Maintaining your outdoor machinery requires a clear understanding of its various elements and how they interact with each other. This knowledge is essential for effective repairs and ensuring optimal performance. By examining the layout and functionality of individual components, users can gain insights into their equipment’s operational efficiency.

Visual representations of machinery arrangements serve as invaluable tools for both seasoned technicians and novices alike. These illustrations break down complex systems into manageable sections, highlighting the relationship between parts and their specific roles. Whether it’s for troubleshooting or routine maintenance, having access to these guides can significantly streamline the process.

Moreover, familiarizing oneself with the intricate details of mechanical systems fosters greater confidence in handling repairs. By learning about each segment and its purpose, users can tackle issues with a more informed perspective. This knowledge not only enhances repair skills but also contributes to the longevity of the machinery.

Understanding the Husqvarna 123L Model

This section delves into the features and functionalities of a specific model designed for outdoor tasks. It is crucial for users to comprehend its components and how they work together to enhance performance and efficiency. Familiarity with the machinery can lead to improved maintenance practices and better operational outcomes.

Key Features and Advantages

This particular model boasts a lightweight design, making it easy to maneuver during various landscaping activities. Its powerful engine delivers robust performance, ensuring that even challenging tasks can be completed with ease. Additionally, the ergonomic handle contributes to user comfort, reducing fatigue during extended use.

Maintenance and Care

Understanding the essential elements of maintenance is vital for prolonging the life of the equipment. Regular inspections of the critical components, such as the air filter and spark plug, can prevent potential issues. Proper lubrication and timely replacements will ensure optimal functionality and reliability over time.

Essential Components of the 123L

This section explores the fundamental elements that make up a well-functioning trimmer, highlighting their importance and interconnectivity. Each part plays a vital role in ensuring optimal performance and efficiency during operation.

The engine serves as the powerhouse, driving the entire mechanism with precision. Coupled with the fuel system, it ensures a reliable supply of energy for uninterrupted use. The cutting head is essential for achieving a clean and effective trim, featuring blades or strings tailored for different tasks.

The handle and grip enhance user comfort, allowing for better maneuverability and control. Additionally, the safety features incorporated into the design are crucial for protecting the operator while ensuring smooth operation. Understanding these components is key to maintaining and optimizing performance.

