In the world of heavy machinery, having a clear view of every component is crucial for effective maintenance and optimal performance. This resource aims to provide insights into the intricate workings of a specific model, focusing on the various elements that contribute to its functionality.

Maintenance and repair can often be daunting tasks, but with the right information, they become manageable. By exploring the essential elements and their interconnections, operators can ensure that their machinery remains in peak condition, reducing downtime and enhancing productivity.

Whether you’re a seasoned professional or a novice user, understanding the relationships between different components is vital. This exploration will not only help you identify issues quickly but also empower you to make informed decisions regarding replacements and upgrades.

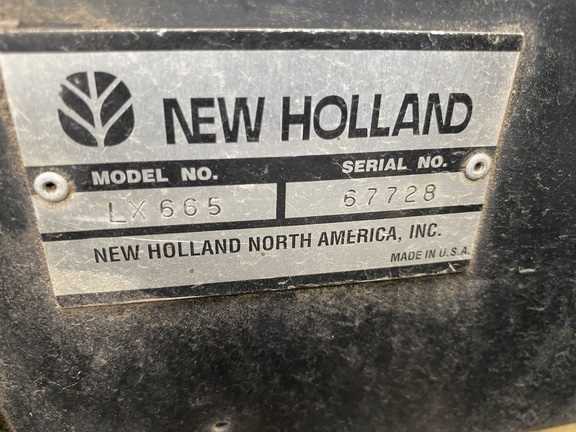

Understanding New Holland LX665 Parts

Gaining insight into the components of machinery is crucial for effective maintenance and repair. This knowledge empowers users to optimize performance and extend the lifespan of their equipment.

Key elements to consider include:

- Engine and transmission systems

- Hydraulic components

- Electrical systems

- Chassis and structural parts

Each of these sections plays a vital role in the overall functionality of the equipment. Familiarity with them helps in identifying issues and making informed decisions during repairs.

Additionally, understanding the relationships between these components can lead to enhanced operational efficiency. Here are some aspects to focus on:

- Routine inspections

- Scheduled maintenance practices

- Replacement strategies for worn-out elements

By delving into these areas, users can achieve the ultimate level of proficiency in managing their machinery effectively.

Overview of LX665 Features

This section provides a comprehensive look at the exceptional attributes of a versatile compact loader. Renowned for its efficiency and power, this machine is engineered to tackle various tasks with ease, making it a valuable asset in numerous applications.

One of the standout characteristics is its robust engine, which delivers impressive horsepower, ensuring optimal performance even in demanding conditions. The well-designed hydraulic system enhances lifting capabilities, allowing operators to handle heavier loads effortlessly.

Furthermore, the operator’s cabin is designed for comfort and visibility, enabling users to navigate their surroundings with precision. The intuitive controls facilitate seamless operation, making it accessible for both seasoned professionals and novices alike.

In addition to its operational strengths, the compact design allows for maneuverability in tight spaces, making it ideal for construction sites and landscaping projects. Overall, this machine exemplifies the perfect blend of power, comfort, and versatility.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools for identifying components and their relationships within a system, streamlining the troubleshooting process.

Enhanced Clarity

- Visual aids simplify complex information.

- Clear identification of individual elements improves workflow.

- Reduces the likelihood of errors during repairs.

Efficient Maintenance

- Facilitates quick access to specific components.

- Enables precise ordering of necessary replacements.

- Supports a better understanding of overall machine functionality.

Key Components of LX665

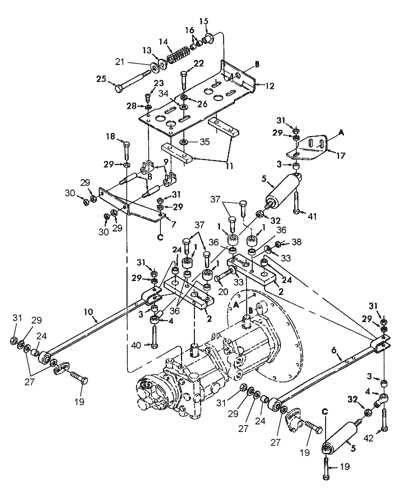

This section explores the essential elements that contribute to the efficient operation and versatility of the equipment. Understanding these components is vital for maintenance and enhancing performance.

