This section provides a comprehensive exploration of essential elements for agricultural machinery. Understanding the various components is crucial for effective maintenance and repair. Each part plays a significant role in ensuring optimal performance and longevity of the equipment.

By delving into the intricate assembly of these elements, users can gain insights into their functionalities and interconnections. Detailed illustrations facilitate a clearer understanding of how each component interacts within the larger system, promoting efficient troubleshooting and repairs.

Whether you are a seasoned operator or a newcomer to the field, familiarizing yourself with the various components will empower you to manage your machinery effectively. This knowledge is invaluable for maintaining productivity and ensuring the smooth operation of your equipment.

Overview of Farmall 140 Parts

The machinery in question boasts a variety of components that play a crucial role in its functionality. Each element is designed to enhance performance and efficiency, contributing to the overall operation of the equipment. Understanding these components is essential for effective maintenance and repair, ensuring longevity and optimal performance.

Key Components

Among the significant elements are the engine assembly, transmission, and hydraulic system. The engine serves as the heart of the machinery, providing the necessary power for various tasks. The transmission system facilitates smooth gear shifting, allowing for better control and adaptability to different working conditions. Meanwhile, the hydraulic system plays a vital role in operating attachments, enhancing the versatility of the equipment.

Maintenance Considerations

Regular upkeep of these components is paramount. Routine inspections and timely replacements of worn-out elements can prevent unexpected breakdowns. Utilizing quality replacements ensures that the machinery continues to function efficiently and effectively, maximizing productivity and minimizing downtime.

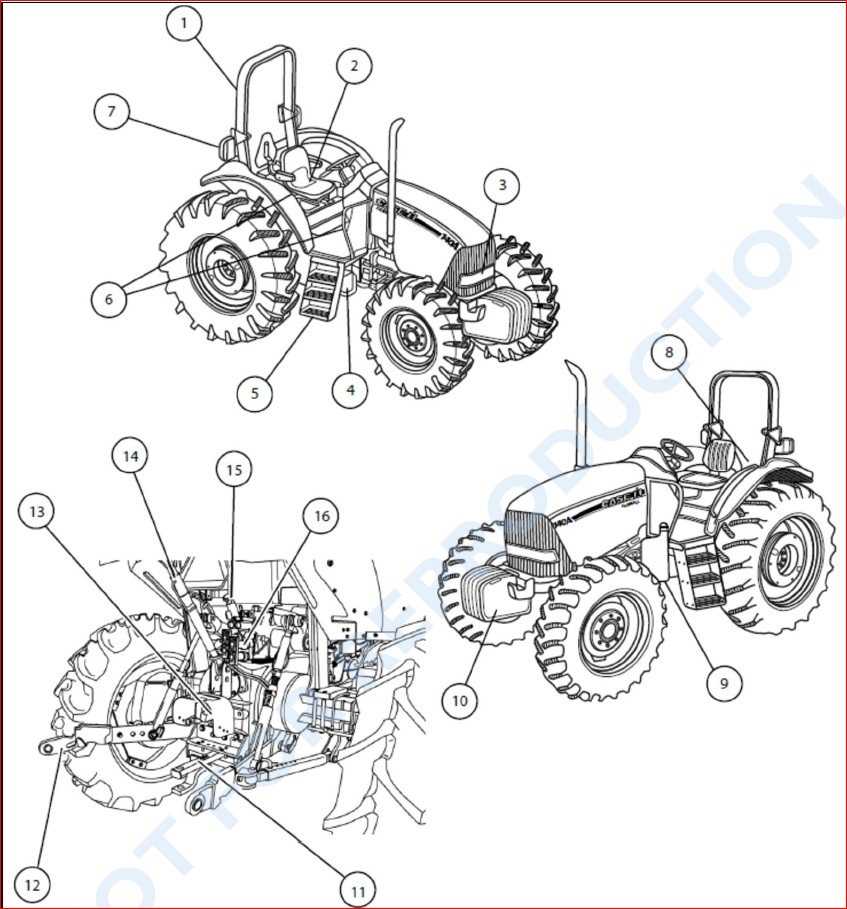

Essential Components of the Tractor

Understanding the vital elements of a tractor is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, contributing to the overall efficiency of agricultural tasks.

