In the realm of modern convenience, the efficiency of your Ge system hinges on the intricate interplay of its various elements. Recognizing how these components function together can greatly enhance your overall experience and performance. Each element serves a specific purpose, contributing to the seamless operation that many rely on daily.

Familiarity with these essential features allows homeowners to identify potential issues swiftly, leading to timely maintenance and improvements. As you delve deeper into the specifics, the ultimate goal is to foster a greater understanding of how your device operates, ensuring longevity and reliability.

By examining the layout and connections within your Ge unit, you can better appreciate the engineering behind it. This knowledge not only empowers you to troubleshoot effectively but also enhances your ability to make informed decisions regarding repairs and upgrades.

Understanding GE Hot Water Heaters

When it comes to maintaining comfort in your home, the efficiency and reliability of GE’s systems play a crucial role. These appliances are designed to provide a consistent supply of warmth, catering to various household needs. Knowing how these units operate and the components involved can enhance your overall experience and ensure optimal performance.

GE offers a range of models, each equipped with specific features that cater to different preferences and requirements. Familiarizing yourself with these functionalities allows for informed choices regarding installation, maintenance, and troubleshooting. This knowledge can lead to improved longevity and efficiency, ultimately benefiting your household.

Understanding the essential elements within these systems is vital for effective usage and care. Each component works in harmony, contributing to the seamless operation of the unit. A thorough grasp of these intricacies empowers homeowners to make better decisions and take proactive measures when necessary.

