Understanding the internal components and how they fit together is essential for anyone looking to ensure the longevity and proper functionality of their cleaning assistant. Whether it’s for routine maintenance or diagnosing an issue, knowing the structure and connection of individual elements can make a big difference. This section will provide an overview, helping you to become familiar with the key features and their respective roles.

Each mechanical and electrical part plays a specific function, contributing to the smooth operation of the entire system. From the sensors that guide movement to the brushes responsible for picking up debris, every piece has its own significance. Exploring how these elements interact can be useful for troubleshooting and optimizing performance.

In this guide, we will break down the main components of the cleaning system, focusing on their practical use and how they can be maintained or replaced when necessary. This knowledge will empower you to better care for your device and extend its lifespan.

Understanding the Components of the iRobot Roomba 960

When exploring the design and functionality of modern automated cleaning devices, it’s important to understand the key elements that work together to ensure smooth operation. Each element, from sensors to motors, plays a critical role in navigating the environment and executing cleaning tasks effectively. Recognizing these essential parts can help in troubleshooting and maintaining the device over time.

Core Mechanical Elements

The main structural components include the motorized brush system and the wheels that allow it to move and clean various surfaces. The brush assembly ensures dirt and debris are collected efficiently, while the wheels provide stable mobility, adapting to different floor types and obstacles.

Navigation

Exploring the Brush System in Roomba 960

The cleaning efficiency of a robotic vacuum heavily relies on the design and functionality of its brush mechanism. This essential system works by loosening debris and dirt from various floor types, ensuring that the suction can efficiently collect the particles. In this section, we’ll take a closer look at how the rotating components contribute to a seamless cleaning experience.

Main Components of the Brush System

At the heart of the cleaning process are the rotating rollers, which consist of a combination of bristles and rubber. These rollers are designed to handle different surfaces, from carpets to hard floors, ensuring that no dust or debris is left behind. The dual-roller system works in tandem to agitate and lift dirt, making the vacuum’s task easier.

Maintenance and Performance Tips

To maintain optimal performance, it’s crucial to regularly check for hair and other objects that might become entangled in the rotating mechanism. Proper upkeep ensures that the device continues to deliver efficient results and prolongs its operational life. Simple

The Role of the Battery in Roomba’s Operation

The power source plays a crucial role in the functionality of robotic vacuum cleaners. It serves as the main component that fuels the device, ensuring it can perform cleaning tasks autonomously. Without this energy supply, the device would not be able to operate efficiently or navigate through different environments.

In addition to providing energy, the battery is responsible for maintaining consistent performance throughout cleaning sessions. A reliable power source allows the device to cover large areas without interruptions, ensuring smooth operation and optimal results. Proper maintenance of this component extends the life of the entire system.

How the Dustbin and Filter Work Together

The interaction between the container for debris and the filtration system is essential for ensuring efficient cleaning performance. These two components complement each other, with one capturing larger particles and the other filtering out finer dust and allergens. Together, they maintain airflow and prevent clogging, resulting in more consistent and effective operation.

The container holds the bulk of dirt and debris, ensuring the main pathways remain clear. Meanwhile, the filter serves a critical role by trapping microscopic particles that could otherwise escape back into the air. This cooperation between both elements not only improves cleanliness but also extends the overall longevity of the device.