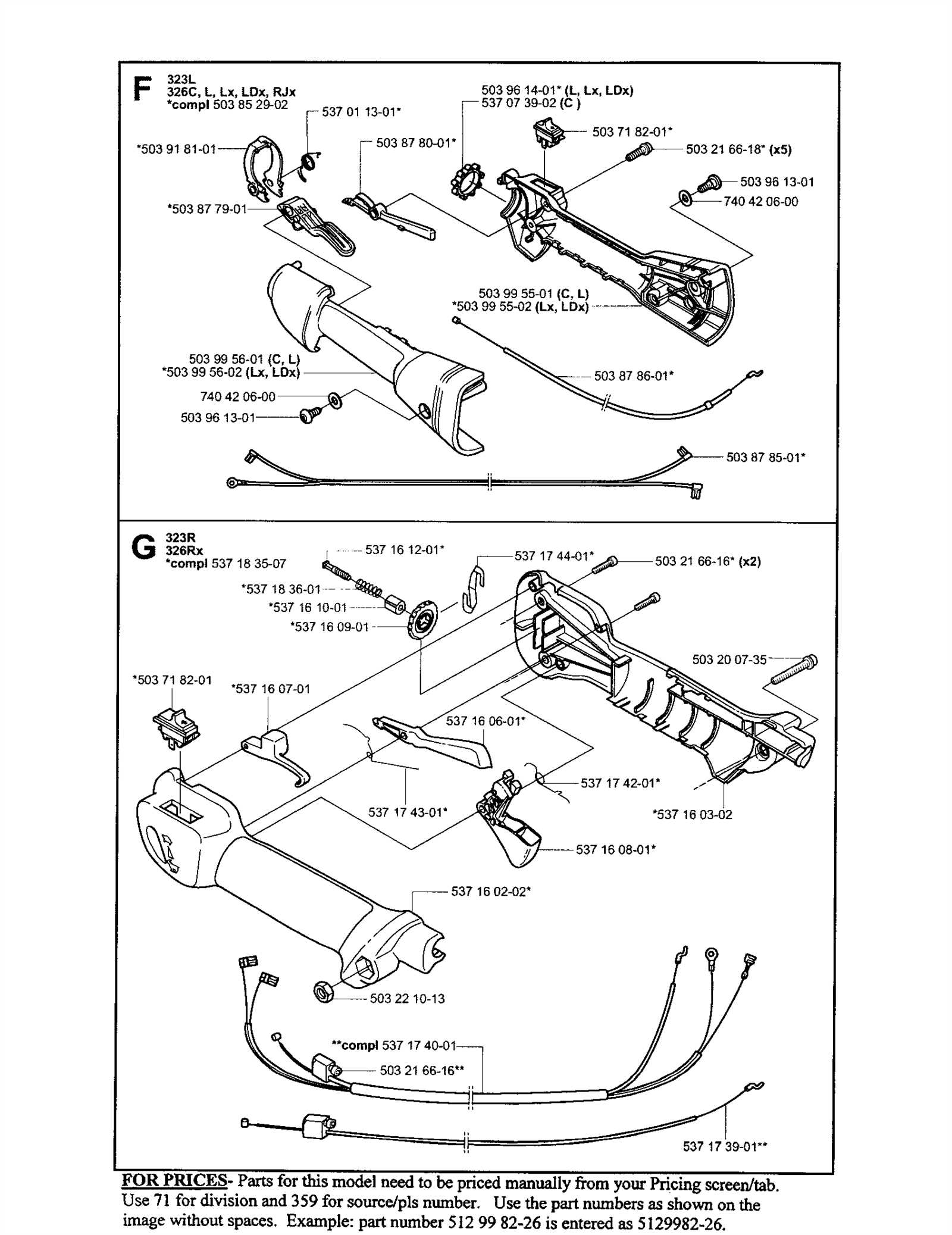

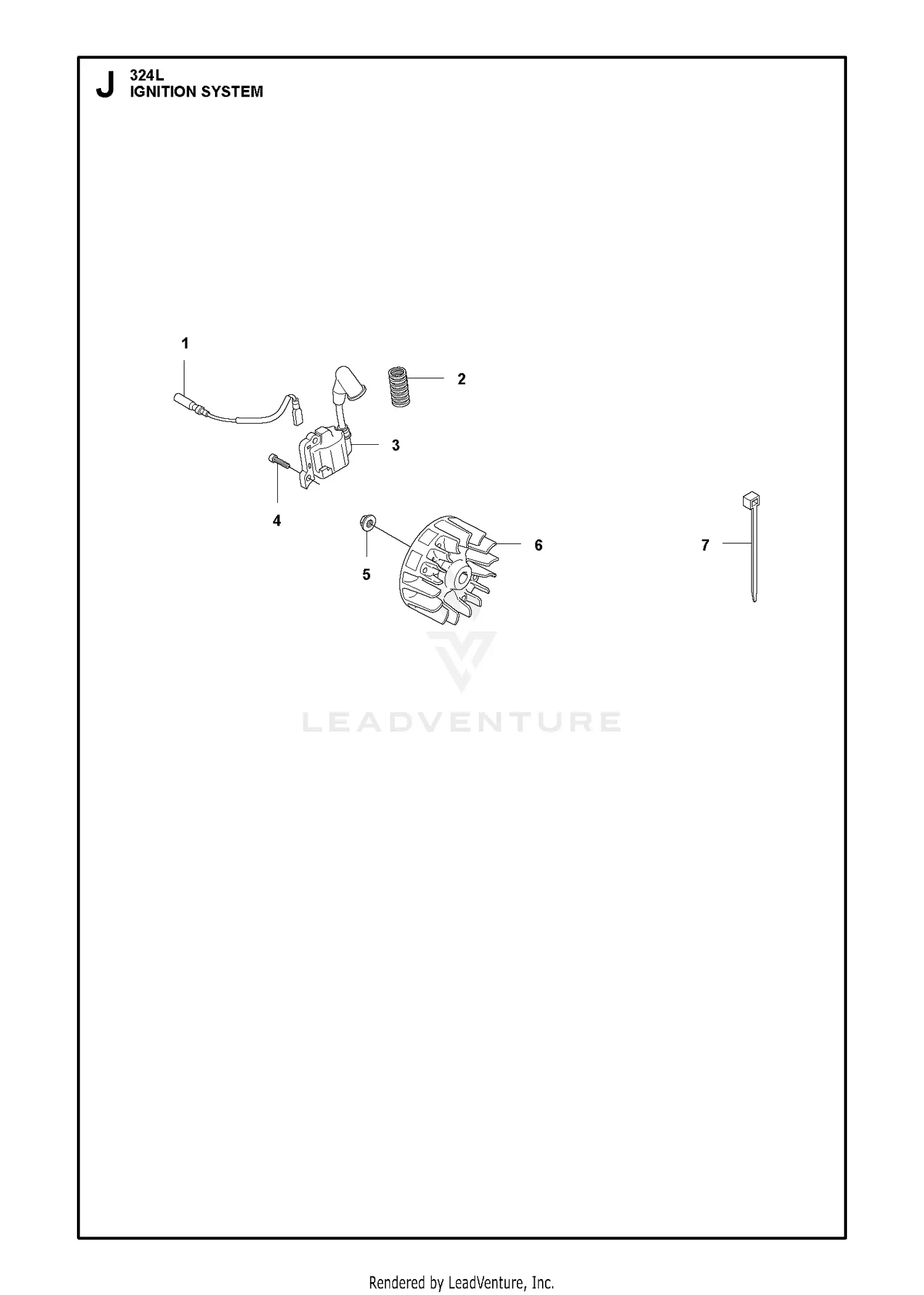

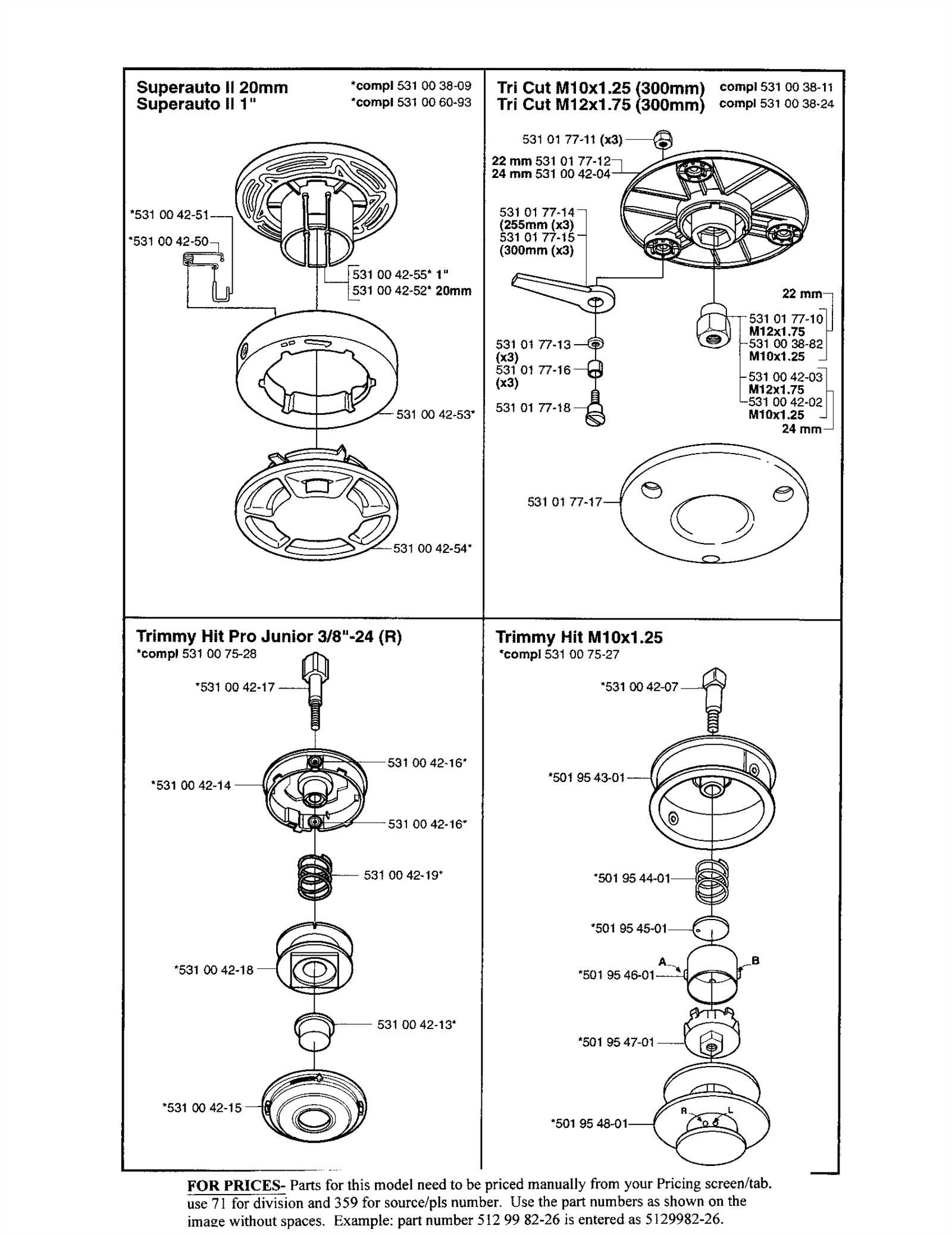