Major Functional Parts

- Engine: Provides power and ensures reliable operation.

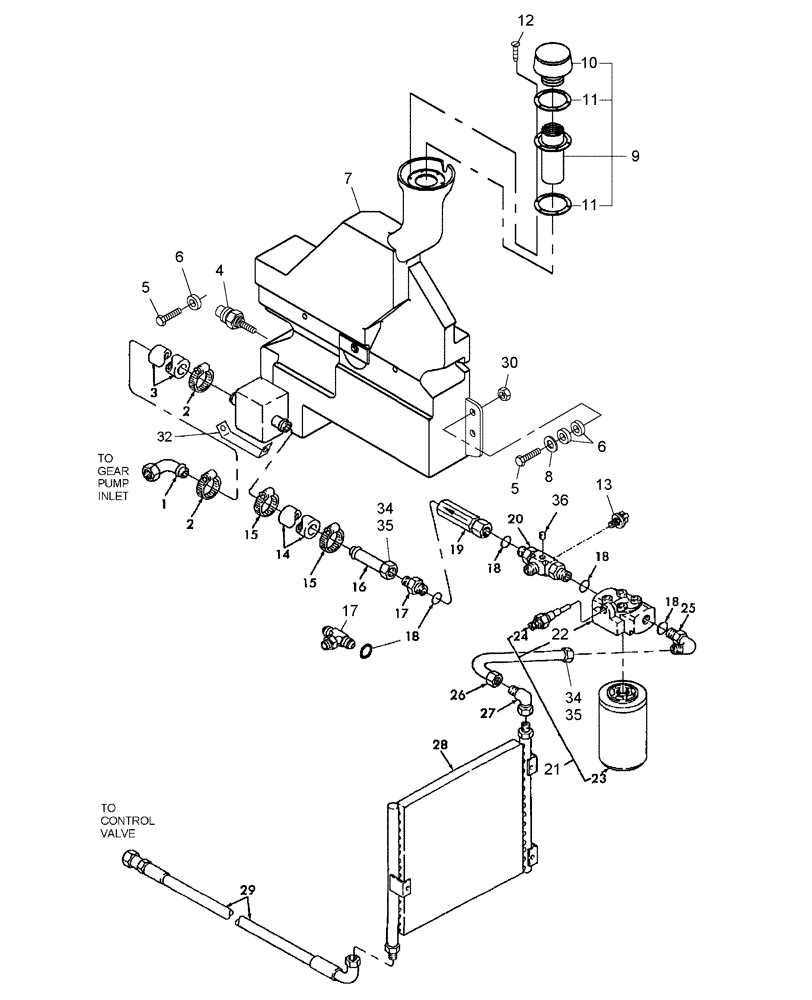

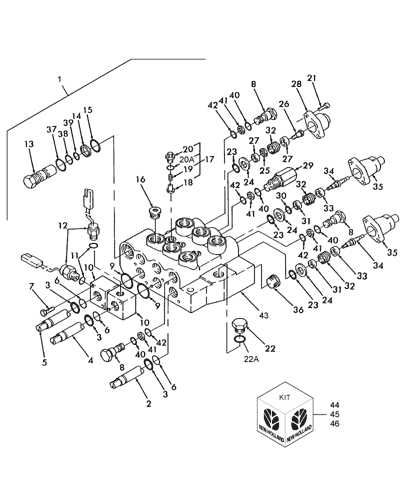

- Hydraulic System: Facilitates movement and attachment functionality.

- Transmission: Transfers power from the engine to the wheels for optimal mobility.

Additional Features

- Cab: Designed for operator comfort and visibility.

- Chassis: Supports overall structure and stability during use.

