When it comes to maintaining a robust vehicle, having a clear understanding of its structural elements is essential. This section aims to provide an overview of the various components that contribute to the stability and performance of large trucks. By familiarizing yourself with these key features, you can enhance your knowledge and improve the functionality of your vehicle.

Each component plays a vital role in ensuring that the vehicle operates smoothly and efficiently. Knowing how these elements interact can aid in troubleshooting common issues and planning necessary repairs. Additionally, understanding the configuration of these components can assist in making informed decisions when upgrading or replacing specific parts.

In this exploration, we will delve into the essential components, highlighting their functions and significance. This will serve as a valuable resource for anyone looking to deepen their comprehension of heavy-duty truck mechanics, enabling better maintenance and performance of their vehicle.

tags, with distinct headings: Understanding Front End Components”>

tags, with distinct headings: Understanding Front End Components”>

This section aims to provide a comprehensive overview of the various elements that make up the front structure of a heavy-duty vehicle. By understanding these components, readers can gain insight into how they work together to ensure stability, safety, and performance. This knowledge is essential for anyone looking to maintain or repair their vehicle effectively.

Key Elements of the Vehicle’s Structure

Understanding the main components involved in the front assembly can help identify potential issues and improve overall functionality. Each element plays a crucial role in supporting the vehicle’s weight, handling steering mechanisms, and providing safety features.

Common Issues and Maintenance Tips

Regular inspection and maintenance of these components can prevent costly repairs and enhance vehicle longevity. It’s important to be aware of common problems that can arise, such as wear and tear, misalignment, or damage due to external factors.

| Component | Description | Maintenance Tips |

|---|---|---|

| Suspension System | Supports the vehicle and absorbs shocks. | Check for leaks and worn-out parts. |

| Steering Mechanism | Enables direction control. | Inspect for play and lubrication needs. |

| Braking System | Slows down or stops the vehicle. | Monitor brake pad thickness and fluid levels. |

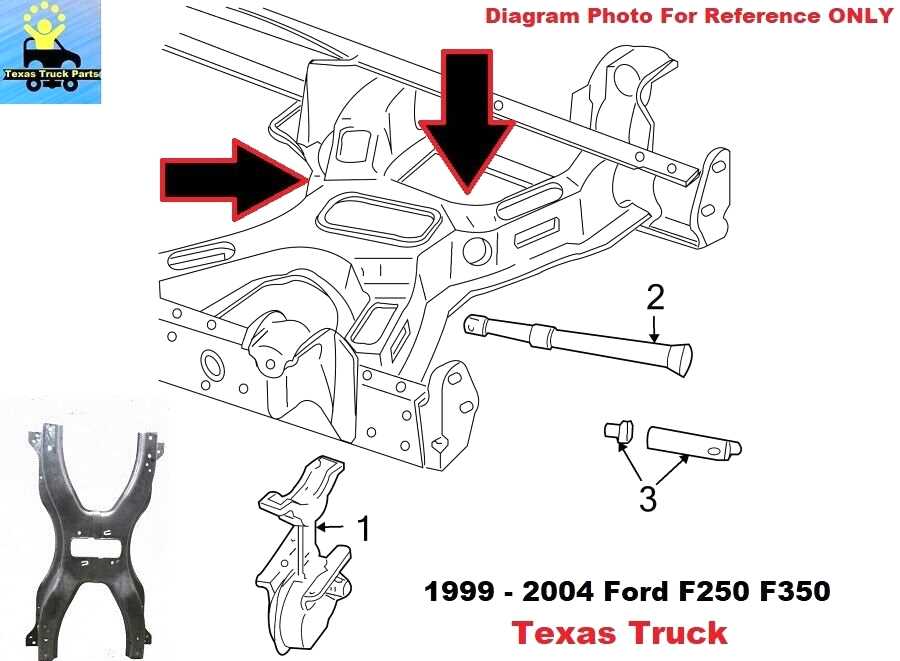

| Frame | The backbone that holds the vehicle together. | Check for rust and structural integrity. |

