Do not a

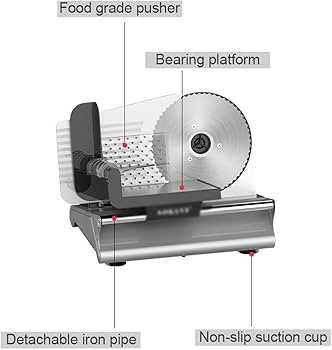

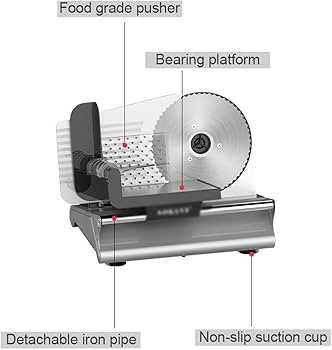

Importance of the Food Pusher

The food pusher plays a crucial role in ensuring safe and efficient operation during the slicing process. This essential component not only facilitates the movement of items toward the cutting blade but also protects users from potential accidents. Understanding its significance enhances awareness of safe food handling practices.

Functionality and Benefits

Several key aspects highlight the importance of the food pusher:

- Safety: The food pusher minimizes the risk of injury by keeping hands away from sharp blades.

- Efficiency: It allows for consistent slicing, promoting uniformity in thickness and presentation.

- Control: Users can easily guide various food items with precision, ensuring optimal results.

Maintenance and Care

Proper maintenance of the food pusher is essential for its longevity and effectiveness. Consider the following tips:

- Regularly clean the component to prevent food buildup.

- Inspect for wear or damage, replacing it as necessary.

- Ensure proper alignment with the cutting mechanism for smooth operation.

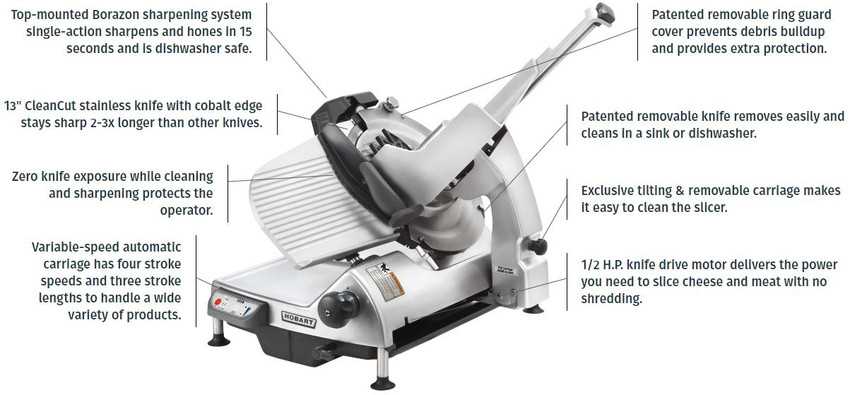

Maintaining the Blade Sharpener

Ensuring the longevity and effectiveness of a blade sharpener is essential for optimal performance. Regular upkeep not only enhances the sharpening process but also contributes to the overall safety and efficiency of the equipment.

Here are some key practices to consider:

- Regular Cleaning: After each use, clean the sharpener to remove any food particles or debris. This helps prevent contamination and maintains the sharpness of the blades.

- Inspect for Damage: Periodically check for any signs of wear or damage. Look for cracks or dull edges, as these can affect performance and safety.

- Lubrication: Apply appropriate lubricants to moving parts to ensure smooth operation. This reduces friction and prolongs the lifespan of the sharpener.

- Calibration: Regularly calibrate the sharpener to ensure it is set to the correct angle. This is vital for achieving optimal sharpening results.

By following these maintenance practices, you can ensure that the blade sharpener operates efficiently, enhancing the overall performance of your cutting equipment.