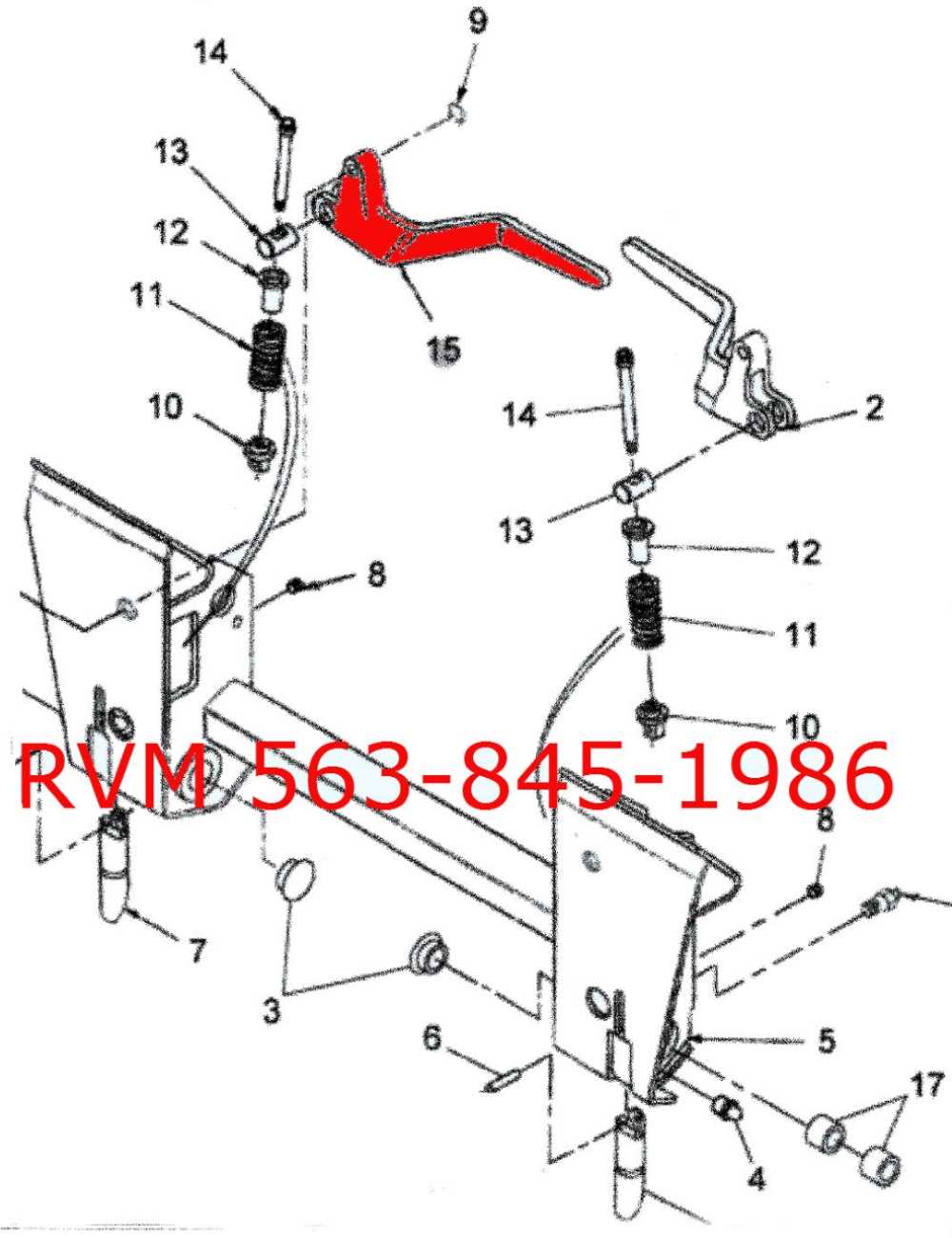

- Controls: User-friendly interface for ease of operation.

