Exploring the intricate assembly of agricultural machinery can significantly enhance operational efficiency. Gaining insight into the various elements that contribute to functionality allows users to maintain their equipment effectively. A comprehensive overview of these components helps ensure that each element performs its role optimally.

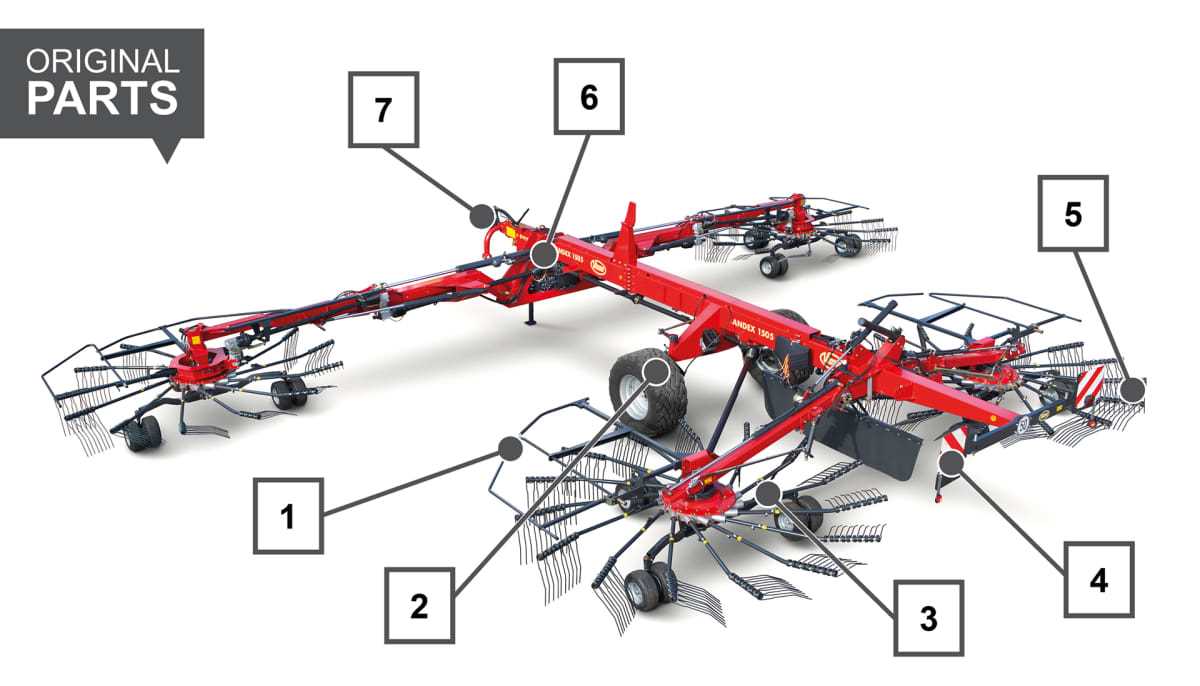

Visual representations serve as valuable tools for understanding the layout and interaction of different components within the system. By examining these illustrations, one can identify essential features and their respective functions. This knowledge facilitates informed decision-making regarding maintenance, repair, and upgrades.

Furthermore, an organized view of the machinery’s structure promotes a deeper appreciation for its engineering. Understanding how individual parts collaborate enhances the overall user experience and encourages proactive engagement with the equipment. Familiarity with these aspects ultimately leads to improved productivity and longevity of the implement.

This section provides a comprehensive introduction to a specialized agricultural implement designed for enhancing the efficiency of hay and grass handling. Understanding its functionality and components is essential for users aiming to optimize their operations. The implement plays a crucial role in the process of preparing forage for storage, ensuring that the crop is gathered effectively and efficiently.

Functionality of the Equipment

The implement serves several important purposes:

- Facilitates the collection of cut grass or hay.

- Ensures even distribution across the field.

- Enhances drying processes through improved airflow.

Key Components

Familiarity with the primary components is vital for maintenance and effective usage:

- Frame: Provides structural integrity and support.

- Wheels: Aid in mobility and maneuverability across fields.

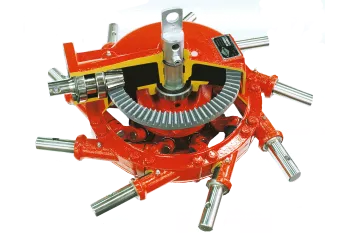

- Rotors: Essential for gathering and lifting the crop material.

- Linkage: Connects various parts for synchronized operation.

Key Features of Kuhn Speed Rake

This section delves into the essential characteristics of an advanced agricultural implement designed for efficient hay and forage handling. Its innovative design ensures optimal performance, making it an indispensable tool for farmers seeking to enhance their productivity.

One of the standout features of this implement is its adjustable working width, allowing users to customize the machine to suit various field conditions and crop types. This flexibility contributes to increased efficiency and reduced operational time.

