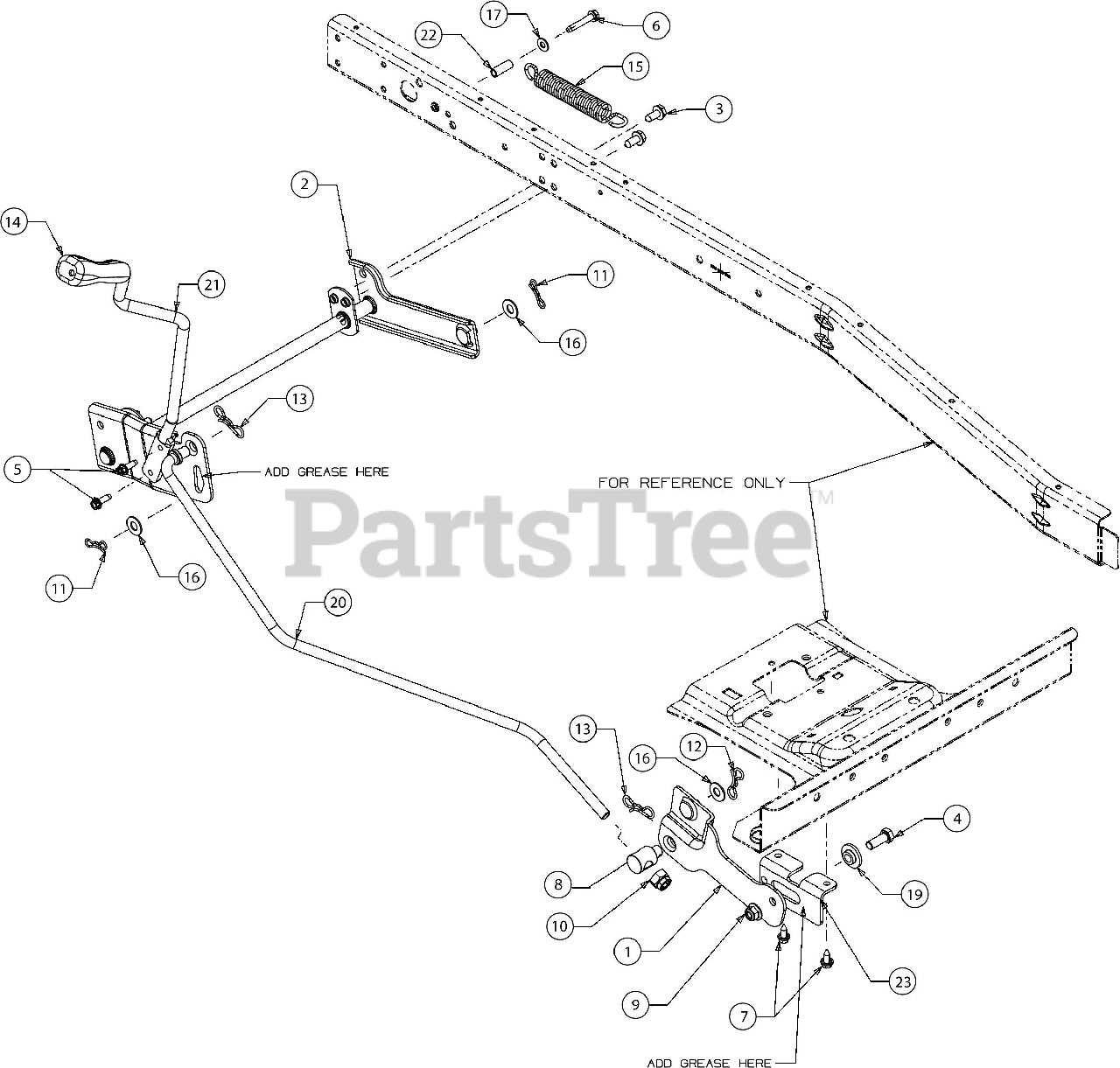

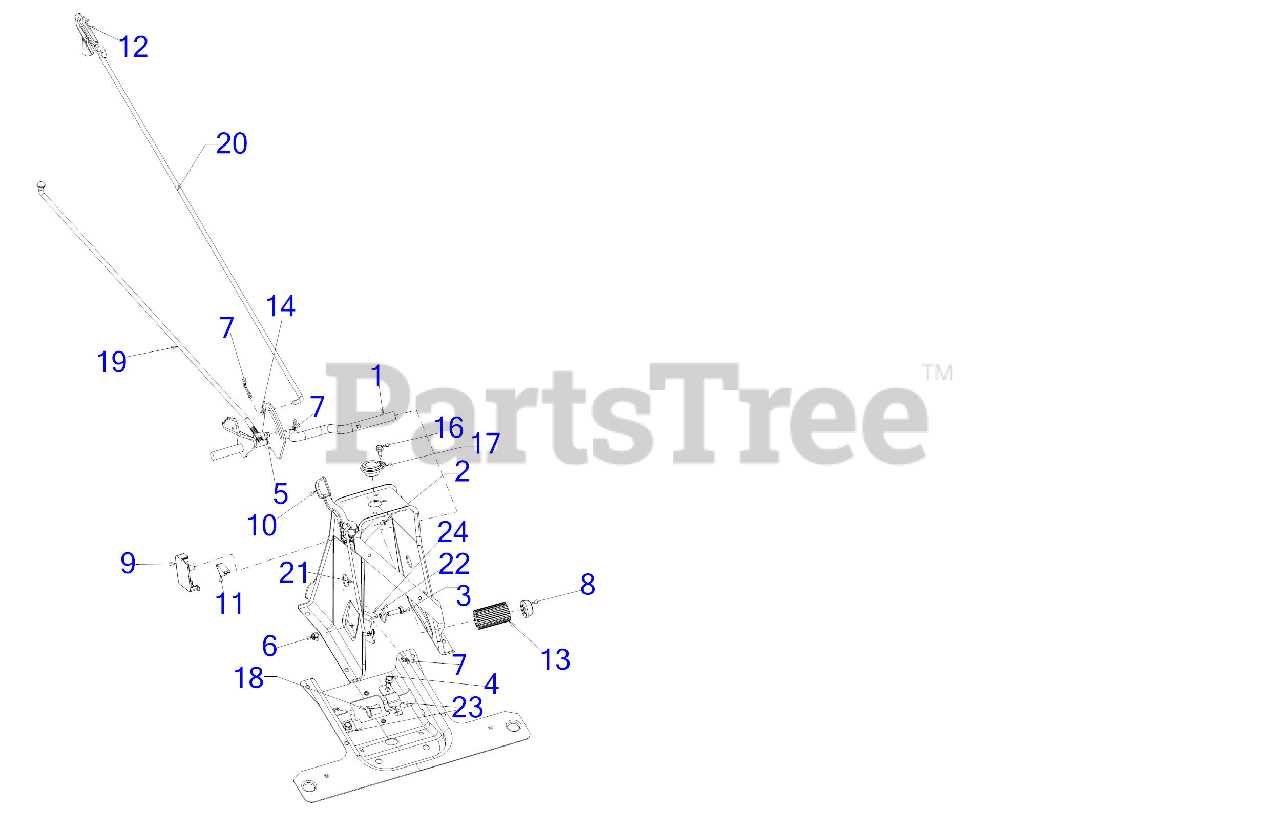

- Begin by identifying the key sections that correspond to the area of concern.

- Examine the visual guide to note the relationships between components, ensuring all elements are correctly positioned.

- Check any references or numbers listed alongside each element to ensure proper part identification during reassembly or replacement.

Using the Parts Diagram Effectively

Understanding how to utilize visual breakdowns for maintenance and repair tasks is essential for ensuring long-lasting performance and accurate fixes. By familiarizing yourself with each component’s placement and function, you can significantly reduce troubleshooting time and prevent common assembly errors.