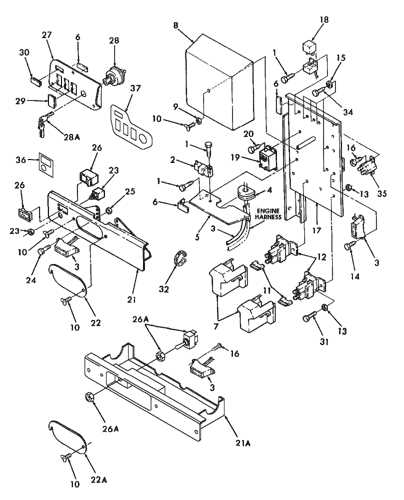

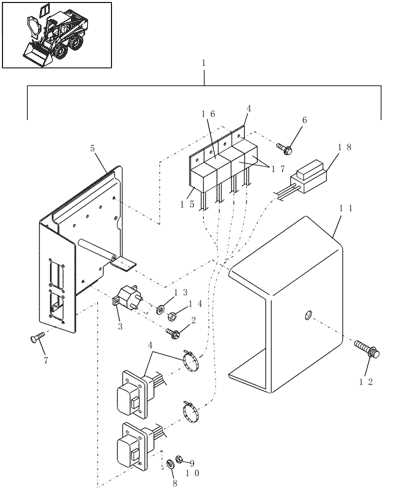

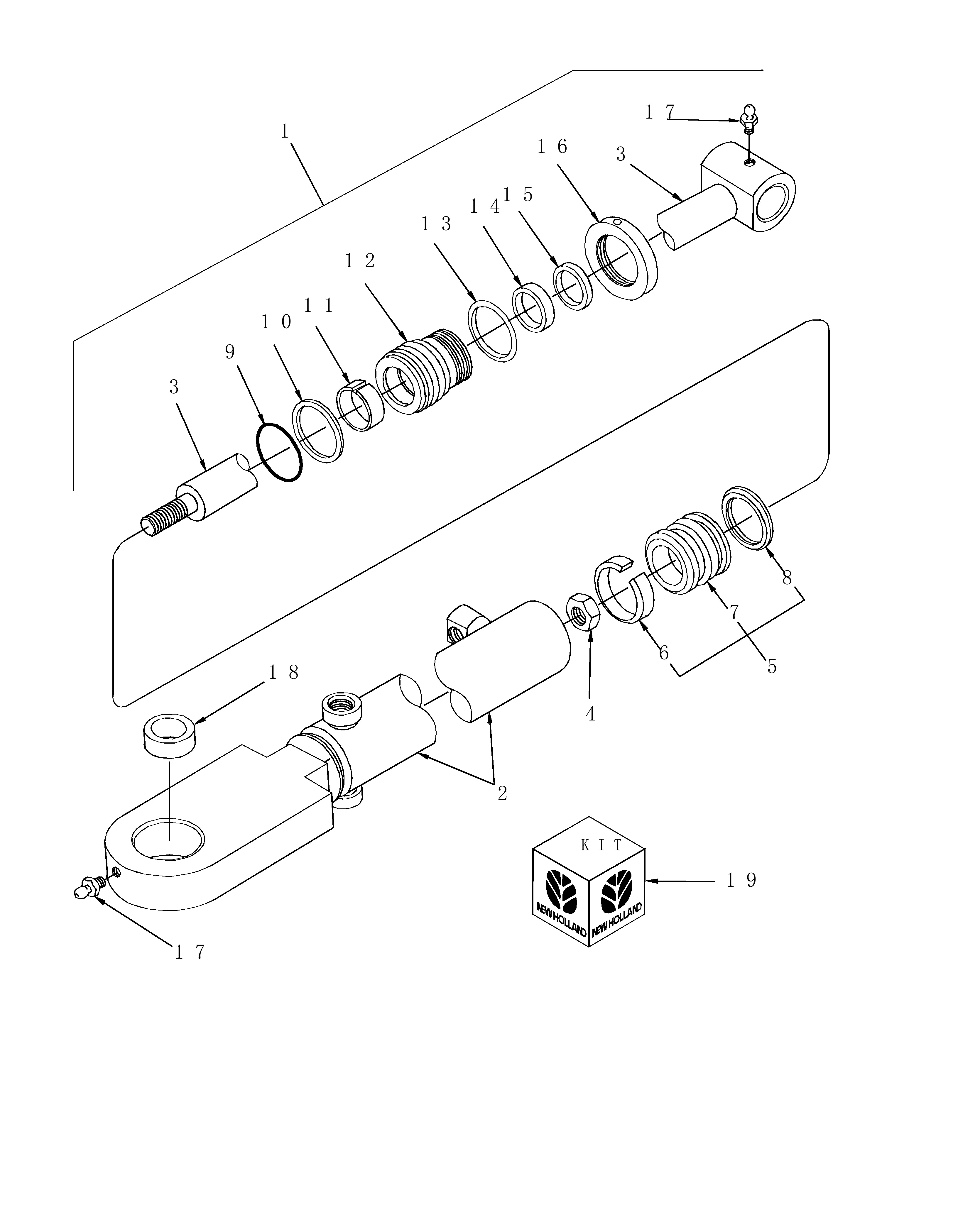

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a structured overview, allowing users to identify and locate individual elements easily.

Familiarize Yourself with Symbols

Each visual may use specific symbols to denote various items. Get to know these icons to interpret the illustration accurately. Pay attention to lines and connections that signify relationships between components.

Follow the Structure

Typically, these visuals are organized hierarchically. Start from the main assembly and work your way down to smaller sections. This methodical approach will help you comprehend how each piece fits into the overall system.

Common Replacement Parts Explained

In the realm of machinery maintenance, understanding essential components is crucial for optimal performance and longevity. This section delves into frequently needed elements that are vital for ensuring smooth operation and preventing unexpected breakdowns.

Hydraulic Cylinders play a pivotal role in powering various functions. Their integrity is essential for maintaining efficiency, as wear and tear can lead to reduced performance and potential leaks.

Filters are necessary for keeping fluids clean, thereby protecting internal systems from contaminants. Regular replacement of oil and air filters is key to preventing engine damage and ensuring the machinery runs smoothly.

Batteries provide the necessary power for starting and operating electrical systems. Over time, batteries can lose their capacity, making timely replacements critical for reliable functionality.

Belts and Hoses are fundamental for transferring power and fluids throughout the system. Regular inspection and replacement of these components can avert breakdowns and costly repairs.

Lights and Indicators are essential for safety and operational awareness. Ensuring these components are functional enhances visibility and helps operators monitor machine status effectively.