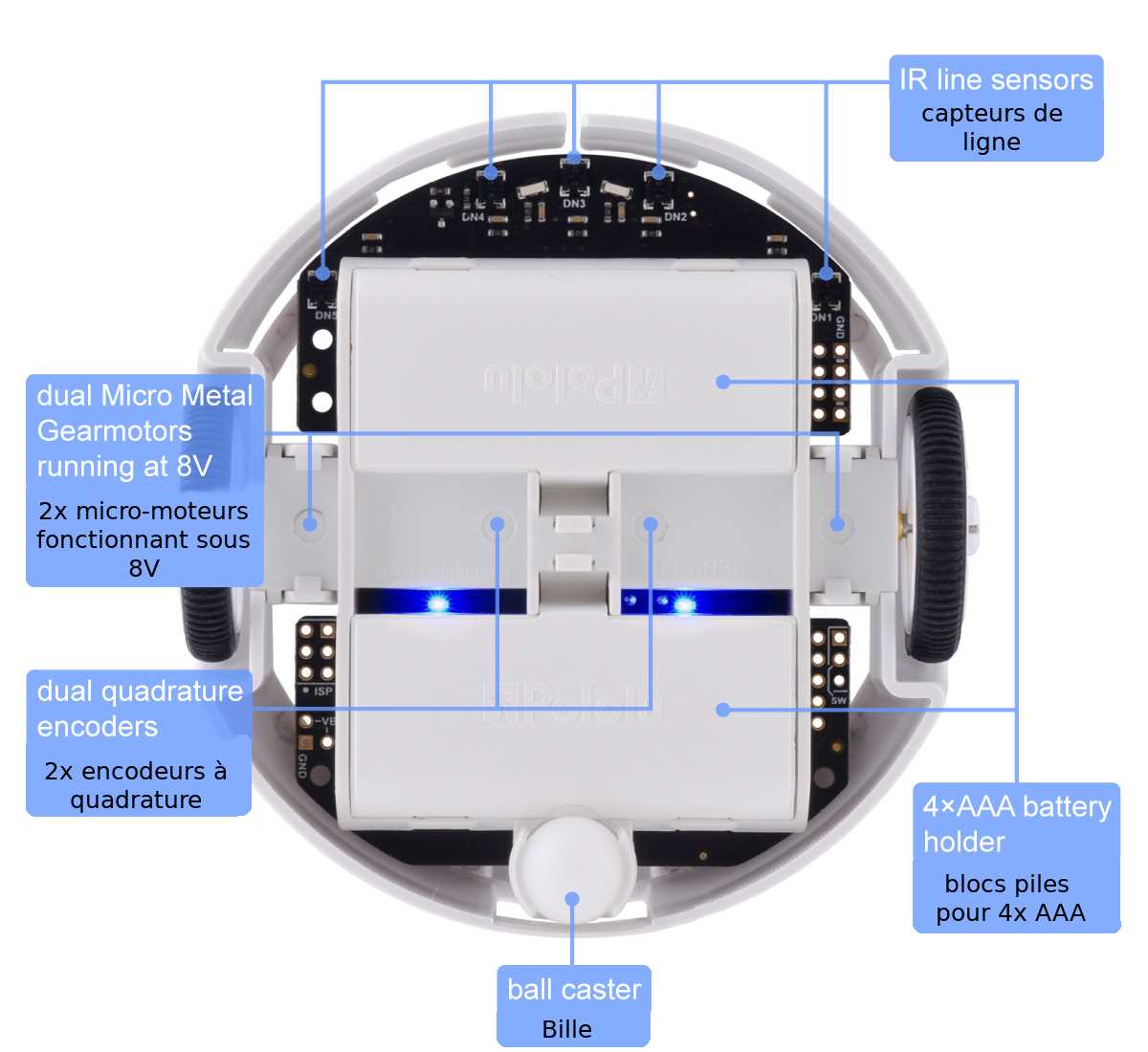

The Navigation Sensors of Roomba 960

Navigation technology plays a crucial role in ensuring smooth movement and efficient cleaning paths. This section explores the various sensors that work together to create a comprehensive map of the environment, allowing the device to move seamlessly around obstacles and cover every area of the floor.

Infrared sensors help detect objects in the immediate vicinity, preventing collisions and guiding the cleaner around furniture. These sensors measure distance, providing real-time feedback that aids in avoiding obstacles.

Another vital component is the cliff detection system, which ensures the machine doesn’t accidentally fall off edges such as stairs. By constantly scanning the ground, it adjusts its course to avoid potential hazards, enhancing safety.

Lastly, the optical flow sensor located on the underside tracks

Functionality of the Side Wheels

The side wheels play a crucial role in enhancing the maneuverability of robotic cleaners. These components enable the device to navigate various surfaces and obstacles, ensuring effective cleaning throughout the home. Their design and functionality contribute to the overall performance of the unit, allowing for precise movement in tight spaces.

Key functions of the side wheels include:

- Navigation: The wheels allow the unit to change direction smoothly, making it easier to move around furniture and other barriers.

- Climbing Ability: These components enable the cleaner to traverse small thresholds and transitions between different floor types.

- Stability: Side wheels provide balance, preventing the device from tipping over when encountering uneven surfaces.

- Detection: Equipped with sensors, these wheels help the cleaner detect edges, preventing falls from stairs or ledges.

In summary, the side wheels are essential for efficient navigation and performance, allowing the robotic unit to operate effectively across various environments.

Charging System Overview and Maintenance Tips

The efficient operation of autonomous cleaning devices relies significantly on their charging systems. Proper maintenance of these systems is essential to ensure longevity and optimal performance. In this section, we will explore the functionality of charging mechanisms and provide useful tips for their upkeep.

