In the world of power equipment, having a clear understanding of the various components that make up a machine is essential for effective operation and maintenance. Each part plays a crucial role in ensuring the device functions smoothly and efficiently. Familiarity with these elements can empower users to troubleshoot issues and perform necessary repairs with confidence.

Detailed illustrations of equipment parts serve as valuable references, enabling users to identify specific components easily. Such visual guides can enhance one’s ability to comprehend the assembly and disassembly of the tool, leading to better care and longevity of the machinery.

By exploring these visual resources, users can gain insights into the intricate workings of their equipment. This knowledge not only aids in routine maintenance but also assists in making informed decisions when it comes to upgrades or replacements, ultimately enhancing the overall performance of the tool.

Understanding the significance of every individual part in a tool is essential for its efficient operation and maintenance. Each element plays a specific role, contributing to the overall functionality and effectiveness of the device. Recognizing how these components interact can lead to better performance and longevity.

Key Roles of Components

- Power Source: Supplies the necessary energy to operate the equipment, determining its performance level.

- Cutting Mechanism: Essential for achieving precision in tasks, affecting the quality of the end result.

- Handle: Provides grip and control, ensuring comfort during use and reducing fatigue.

- Safety Features: Critical for protecting users from accidents, enhancing overall safety during operation.

Impact on Performance

Each part not only serves its unique purpose but also influences how well the tool performs as a whole. A malfunction in any component can lead to inefficiencies or potential hazards. Therefore, regular inspection and maintenance of each section are crucial for optimal functioning.

- Regular checks can help identify wear and tear.

- Understanding component roles aids in troubleshooting issues effectively.

- Replacing damaged parts ensures consistent performance over time.

Common Replacement Parts

Maintaining outdoor power equipment often requires replacing certain components to ensure optimal performance. Identifying which elements are most frequently substituted can help users keep their tools running smoothly.

- Cutting Blade: A sharp blade is essential for efficient operation, making this a common item for replacement.

- Battery: As the primary power source, batteries may degrade over time and need to be swapped out to maintain functionality.

- Handle Grip: A worn or damaged grip can affect user comfort and control, prompting replacements.

- Motor Brushes: These components are critical for the motor’s function and often require periodic replacement to ensure longevity.