The implement is also equipped with high-quality tines that effectively gather and distribute material, ensuring a uniform finish. This aspect is crucial for maintaining the quality of the forage, ultimately leading to better feed for livestock.

Additionally, the robust construction of the machine guarantees durability and longevity, minimizing maintenance requirements. The user-friendly controls further enhance the overall experience, making it easier for operators to navigate and manage the implement in diverse agricultural settings.

Importance of Proper Maintenance

Regular upkeep of agricultural machinery plays a crucial role in ensuring optimal performance and longevity. Neglecting maintenance can lead to various issues that hinder efficiency and productivity. Therefore, implementing a structured maintenance routine is essential for any operator.

Key benefits of maintaining equipment include:

- Enhanced Efficiency: Well-maintained machinery operates more effectively, leading to better results and less wasted time.

- Reduced Downtime: Regular inspections and servicing can help identify potential problems before they escalate, minimizing unexpected breakdowns.

- Cost Savings: Investing in maintenance can prevent costly repairs and extend the lifespan of the equipment, saving money in the long run.

- Safety Improvements: Properly maintained machinery is safer to operate, reducing the risk of accidents and injuries.

By prioritizing maintenance, operators can ensure that their equipment remains reliable and efficient, ultimately leading to improved productivity and success in agricultural operations.

Understanding Rake Operation Principles

The functionality of a tool designed for gathering and managing agricultural materials relies on several key concepts. This mechanism plays a crucial role in optimizing efficiency during fieldwork, allowing for the effective collection and arrangement of various organic materials. A clear comprehension of these operational principles can enhance the overall performance and utility of the equipment.

Key Functional Elements

Central to the operation are components that facilitate movement and interaction with the ground. These elements work in harmony to ensure smooth navigation across diverse terrains while effectively collecting and distributing the gathered materials. Their design influences not only the speed of operation but also the quality of the outcome, making them essential for achieving desired results.

Importance of Maintenance

Regular upkeep of the machinery is vital for sustaining optimal performance. Ensuring that each component is functioning correctly prevents potential issues that may arise during use. Routine checks and timely replacements of worn-out parts help in maintaining the efficiency and longevity of the tool, thereby supporting productive agricultural practices.

Common Components of the Speed Rake

The efficiency of agricultural equipment is significantly influenced by its individual elements. Understanding these components is essential for optimizing performance and ensuring smooth operation. Each part plays a vital role in enhancing functionality and durability, contributing to the overall effectiveness of the machinery.

| Component | Description |

|---|---|

| Frame | The sturdy structure that supports all other components, ensuring stability during use. |

| Tines | The flexible prongs that gather and lift material from the ground. |

| Wheel Assembly | A set of wheels that provides mobility and assists in maneuvering across different terrains. |

| Lift Mechanism | The system that enables raising and lowering of the working components for optimal efficiency. |

| Drivetrain | The assembly that transmits power from the tractor to the working parts, ensuring proper operation. |

How to Identify Parts on Diagram

Understanding the components of a machinery illustration is crucial for efficient operation and maintenance. This section will guide you through the process of recognizing and distinguishing various elements depicted in the schematic. Mastery of this skill enables users to troubleshoot effectively and perform necessary repairs.

Key Features to Look For

When examining the visual representation, focus on specific characteristics that aid in identification. Pay attention to shapes, sizes, and markings that correspond to particular functionalities. Familiarizing yourself with common symbols and conventions used in such illustrations is essential.

Using the Reference Table

The following table serves as a helpful resource, listing common elements and their corresponding descriptions. Referencing this will assist in understanding the layout and function of each component.

| Symbol | Description |

|---|---|

| ◯ | Connector for hydraulic lines |

| △ | Adjustment lever for height control |

| □ | Attachment point for accessories |

| ◆ | Drive mechanism |

Replacing Worn-Out Components

Over time, certain elements of agricultural machinery can become fatigued or damaged due to continuous use. Addressing these issues promptly is crucial to maintaining optimal performance and ensuring longevity. Identifying and substituting worn components will enhance the efficiency and reliability of the equipment.

Assessment of Condition: Begin by thoroughly examining each element of the machine. Look for signs of wear such as cracks, bends, or excessive abrasion. Regular inspections are vital to catch these problems early.

Selection of Replacement: Once the worn components are identified, choose suitable replacements that match the original specifications. It is essential to opt for high-quality items that can withstand the demands of rigorous usage.

Installation Process: Follow the manufacturer’s guidelines during the installation of new elements. Ensure all connections are secure and that the newly installed components are properly aligned. This step is critical to avoid future issues and maintain smooth operation.

Testing: After replacing the worn-out components, conduct a test run to verify the functionality of the machinery. Pay close attention to any unusual sounds or behaviors that might indicate further adjustments are needed.

