In the realm of outdoor machinery, grasping the intricate layout of various elements is crucial for efficient maintenance and operation. Each component plays a vital role, contributing to the overall functionality of the equipment. This section aims to illuminate the arrangement and relationship of these essential parts, providing clarity to users and technicians alike.

Familiarity with the configuration of these components enhances troubleshooting capabilities and ensures optimal performance. By delving into the specifics of each segment, one can appreciate how they interact and support the overall system. This knowledge not only empowers users but also promotes a deeper understanding of the mechanics involved.

Whether you are a seasoned professional or a novice, exploring the layout of these elements will prove invaluable. It lays the foundation for effective repairs, adjustments, and upgrades, fostering a greater appreciation for the engineering behind outdoor tools.

Overview of Srm 225 Components

This section provides a comprehensive look at the various elements that make up a specific piece of equipment designed for efficiency and performance. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring optimal functionality and longevity.

Key Elements and Their Functions

The main components are integral to the operation, each serving a distinct purpose. For instance, the engine is responsible for power generation, while the cutting mechanism is designed to handle various tasks with precision. Familiarity with these parts enhances the user’s ability to operate and maintain the machinery effectively.

Importance of Regular Maintenance

Regular upkeep of these components is essential to prevent wear and tear, ensuring the equipment operates smoothly. Neglecting maintenance can lead to inefficiencies and potential breakdowns, emphasizing the need for a proactive approach. Implementing routine checks not only extends the lifespan but also improves overall performance.