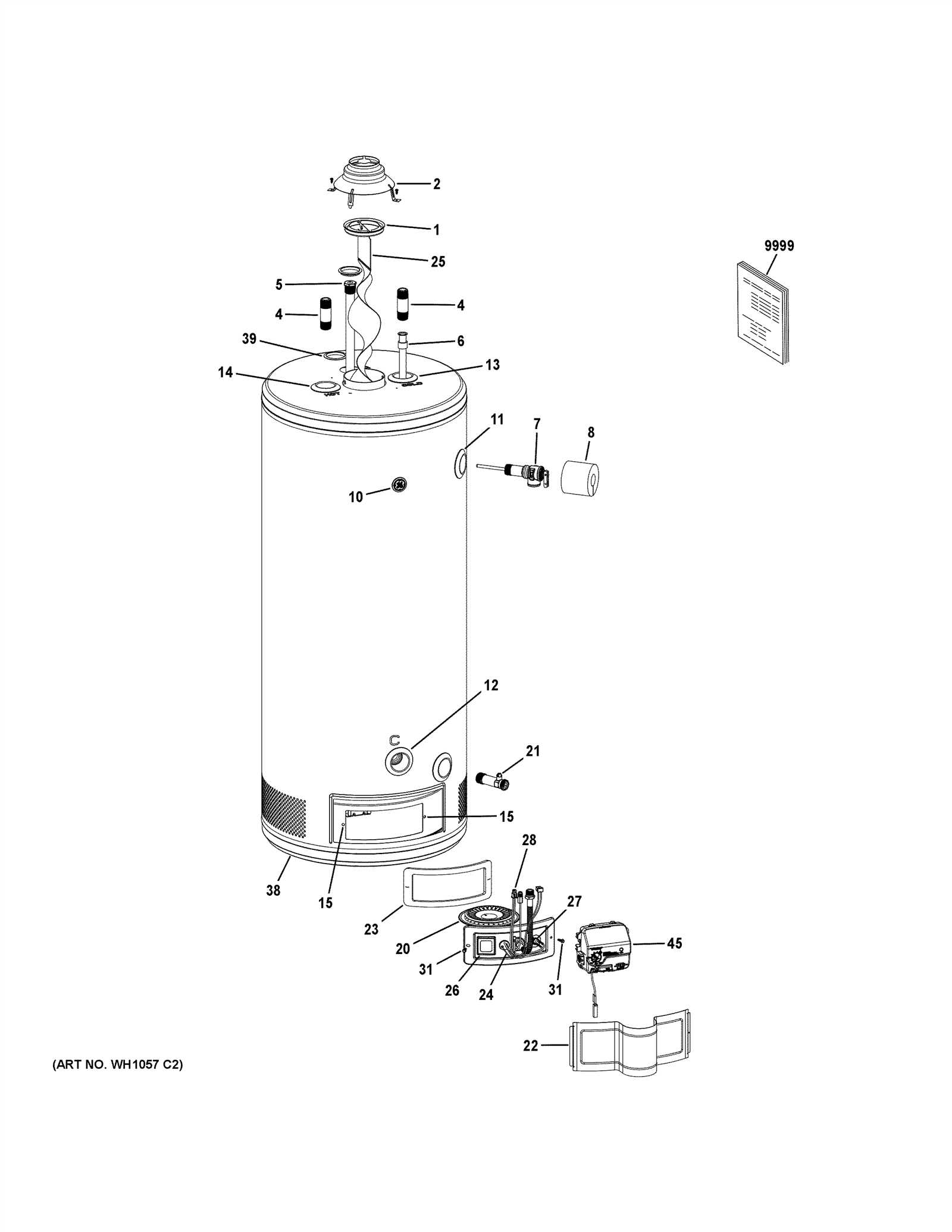

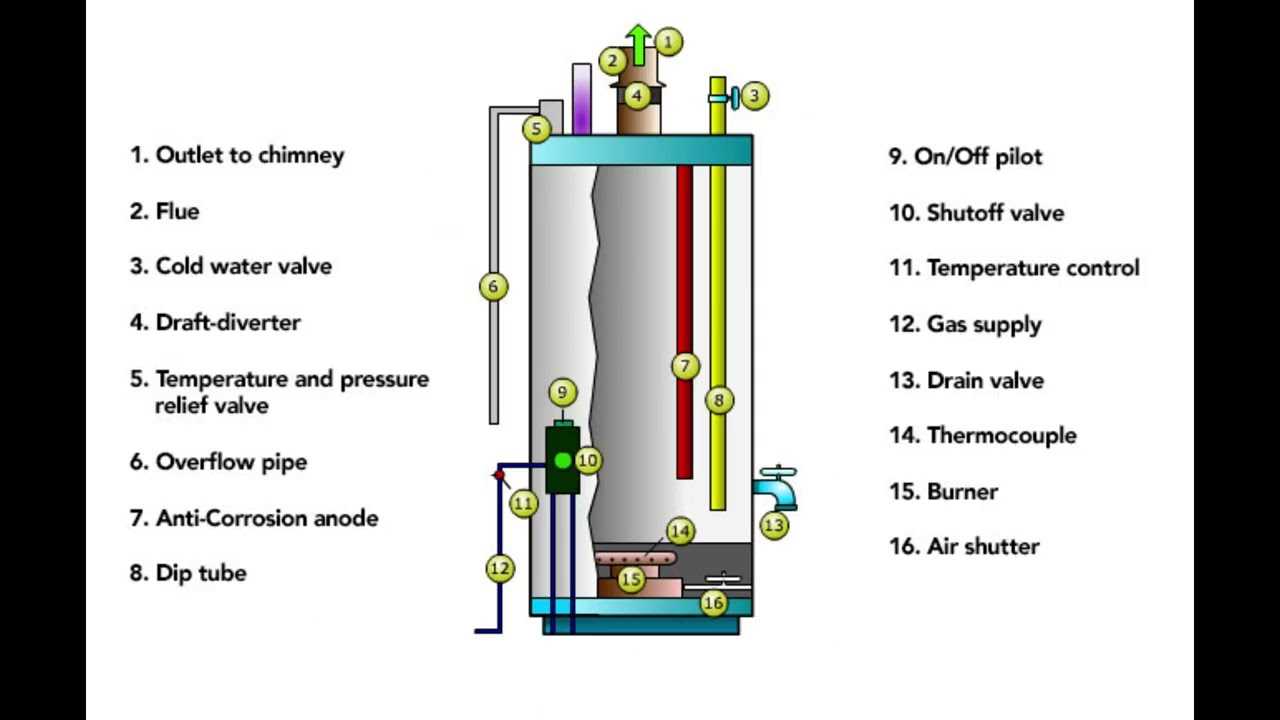

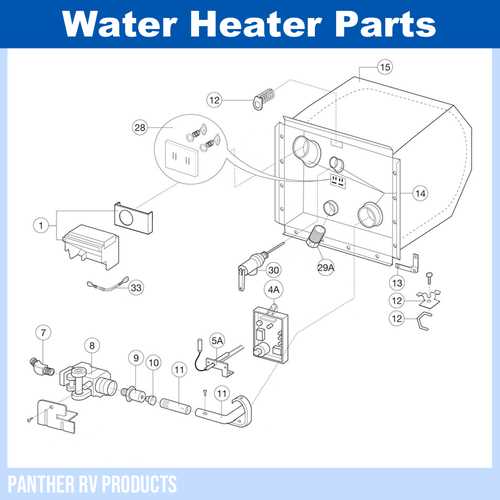

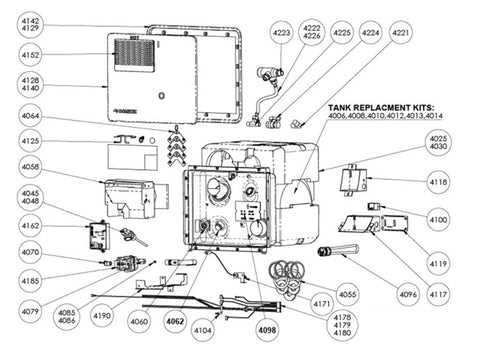

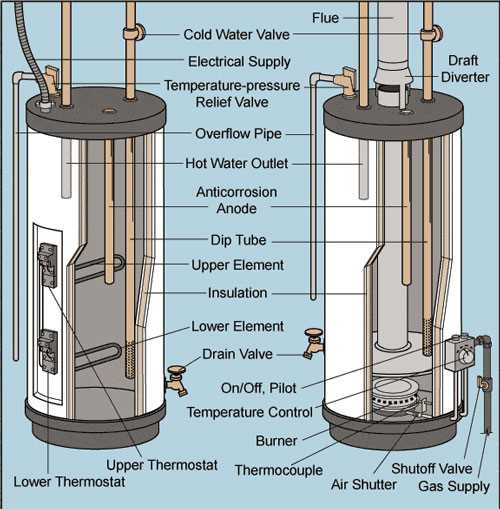

Common Components of Water Heaters

The functionality of a thermal storage system relies on various essential elements, each playing a pivotal role in the overall operation. Understanding these components is crucial for maintenance and troubleshooting.

Thermal Tank: This is the main vessel where the liquid is stored and heated, ensuring a steady supply for use.

Heating Element: Typically an electric or gas burner, this component is responsible for elevating the temperature of the fluid to the desired level.

Thermostat: An integral device that monitors and regulates the temperature, ensuring optimal performance and safety.

Relief Valve: A crucial safety feature that prevents excessive pressure buildup by releasing excess fluid or steam when necessary.

