When it comes to maintaining and enhancing mechanical systems, having a clear and detailed overview of individual elements is crucial. This type of information allows both professionals and enthusiasts to quickly identify necessary replacements or improvements, ensuring the smooth operation of various structures. By thoroughly examining these elements, it becomes easier to diagnose issues and make informed decisions.

In the following breakdown, we will explore the core elements that make up a robust and reliable system. Each section will highlight the key elements, offering a comprehensive understanding of how different components interact to form an efficient and functional whole. Understanding the layout of these elements can significantly improve troubleshooting efforts and enhance long-term performance.

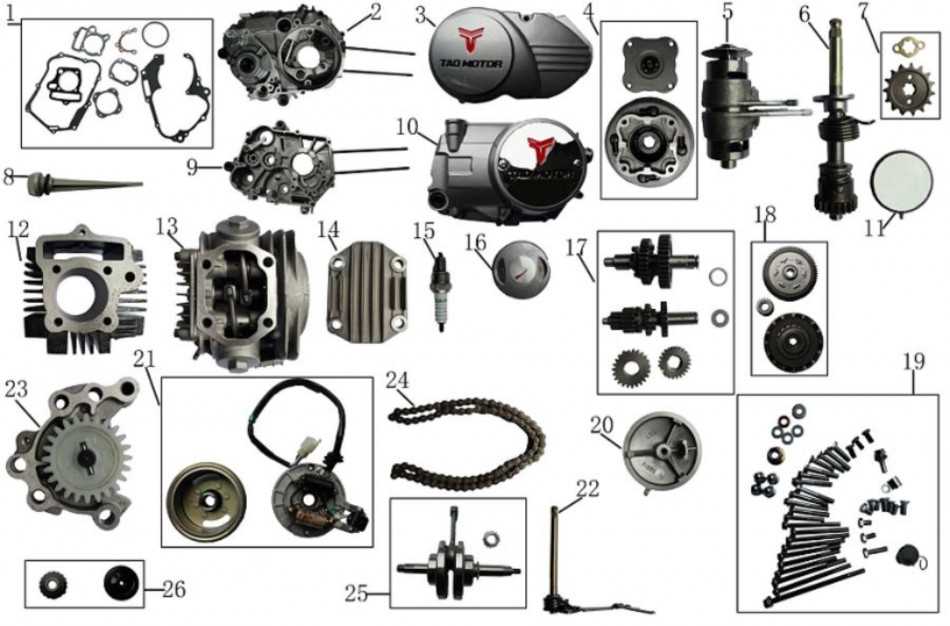

Overview of Tao DB10 Mechanical Components

The core structure of this model relies on a

Key Engine Parts and Their Functions

The internal combustion engine operates through the coordinated effort of several crucial components. Each element plays a vital role in converting fuel into motion, ensuring the smooth operation and overall efficiency of the vehicle. These elements work together in a precise manner, making it essential to understand their roles within the engine’s system.

Piston: A critical component that moves up and down inside the cylinder, the piston is responsible for converting the force of the expanding gas into mechanical energy. This motion ultimately powers the vehicle.

Crankshaft: As the piston moves, the crankshaft turns that linear motion into rotational energy, which is then transferred to the wheels. It plays a key role in the engine’s ability to propel the vehicle forward.

Camshaft: Responsible for opening and closing the valves at the correct intervals, the camshaft ensures that the engine breathes properly