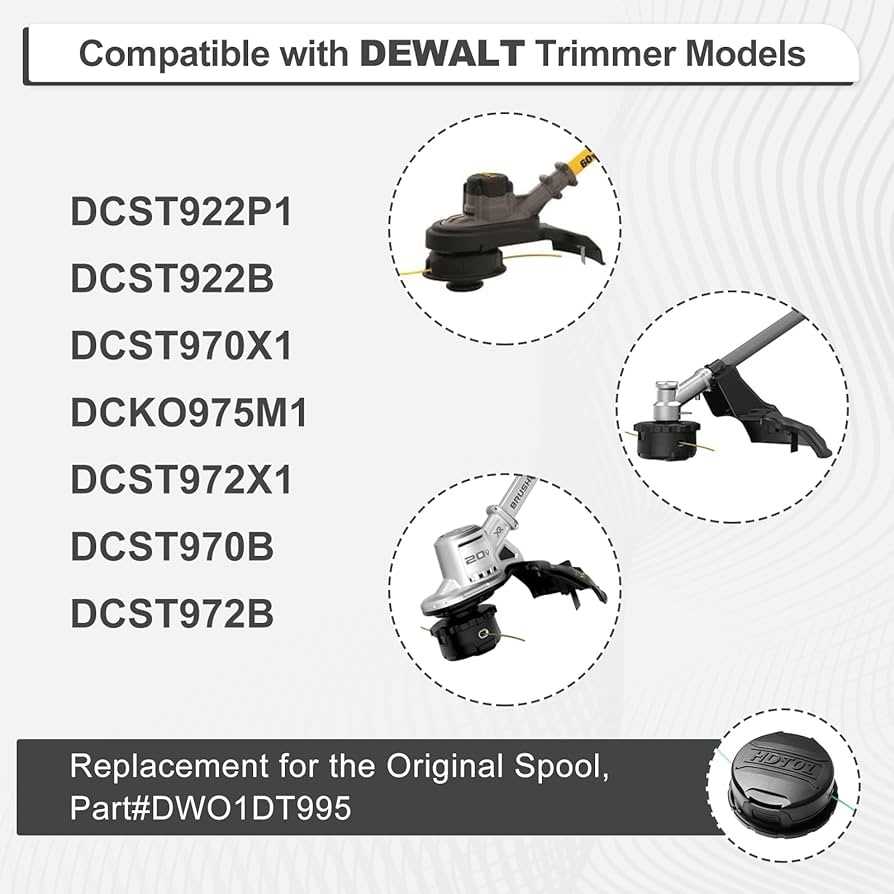

- Spool Assembly: The spool holds the cutting line, and a damaged assembly can lead to decreased performance.

Regularly checking and replacing these components can extend the life of outdoor power tools, ensuring they remain effective for a variety of tasks.

How to Identify Damaged Parts

Recognizing faulty components in equipment is essential for maintaining optimal performance and safety. Understanding the signs of wear and damage can help prevent further issues and extend the lifespan of the device. Here are some common indicators to look for when assessing the condition of various elements.

Common Signs of Damage

- Visible Cracks: Inspect for any noticeable fractures on the surface of the component.

- Excessive Wear: Check for unusual signs of erosion or deterioration, especially around moving parts.

- Discoloration: Look for any change in color that may indicate overheating or chemical exposure.

- Loose Connections: Ensure all joints and fittings are secure and not showing signs of looseness.

Steps for Assessment

- Begin with a thorough visual inspection of the equipment.

- Test the functionality of each component to identify any malfunctions.

- Consult the manufacturer’s guidelines for specific indicators of damage.

- Replace any parts that show significant wear or failure.

By being vigilant and proactive in evaluating the condition of your equipment, you can ensure its efficiency and longevity.

Assembly Instructions for Beginners

Assembling equipment for the first time can be a daunting task, but with the right guidance, it becomes a straightforward process. This section will provide essential steps and tips for novices, ensuring a smooth assembly experience.

Preparation Steps

- Gather all necessary components and tools before starting.

- Find a clean, well-lit workspace to facilitate the assembly process.

- Read through the instructions thoroughly to familiarize yourself with the parts involved.

Assembly Process

- Start by identifying the main body of the equipment and laying it out flat.

- Attach any handles or supports as indicated in the guidelines.

- Secure any movable parts carefully, ensuring they operate smoothly.

- Double-check all connections for tightness and alignment.

- Conduct a final inspection to confirm everything is assembled correctly before usage.

By following these steps, beginners can build their confidence and achieve a successful assembly, leading to a rewarding experience with their equipment.

Tools Required for Maintenance

Proper upkeep of equipment is essential for ensuring optimal performance and longevity. To effectively maintain your devices, certain tools are indispensable. These instruments not only facilitate repairs but also enhance the overall efficiency of the maintenance process.

Essential Hand Tools

Basic hand tools play a crucial role in routine maintenance tasks. A set of screwdrivers, pliers, and wrenches are fundamental for tightening or loosening components. Additionally, having a reliable torque wrench is vital to ensure that fittings are secured to the manufacturer’s specifications, preventing potential damage.

Power Equipment

In some cases, power tools may be required for more intensive maintenance. A cordless drill can significantly expedite the removal and installation of various parts. Moreover, having a high-quality impact driver can make it easier to tackle stubborn fasteners, allowing for a smoother maintenance experience.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a few straightforward guidelines, you can extend the lifespan of your tools and maintain their efficiency over time.

Regular Cleaning: After each use, make it a habit to clean your device thoroughly. Removing debris and dust will prevent buildup that can affect functionality.