Pipe Connections: These conduits facilitate the flow of the heated liquid to and from the storage unit, connecting it to various outlets.

By delving into these components, users can gain a deeper understanding of their system’s operation and maintenance needs.

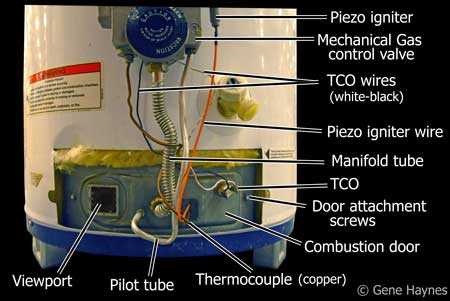

Importance of Diagrams in Repairs

Visual representations play a crucial role in the repair process, providing clarity and guidance that enhance understanding. They serve as essential tools for both novice and experienced technicians, allowing for quicker diagnosis and efficient troubleshooting.

Enhancing Understanding

Clear illustrations simplify complex systems, enabling users to identify components and their functions with ease. This comprehension is vital for accurate repairs and can prevent costly mistakes.

Streamlining the Repair Process

Utilizing visual aids not only saves time but also boosts confidence during maintenance tasks. When individuals can easily navigate through intricate setups, the ultimate goal of effective repair becomes more attainable.

