For professionals and enthusiasts alike, maintaining and repairing multifunctional tools can be a rewarding experience. Knowing the intricacies of each component is crucial for ensuring optimal performance and longevity. This guide will walk you through the layout and key elements of a widely used tool in the landscaping and gardening sector, helping you better understand how each piece fits into the overall mechanism.

From mechanical joints to replaceable segments, every element plays a vital role in the tool’s functionality. By familiarizing yourself with the configuration and interconnectivity of these elements, you can troubleshoot issues more efficiently and perform maintenance with greater confidence. Whether you’re replacing a single element or overhauling the entire system, this guide will provide you with valuable insights into the layout and arrangement of this indispensable equipment.

Stihl 131r Kombi Overview

This multifunctional tool is designed for versatility, allowing users to efficiently handle a wide range of outdoor tasks. With its powerful engine and adaptable attachment system, it ensures seamless operation in various conditions.

- Engine Efficiency: The device is equipped with a highly efficient motor that provides sufficient power for heavy-duty jobs, while maintaining fuel economy.

- Attachment Compatibility: A key feature is its ability to connect to different accessories, enabling users to switch between trimming, cutting, and other gardening tasks.

- User Comfort: The ergonomic design reduces strain during prolonged use, ensuring comfort even for extended periods of operation.

- Durability: Made from high-quality materials, the tool is built to withstand to

Main Components of the Stihl 131r

The core mechanism of this versatile power tool consists of several essential parts that work together to ensure efficient operation and performance. Understanding these key components allows users to maintain and optimize the tool for a variety of tasks.

Engine Assembly

At the heart of the tool lies the engine, which powers the entire system. This engine is designed for high output and reliability, ensuring that the device can handle heavy workloads. Key elements within the engine include the crankshaft, piston, and cylinder, which convert fuel into mechanical energy.

Drive Shaft and Transmission

The drive shaft connects the motor to the working end of the device, transmitting power from the engine to the cutting or trimming attachment. The transmission ensures that the power is delivered efficiently,

How the Powerhead Works

The powerhead is the central component of the tool’s engine system, responsible for generating the necessary energy to drive the attached implement. It acts as the core of the operation, converting fuel into mechanical force. This section delves into the mechanics behind this process, explaining how the engine’s various elements work in harmony to ensure efficient performance.

At its core, the engine operates by drawing fuel from the tank, mixing it with air, and igniting it within the combustion chamber. This controlled explosion produces energy, which powers the crankshaft. The crankshaft’s rotation then drives the cutting or trimming attachment through a series of gears and couplings, enabling the tool to function efficiently in various conditions. The process is cyclic, ensuring a continuous supply of energy

Fuel System and Its Maintenance

The fuel system plays a critical role in ensuring efficient engine operation. Proper maintenance of this system is essential to prevent breakdowns and maintain optimal performance. Understanding how the components interact, along with routine inspections, can help avoid costly repairs and extend the lifespan of your equipment.

Key Components of the Fuel System

The system typically includes a fuel tank, filters, lines, and a carburetor. Each of these elements needs to be kept clean and free of debris to avoid blockages that can impair engine function. Regularly checking for leaks, cracks, or wear in the fuel lines ensures that fuel flows without interruption. The filter, which prevents contaminants from entering the engine, should be replaced or cleaned periodically for smooth operation.

Maintenance Tips

To maintain the fuel system, always use clean, high-quality fuel to reduce the risk of contamination. If the equipment is stored for long periods, it’s crucial to empty the fuel tank or use a stabilizer to prevent fuel degradation. Additionally, it’s advisable to inspect and clean the carburetor, ensuring it delivers the correct fuel-air mixture for the engine to run efficiently

Understanding the Ignition Assembly

The ignition assembly is a crucial component in ensuring a machine’s smooth operation. It is responsible for generating the electrical spark required to ignite the engine’s fuel mixture, allowing it to start and run efficiently. This system typically includes elements such as a spark plug, ignition coil, and wiring that connect these parts together. A properly functioning ignition assembly ensures reliable performance and helps prevent engine misfires or failure to start.

The ignition coil plays a central role by transforming the battery’s low voltage into the high voltage necessary to create a spark at the plug. Worn or damaged components in this assembly can result in weak or inconsistent sparks, leading to poor engine performance or complete failure to operate. Regular inspection and maintenance of the ignition assembly can help avoid such issues and ensure the equipment remains in optimal working condition.