Understanding these key elements and their significance will aid in proactive maintenance, ultimately extending the lifespan and reliability of your equipment.

Finding Genuine New Holland Parts

When maintaining heavy machinery, sourcing authentic components is crucial for optimal performance and longevity. Utilizing reliable suppliers ensures that you receive high-quality items designed specifically for your equipment. This section will guide you through the process of acquiring these essential resources.

Benefits of Authentic Components

Choosing original items provides several advantages, including improved efficiency, enhanced safety, and increased reliability. Authentic components are manufactured to meet specific standards, ensuring compatibility and peak functionality. This investment not only prolongs the lifespan of your machinery but also reduces the likelihood of unexpected breakdowns.

Where to Find Quality Resources

There are various avenues for sourcing genuine components, each with its own merits. Authorized dealers and reputable online retailers often carry a wide selection. Additionally, industry expos and trade shows can be excellent opportunities to connect with trusted suppliers.

| Source | Description |

|---|---|

| Authorized Dealers | Official outlets offering a wide range of original items with manufacturer support. |

| Online Retailers | Reputable e-commerce platforms that specialize in machinery components. |

| Industry Expos | Events showcasing the latest products and services, providing networking opportunities. |

Maintenance Tips for LX665

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a systematic maintenance schedule, you can prevent potential issues and enhance operational efficiency. Here are some practical suggestions to keep your machine in top condition.

1. Regular Fluid Checks: Frequently inspect and change essential fluids, such as hydraulic fluid, engine oil, and coolant. Clean filters and ensure all levels are within recommended limits to avoid overheating or mechanical failures.