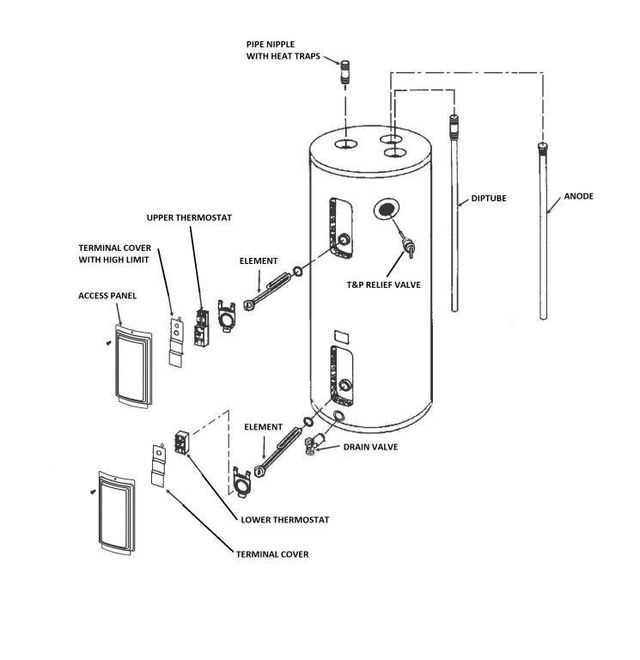

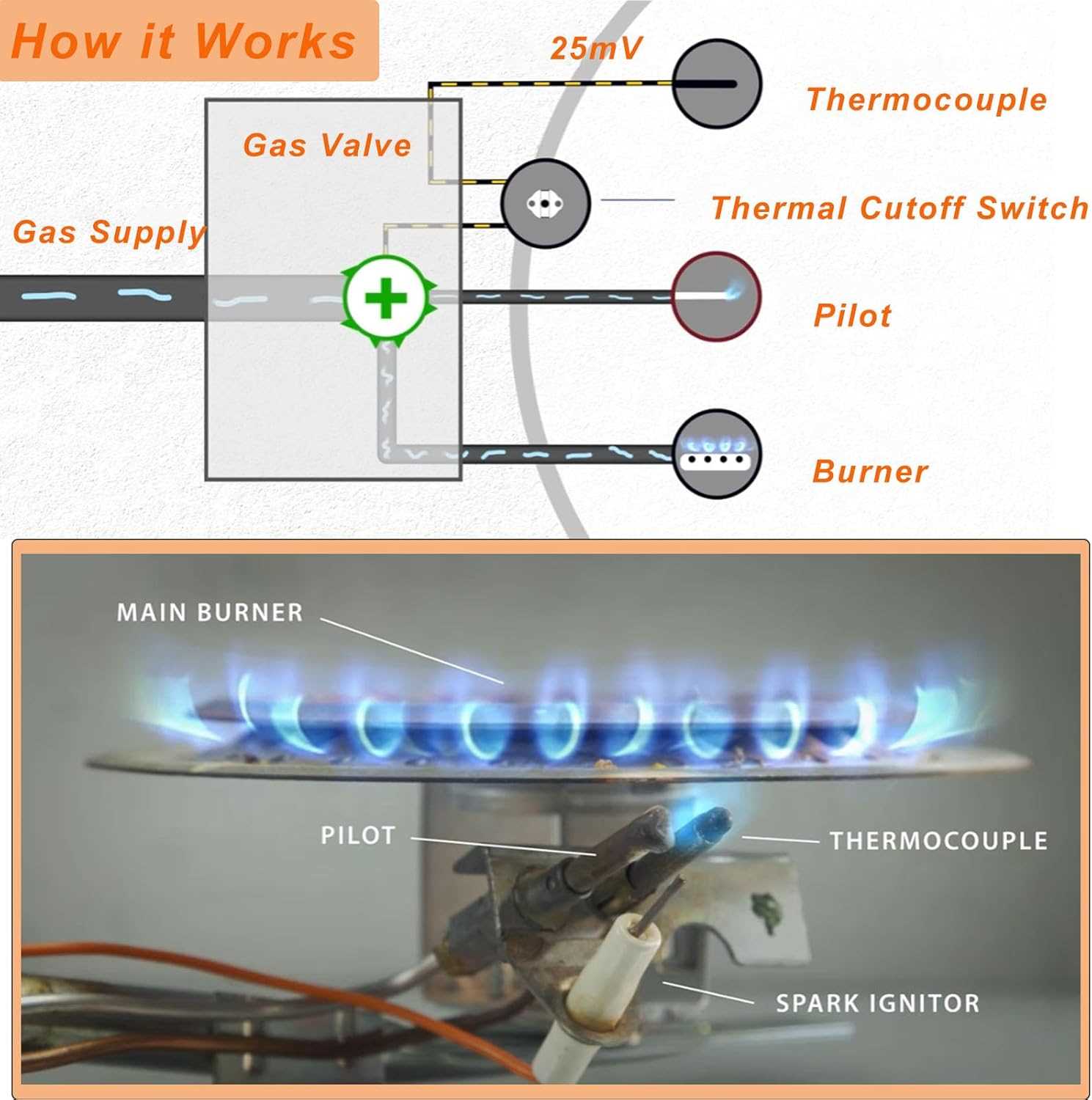

Heating Elements Explained

Understanding the components that generate warmth is essential for efficient functionality. These vital elements play a crucial role in transforming energy into thermal output, ensuring optimal performance.

Key aspects of these components include:

- Material Composition: Different materials influence efficiency and longevity.

- Wattage Ratings: Higher ratings typically equate to faster energy conversion.

- Placement: Location affects heat distribution within the system.

When selecting the appropriate elements, consider the following:

- Compatibility with the system type.

- Energy efficiency ratings.

- Manufacturer specifications for optimal operation.

Delving into these factors will ultimately enhance your understanding of their function and importance in maintaining a reliable heating system.

Thermostats: Function and Types

Thermostats play a crucial role in regulating temperature within various systems, ensuring optimal performance and efficiency. They act as vital components that monitor and control the temperature, allowing devices to operate within designated parameters.

Function: The primary function of a thermostat is to maintain a set temperature by activating or deactivating the associated equipment. This regulation prevents overheating or excessive cooling, ultimately contributing to energy conservation and system longevity.

Types: There are several types of thermostats, each serving unique purposes. Mechanical thermostats utilize bi-metallic strips to trigger temperature changes, while digital thermostats offer precise control through electronic sensors. Additionally, smart thermostats provide advanced features, allowing users to program settings and monitor systems remotely.

How to Identify Water Inlet Valve