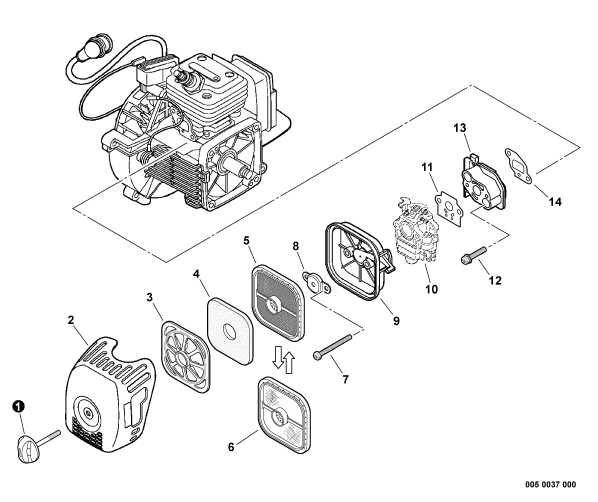

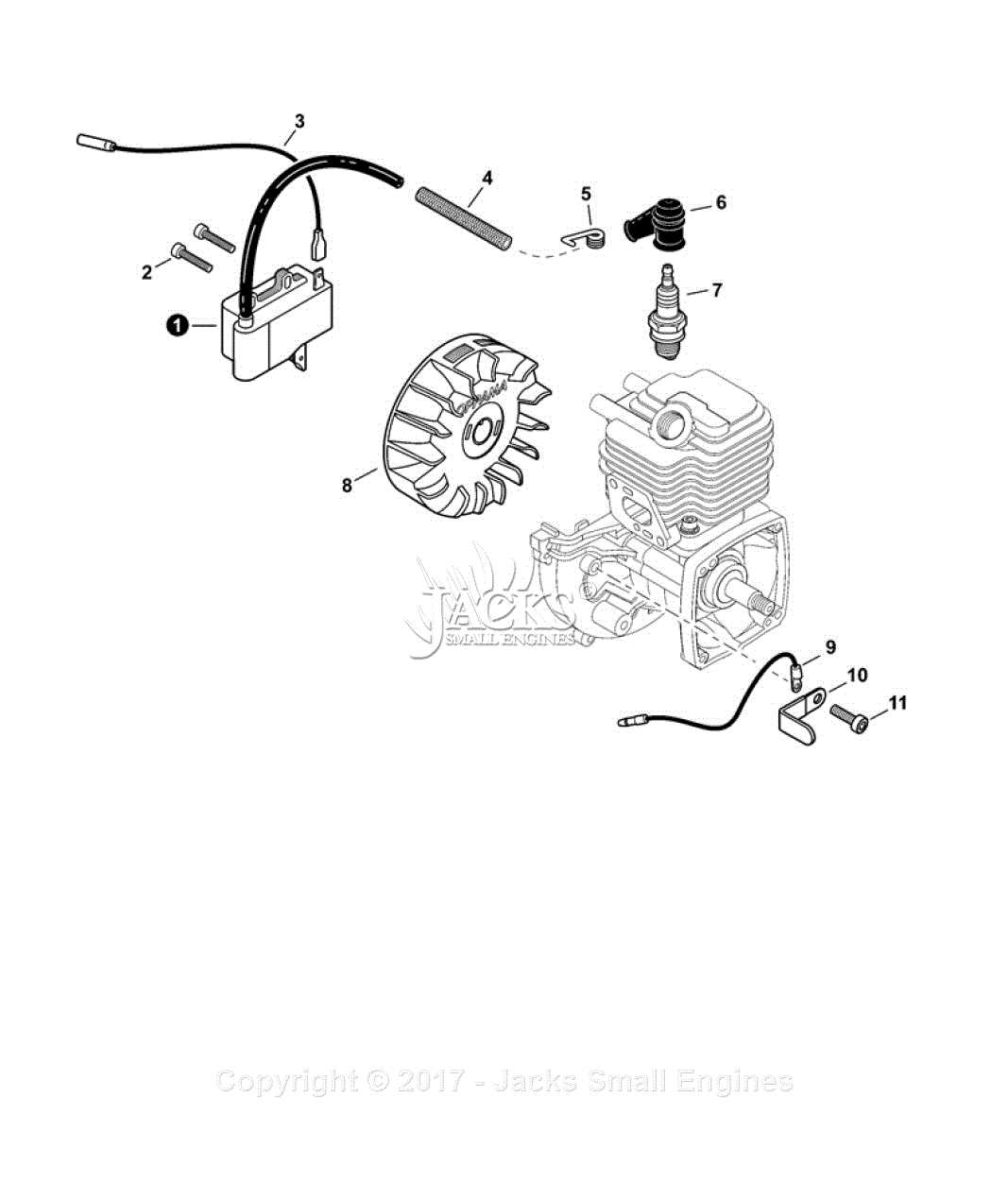

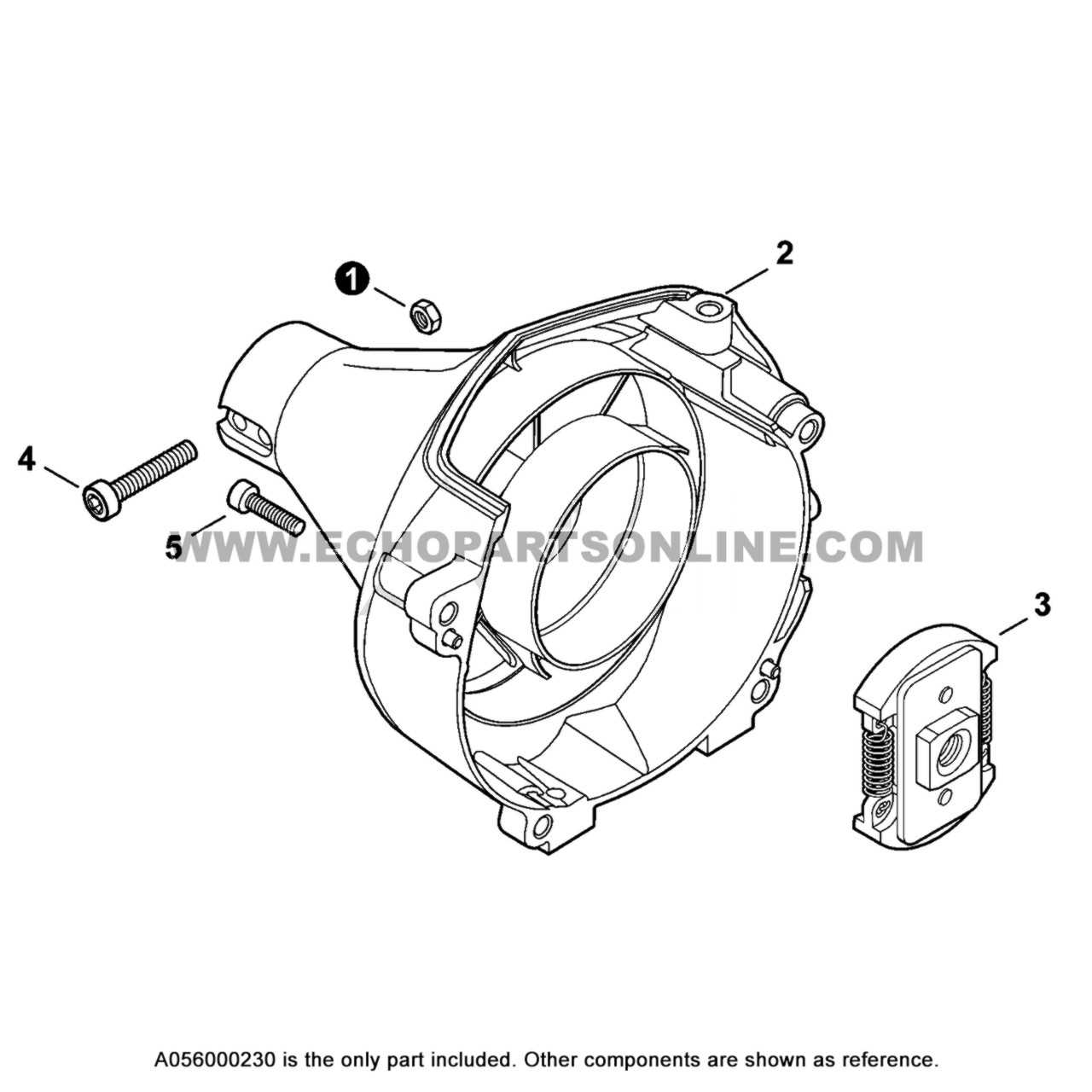

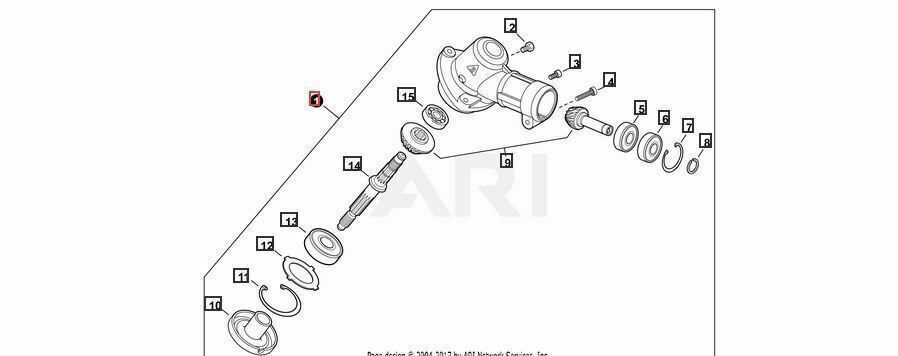

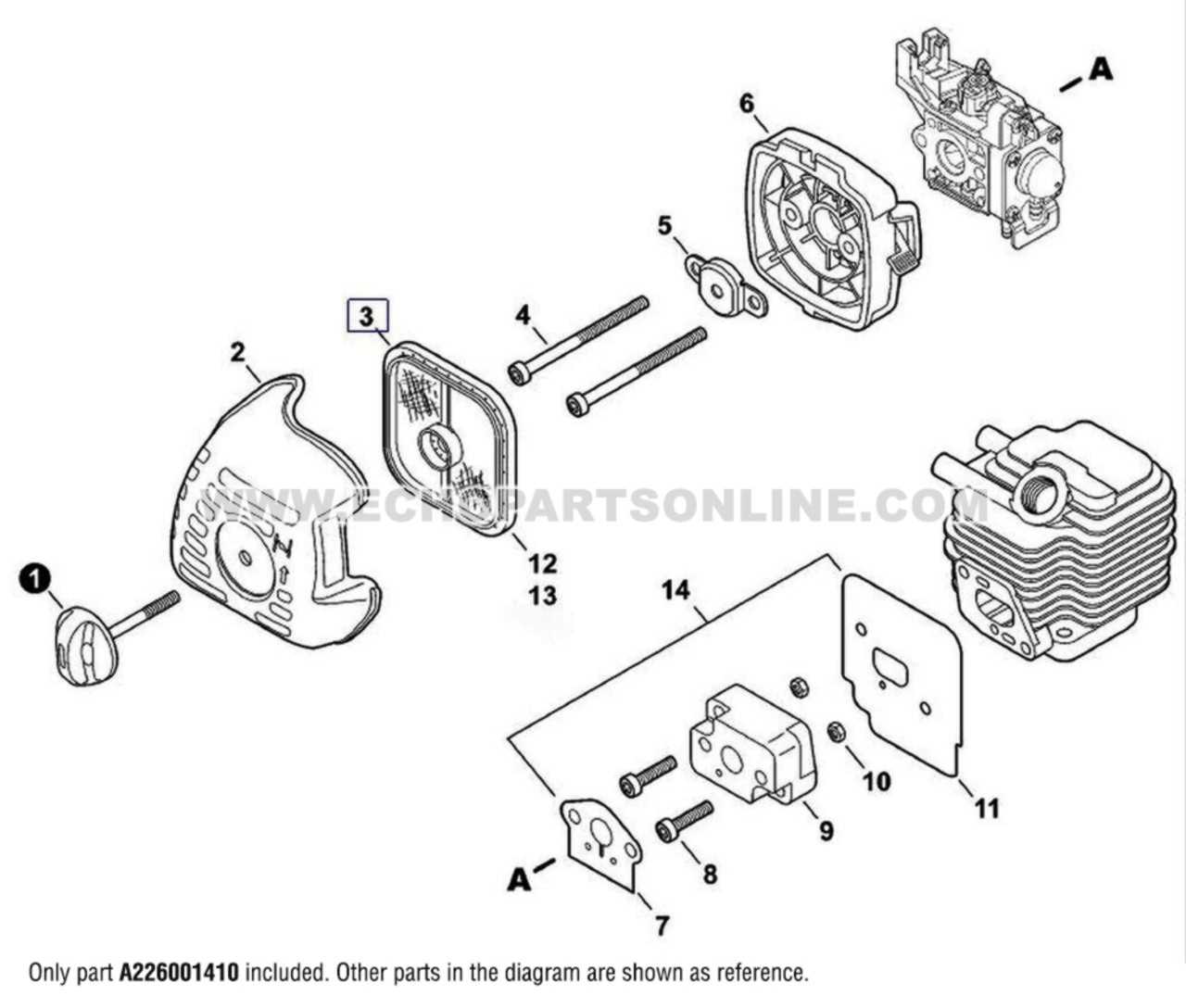

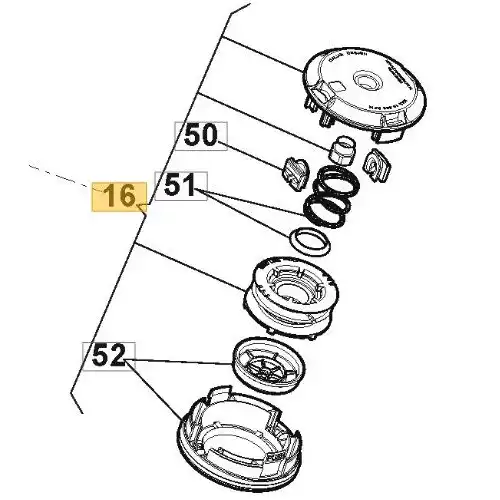

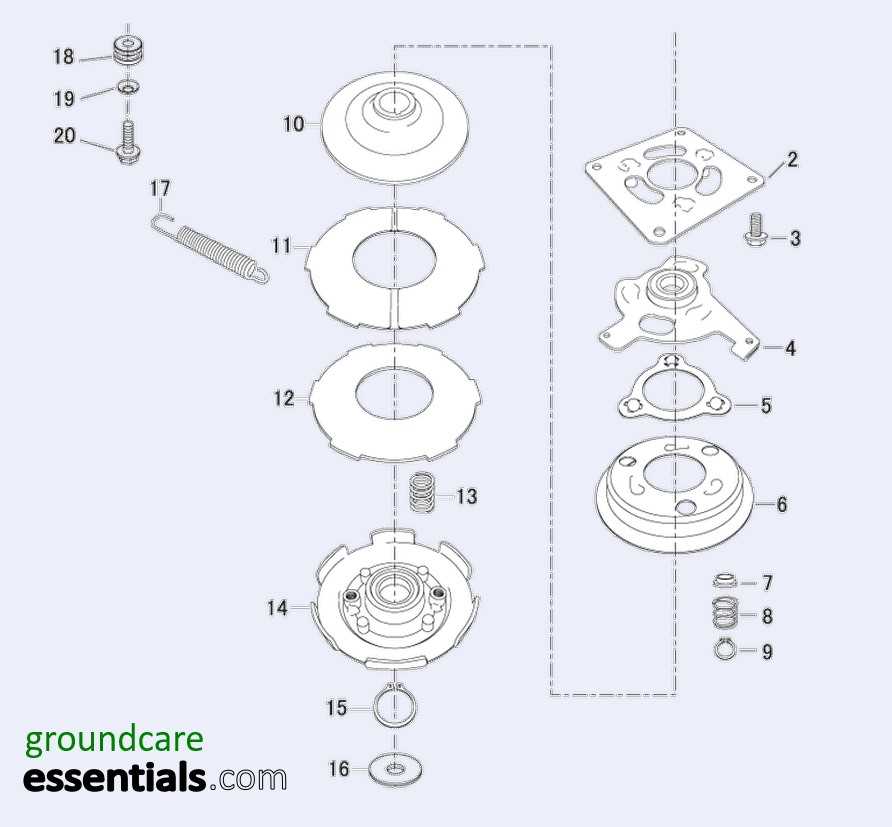

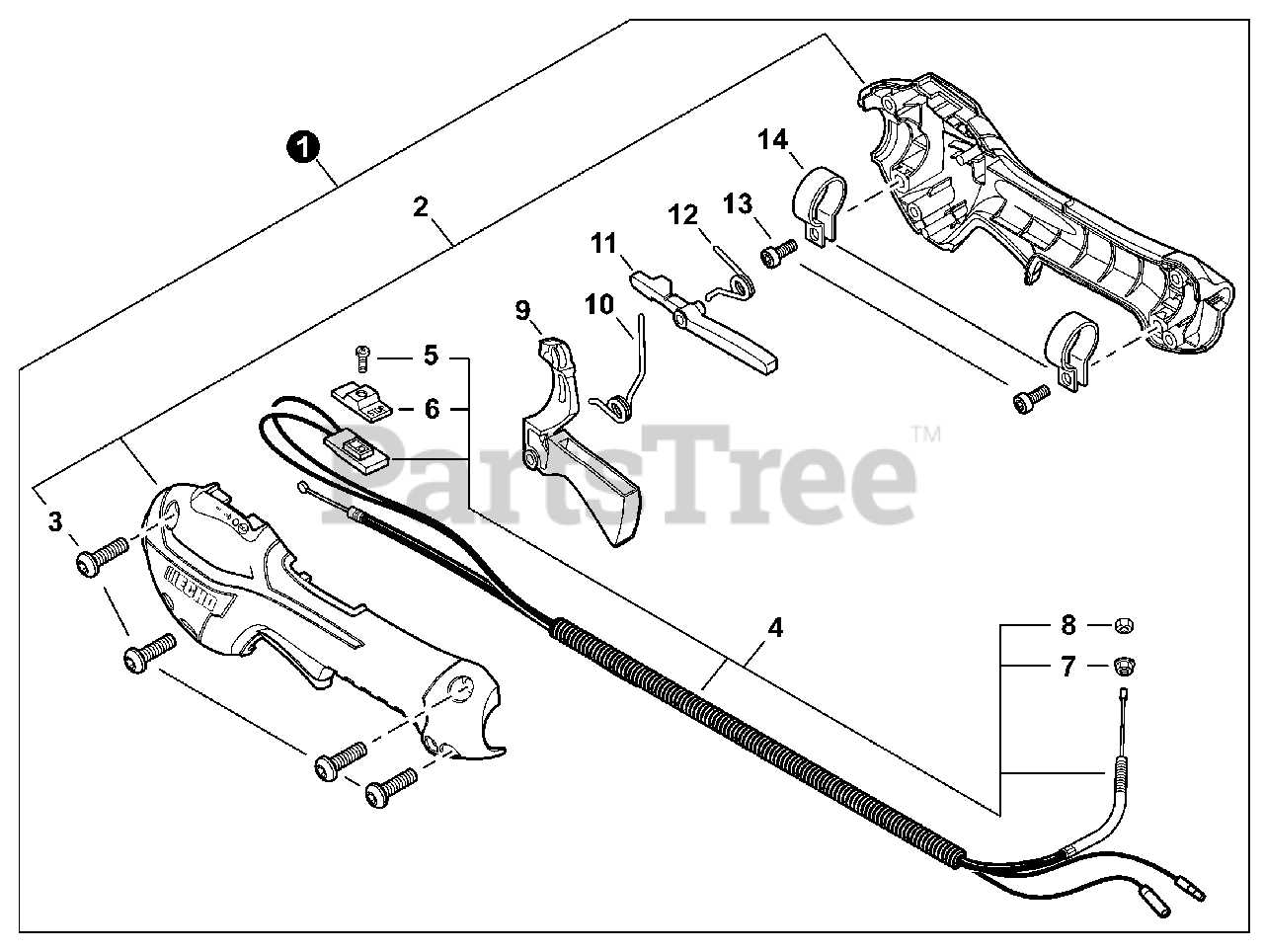

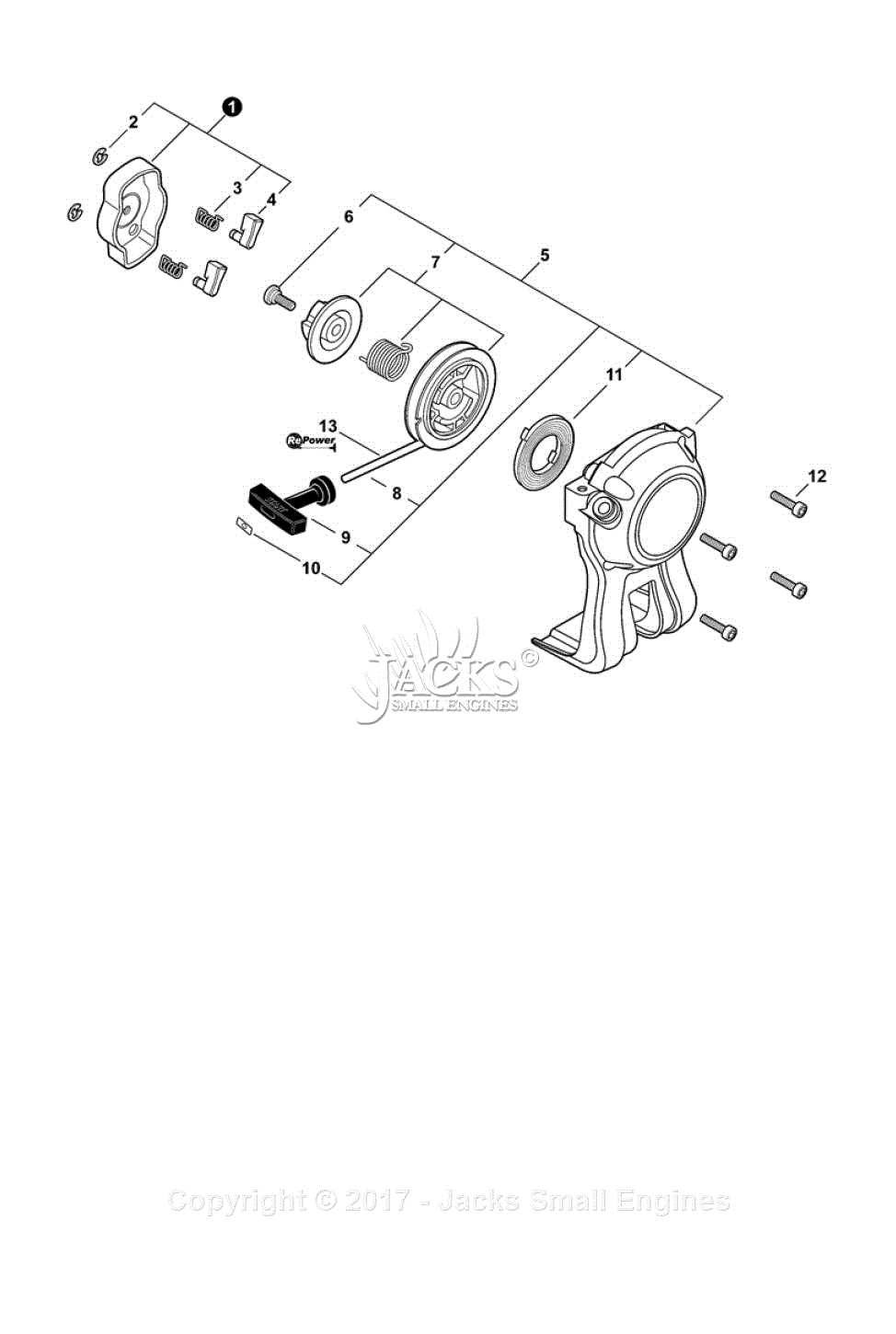

Identifying Key Parts in Diagram

Understanding the components illustrated in a schematic is crucial for effective maintenance and repair. This section will guide you through recognizing essential elements within the visual representation, ensuring a clearer grasp of their functions and interactions.