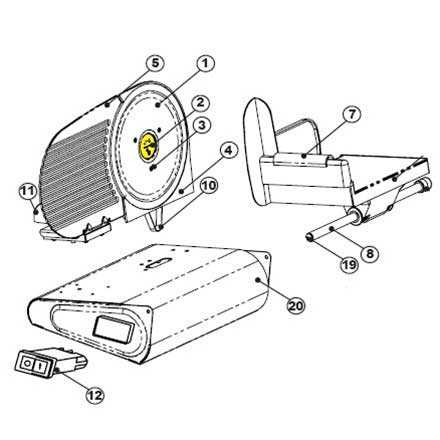

Power Switch and Electrical Components

This section focuses on the essential electrical elements that ensure the efficient operation of the device. Understanding these components is crucial for proper functioning, safety, and maintenance.

Key Electrical Elements

- Power Switch: This device is responsible for initiating or interrupting the flow of electricity, allowing for easy operation and safety.

- Wiring: High-quality wiring ensures that electrical current flows safely between components, minimizing the risk of shorts and overloads.

- Fuse: A safety device designed to protect the electrical circuit by breaking the connection in case of excessive current.

- Transformer: Converts voltage levels to ensure that all components receive the appropriate electrical supply.

- Motor: Powers the mechanical movement of the equipment, crucial for its functionality.

Maintenance Tips

- Regularly inspect the power switch for wear or damage.

- Ensure all wiring connections are secure and free of corrosion.

- Replace fuses as needed to maintain circuit protection.

- Check the motor for proper operation and any signs of overheating.

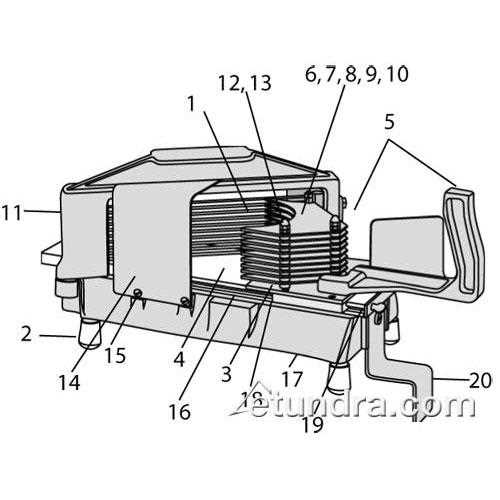

How the Meat Tray Operates

The functionality of the food tray is essential in the preparation process, serving as a platform for items before they are processed. This component ensures that products are efficiently presented for cutting, enhancing both convenience and safety in the kitchen environment.

Structure and Design

The design of the tray plays a critical role in its performance. Key features include:

- Material Quality: Durable materials are used to withstand wear and tear.

- Surface Area: A larger surface allows for accommodating multiple items simultaneously.

- Ergonomic Design: Shapes that facilitate easy handling and transport.

Operational Mechanism

The operational efficiency of the tray is enhanced through several mechanisms:

- Stability: Secure positioning prevents slipping during operation.

- Accessibility: An open design allows for easy loading and unloading of items.

- Compatibility: The tray is designed to fit seamlessly with other kitchen appliances.

Understanding how this component operates contributes to better food handling practices, ensuring safety and efficiency during the preparation process.

Cleaning and Sanitizing Components

Maintaining hygiene is essential in any food preparation setting, especially when it comes to equipment that processes various ingredients. Proper cleaning and sanitizing ensure the longevity of the machine and contribute to food safety. This section outlines effective methods for cleaning and sanitizing the essential elements of your apparatus.