Recognizing the component responsible for regulating the entry of fluid into your system is essential for maintenance and troubleshooting. This guide outlines key features and steps to help you pinpoint this crucial element effectively.

Key Characteristics

- Location: Typically situated at the base of the unit, the valve connects to the supply line.

- Appearance: Often cylindrical or rectangular, made from plastic or brass, and may have markings indicating flow direction.

- Connections: Look for threaded or slip fittings that link it to the piping system.

Identification Steps

- Turn off the main supply to prevent leaks during inspection.

- Locate the valve near the supply line; it is usually adjacent to other control elements.

- Examine the body for any labels or part numbers that could assist in identification.

- Check for the presence of a handle or knob that may control flow.

By following these guidelines, you can confidently identify the component that plays a vital role in managing the fluid intake of your system.

Exploring the Role of Drain Valves

Drain valves play a critical function in maintaining the efficiency and longevity of storage units designed for heating liquids. Understanding their purpose is essential for proper maintenance and troubleshooting.

Functions of Drain Valves

- Facilitate the removal of sediments

- Assist in system flushing and cleaning

- Enable quick drainage for repairs or maintenance

- Prevent over-pressurization during system failure

Importance of Regular Maintenance

Ensuring the functionality of drain valves requires regular inspections. Here are key steps to maintain these components:

- Check for leaks and corrosion.

- Test valve operation periodically.

- Clear any obstructions in the drain line.

- Replace worn or damaged valves promptly.

By paying attention to these details, users can enhance the efficiency of their systems and prevent costly repairs.