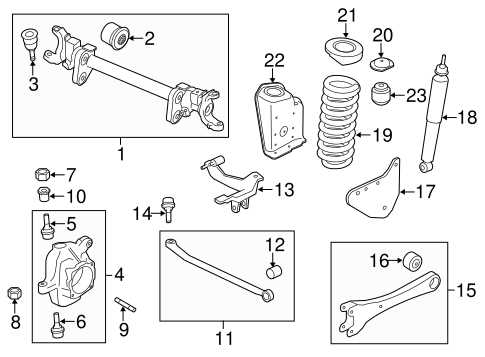

Overview of Front Suspension System

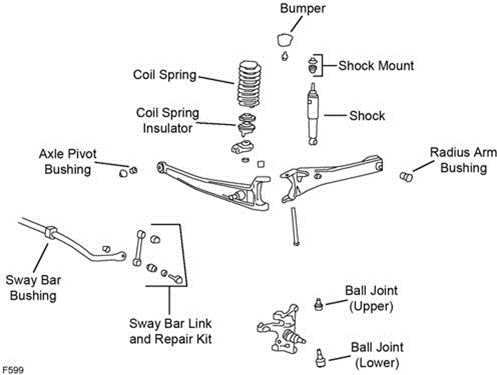

The front suspension system plays a critical role in maintaining vehicle stability and handling. It is designed to absorb shocks from the road, ensuring a smooth ride while also providing support for steering and alignment. This section delves into the essential components and functions of this vital system.

Key components of the front suspension system include:

- Shock Absorbers: These components help to dampen the impact of road irregularities, improving ride quality.

- Control Arms: They connect the chassis to the wheels, allowing for vertical movement while maintaining alignment.

- Struts: Often combined with shock absorbers, struts provide structural support and contribute to the vehicle’s overall stability.

- Springs: These elements support the weight of the vehicle and absorb bumps and dips in the road surface.

- Ball Joints: They allow for smooth movement between the control arms and the wheel hub, facilitating steering and suspension travel.

Understanding the configuration and interaction of these components is essential for diagnosing issues and performing maintenance. A well-functioning front suspension system enhances driving comfort and safety, making it a key aspect of vehicle performance.

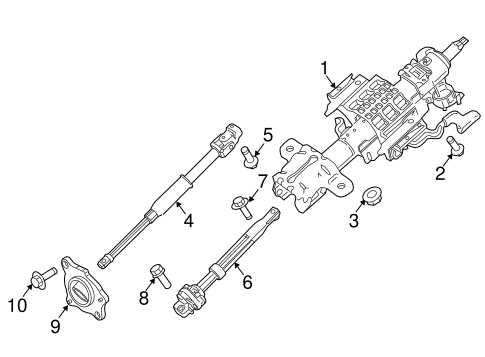

Key Parts in the Steering Mechanism

The steering system is essential for controlling the direction of a vehicle, ensuring safe navigation and maneuverability. It consists of several crucial components that work in unison to provide drivers with precise handling and stability. Understanding these elements can enhance maintenance and repair practices.

| Component | Description |

|---|---|

| Steering Wheel | The primary interface between the driver and the steering system, allowing for directional input. |

| Steering Column | A shaft that connects the steering wheel to the steering mechanism, transmitting driver input. |

| Gearbox | Converts the rotational movement from the steering wheel into linear movement to turn the wheels. |

| Linkage | A series of rods and joints that connect the gearbox to the wheel assembly, facilitating movement. |

| Ball Joints | Articulating connections that allow for flexibility and movement in the steering system. |

Brake System Elements Explained

The brake system is a crucial component of any vehicle, ensuring safety and control during operation. Understanding the various elements involved can help in maintaining and troubleshooting issues effectively.

Key components of the braking mechanism include:

- Brake Pads: These friction materials press against the rotor to create the necessary stopping force.

- Brake Rotors: These circular discs rotate with the wheels and work in conjunction with brake pads to slow down the vehicle.

- Calipers: These devices house the brake pads and apply pressure to them against the rotors when the brake pedal is engaged.

- Brake Lines: These tubes transport hydraulic fluid from the master cylinder to the calipers, enabling effective braking action.