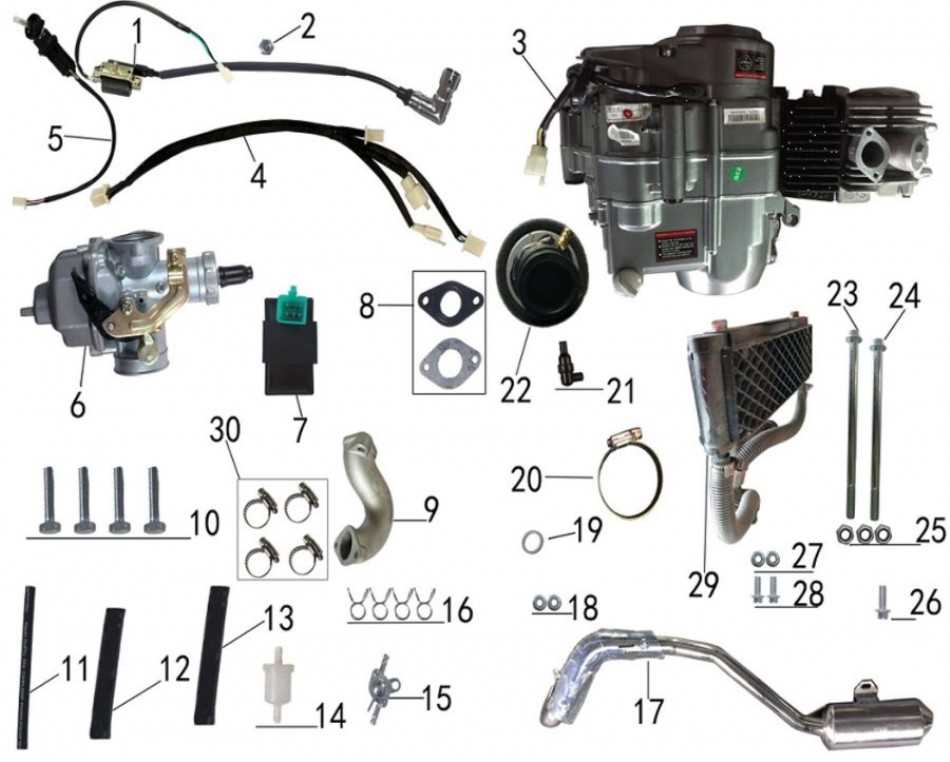

Exhaust System Layout and Details

The exhaust system plays a critical role in ensuring efficient engine operation by guiding gases safely away from the engine. Its design aims to maximize performance while minimizing harmful emissions and noise. Understanding the various components that make up this system is key to maintaining optimal functionality and safety.

Typically, the system includes several interconnected sections that work together to channel gases efficiently. These sections often consist of a header, mid-pipe, muffler, and tailpipe, each serving a specific purpose in the flow and regulation of exhaust gases. High-quality materials are chosen to withstand heat and corrosion, contributing to long-term durability.

In addition, the layout is designed to ensure minimal resistance, allowing gases to exit smoothly, which helps improve overall engine power. Regular inspection of this system is essential, as any blockages or damages can affect engine performance and environmental impact.

Frame Structure and Material Composition

The framework of the vehicle is a fundamental element that provides support and stability, influencing both safety and performance. A carefully designed structure enhances durability and ensures the proper alignment of all mechanical and aesthetic components.

Material selection is critical for achieving a balance between strength and weight. Modern structures often incorporate a combination of metals and alloys, each chosen for its unique properties, such as rigidity or flexibility. These materials are often treated to withstand external stress and environmental conditions, ensuring longevity.

Additionally, the geometric design of the frame plays a crucial role in distributing force evenly across the vehicle, minimizing potential damage and maximizing efficiency during operation.

Braking Mechanism and Associated Parts

The efficiency of the braking system relies on several interconnected components that work together to provide control and safety. Understanding the structure and function of these elements is crucial to ensure proper operation and to maintain overall stability during motion. This section will focus on the integral components responsible for halting movement and the supporting elements that contribute to a smooth and reliable performance.

Main Elements of the System

At the core of the braking setup is a device that directly applies pressure to reduce speed. This is complemented by a series of pads or shoes designed to create friction, which is essential for bringing the vehicle to a stop. The precise interaction between these elements determines the overall effectiveness of the system.

Supporting Components

Several additional parts assist the primary elements in delivering consistent performance.

Suspension System Breakdown for Tao DB10

The suspension framework plays a crucial role in ensuring a smooth and controlled ride. It is designed to absorb shocks from uneven terrain while maintaining stability and handling. This segment will explore the components and functionality of the suspension assembly, highlighting its significance in enhancing performance and comfort.

Key Components of the Suspension Framework

The primary elements that constitute the suspension assembly include springs, dampers, and linkages. Springs are responsible for absorbing energy from bumps and dips, while dampers work to control the oscillations, providing a balanced ride. Additionally, linkages connect various components, allowing for synchronized movement and improved handling.

Functionality and Importance

The effective operation of the suspension assembly not only contributes to a pleasant driving experience but also enhances vehicle safety. By minimizing the impact of road irregularities, the system aids in maintaining tire contact with the surface, which is essential for traction and control. Understanding the intricacies of this framework is vital for optimizing performance and ensuring longevity.

Electrical Wiring and Key Connections

This section focuses on the essential elements of electrical wiring and the critical connections necessary for the effective operation of various systems. Understanding these components is vital for ensuring safety and functionality in electronic setups.

Proper wiring is fundamental in maintaining the integrity of electrical systems. Here are some key aspects to consider:

- Color Coding: Wires are typically color-coded to identify their functions. Familiarizing oneself with these codes helps prevent errors during installation.

- Connector Types: Different connectors are used based on the application. It’s crucial to choose the correct type for optimal performance.

- Insulation: Proper insulation is necessary to prevent short circuits and electrical shocks. Always ensure that wires are adequately insulated.

When establishing connections, consider the following guidelines:

- Secure Connections: Ensure all connections are tight and secure to prevent loss of power or signal.

- Polarity: Pay attention to polarity when connecting wires, especially for power supply and ground connections.

- Use of Soldering: For permanent connections, soldering is recommended to achieve a reliable bond.