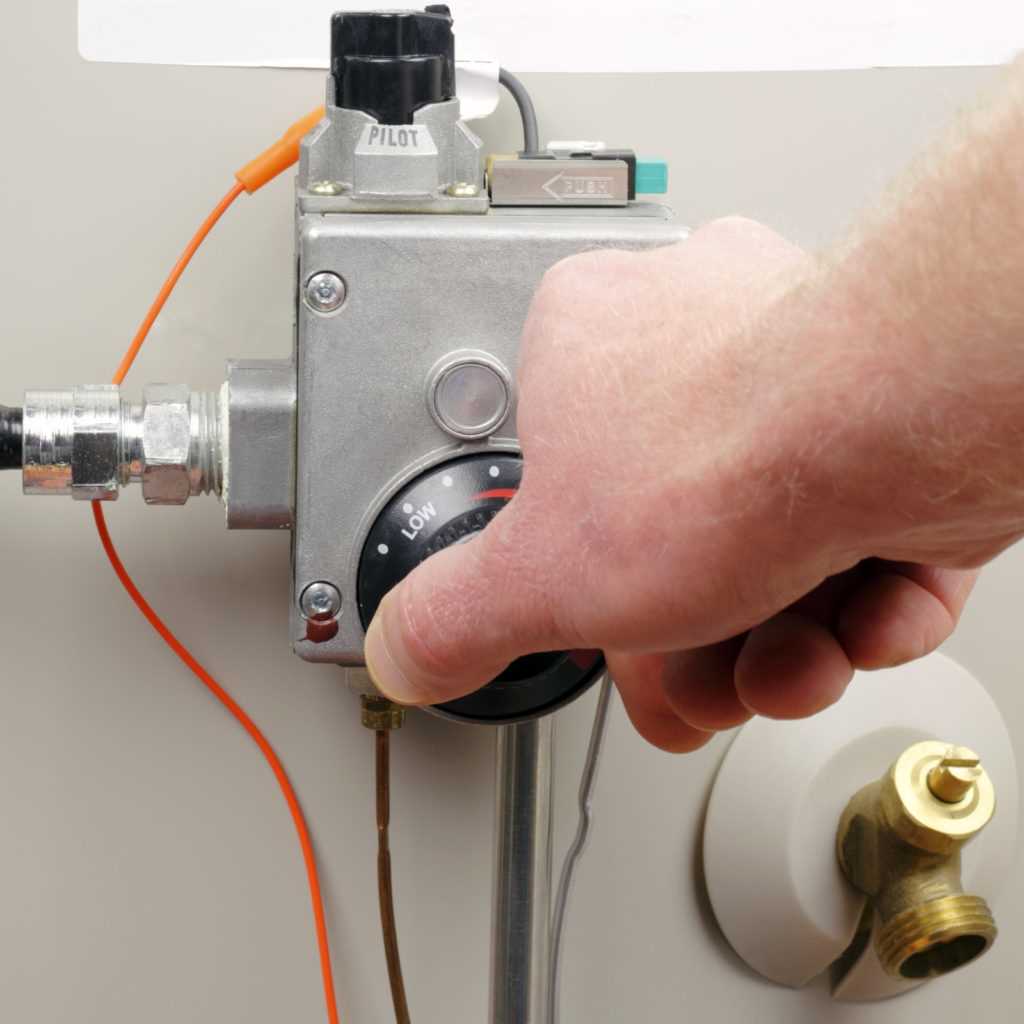

Safety Features in Water Heaters

Ensuring the security of appliances that generate heat is paramount for both efficiency and user protection. Various mechanisms are integrated into these devices to minimize risks associated with overheating, pressure build-up, and potential leaks. Understanding these features helps consumers make informed choices when selecting equipment for their needs.

Temperature Regulation

One of the primary safety measures is temperature regulation. Most models come equipped with a thermostat that maintains a preset level, preventing excessive heat accumulation. This feature not only safeguards the appliance itself but also reduces the risk of burns during usage.

Pressure Relief Systems

Another critical component is the pressure relief valve. This device automatically releases excess pressure, protecting the unit from damage and potential explosions. Regular maintenance ensures that these systems function correctly, further enhancing the safety of the entire setup.