2. Inspect Belts and Hoses: Examine belts and hoses for any signs of wear, cracking, or fraying. Replacing these components promptly can prevent unexpected breakdowns during operation.

3. Clean Air Filters: Maintaining clean air filters is crucial for optimal engine performance. Regularly check and replace filters as needed to ensure proper airflow and prevent engine strain.

4. Tire Maintenance: Monitor tire pressure and tread condition. Properly inflated and well-maintained tires improve traction and fuel efficiency, contributing to a smoother operation.

5. Lubrication: Ensure that all moving parts are adequately lubricated. Regularly grease joints and bearings to minimize friction and wear, enhancing the lifespan of your machinery.

6. Electrical System Check: Inspect the battery and electrical connections regularly. Clean terminals and ensure connections are secure to avoid starting issues or electrical failures.

7. Follow the Manufacturer’s Guidelines: Always refer to the manufacturer’s maintenance manual for specific recommendations regarding service intervals and procedures. Adhering to these guidelines ensures your equipment operates at its best.

Implementing these maintenance practices will significantly enhance the reliability and efficiency of your machinery, helping you avoid costly repairs and downtime.

Popular Aftermarket Options Available

When seeking enhancements for your equipment, exploring aftermarket selections can significantly improve performance and reliability. These alternatives often provide cost-effective solutions tailored to meet various operational needs.

Types of Aftermarket Enhancements

- Replacement Components

- Performance Upgrades

- Safety Accessories

Benefits of Choosing Aftermarket Products

- Cost Savings

- Increased Availability

- Enhanced Customization

By considering these options, users can ultimately enhance their machinery’s functionality and extend its lifespan.