Adjusting Settings for Optimal Performance

To achieve the best results in any agricultural machinery, fine-tuning operational settings is essential. This process enhances efficiency and ensures that tasks are completed effectively, minimizing wear and tear on equipment. Proper adjustments can significantly impact productivity, leading to better crop management and reduced operational costs.

Here are key considerations when adjusting settings:

- Identify Field Conditions: Assess the soil type and moisture levels to determine the appropriate configurations.

- Monitor Working Depth: Adjust the depth settings based on the specific requirements of the task to avoid unnecessary disturbance of the soil.

- Calibrate Speed: Ensure that the operational speed matches the machine’s capability and the task at hand for optimal results.

- Check Equipment Alignment: Regularly verify that all components are aligned correctly to prevent uneven performance.

Regular maintenance and adjustment of these settings can lead to improved functionality and longevity of the machinery. Keeping a record of settings for different conditions will aid in making quick adjustments in future operations.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper awareness and adherence to guidelines can significantly reduce risks associated with repairs. Before starting any work, it’s essential to familiarize yourself with the equipment and follow standard safety protocols.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the work area is clean and free from clutter to avoid trip hazards.

- Disconnect power sources and secure moving parts to prevent unexpected activation.

- Use tools correctly and keep them in good condition to avoid malfunctions.

Emergency Preparedness

Preparation for emergencies is vital in any repair scenario. Familiarize yourself with emergency procedures and keep first aid supplies readily accessible. Knowing how to respond in case of an accident can make a significant difference.

- Establish clear communication channels with team members.

- Have a fire extinguisher nearby and ensure it is in working order.

- Review safety data sheets (SDS) for materials used in repairs.

Tools Required for Maintenance

Proper upkeep of agricultural equipment ensures optimal performance and longevity. Regular maintenance tasks necessitate a selection of essential tools to facilitate efficient service and repairs. Familiarity with these instruments not only enhances productivity but also promotes safety during operations.

The following tools are crucial for effective maintenance:

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening various bolts and nuts.

- Screwdrivers: A set of flathead and Phillips screwdrivers assists in managing screws found throughout the machinery.

- Grease Gun: Essential for applying lubricant to moving parts, ensuring smooth operation.

- Plier Set: Needle-nose and slip-joint pliers help in gripping and manipulating small components.

- Safety Gear: Gloves, goggles, and ear protection are necessary for ensuring personal safety during maintenance tasks.

Having these tools readily available streamlines maintenance procedures and contributes to the overall efficiency of agricultural operations.

Comparative Analysis with Other Models

This section presents a thorough examination of various agricultural implements designed for soil cultivation and residue management. By comparing features and functionalities, we aim to highlight the strengths and weaknesses of different models, providing a comprehensive perspective for users seeking optimal solutions for their farming needs.

Performance and Efficiency

The efficiency of these implements varies significantly based on design and technological advancements. While some models prioritize speed and productivity, others focus on adaptability to diverse soil conditions. Analyzing their performance metrics, such as working speed and operational depth, offers insights into their suitability for specific agricultural tasks.

Durability and Maintenance

Durability is a crucial factor in the long-term viability of any agricultural equipment. Different designs exhibit varying levels of resilience to wear and tear. In this analysis, we explore the maintenance requirements of each model, emphasizing how ease of service impacts overall operational costs. Models that require minimal upkeep tend to be favored by users looking to maximize productivity while minimizing downtime.

Troubleshooting Common Issues

This section provides guidance on addressing frequent challenges encountered during operation. Identifying the underlying causes and implementing effective solutions can enhance functionality and extend the lifespan of your equipment.

Identifying Symptoms

Common issues may manifest as unusual noises, reduced efficiency, or inconsistent performance. Recognizing these symptoms early can prevent further complications. The table below outlines potential problems and their corresponding indicators.

| Problem | Symptoms |

|---|---|

| Mechanical Failure | Unusual sounds, jerky movements |

| Hydraulic Issues | Weak pressure, slow response |

| Electrical Malfunctions | Inconsistent operation, warning lights |

Recommended Solutions

To address these concerns, begin by performing routine maintenance checks. Cleaning, lubricating, and inspecting components regularly can prevent many issues. In cases of persistent problems, consulting the manufacturer’s manual or seeking professional assistance is advisable.

Resources for Further Information

For those seeking to expand their knowledge and understanding of agricultural implements, various valuable resources are available. These materials can enhance comprehension of operational features, maintenance practices, and the intricacies of equipment assembly.

Online platforms, including manufacturer websites and forums, offer extensive manuals and user guides, providing insights into specific models and their functionalities. Additionally, agricultural trade publications and journals often feature articles that delve into advancements in machinery design and efficiency.

Joining local farming associations or online communities can also facilitate discussions with experienced users, fostering knowledge sharing and practical tips. Furthermore, educational videos and tutorials available on streaming platforms can visually demonstrate proper techniques and maintenance procedures.