By adhering to these practices, one can ensure that the electrical framework functions efficiently and safely, minimizing the risk of malfunctions.

Transmission System Overview and Design

The transmission system is a crucial component that facilitates the transfer of power from the engine to the wheels, ensuring optimal performance and efficiency. This assembly comprises various elements working in unison to achieve smooth gear shifts and effective torque delivery. Understanding its design and functionality is essential for maintaining the overall reliability and responsiveness of any vehicle.

The architecture of the transmission involves multiple gears, clutches, and associated mechanisms, each playing a vital role in regulating speed and torque. The choice of materials and precision engineering contributes significantly to the durability and effectiveness of this system. Additionally, modern advancements have led to the integration of electronic controls, enhancing the adaptability and efficiency of the transmission.

Design considerations include factors such as weight, space constraints, and the intended application of the vehicle. Each component must be meticulously designed to withstand the stresses of operation while maintaining performance. An efficient transmission not only improves acceleration and fuel economy but also contributes to the overall driving experience, making it a fundamental aspect of automotive engineering.

Fuel System Components and Placement

The fuel delivery mechanism plays a critical role in the overall performance of an engine. Understanding the various elements involved in this system is essential for ensuring optimal operation. Each component serves a specific purpose and is strategically positioned to facilitate efficient fuel flow, enhance combustion, and maintain engine efficiency.

Key components of the fuel delivery system include the fuel tank, fuel pump, fuel filter, and fuel injectors. The arrangement of these parts is crucial, as it directly impacts the engine’s functionality and responsiveness. Below is a table summarizing the main components and their respective locations:

| Component | Description | Placement |

|---|---|---|

| Fuel Tank | Stores the fuel needed for combustion. | Located at the rear of the vehicle. |

| Fuel Pump | Transports fuel from the tank to the engine. | Usually mounted inside or near the fuel tank. |

| Fuel Filter | Removes impurities from the fuel. | Placed between the fuel pump and the engine. |

| Fuel Injectors | Atomizes fuel for efficient combustion. | Located in the intake manifold or cylinder head. |

By comprehensively understanding these components and their layout, users can better appreciate how the fuel system contributes to overall engine performance. Proper maintenance and inspection of these elements can lead to improved efficiency and longevity of the engine.

Handlebar and Control Parts Layout

The layout of the handlebar and its associated controls is crucial for the effective operation and comfort of the vehicle. This configuration encompasses various components that contribute to maneuverability, safety, and user interaction. Understanding the arrangement of these elements enhances the overall riding experience and ensures accessibility during operation.

Key Components Overview

At the core of the handlebar assembly are several essential elements, each serving a specific function. The positioning and integration of these components are designed to optimize control and provide a seamless user experience. Below is a breakdown of the primary components found in the handlebar setup:

| Component | Description |

|---|---|

| Grips | Designed for comfort, allowing the rider to maintain a secure hold on the handlebars. |

| Throttle | Controls the engine’s power output, enabling acceleration and speed adjustments. |

| Brake Lever | Activates the braking system, providing safety and control during riding. |

| Clutch Lever | Engages and disengages the engine from the drivetrain, allowing for smooth gear changes. |

| Switches | Includes controls for lights, indicators, and horn, facilitating communication and safety. |

Arrangement and Ergonomics

The ergonomic design of the handlebar assembly is tailored to suit the rider’s natural posture. Proper alignment of the components ensures easy reach and minimal strain during operation. Attention to the layout contributes to a safer and more enjoyable riding experience, enhancing the vehicle’s overall functionality.

Wheel Assembly and Tire Specifications

The wheel assembly plays a crucial role in the overall performance and safety of a vehicle. Understanding the components and specifications of this assembly is essential for optimal functionality and maintenance. This section delves into the key elements that make up the wheel assembly and the specific requirements for tires, ensuring a smooth and efficient riding experience.

Components of the Wheel Assembly

- Rim: The outer edge of the wheel that holds the tire in place, typically made of durable materials to withstand various conditions.

- Hub: The central part of the wheel that connects to the axle, allowing for rotation and stability.

- Spokes: The structural supports that connect the rim to the hub, providing strength and stability to the wheel.

- Bearings: Essential for smooth rotation, bearings reduce friction between moving parts in the assembly.

Tire Specifications

Choosing the right tires is vital for performance, safety, and longevity. Here are some important factors to consider:

- Tread Pattern: The design of the tire surface, which affects grip, handling, and water dispersion.

- Size: Proper sizing is crucial for fitting the wheel assembly and ensuring compatibility with the vehicle’s specifications.

- Load Rating: This indicates the maximum weight a tire can support, ensuring safety and stability during operation.

- Inflation Pressure: Maintaining the correct air pressure is essential for optimal tire performance and fuel efficiency.