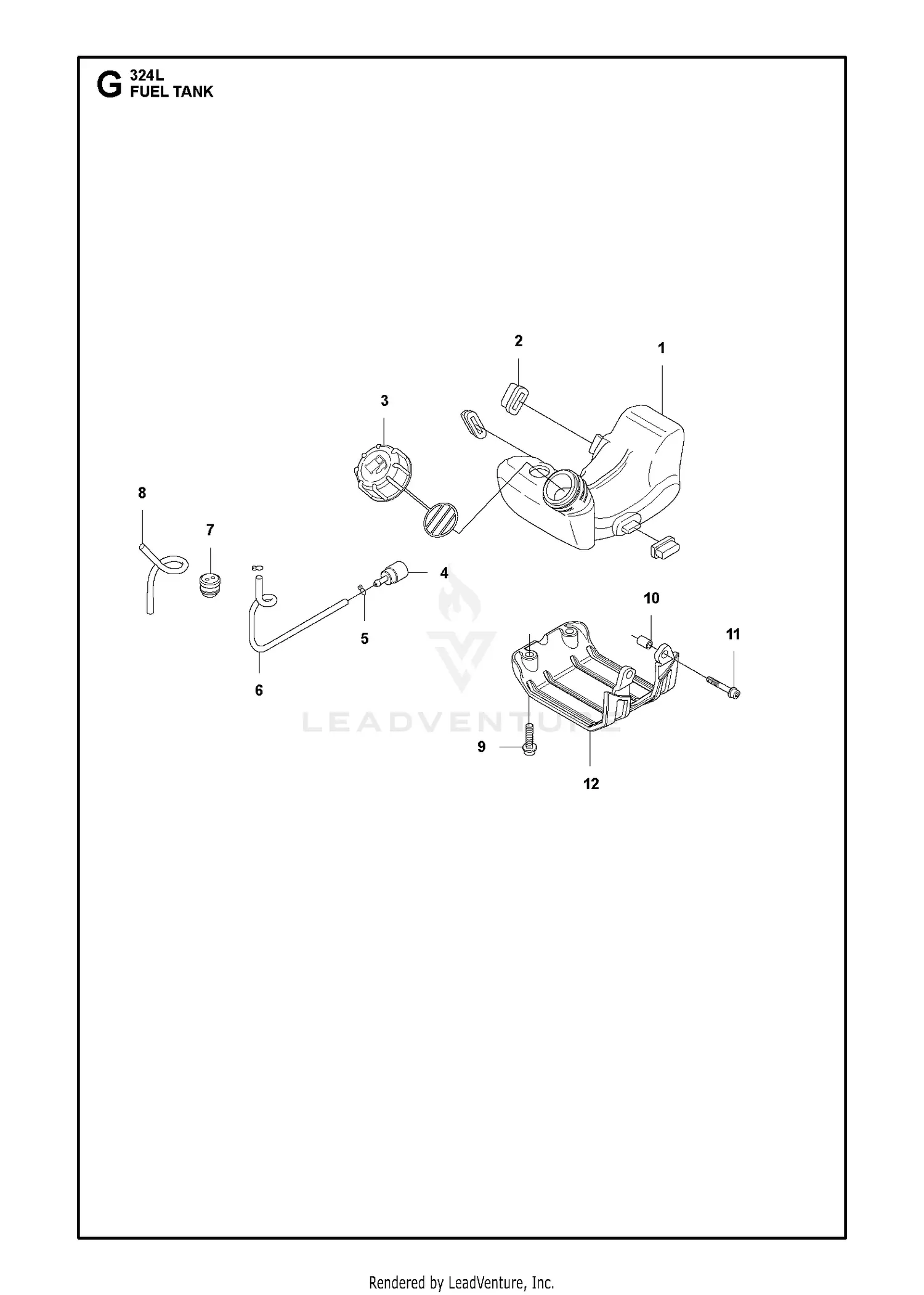

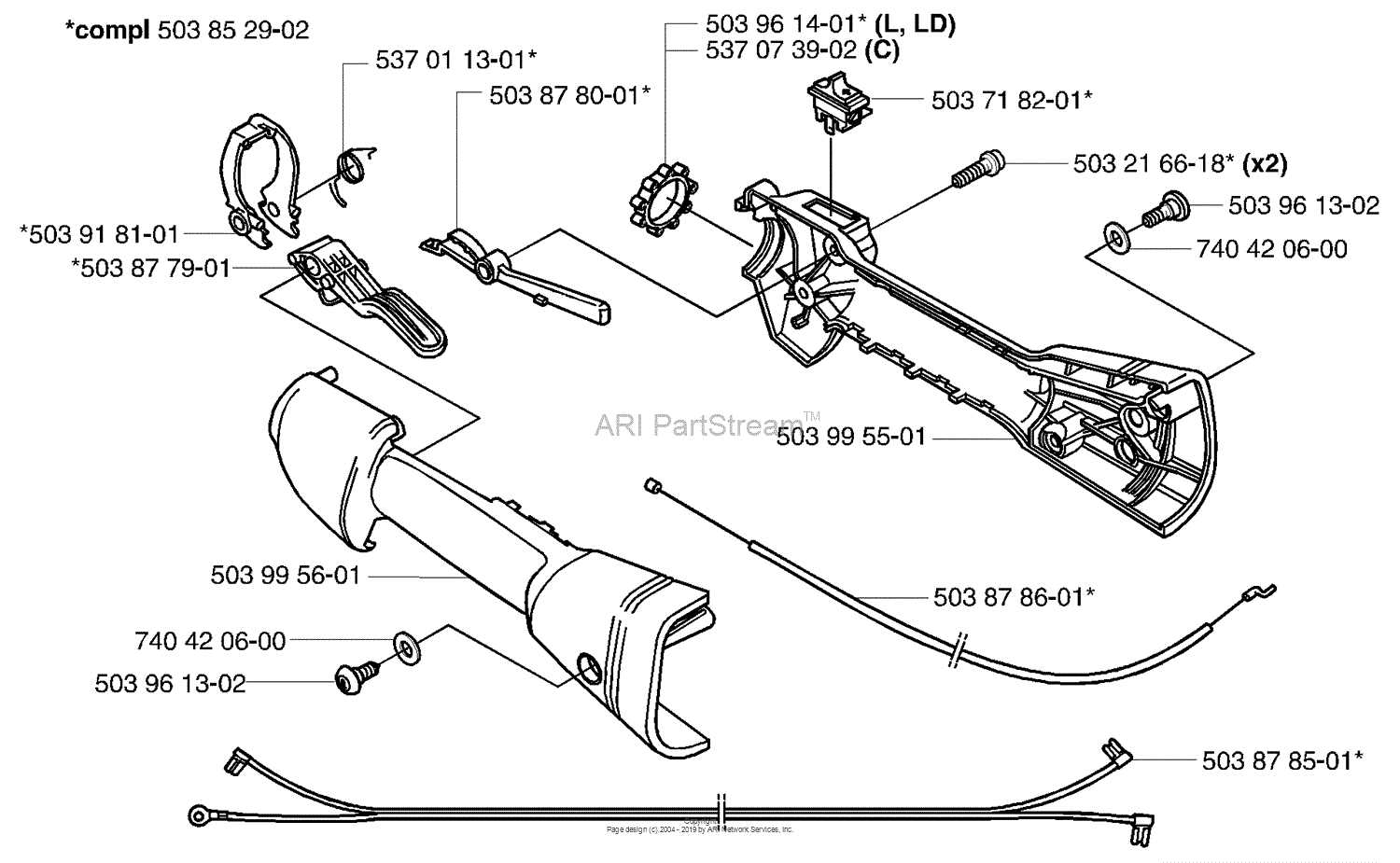

Parts Diagram Overview

This section aims to provide a comprehensive look at the components involved in the machine, highlighting their interconnections and functionality. Understanding these elements is essential for effective maintenance and repair, ensuring optimal performance and longevity.