Essential Cleaning Procedures

Before sanitizing, it is crucial to clean all surfaces thoroughly to remove food residues, grease, and other contaminants. The following steps can be taken:

| Step |

Action |

Notes |

| 1 |

Disassemble components |

Remove all detachable elements for easy access. |

| 2 |

Wash with warm soapy water |

Use a non-abrasive sponge to avoid scratches. |

| 3 |

Rinse thoroughly |

Ensure all soap is removed to prevent residue. |

Sanitizing Techniques

After cleaning, it’s important to sanitize the components to kill any remaining germs and bacteria. Here are some effective sanitizing methods:

| Method |

Instructions |

| Chemical Sanitizers |

Apply a food-safe sanitizer following the manufacturer’s instructions, ensuring proper contact time. |

| Hot Water Rinse |

Rinse components with water at least 180°F (82°C) for effective sanitization. |

Handle and Grip Design Features

The design of the handle and grip is crucial in ensuring user comfort and safety during operation. An ergonomic approach enhances control and reduces fatigue, allowing for a more efficient and enjoyable experience. Features such as texture, shape, and material play significant roles in how the device is handled, impacting both usability and overall effectiveness.

Ergonomics and Comfort

An ergonomic handle design minimizes strain on the user’s hands, which is essential during prolonged use. Features like contouring and strategic placement of grips enhance the natural position of the hand, promoting a secure hold. Materials that offer a soft touch can also contribute to a comfortable experience, reducing the likelihood of slipping.

Grip Texture and Material

The texture of the grip can significantly affect the user’s ability to maintain control. Textured surfaces provide a better hold, especially in wet or slippery conditions. Additionally, the choice of materials, such as rubber or silicone, can enhance grip stability and comfort. The following table summarizes common grip materials and their characteristics:

| Material |

Grip Quality |

Durability |

| Rubber |

Excellent |

High |

| Silicone |

Good |

Medium |

| Plastic |

Variable |

Medium to High |

Lubrication Points for Smooth Operation

Effective lubrication is essential for maintaining optimal performance and longevity of machinery. Proper application of lubricants at designated locations ensures seamless functionality, reduces wear and tear, and minimizes the risk of malfunction. Understanding where to apply lubrication can significantly enhance the efficiency of the equipment.

Key areas that require regular lubrication include moving components such as bearings, gears, and any other friction points. It is vital to use the appropriate type of lubricant suited for each specific part to achieve the best results. This not only aids in reducing friction but also helps in dissipating heat generated during operation.

Regular inspection and maintenance of lubrication points should be part of a scheduled routine. Neglecting these areas can lead to decreased performance, increased noise levels, and potential damage to the overall system. By ensuring these points are adequately serviced, operators can significantly prolong the lifespan of their equipment and maintain peak efficiency.

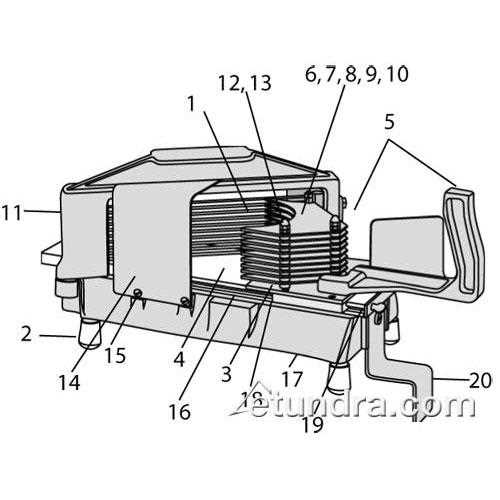

Replacing Worn-Out Parts

Regular maintenance is essential to ensure optimal performance and longevity of any machine. Over time, components may become degraded, affecting efficiency and safety. Identifying and replacing these worn elements promptly is crucial for maintaining operational standards.

Signs of Wear and Tear

- Unusual noises during operation

- Decreased efficiency or performance

- Visible damage or wear on components

- Frequent breakdowns or malfunctions

Replacement Process

- Turn off the equipment and unplug it to ensure safety.

- Consult the user manual for specific instructions on accessing the components.

- Carefully remove the damaged parts using appropriate tools.

- Install the new components, ensuring they are securely fitted.

- Reassemble any covers or panels and plug the device back in.

- Test the machine to confirm that it operates correctly.