Inspection: Routinely examine your tool for any signs of wear or damage. Early detection of issues can save you from costly repairs and ensure safe operation.

Lubrication: Keep moving parts well-lubricated to minimize friction and reduce wear. Using the appropriate lubricant will enhance performance and prolong the life of components.

Storage: Store your equipment in a dry, temperature-controlled environment. Protecting your tools from moisture and extreme temperatures can prevent rust and degradation.

Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance recommendations. Adhering to these guidelines ensures that you are using the tool as intended and caring for it appropriately.

Frequently Asked Questions

This section addresses common inquiries regarding the assembly and maintenance of power tools. Understanding these aspects can enhance the efficiency and longevity of your equipment.

- What should I do if a component is missing?

If you find that a piece is absent, check the packaging thoroughly and consult your retailer for assistance in obtaining a replacement.

- How can I identify the right accessory for my tool?

Refer to the user manual or manufacturer’s website for a list of compatible attachments and enhancements tailored for your specific model.

- Is it necessary to lubricate moving parts?

Regular lubrication is essential for maintaining optimal performance. Follow the guidelines outlined in the maintenance section of your manual.

- Where can I find detailed assembly instructions?

Assembly instructions can usually be found in the user manual or on the manufacturer’s support page, offering step-by-step guidance.

- How often should I perform maintenance checks?

It is advisable to conduct maintenance checks after every few uses or at least once a month to ensure everything is functioning properly.

Where to Purchase Spare Components

When seeking replacements for your tools, it is essential to know the best avenues for sourcing these necessary items. Various platforms and retailers offer a wide range of options, ensuring you can find what you need to keep your equipment functioning efficiently.

Online Retailers

Many online shops specialize in tool accessories and replacements. Consider the following options:

- Major e-commerce websites with dedicated sections for power tools

- Specialized tool suppliers that focus on replacement items

- Manufacturer’s official website, often providing direct sales of components

Local Stores

Visiting physical locations can also be beneficial for acquiring spare elements. Look for:

- Home improvement centers with extensive tool departments

- Hardware shops that frequently stock repair and replacement supplies

- Specialty tool retailers known for their comprehensive inventory

Comparing Prices from Retailers

When looking to purchase equipment, it’s essential to evaluate pricing from various suppliers to ensure you get the best deal. Retailers often offer different prices for similar items, so conducting thorough research can lead to significant savings.

Here are some strategies to effectively compare prices:

- Online Research: Utilize websites that aggregate prices from multiple stores, allowing you to see a range of options quickly.

- Check Local Stores: Visit nearby retailers to compare prices firsthand. Sometimes local shops may have exclusive promotions or discounts.

- Look for Seasonal Sales: Take advantage of holiday sales, end-of-season clearances, or special events that retailers may offer.

In addition to these strategies, it’s crucial to consider the reputation of the retailer, return policies, and shipping costs, as these factors can influence the overall value of your purchase.

User Experiences and Reviews

This section delves into the feedback and opinions of individuals who have utilized the equipment, shedding light on their practical encounters and satisfaction levels. Understanding user sentiments can provide valuable insights for prospective buyers.

Many users have shared their thoughts on the overall performance and reliability of the tool:

- Efficiency: Numerous reviews highlight the effectiveness of the device in various tasks, particularly in landscaping and yard maintenance.

- Ease of Use: Many individuals appreciate the user-friendly design, making it accessible for both beginners and experienced users.

- Durability: Several customers have noted the long-lasting quality, expressing confidence in the tool’s ability to withstand regular use.

Additionally, here are some common themes from user reviews:

- Performance: Users frequently commend the power and efficiency of the equipment, especially in heavy-duty applications.

- Weight and Portability: While some find it slightly heavier than expected, many appreciate its portability for outdoor tasks.

- Customer Support: Positive experiences with customer service have been reported, indicating a responsive and helpful support team.

In summary, user feedback paints a generally positive picture, emphasizing the tool’s effectiveness and reliability for various applications.