Importance of Component Understanding

Grasping the layout and relationship of each element enables users to troubleshoot issues more efficiently. Familiarity with the configuration enhances the ability to replace worn or damaged pieces, ultimately leading to improved operation.

Utilizing the Visual Representation

The visual representation serves as a valuable reference tool, allowing users to delve into specifics. By consulting this guide, one can ensure that all necessary components are identified, paving the way for successful upkeep and repairs.

Importance of Using Genuine Parts

Utilizing authentic components is crucial for ensuring the longevity and performance of any machinery. When quality elements are used, the overall functionality and reliability are significantly enhanced, leading to smoother operation and reduced downtime.

Enhanced Performance

Original components are engineered specifically for particular models, guaranteeing optimal fit and compatibility. This precision minimizes the risk of malfunctions and promotes efficient energy use, ultimately delivering superior results.

Cost-Effectiveness

While counterfeit alternatives may seem more economical initially, they often lead to increased wear and potential damages. Investing in genuine items ensures durability and reduces the need for frequent replacements, saving money in the long run.

Common Issues and Solutions

This section addresses frequent problems encountered with outdoor power equipment and provides effective solutions. Understanding these issues can enhance the overall performance and longevity of the device.

| Issue | Description | Solution |

|---|---|---|

| Engine Won’t Start | The engine fails to initiate, often due to fuel delivery problems or ignition failures. | Check fuel levels, ensure fresh gasoline is used, and inspect spark plug conditions. |

| Overheating | The equipment becomes excessively hot during operation, which can lead to malfunctions. | Examine air filters for blockages and ensure the cooling fins are clear of debris. |

| Unstable Idling | The engine idles unevenly, causing vibrations and discomfort during use. | Adjust the idle speed and clean the carburetor to maintain optimal performance. |

| Excessive Vibration | Unusual vibrations can occur, potentially indicating worn components or misalignment. | Inspect all parts for wear, tighten any loose screws, and balance the cutting head. |

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide valuable insights into how different elements fit together and function in unison. By familiarizing yourself with the layout and symbols used, you can streamline your repair process and ensure accurate assembly.

Identify the Components

The first step in interpreting these visuals is to identify the individual elements depicted. Each part will typically be labeled with a unique identifier, allowing you to cross-reference with a list of components. Familiarizing yourself with the common terminology will enhance your comprehension and facilitate easier troubleshooting.

Understand the Connections

Next, focus on how the components interact with one another. Lines and arrows may indicate connections, assembly order, or operational flow. Recognizing these relationships is crucial for proper installation or replacement, as it ensures that each piece functions harmoniously within the overall system.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is crucial for optimal performance. Whether you’re looking to replace a worn-out item or upgrade your machinery, knowing where to find reliable sources can save time and ensure that your devices run smoothly.

Authorized Retailers

One of the best places to start your search is through authorized retailers. These suppliers often provide genuine items and have knowledgeable staff to assist with your needs.

- Visit local dealers that specialize in outdoor equipment.

- Check online platforms that are affiliated with certified vendors.

- Inquire about warranty options for newly purchased components.

Online Marketplaces

The internet offers a vast array of options for acquiring necessary replacements. Utilizing well-known online marketplaces can lead you to competitive prices and a wide selection.

- Explore popular e-commerce websites.

- Read reviews and ratings to gauge seller reliability.

- Consider second-hand items for more budget-friendly choices.

Maintenance Tips for Longevity

To ensure the extended life of your equipment, it is essential to adopt regular upkeep practices. Proper maintenance not only enhances performance but also minimizes the risk of unforeseen breakdowns. This section offers valuable insights to keep your machine operating efficiently for years to come.

Regular Cleaning

Keeping the machinery clean is crucial for optimal functioning. Accumulated dirt and debris can lead to overheating and decreased efficiency. Ensure to wipe down the exterior and remove any buildup from air intakes and cooling vents.