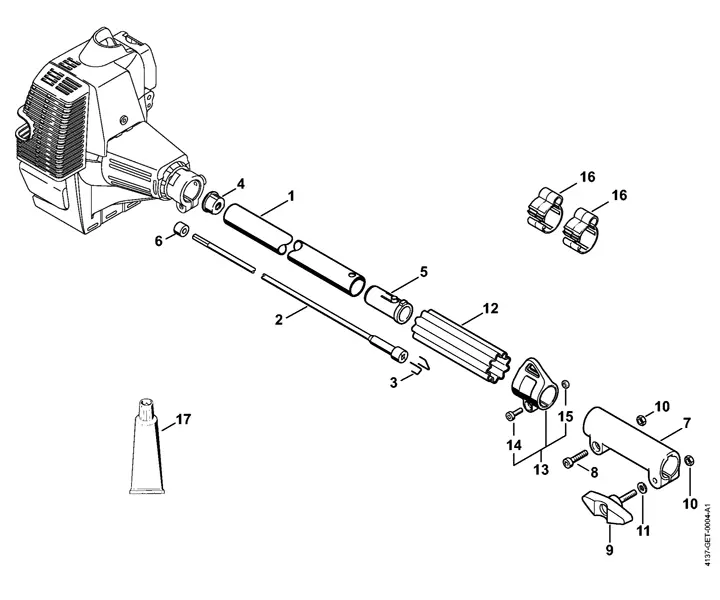

Drive Shaft Mechanism Explained

The drive shaft is a crucial component in many mechanical systems, serving to transmit power from the engine to various attachments. This mechanism plays a vital role in ensuring efficient operation and optimal performance, allowing different tools to function effectively. Understanding its design and function can provide valuable insights into the overall efficiency of the system.

Functionality of the Drive Shaft

The primary purpose of the drive shaft is to convey rotational energy from the engine to the working parts of the machine. It is typically constructed from durable materials to withstand the stress and forces exerted during operation. This mechanism not only transfers power but also helps maintain the necessary alignment between the engine and the attachment, ensuring smooth and reliable performance.

Components of the Drive Shaft System

A typical drive shaft assembly comprises several key components, including universal joints, couplings, and bearing supports. Universal joints allow for angular movement, accommodating changes in alignment as the machine operates. Couplings connect the drive shaft to the engine and the attachment, providing a secure link while enabling easy disconnection for maintenance. Bearing supports reduce friction and wear, enhancing the longevity of the system. Together, these elements work harmoniously to ensure that power is efficiently transmitted without compromising stability.

Handle and Control Layout

The arrangement of the handles and controls on outdoor power equipment is crucial for ensuring user comfort and operational efficiency. A well-designed layout allows for intuitive access to various functions, promoting safer and more effective usage. This section delves into the ergonomic features and control configurations that enhance the overall experience while operating such devices.

Typically, the handle system is engineered to provide a secure grip, facilitating optimal maneuverability. Users can expect strategically placed controls for throttle management, power engagement, and other functionalities, allowing for seamless operation without compromising safety. The layout is often designed to accommodate different hand sizes and operating positions, ensuring versatility and comfort.

Control Description Throttle Control Regulates engine speed, allowing for precise adjustments during operation. Power Switch Turns the equipment on and off, providing a simple method for power management. Safety Lock Prevents accidental activation, ensuring safe handling when the unit is not in use. Vibration Dampeners Reduces user fatigue by minimizing the effects of engine vibrations during extended use. In summary, an effective handle and control layout is essential for optimizing the user experience. Thoughtful design and placement of controls not only enhance functionality but also contribute to safety and ease of use in various operating conditions.

Air Filter and Its Role

The air filter is a crucial component in many outdoor power tools, serving as the first line of defense against contaminants that could harm the engine. By trapping dirt, dust, and debris, it ensures that only clean air enters the combustion chamber, which is vital for optimal performance and longevity of the equipment.

Functionality plays a significant role in the overall efficiency of the machinery. When the air filter is clean and functioning correctly, it allows for proper airflow, facilitating effective combustion. This results in enhanced power output and fuel efficiency, contributing to the tool’s operational effectiveness.

Over time, however, the air filter can become clogged with particles, which restricts airflow and leads to decreased engine performance. In this situation, regular maintenance is essential to prevent potential issues such as overheating and misfiring. Cleaning or replacing the air filter at recommended intervals helps maintain optimal airflow, ensuring the engine operates smoothly and efficiently.

In summary, the air filter is an integral part of outdoor power equipment, significantly impacting performance and durability. Proper care and maintenance of this component are vital to ensure the longevity and effectiveness of the machine.