- Master Cylinder: This component converts the force applied to the brake pedal into hydraulic pressure, activating the calipers.

- Brake Fluid: This specialized fluid transmits force within the brake lines and helps maintain the braking system’s effectiveness.

Each of these elements plays a vital role in the overall functionality of the braking system, and understanding them can aid in identifying potential issues and ensuring proper maintenance.

Importance of Control Arms

Control arms play a crucial role in the suspension system of vehicles, connecting the chassis to the wheels. These components are essential for maintaining stability, handling, and overall performance. Their design and functionality directly impact the driving experience and safety of the vehicle.

Key Functions of Control Arms

- Stability: Control arms help keep the wheels aligned with the body of the vehicle, providing stability during various driving conditions.

- Handling: They facilitate smooth and responsive handling by allowing the wheels to move up and down while maintaining proper alignment with the road.

- Impact Absorption: Control arms assist in absorbing shocks from bumps and uneven surfaces, contributing to a comfortable ride.

Signs of Wear and Damage

It’s essential to monitor the condition of control arms as wear can lead to several issues:

- Uneven Tire Wear: Damaged control arms can cause misalignment, leading to irregular tire wear.

- Steering Issues: A compromised control arm may result in poor steering response or drifting.

- Increased Noise: Unusual noises while driving can indicate worn control arms or associated components.

Regular inspection and maintenance of control arms are vital to ensure the safety and performance of any vehicle.

Functions of Ball Joints

Ball joints play a crucial role in the overall performance and safety of a vehicle’s suspension system. They serve as pivot points, allowing for smooth movement and flexibility between various components. This interaction is essential for maintaining proper alignment and handling, ensuring that the vehicle can navigate various terrains effectively.

These joints connect the steering knuckles to the control arms, enabling the wheels to move up and down while also allowing for side-to-side motion during steering. Their design accommodates the dynamic forces exerted on the suspension, absorbing shocks and vibrations from the road. This functionality contributes significantly to ride comfort and stability.

Furthermore, ball joints are engineered to withstand wear and tear, maintaining their integrity over time. Regular inspection and maintenance of these components are vital to prevent premature failure, which can lead to serious safety issues. By ensuring that ball joints are in good condition, drivers can enhance their vehicle’s performance and longevity.

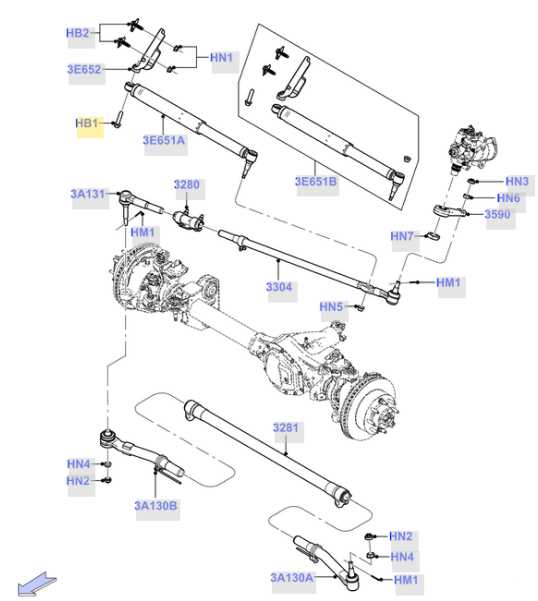

Examining Tie Rod Assemblies

When it comes to steering systems, tie rod assemblies play a crucial role in ensuring proper alignment and control of the vehicle. These components connect the steering mechanism to the wheels, allowing for precise directional changes. Understanding their construction and function is essential for maintaining optimal performance and safety on the road.

Typically, tie rod assemblies consist of inner and outer tie rods, which are connected by an adjustable sleeve. This design allows for fine-tuning of the wheel alignment, which is vital for even tire wear and stable handling. Regular inspection of these components can help identify signs of wear or damage, such as looseness or abnormal play, which may indicate the need for replacement.

Proper installation and adjustment of tie rod assemblies are vital for the overall performance of the steering system. If these components are misaligned, it can lead to a host of issues, including steering difficulties and uneven tire wear. Therefore, ensuring that tie rod assemblies are in good condition and correctly adjusted is essential for vehicle safety and longevity.

