Understanding the internal structure of modern chainsaws is essential for ensuring optimal functionality and performance. Knowing how the individual elements fit together allows for better maintenance, repairs, and enhancements. This section provides a detailed look at the core components of popular chainsaw models, offering valuable insights into their configuration.

Each mechanical unit is designed with precision, combining various elements that work together to deliver efficiency and power. By exploring the relationships between these components, users can gain a deeper understanding of how to troubleshoot common issues and keep their equipment in peak condition.

Whether you are replacing specific items or seeking to improve overall performance, familiarity with the layout of the machine’s internal mechanisms is crucial. This section will guide you through the essential elements of these devices, giving you the knowledge needed for both routine upkeep and more complex repairs.

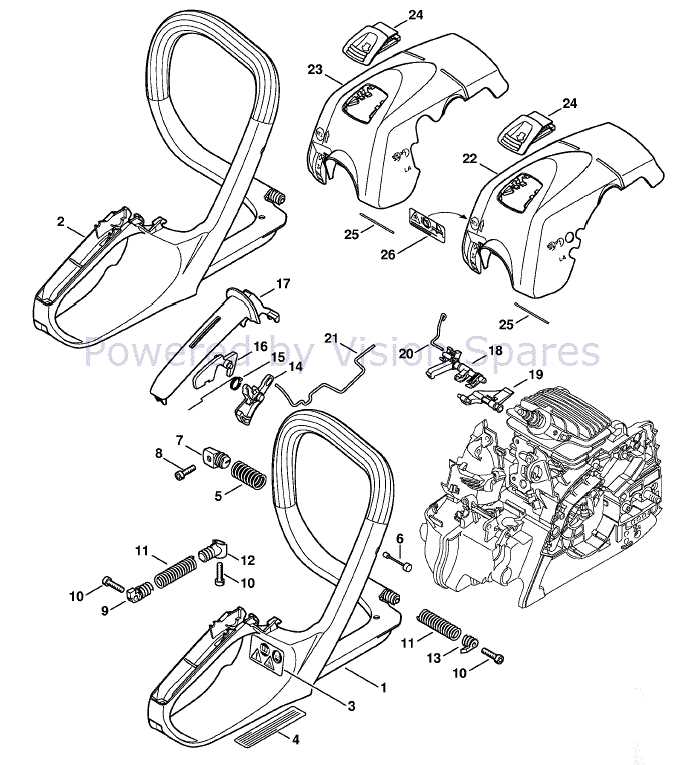

Overview of MS181 Components

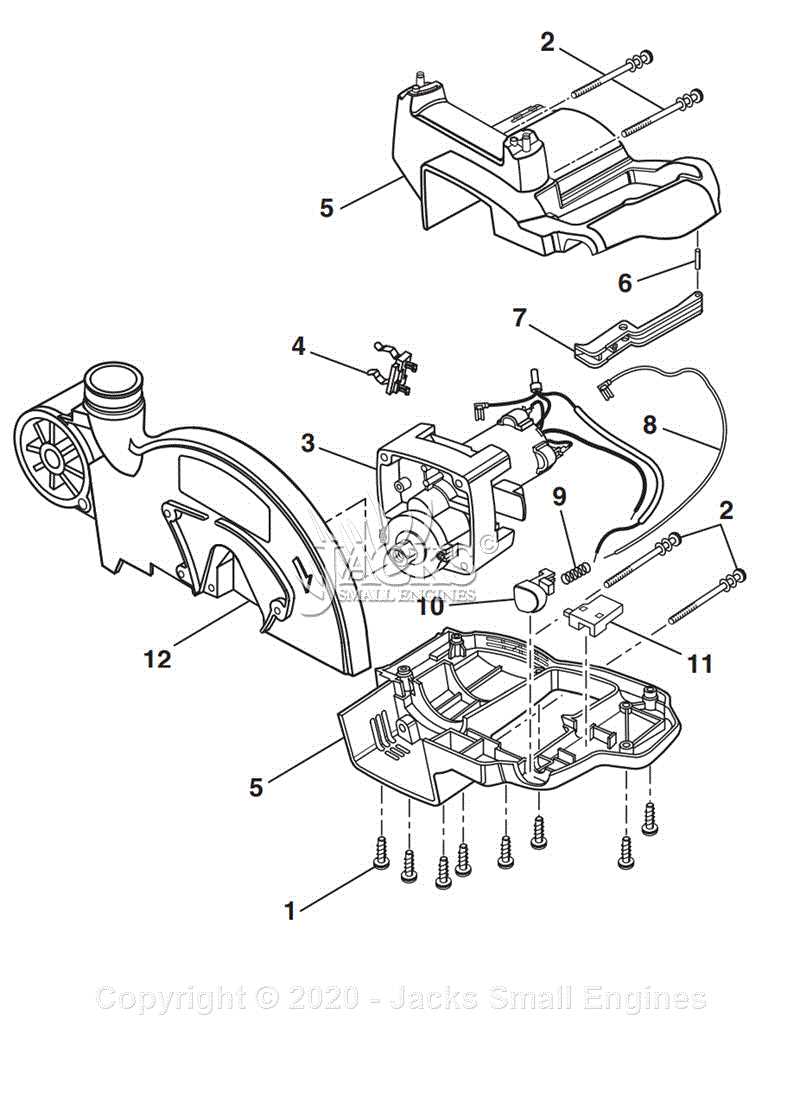

This section provides a detailed explanation of the various mechanical elements and assemblies that make up the structure of this tool. Understanding the key elements is essential for proper operation and maintenance, ensuring efficient performance.

The key mechanical elements include the engine block, which drives the system, and the cutting mechanism, responsible for the tool’s primary function. Other components like the fuel system, ignition, and air filtration contribute to its smooth and continuous operation. Together, these units form a well-balanced and reliable machine.