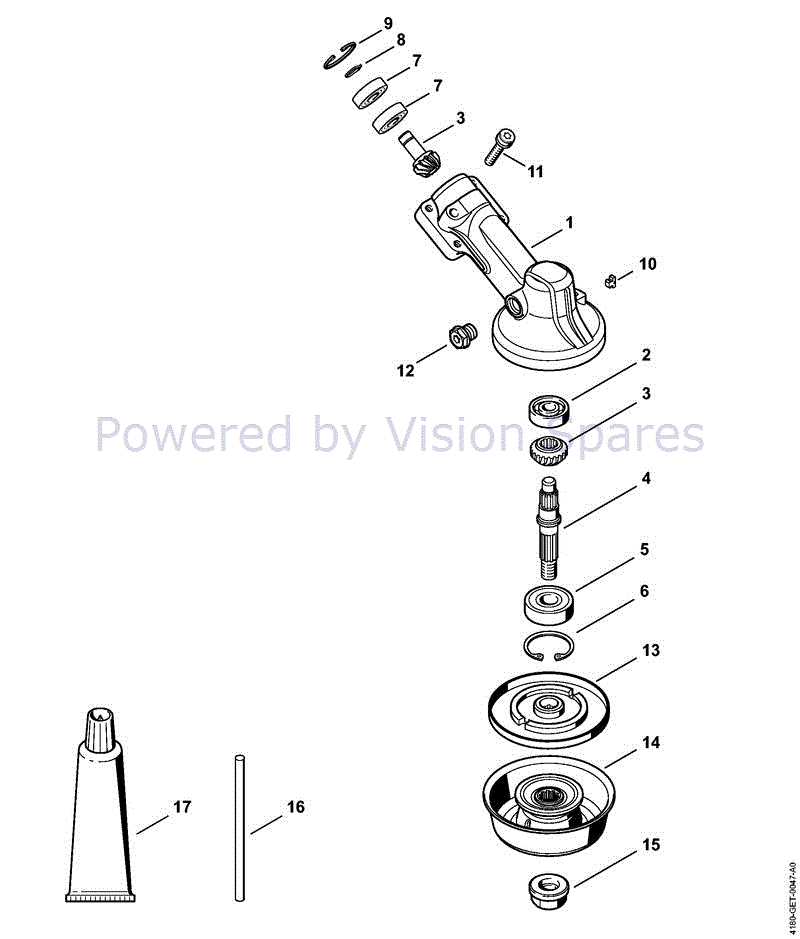

Blades and Cutting Attachments

The effectiveness of a gardening tool largely depends on the type of blades and cutting implements used. Various attachments serve specific purposes, enhancing the versatility and performance of the equipment. Understanding the characteristics and applications of different cutting accessories is essential for achieving optimal results in outdoor tasks.

Several blade types are available, each designed for particular cutting tasks. For instance, a grass blade is ideal for trimming and mowing, while a brush blade excels at clearing thicker vegetation. Additionally, specialized attachments like hedge trimmers and pruners cater to specific needs, allowing users to tackle a range of gardening challenges efficiently.

Proper maintenance and selection of these attachments significantly impact their performance and longevity. Regular inspection for wear and tear, along with timely sharpening, ensures that the blades operate at peak efficiency. Moreover, choosing the right attachment for the job not only enhances productivity but also promotes safety during operation.

In summary, understanding the various blades and cutting implements available can greatly enhance the effectiveness of your gardening tasks. By selecting the appropriate attachments and maintaining them properly, you can ensure that your outdoor equipment remains a valuable asset in your gardening endeavors.

Best Practices for Assembly

Proper assembly of equipment is essential for ensuring optimal performance and longevity. Following systematic procedures can help prevent mistakes and enhance efficiency. The following guidelines will aid in achieving a successful assembly process.

Preparation Steps

- Read the instruction manual thoroughly to understand all components and their functions.

- Gather all necessary tools and components before starting the assembly.

- Work in a clean, organized area to minimize the risk of losing parts or making errors.

Assembly Techniques

- Begin with the base unit, ensuring it is stable and secure.

- Attach components sequentially, verifying proper alignment and fit as you progress.

- Use the recommended fastening techniques to ensure all connections are tight and reliable.

- Double-check each connection before moving on to the next step to avoid rework.

Adhering to these best practices will result in a well-assembled unit that operates efficiently and effectively. Taking the time to assemble components correctly pays off in performance and durability.

Troubleshooting Common Issues

When using outdoor power equipment, encountering operational difficulties is not uncommon. Recognizing and addressing these challenges promptly can enhance performance and extend the lifespan of your tools. This section aims to provide practical insights into frequently observed problems and their potential solutions, enabling users to maintain optimal functionality.

Engine Won’t Start

If the engine fails to ignite, several factors may be at play. First, ensure that there is adequate fuel in the tank and that it is fresh. Stale fuel can lead to starting issues. Additionally, inspect the spark plug for wear or damage, as a faulty spark plug can prevent ignition. Checking the air filter for blockages is also advisable, as a clogged filter can hinder airflow and affect engine performance.

Loss of Power During Operation

A decrease in power while operating the equipment may indicate various underlying issues. One common cause is the accumulation of debris in the air filter, which restricts airflow. Cleaning or replacing the air filter can often resolve this problem. Additionally, inspect the fuel lines for any signs of leaks or blockages, as fuel delivery issues can significantly impact performance. Regular maintenance of the spark plug is also crucial, as a worn plug can contribute to power loss.