Electrical Wiring Basics for Heaters

Understanding the fundamentals of electrical connections is essential for efficient operation and safety. Proper wiring ensures that devices function correctly while minimizing risks associated with electrical failures. This section explores the essential aspects of wiring systems related to heating appliances, providing a foundation for safe and effective installation.

Key Components of Electrical Systems

Every electrical setup includes various elements that work together. Conductors, switches, and circuit breakers play pivotal roles in managing the flow of electricity. Conductors carry current, switches control the flow, and circuit breakers provide protection against overloads. Familiarity with these components helps ensure that installations are done safely and according to regulations.

Safety Considerations

When dealing with electrical connections, safety should always be the top priority. Proper grounding and the use of appropriate circuit protection are critical to prevent hazards such as shocks or fires. Always follow local codes and standards when working on electrical installations, and consult a professional if unsure about any aspect of the process.

Maintenance Tips for Longevity

Ensuring the durability of your appliance requires consistent attention and proper care. By following a few simple practices, you can enhance its efficiency and extend its lifespan, ultimately saving you time and money.

Regular Inspections

- Schedule periodic checks to identify any potential issues early.

- Look for leaks, unusual noises, or fluctuations in performance.

- Ensure connections are secure and free from corrosion.

Routine Cleaning

- Clear any debris or buildup around the unit to promote airflow.

- Flush the system periodically to remove sediment and contaminants.

- Check filters and replace them as needed to maintain optimal performance.

Troubleshooting Common Issues

When it comes to maintaining efficient systems, encountering challenges is not uncommon. Understanding how to identify and resolve frequent problems can significantly enhance functionality and extend the lifespan of your equipment. This section will guide you through the typical issues faced and provide effective solutions.

Identifying Unresponsive Systems

If your unit shows no signs of activity, it’s essential to check the power supply first. Ensure that the device is properly connected and that circuit breakers have not tripped. Additionally, inspect any fuses that may have blown. A systematic approach to checking these elements can often resolve the issue swiftly.

Dealing with Inconsistent Performance

Should you notice fluctuations in output, various factors could be at play. One common culprit is sediment buildup within the system. Regular maintenance, including flushing the system, can help alleviate this. Additionally, verify the thermostat settings, as incorrect adjustments may lead to inconsistent functioning. Addressing these aspects can help restore reliable operation.

When to Replace Parts

Understanding the optimal times for component replacement is crucial for maintaining efficiency and functionality. Regular inspections can help identify issues before they lead to significant malfunctions. Being proactive can extend the lifespan of the entire system and improve performance.

Signs Indicating Replacement

Several indicators can signal the need for component renewal. Recognizing these signs early can prevent further complications.

| Indicator | Description |

|---|---|

| Leaks | Presence of moisture around components may indicate deterioration or failure. |

| No Output | If the system fails to produce the expected results, it may be time to assess the integrity of its components. |

| Unusual Noises | Strange sounds during operation can suggest internal issues requiring attention. |

Best Practices for Replacement

Adhering to a regular maintenance schedule can help identify when replacements are necessary. Consulting a professional for assessments can also ensure that all components are functioning optimally.

Resources for Further Learning

Expanding your knowledge in any field requires access to quality information and reliable references. This section aims to guide you toward valuable materials that can enhance your understanding and skills related to systems and components involved in energy management.

Books: Consider exploring comprehensive guides and manuals that focus on the technical aspects and operational principles of various systems. These texts often provide in-depth insights and practical applications.

Online Courses: Many platforms offer specialized courses covering installation, maintenance, and troubleshooting techniques. These courses can provide interactive learning experiences and expert-led instruction.

Video Tutorials: Video resources can be particularly useful for visual learners. Websites like YouTube host a myriad of instructional videos that demonstrate hands-on procedures and best practices.

Forums and Communities: Engaging with online forums and community groups can facilitate discussions with peers and professionals. Sharing experiences and solutions can deepen your understanding and help you stay updated on the latest trends.

Manufacturer Websites: Most manufacturers provide extensive resources, including product manuals, troubleshooting guides, and FAQs. These resources are invaluable for anyone seeking to familiarize themselves with specific models or technologies.

By utilizing these resources, you can significantly broaden your knowledge and proficiency in the field, making informed decisions and enhancing your practical skills.