Component Overview

Each element serves a specific purpose, contributing to the overall operation. Familiarity with these components allows for more efficient troubleshooting and repair processes. Common features include various types of connectors, fasteners, and mechanisms that facilitate movement and energy transfer.

Locating and Understanding Symbols

Symbols play a significant role in conveying information about each part’s functionality. Familiarizing yourself with these symbols will enhance your ability to interpret the schematic accurately. Pay attention to any notations that indicate specific roles or specifications, as these will aid in identifying the correct elements for your project.

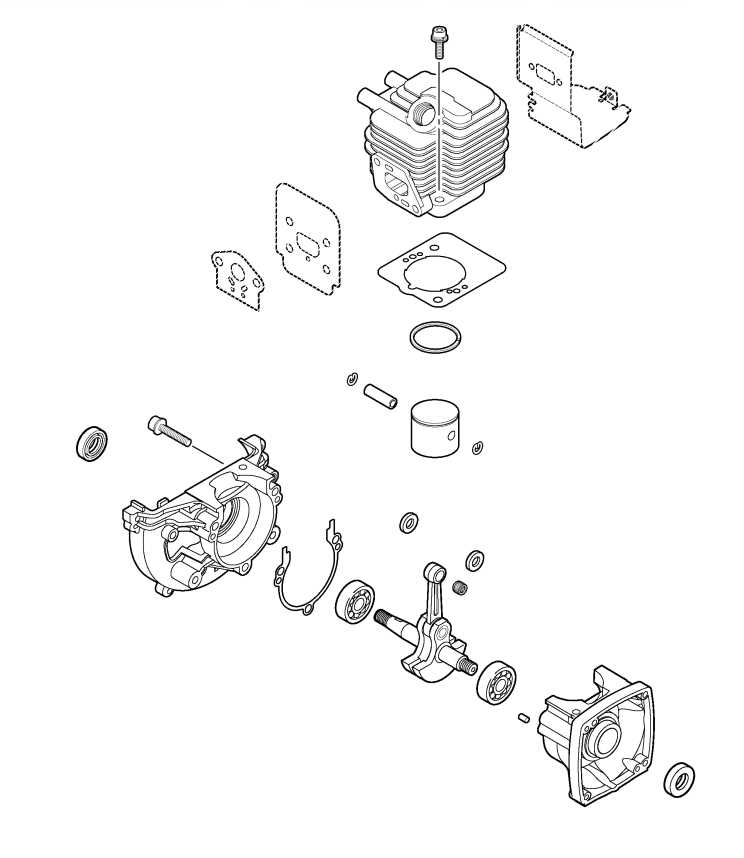

Functionality of Each Element

This section explores the roles and responsibilities of various components within a particular assembly. Understanding how each element interacts contributes to the overall efficiency and performance of the system.

Core Components

The primary constituents are essential for the operational integrity of the unit. These elements work synergistically, ensuring smooth functionality and reliability during use.

Supporting Elements

Supplementary components play a crucial role in enhancing the effectiveness of the main parts. By providing stability and additional support, these elements help maintain optimal performance levels.

Maintenance Tips for Optimal Use

To ensure the longevity and efficiency of your equipment, regular upkeep is essential. By following a few straightforward practices, you can enhance performance and minimize the risk of malfunctions.

Regularly checking and cleaning components not only improves functionality but also prevents wear and tear. Additionally, adhering to the manufacturer’s recommendations regarding servicing intervals is crucial for maintaining optimal performance.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Fuel Levels | Before Each Use | Ensure adequate fuel supply for uninterrupted operation. |

| Inspect Blades | Weekly | Examine for dullness or damage; sharpen or replace as needed. |

| Clean Air Filter | Monthly | Remove dust and debris to promote proper airflow and efficiency. |

| Examine Cables and Hoses | Monthly | Look for signs of wear or cracks to ensure safety during operation. |

| Change Oil | Every 25 Hours | Replace oil to maintain engine performance and reduce friction. |

By implementing these strategies, you can enhance the reliability and effectiveness of your equipment, ensuring it operates smoothly for years to come.