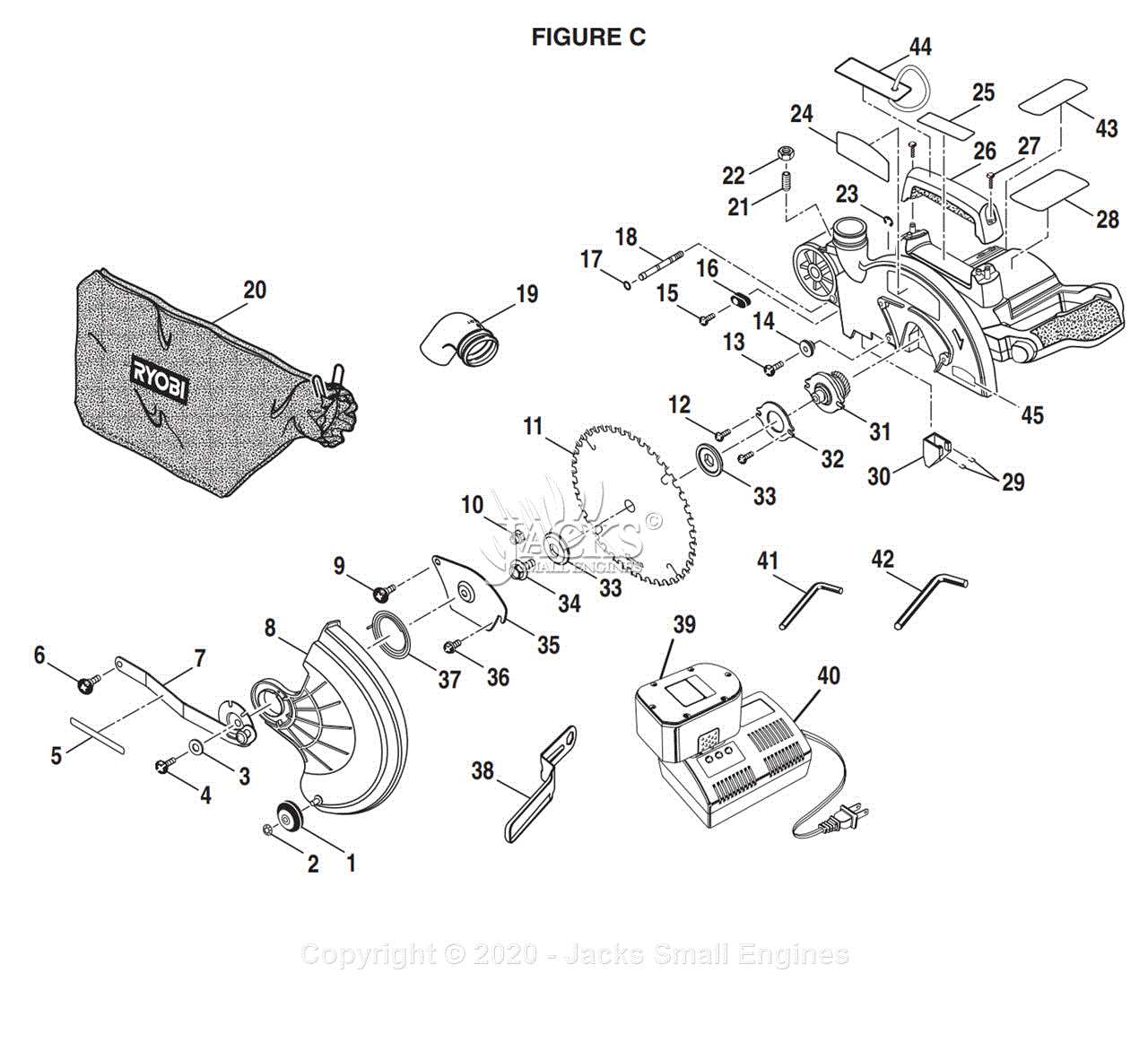

Understanding the Chain Mechanism

The operation of the chain mechanism is crucial for ensuring effective performance during cutting tasks. This mechanism relies on a coordinated movement of several components, working together to achieve optimal rotation and tension. By understanding the way these elements interact, users can ensure smooth functionality and prolong the lifespan of the tool.

Below is a simplified breakdown of the key elements involved in the chain’s operation:

| Component | Function | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drive Links | Engages with the drive sprocket to move the chain around the bar. | |||||||||

| Guide Bar | Provides the track for the chain to follow during operation. | |||||||||

Chain Tension

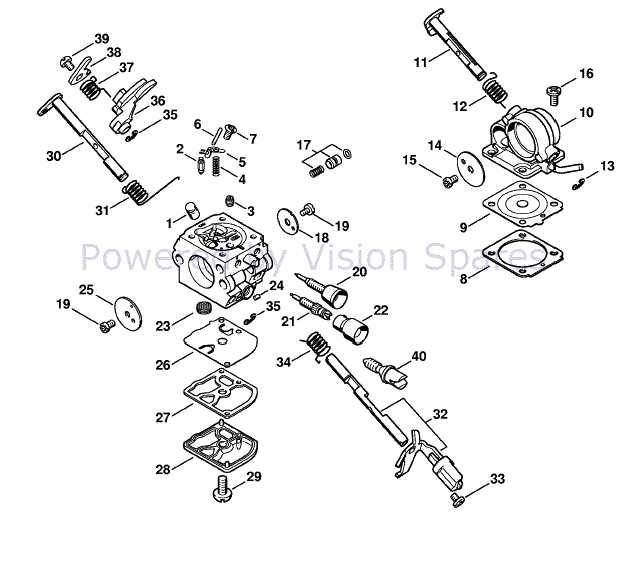

Guide Bar and Its Key FunctionsThe guide bar is an essential component in ensuring smooth and precise cutting during operations. It serves as the path for the cutting chain, allowing for accurate movement and control. Without a well-maintained bar, the equipment’s performance can be significantly reduced, leading to inefficient results and possible damage to the machinery. Stability is one of the most important roles of the guide bar. It keeps the cutting process even and balanced, reducing the likelihood of uneven cuts or vibrations. This stability enhances the overall safety and efficiency of the equipment. Another critical function is supporting the chain during operation. The bar guides the chain to move smoothly around its track, ensuring that each link remains in its proper position. This ensures that the cutting process remains consistent and minimizes the risk of mal Internal Engine Parts BreakdownUnderstanding the structure and function of various components within the motor is essential for proper maintenance and repair. These elements work together to ensure smooth operation, from power generation to fuel efficiency. Knowing how these units interact can help diagnose issues and optimize performance. Main Power ComponentsThe core of the engine houses several key mechanisms responsible for converting energy. This includes the piston, which moves within the cylinder, driven by the combustion process. The crankshaft transforms this linear motion into rotational force, which powers other essential systems. Additionally, the connecting rod links these components, ensuring the transfer of energy remains smooth and efficient. Supporting SystemsSurrounding the central power mechanism are numerous supportive systems. The carburetor regulates the air-fuel mixture, ensuring optimal combustion. The ignition system, including the spark plug, initiates the process, while the exhaust system Ignition System Components ExplainedThe ignition system plays a crucial role in ensuring the proper functioning of any engine by creating the spark needed to ignite the fuel mixture. It is made up of several interconnected elements, each responsible for a specific task. Together, they ensure the engine operates smoothly and efficiently.

|