Understanding the Charging Mechanism

The charging system typically comprises a docking station and a battery unit. The docking station serves as a base where the device returns to recharge its battery when needed. The connection points ensure a secure electrical link, allowing for efficient power transfer. Understanding how this system operates can help in troubleshooting any issues that may arise.

Maintenance Recommendations

To maintain the efficiency of the charging system, consider the following tips:

- Regularly clean the docking station and charging contacts to remove dust and debris.

- Ensure that the charging station is placed in a location free from obstructions to allow easy access for the device.

- Check the power supply and cable for any signs of wear or damage to prevent charging interruptions.

- Monitor the battery’s health periodically, as a degraded battery can affect charging efficiency.

| Tip | Description |

|---|---|

| Cleaning | Remove any dirt from the docking station and contacts. |

| Placement | Ensure the station is in an unobstructed area for easy access. |

| Inspection | Regularly check power cables for damage. |

| Battery Health | Periodically evaluate the battery’s performance. |

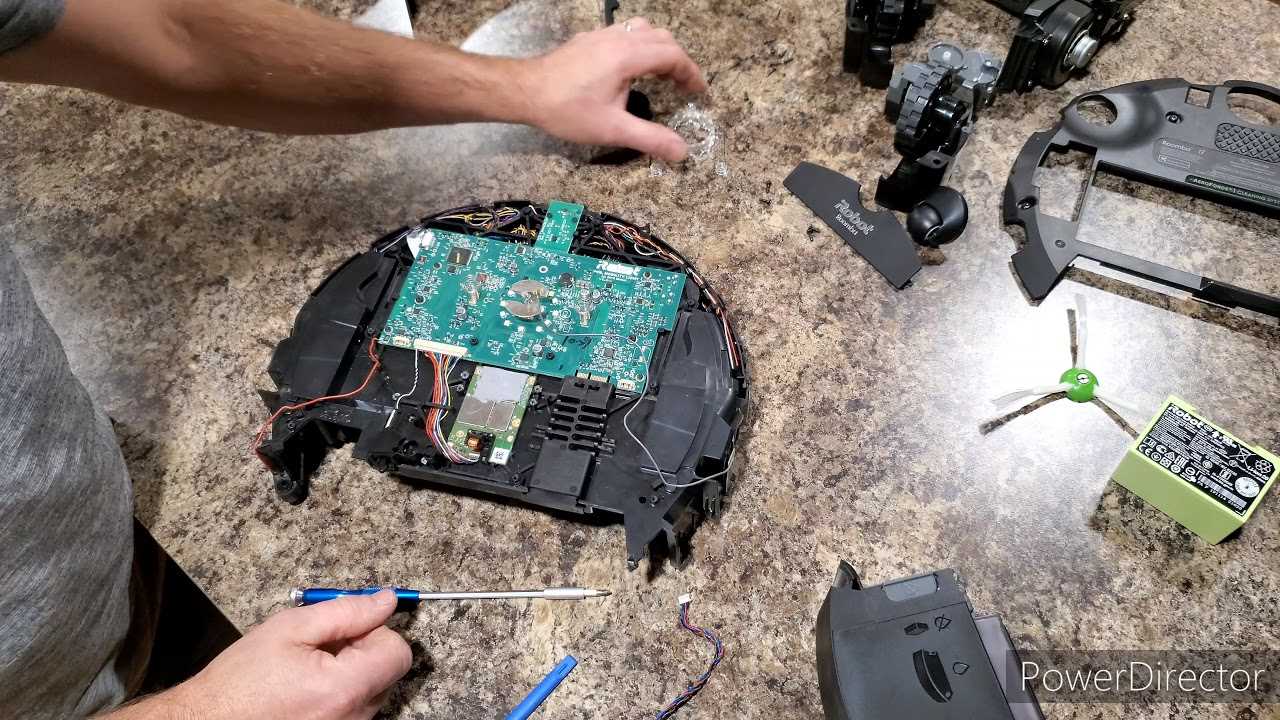

Internal Processor and Circuitry Explained

The internal computing unit plays a crucial role in the functionality of modern robotic cleaners, coordinating various operations and enabling seamless interaction with the environment. This sophisticated system includes a combination of microcontrollers, sensors, and circuit components that work together to facilitate tasks such as navigation, obstacle detection, and efficient cleaning patterns.

At the heart of the unit lies a powerful microprocessor that processes data from numerous sensors, including infrared and ultrasonic devices. These sensors help the machine map its surroundings and avoid obstacles, ensuring a thorough cleaning experience. Additionally, the integrated circuitry is designed to optimize power consumption, allowing for extended operation times while maintaining high performance.