Step-by-Step Approach

Tips for Effective Use

- Always cross-check the guide with your specific model for compatibility before starting any task.

- Take note of the tools required for each component to avoid unnecessary delays during the process.

- Ensure the device is turned off and disconnected from any power sources.

- Wear appropriate protective gear, such as gloves and safety glasses, to shield yourself from sharp or moving components.

- Read the manufacturer’s manual carefully to understand the proper procedures and warnings.

Ordering Parts for Your Mower

Maintaining your equipment requires timely replacement of components to ensure efficient operation. Whether it’s for routine maintenance or addressing specific issues, understanding how to obtain compatible items is key to keeping your machine in top shape.

Choosing the Right Components

Before making any purchase, identify the correct elements based on your model. Refer to the manual or use online resources to find the precise matches. Be mindful of variations in sizes or configurations to avoid compatibility issues. Always prioritize original or certified alternatives to ensure durability and long-term performance.

Finding Reliable Suppliers

It’s essential to source components from trusted retailers or certified online platforms. Look for vendors that offer detailed product descriptions, customer reviews, and guarantees. Choosing a reliable provider ensures the quality of the components and can help prevent future problems with your machine.

Installation Guidelines for New Parts

When replacing components in any mechanical equipment, it’s essential to follow proper procedures to ensure smooth and efficient operation. The following steps provide clear instructions on how to correctly install new elements, ensuring durability and optimal performance.

Step 1: Prepare the Work Area

Begin by clearing the workspace of any debris or obstructions. This will help create a safe and organized environment, minimizing the risk of damage during installation.

Step 2: Remove Old Components

Carefully detach the old elements, ensuring all bolts, screws, and fasteners are removed properly. Use appropriate tools to avoid damaging adjacent parts. Keep track of all hardware for reuse if needed.

Step 3: Align and Place New Elements

Once the old parts are removed, position the new ones by aligning them with the designated slots or brackets. Make sure the fit is snug and accurate before secur

Comparison of Genuine and Aftermarket Parts

When it comes to maintaining outdoor equipment, choosing between original components and alternative options can have a significant impact on both performance and longevity. Understanding the differences between these choices is crucial for making informed decisions that align with your equipment’s needs and your budget.

Durability and Reliability

Original components are designed specifically for the machine, ensuring perfect compatibility and long-lasting operation. These parts typically undergo extensive testing by the manufacturer to meet high standards. On the other hand, alternative options can vary in quality, and while some offer comparable durability, others may wear out faster or not fit as precisely.

Cost Efficiency

One of the main reasons users opt for alternatives is the price difference. Genuine parts tend to be more expensive due to the brand name and the assurance of reliability. However, aftermarket components often

Safety Precautions While Repairing

When conducting maintenance or fixing outdoor equipment, it is essential to follow strict safety measures to prevent accidents and ensure a smooth repair process. Below are key guidelines to keep in mind before, during, and after working on such machinery.

Preparing for Maintenance

During the Repair Process

- Avoid using damaged or improper tools as they may cause injury or worsen the issue.

Frequently Asked Questions About Repairs

Many users have questions when it comes to addressing common issues with their outdoor maintenance equipment. Understanding how to troubleshoot and fix these machines can save time and effort. This section aims to provide clear answers to frequently asked questions about general maintenance and repair processes.

What Should I Do if My Equipment Stops Running?

One of the most common issues involves the machine failing to start or suddenly stopping during operation. This can be caused by several factors, including fuel problems, spark plug malfunctions, or clogged air filters. Start by checking the fuel supply, making sure the tank isn’t empty, and inspect the spark plug for any signs of damage or dirt. Additionally, ensure the air filter is clean and free of debris.

How Often Should I Replace Blades and Other Components?

The frequency of replacing certain components depends on how often the