Engine: The heart of the machine, the engine, provides the necessary power to perform various functions. It converts fuel into mechanical energy, driving the entire system.

Transmission: This mechanism transmits power from the engine to the wheels. It allows the operator to select different speeds and torque levels, facilitating various tasks from plowing to hauling.

Chassis: The chassis serves as the frame, providing structural support and housing critical systems such as the drivetrain and suspension. It is essential for maintaining stability and durability during operation.

Hydraulic System: This system controls various attachments and implements, allowing for adjustments in movement and positioning. It enhances the tractor’s versatility and efficiency in handling different tasks.

Electrical System: Responsible for powering lights, ignition, and other electronic components, the electrical system ensures the tractor operates smoothly and efficiently. Proper maintenance is essential to avoid failures.

Cooling System: To prevent overheating, the cooling system regulates the engine’s temperature. It plays a critical role in maintaining performance and extending the life of the engine.

Each of these components contributes to the tractor’s functionality, making it an indispensable tool in modern agriculture.

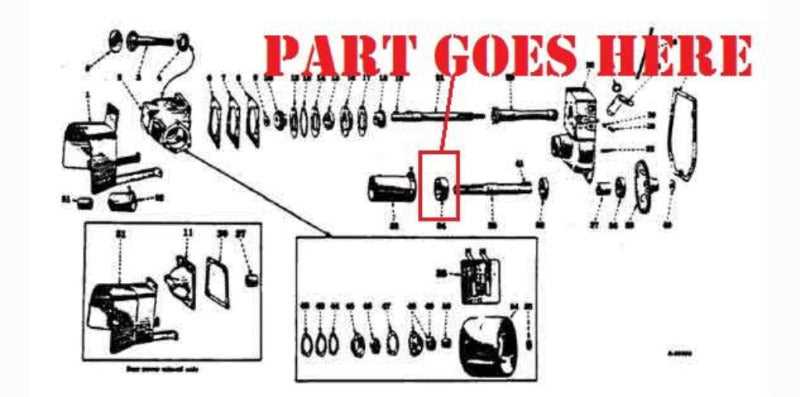

Understanding the Parts Diagram

Grasping the components layout is essential for effective maintenance and repair of machinery. A visual representation serves as a valuable tool, providing insight into the various elements and their interconnections. This overview aids in identifying parts, facilitating troubleshooting, and enhancing overall comprehension of the equipment’s structure.

By examining the schematic representation, users can better appreciate how different elements work together. Each section typically highlights specific features, allowing for a clear understanding of functionality. Recognizing these relationships not only streamlines the repair process but also empowers operators to perform routine checks more confidently.

Furthermore, familiarity with this visual guide assists in locating replacement components, ensuring compatibility and efficiency during upgrades or repairs. Overall, utilizing such representations is a fundamental practice for anyone involved in the upkeep of agricultural machinery.

How to Read the Diagram

Understanding the visual representation of components can significantly enhance your ability to identify and manage machinery elements. This guide will help you interpret the schematic effectively, ensuring that you can navigate through the various segments and locate the necessary items with ease.

When approaching the illustration, consider the following key points:

- Symbols: Familiarize yourself with the various icons and their meanings. Each symbol represents a specific component or function within the system.

- Labels: Pay attention to the annotations that accompany the visuals. These notes provide crucial information regarding part numbers, descriptions, and placement.

- Connections: Observe how elements are linked. Arrows or lines often indicate the flow of operation or how different parts interact with one another.

By breaking down the representation into these fundamental aspects, you can gain a clearer understanding of the mechanical structure and improve your maintenance and repair skills.