Furthermore, the architecture of the internal electronics supports various connectivity options, enabling the device to communicate with user interfaces and smart home systems. This connectivity enhances user experience, allowing for remote control and customization of cleaning schedules. Overall, the design and engineering of the internal processing unit and its circuitry are essential for achieving the desired efficiency and effectiveness in robotic cleaning technology.

Cleaning Head Module: Key Features

The cleaning head module serves as a vital component in robotic vacuums, playing a significant role in ensuring effective floor maintenance. Its design incorporates various elements that enhance the efficiency and performance of the cleaning process, adapting to different surfaces and debris types. Understanding its key features can help users maximize the benefits of their cleaning devices.

Core Components

This module is equipped with several essential components that work together to provide optimal cleaning capabilities. Each part is engineered to perform specific functions, contributing to the overall effectiveness of the unit.

| Component | Function |

|---|---|

| Brush Roll | Agitates dirt and debris from carpets and hard floors. |

| Side Brushes | Enhances edge cleaning by reaching corners and walls. |

| Debris Extractors | Prevents tangling and ensures continuous suction. |

| Height Adjustment Mechanism | Adapts to different floor types for efficient cleaning. |

Benefits of Advanced Design

The innovative design of this module not only improves cleaning performance but also reduces maintenance needs. With durable materials and smart engineering, users can enjoy a reliable cleaning experience while minimizing the time spent on upkeep.

Understanding the Camera and Mapping Technology

The integration of visual sensors and mapping systems in autonomous cleaning devices represents a significant advancement in home automation. This technology enables efficient navigation and spatial awareness, allowing the device to create a comprehensive layout of its environment. By utilizing sophisticated algorithms, it analyzes the captured data to optimize cleaning routes and ensure thorough coverage.

At the core of this functionality are cameras and sensors that facilitate real-time data collection. These components work together to identify obstacles, detect changes in the environment, and continuously update the device’s position within the mapped area.

| Component | Function |

|---|---|

| Cameras | Capture visual data for navigation and mapping |

| Infrared Sensors | Detect obstacles and cliffs to prevent falls |

| Mapping Algorithms | Process data to create efficient cleaning paths |

| Data Storage | Save the layout for future cleaning sessions |

Understanding how these elements function together is crucial for optimizing the performance of these innovative devices. Enhanced navigation capabilities not only improve cleaning efficiency but also contribute to the overall longevity and effectiveness of the system.

Replacement Parts for Long-Term Maintenance

To ensure the longevity and optimal performance of your cleaning device, it is essential to consider the regular replacement of specific components. Over time, wear and tear can impact the efficiency of the unit, leading to decreased functionality. Understanding which components require periodic attention will help maintain peak performance and extend the lifespan of your equipment.

Filters play a crucial role in trapping dust and allergens, making it necessary to replace them regularly. Clogged filters can hinder airflow and reduce suction power. Additionally, brushes are vital for effectively picking up debris from various surfaces. Worn-out bristles can diminish cleaning effectiveness, so replacing them when they show signs of wear is advisable.

Furthermore, the batteries that power the unit will eventually lose their ability to hold a charge. Regularly checking and replacing the batteries ensures uninterrupted operation. Finally, inspecting the wheels for any damage or obstruction can prevent mobility issues. By proactively managing these elements, you can enjoy a consistently reliable cleaning experience.

Common Issues with Roomba 960 Parts

Maintaining the efficiency of automated cleaning devices often involves addressing various challenges that arise from their components. Understanding the typical problems that can occur with these elements can significantly enhance the longevity and functionality of the device. Below are some common issues faced by users, along with potential solutions.

Frequent Problems

- Battery Life Degradation: Over time, rechargeable batteries may lose their capacity, leading to shorter cleaning sessions.

- Brush Wear and Tear: Brushes can become worn or tangled, affecting the cleaning performance and requiring regular inspection and replacement.

- Sensor Malfunctions: Sensors may become dirty or misaligned, causing navigation issues and inefficient cleaning paths.

- Clogged Filters: Dust and debris can accumulate in filters, reducing suction power and airflow, necessitating frequent cleaning or replacement.

Solutions and Maintenance Tips

- Regularly clean and replace the battery to maintain optimal performance.

- Inspect brushes for tangles and wear; replace them every few months to ensure effective cleaning.

- Keep sensors clean by gently wiping them with a soft cloth to prevent navigation errors.

- Check and clean filters regularly to enhance airflow and suction efficiency.