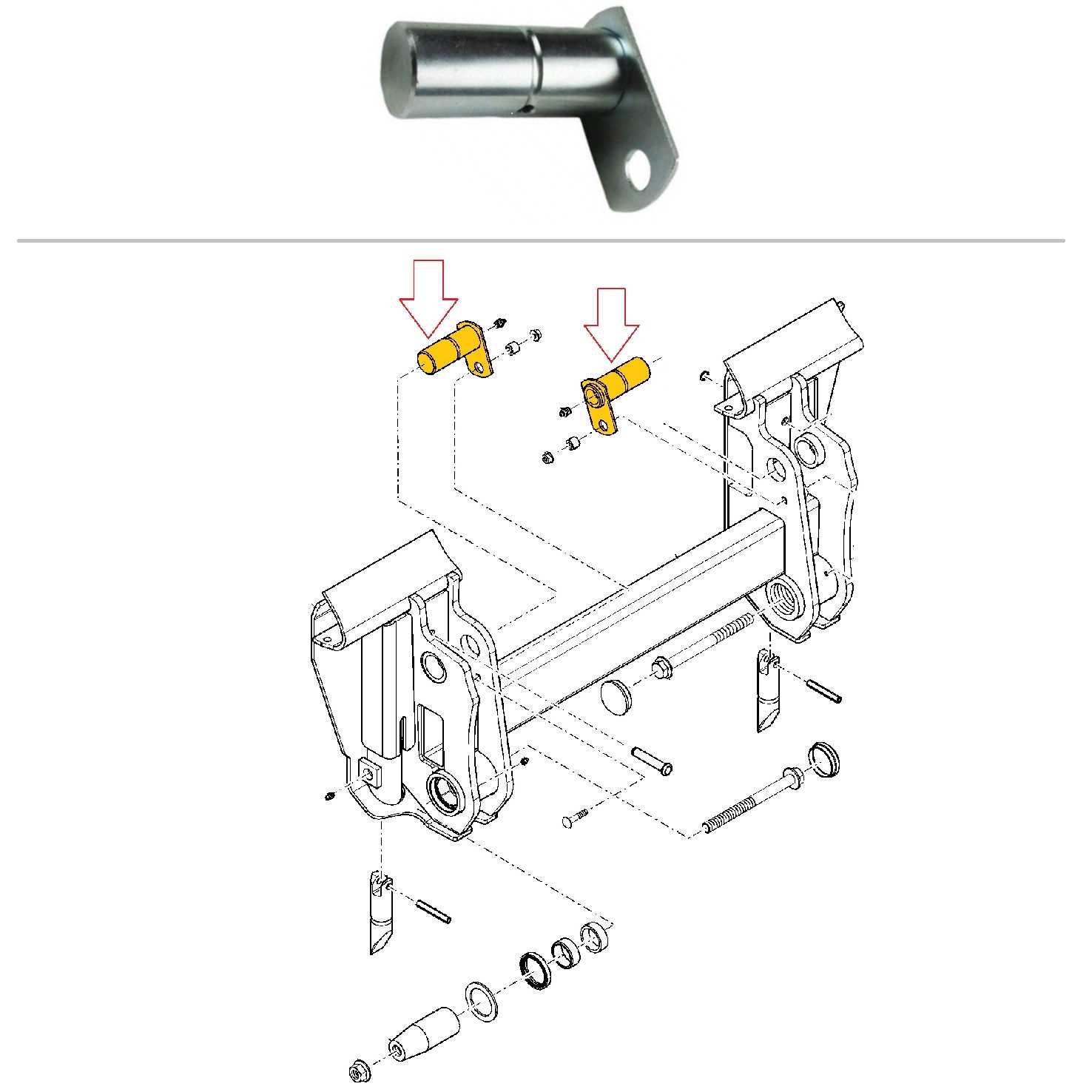

Assembly Instructions for Key Parts

This section provides essential guidance for the correct assembly of critical components, ensuring optimal performance and longevity. Following these instructions meticulously will help achieve a seamless integration of parts, minimizing the risk of issues during operation.

Step-by-Step Assembly

Begin by organizing all necessary components and tools. Refer to the provided schematic for specific locations and orientations. Assemble larger elements first, ensuring they are securely fastened before moving on to smaller parts. Double-check connections to guarantee a stable assembly.

Final Checks

Once the assembly is complete, conduct a thorough inspection of all connections and fastenings. Test each component’s functionality individually, ensuring they operate smoothly. This final review is crucial for confirming that everything is set for optimal use.

Resources for Parts Diagrams Online

Accessing comprehensive illustrations of machinery components is essential for effective maintenance and repairs. Various platforms offer valuable resources that provide visual guides and detailed information about individual parts, enabling users to understand their equipment better. Utilizing these resources can significantly streamline the process of sourcing and replacing necessary elements.

Online Platforms and Catalogs

Numerous websites specialize in providing extensive catalogs that feature detailed visuals of equipment components. These platforms allow users to search for specific models and access a range of illustrations, making it easier to identify the necessary parts. Additionally, many of these sites include user-friendly navigation tools, enhancing the overall experience.

Community Forums and Support Groups

Engaging with online communities can also be beneficial. Many enthusiasts and professionals share their experiences and insights regarding various machinery. Forums often contain threads dedicated to troubleshooting, maintenance tips, and visual resources, fostering a collaborative environment where users can find assistance and learn from each other.

Leveraging these online resources can greatly improve your understanding of equipment maintenance and ensure that you are well-equipped to tackle any repairs. Exploring these platforms will provide you with the necessary knowledge to enhance the longevity and performance of your machinery.

Expert Recommendations for Repairs

When it comes to maintaining machinery, understanding the intricate components is crucial for effective repairs. Professionals emphasize the importance of a systematic approach, ensuring that each element is inspected and serviced properly. Adhering to recommended practices can prolong the lifespan of the equipment and enhance its performance.

Routine Maintenance

Regular checks are essential. Schedule periodic inspections to identify wear and tear before they lead to significant issues. This proactive strategy not only saves time but also reduces overall repair costs. Always follow the manufacturer’s guidelines for service intervals to keep the machinery in optimal condition.

Quality Components

When replacing any elements, prioritize high-quality materials. Using subpar replacements can compromise functionality and safety. Consult with experts or trusted suppliers to ensure that the selected components meet the necessary specifications and standards for your specific model.