Common Issues and Solutions

Understanding the typical challenges faced with equipment components can significantly enhance maintenance and repair efforts. This section addresses frequent problems encountered and offers practical solutions to improve functionality and longevity.

Frequent Problems

Many users report issues such as overheating, irregular performance, and unusual noises. Identifying these symptoms early can prevent further complications.

Effective Solutions

Implementing the following solutions can alleviate common issues:

| Issue | Recommended Solution |

|---|---|

| Overheating | Ensure proper ventilation and clean filters regularly. |

| Irregular performance | Check for blockages and replace worn components as needed. |

| Unusual noises | Inspect moving parts for wear and lubricate as required. |

Tools Required for Repair Tasks

When undertaking maintenance or restoration of equipment, having the right tools is essential to ensure efficiency and precision. A well-equipped workspace not only facilitates smoother operations but also enhances safety, allowing for effective handling of various components.

Essential Tools

The following tools are typically necessary for most repair activities:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening or tightening screws on various parts. |

| Wrench Set | Used for gripping and turning nuts and bolts. |

| Plier Set | Useful for holding, bending, or cutting wires and small parts. |

| Multimeter | For measuring voltage, current, and resistance. |

| Torque Wrench | Ensures proper tightening of fasteners to specified torque. |

Additional Equipment

In addition to basic tools, specialized equipment may also be beneficial:

| Equipment | Usage |

|---|---|

| Heat Gun | For softening adhesives or removing paint. |

| Safety Gear | Includes goggles and gloves for protection during repairs. |

| Cleaning Supplies | To maintain a clean working area and parts. |

Ordering Replacement Parts Efficiently

Streamlining the process of acquiring essential components can significantly enhance maintenance efforts. By following strategic steps, you can minimize downtime and ensure that your equipment operates smoothly.

| Step | Description |

|---|---|

| 1. Identify Needs | Determine the specific items required for replacement to avoid unnecessary purchases. |

| 2. Research Suppliers | Look for reputable vendors that offer quality components at competitive prices. |

| 3. Compare Options | Evaluate different suppliers based on pricing, availability, and shipping options. |

| 4. Place Orders | Order the identified components promptly to ensure timely delivery. |

| 5. Keep Records | Document all orders for future reference and track your maintenance inventory. |