Role of the Sway Bar

The sway bar, also known as an anti-roll bar, plays a crucial role in enhancing vehicle stability during cornering. It helps minimize body roll, allowing for a smoother and safer driving experience, particularly when navigating sharp turns or uneven terrain.

Here are some key functions of the sway bar:

- Improves Handling: By reducing body roll, the sway bar enhances the vehicle’s handling characteristics, providing a more responsive and controlled ride.

- Increases Safety: A well-functioning sway bar can prevent excessive leaning during turns, reducing the risk of losing control.

- Balances Weight Distribution: It helps distribute weight evenly across the axles, ensuring that all wheels maintain optimal contact with the road.

- Enhances Comfort: By minimizing body movement, it contributes to a more comfortable driving experience for passengers.

Overall, the sway bar is an essential component that significantly contributes to vehicle performance and safety, making it an important element in automotive design.

Inspection of Wheel Hubs

The evaluation of wheel hubs is crucial for maintaining optimal vehicle performance and safety. Regular checks can prevent potential issues that may arise from wear and tear, ensuring a smooth driving experience.

Begin by visually inspecting the hubs for any signs of damage, such as cracks or excessive rust. Ensure that there is no play in the hub assembly by grasping the wheel at the 12 and 6 o’clock positions and checking for any movement. This can indicate worn bearings that may require replacement.

Additionally, listen for unusual noises while driving, particularly during turns, as this could signify a problem with the hub assembly. If any abnormalities are detected, it is advisable to perform a more detailed examination or consult a professional to ensure proper functionality.

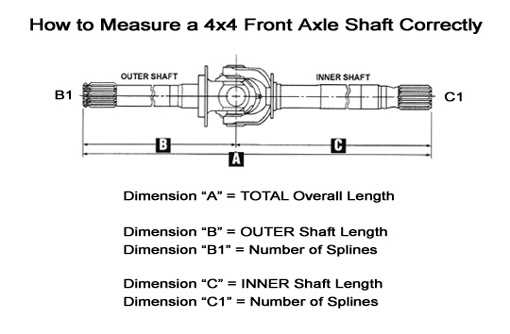

Replacing Front End Parts

When it comes to enhancing the stability and performance of your vehicle, addressing the components at the front is crucial. Over time, wear and tear can affect the functionality of these elements, leading to issues such as uneven tire wear, poor steering response, and compromised safety. This section will guide you through the essential steps to replace these critical components effectively.

| Component | Replacement Steps |

|---|---|

| Steering Linkage | 1. Raise the vehicle and secure it on jack stands. 2. Remove the old linkage by disconnecting it from the steering gear and the spindle. 3. Install the new linkage and ensure proper alignment. |

| Suspension Arms | 1. Lift the vehicle and take off the wheels. 2. Detach the old arms by unscrewing the bolts. 3. Attach the new arms and torque the bolts to the manufacturer’s specifications. |

| Ball Joints | 1. Secure the vehicle and remove the wheel. 2. Take out the old ball joint from the control arm. 3. Install the new joint and ensure it is properly seated. |

Common Issues and Solutions

This section addresses frequent problems encountered with the vehicle’s structural components, along with effective remedies to ensure optimal performance and safety.

Understanding these challenges is essential for maintaining the integrity of the vehicle. Here are some typical concerns along with their solutions:

| Issue | Description | Solution |

|---|---|---|

| Steering Play | Excessive movement in the steering wheel can lead to imprecise handling. | Inspect and tighten the tie rod ends and steering linkage; consider replacement if wear is excessive. |

| Vibration | Unwanted vibrations during driving can indicate misalignment or worn components. | Check wheel alignment and balance; replace any damaged or worn parts. |

| Noise While Turning | Unusual sounds when turning the steering wheel can suggest issues with the suspension. | Examine the suspension components for wear; lubricate or replace as necessary. |

| Uneven Tire Wear | Tires wearing unevenly can be a sign of alignment issues or suspension problems. | Regularly check and adjust the alignment; inspect suspension for any damage. |