Routine Inspections

Conducting periodic checks on essential components helps identify wear and tear before they escalate into significant issues. Pay attention to parts that experience heavy usage, and replace them as needed to maintain peak performance.

| Maintenance Task | Frequency |

|---|---|

| Clean the exterior and air filters | After every use |

| Check oil levels | Weekly |

| Inspect and tighten bolts | Monthly |

| Replace worn parts | As needed |

Tools Needed for Assembly

When undertaking the reassembly of your equipment, having the right tools at your disposal is essential for a smooth and efficient process. Properly chosen instruments not only facilitate the assembly but also ensure that each component is securely fitted, promoting optimal performance and longevity.

Essential Hand Tools

Basic hand tools are vital for most assembly tasks. A set of screwdrivers in various sizes will help tackle different screw types, while a wrench set is necessary for tightening bolts securely. Additionally, pliers can assist in gripping and manipulating smaller parts, providing the extra leverage needed for those tricky adjustments.

Specialized Equipment

In some cases, specialized tools may be required to achieve a precise fit. For example, torque wrenches ensure that bolts are tightened to the manufacturer’s specifications, preventing over-tightening and potential damage. Furthermore, using gaskets or sealants as needed can enhance the assembly’s integrity, preventing leaks and ensuring optimal operation.

Assembly Process Explained

The assembly of a garden tool is a crucial step that ensures optimal performance and longevity. Understanding the components involved and their arrangement can simplify the process, making it more efficient and manageable for users. This section outlines the key elements and steps necessary to successfully assemble the device, enhancing user experience and functionality.

Initially, it is important to gather all necessary components before starting the assembly. This preparation helps prevent confusion and ensures that each piece is readily available when needed. Below is a table that summarizes the essential components typically involved in the assembly:

| Component | Description |

|---|---|

| Body Housing | The main structure that houses the engine and other internal components. |

| Handle | The part that provides grip and control during operation. |

| Engine | The power unit responsible for driving the tool’s functions. |

| Fuel Tank | The reservoir for storing fuel needed for operation. |

| Blade | The cutting element that performs the main task of the tool. |

Following the preparation phase, the next steps involve carefully attaching each component according to the provided guidelines. Starting with the engine, it should be securely mounted within the body housing. Next, the handle is affixed, ensuring that it is stable and positioned correctly for ease of use. The fuel tank should then be installed, followed by the attachment of the blade. Each step must be executed with precision to guarantee safety and efficiency.

Once all parts are assembled, conducting a thorough inspection is essential to ensure everything is correctly installed. This final check helps identify any loose connections or misplaced components, allowing for adjustments before the tool is put to use.

Upgrading Your 123L Equipment

Enhancing your outdoor tool can significantly improve its performance and longevity. By investing in quality components, you can elevate the functionality of your machinery, ensuring it operates at its best. This section will explore essential upgrades that can transform your equipment into a more efficient and reliable asset.

Key Improvements to Consider

When contemplating enhancements, focus on elements that directly affect efficiency and user experience. For instance, upgrading the cutting attachment can yield better results in terms of speed and precision. Additionally, considering ergonomic handles can enhance comfort during extended usage, reducing fatigue and improving control.

Maintenance and Regular Updates

Regular maintenance is crucial for maximizing the performance of your tools. Keep an eye on wear and tear, and replace components as needed. Incorporating new technology, such as advanced ignition systems or fuel-efficient engines, can also lead to significant improvements in overall effectiveness. Always consult your user manual for guidance on compatible enhancements.

Customer Reviews and Experiences

This section focuses on the feedback and insights shared by users regarding their experiences with the product. Customers often provide valuable information that highlights the strengths and weaknesses of the item, helping potential buyers make informed decisions. Personal stories and practical advice can greatly enhance understanding of the product’s performance and reliability.

Positive Feedback

Many users express satisfaction with the overall functionality and efficiency of the device. The ease of use and effective performance in various tasks are commonly mentioned benefits. Users appreciate the durability and how well the machine handles different challenges, often noting that it exceeds their expectations in terms of quality and longevity.

Challenges and Considerations

While there are numerous positive reviews, some customers highlight specific challenges they faced. Common concerns include maintenance requirements and occasional difficulties with certain components. Understanding these challenges can assist potential buyers in preparing for any issues they may encounter and emphasize the importance of proper care and attention.