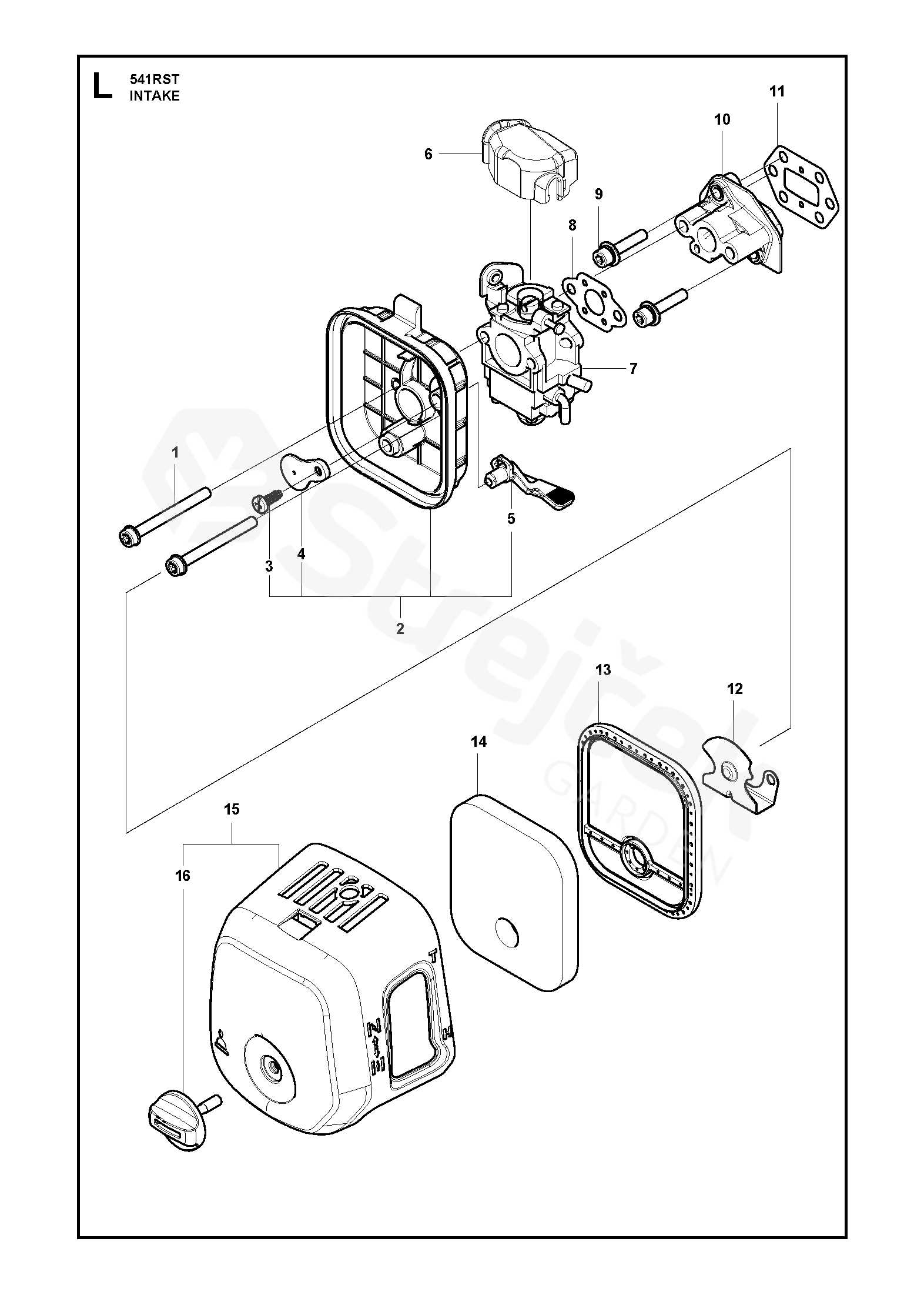

Diagram Analysis for Troubleshooting

Effective evaluation of technical schematics is crucial for identifying and resolving issues within mechanical systems. By understanding the layout and relationships between various components, users can diagnose problems more efficiently and apply the necessary solutions.

Key Components to Examine

- Connections: Verify the integrity and correctness of all linkages.

- Functionality: Assess the role of each part and its impact on overall operation.

- Flow Paths: Analyze the movement of energy or materials to spot potential blockages or inefficiencies.

Troubleshooting Steps

- Study the schematic carefully, identifying each element and its function.

- Check for discrepancies between expected and actual performance.

- Test individual components to isolate faults.

- Consult technical resources for additional insights on specific sections.

Understanding Component Interactions

Grasping how individual elements within a system work together is crucial for optimizing performance and ensuring efficiency. Each component plays a distinct role, and their interactions can significantly affect overall functionality. A comprehensive understanding allows for better troubleshooting and enhances the potential for system improvements.

Key Interactions to Consider

- Mechanical Connections: The physical linkages between elements dictate how forces and motions are transmitted.

- Electrical Signals: The flow of energy between parts enables communication and control, influencing response times and efficiency.

- Material Compatibility: The selection of materials affects durability and performance, especially under varying environmental conditions.

Analyzing Component Synergy

- Identify each element’s function within the system.

- Examine how changes in one part can impact others.

- Consider the cumulative effects of these interactions on overall performance.

Safety Precautions During Repairs

When conducting maintenance or troubleshooting on any machinery, ensuring personal safety and protecting the equipment is paramount. Adhering to proper safety protocols can significantly reduce the risk of accidents and enhance the efficiency of the repair process.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and ear protection.

- Ensure the workspace is clean and organized to prevent trips and falls.

- Disconnect the power source before starting any repair to avoid electric shock or unintended activation.

- Use tools that are in good condition and suited for the task to prevent injury and damage.

Additionally, it is essential to familiarize yourself with the equipment’s operation manual to understand its components and functions thoroughly. This knowledge will aid in identifying potential hazards and ensuring that repairs are conducted safely.

- Keep flammable materials away from the repair area.

- Have a fire extinguisher nearby in case of emergencies.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

By following these safety measures, individuals can minimize risks and ensure a smoother, more effective repair experience.

Visual Aids for Better Clarity

Incorporating visual resources can significantly enhance the understanding of complex mechanisms. These tools provide clear representations, allowing individuals to grasp intricate details that might otherwise be overlooked. By presenting information visually, users can engage more effectively with the subject matter, leading to improved comprehension and retention.

Benefits of Illustrative Materials

Illustrative materials serve multiple purposes, from simplifying intricate concepts to highlighting essential components. They facilitate quick reference and can often clarify relationships between different elements. By breaking down complex information into visual formats, learners can process data more intuitively, making it easier to follow instructions and identify critical features.

Enhancing Learning Experiences

Utilizing visual resources in educational settings promotes interactive learning. Diagrams, charts, and sketches encourage exploration and discovery, allowing individuals to visualize the interconnections of various elements. This approach not only enriches the learning experience but also fosters a deeper appreciation for the subject.

Resources for Further Learning

Exploring a variety of educational materials can greatly enhance your understanding of maintenance and repair techniques. Whether you’re seeking technical manuals, online tutorials, or community forums, a wealth of resources is available to deepen your knowledge and skills.

Online Tutorials and Courses

Numerous websites offer comprehensive guides and video tutorials that cover essential aspects of equipment maintenance. These platforms provide step-by-step instructions, allowing learners to grasp concepts at their own pace.

Community Forums and Discussion Groups

Engaging with fellow enthusiasts through forums can provide valuable insights and solutions to common challenges. Participating in discussions not only expands your knowledge but also connects you with individuals who share similar interests.