Additionally, practice regularly by reviewing different schematics to become more proficient. As you gain experience, recognizing patterns and common features will become second nature, allowing for quicker assessments and decisions.

Common Issues with Parts

When maintaining machinery, several challenges often arise concerning components. Understanding these issues can help enhance efficiency and longevity, preventing potential breakdowns and ensuring smooth operation. This section highlights frequent problems encountered with various elements, offering insights into their management and solutions.

Wear and Tear

Durability is crucial for any equipment, yet many components suffer from significant wear over time. Factors such as exposure to harsh conditions, improper maintenance, and extended usage can lead to degradation. Regular inspections and timely replacements are essential to avoid operational disruptions.

Compatibility Issues

Another common concern involves fitting discrepancies between different models. Not all components are interchangeable, and using incompatible items can result in performance issues. It’s vital to consult specifications and ensure that replacements match the original equipment standards to maintain optimal functionality.

Identifying Replacement Parts Easily

Finding suitable components for your machinery can be a straightforward process when you know where to look and what to consider. This section will guide you through effective strategies for locating the necessary items to keep your equipment functioning optimally.

Understanding Component Types

Familiarizing yourself with the various categories of elements will streamline your search. Key classifications include:

- Mechanical Elements: These include gears, shafts, and other moving parts.

- Electrical Components: Such as wiring, connectors, and sensors.

- Hydraulic and Pneumatic Parts: Including cylinders, hoses, and fittings.

Utilizing Resources for Effective Searching

To enhance your identification process, consider the following resources:

- Online Retailers: Websites dedicated to machinery often provide detailed catalogs.

- Manufacturer’s Manuals: These documents typically contain invaluable information regarding specifications.

- Community Forums: Engaging with fellow users can yield insights and recommendations for reliable sources.

Where to Find Farmall 140 Parts

Locating components for your vintage agricultural equipment can be a daunting task. However, several reliable resources can assist in your search for essential items. Whether you are looking for specific replacement elements or general maintenance supplies, exploring various channels can lead to successful procurement.

Online Marketplaces

Many individuals turn to digital platforms to find the necessary components for their machinery. Websites dedicated to agriculture equipment, as well as general marketplaces, often list various items for sale. Here are some popular online resources:

| Website | Description |

|---|---|

| eBay | A global auction site where you can find new and used components from various sellers. |

| Agricultural Supply Stores | Many stores offer online shopping and specialize in farming equipment supplies. |

| Facebook Marketplace | A social media platform where local sellers list items, allowing for easy communication. |

Local Dealerships and Salvage Yards

In addition to online options, local resources can provide valuable assistance. Visiting dealerships that specialize in agricultural machinery can yield important findings. Salvage yards may also have a variety of components salvaged from older models, providing another avenue for discovery.

Best Suppliers for Tractor Components

When it comes to sourcing high-quality components for agricultural machinery, finding reliable vendors is crucial. The right suppliers not only provide essential items but also ensure durability and efficiency, which are vital for optimal performance in the field. This section will explore some of the top suppliers that cater to the needs of machinery enthusiasts and professionals alike.

Top Recommended Suppliers

- Tractor Supply Co. – Known for a vast selection of farming tools and machinery accessories, Tractor Supply Co. offers both online and in-store shopping options.

- Agri Supply – This supplier features an extensive inventory that includes components for various agricultural machines, making it a go-to choice for many farmers.

- Messicks – With a reputation for exceptional customer service, Messicks provides a wide array of machinery parts and equipment.

Online Marketplaces

- eBay – A platform where users can find both new and used components, often at competitive prices.

- Amazonsupply – A division of Amazon focused on supplying agricultural tools and equipment with fast shipping options.

- Alibaba – Ideal for bulk purchasing, Alibaba connects buyers with manufacturers from around the world, ensuring access to a broad range of products.

Each of these suppliers offers unique benefits, from extensive inventories to competitive pricing, making them valuable resources for anyone in need of machinery components.

Maintenance Tips for Farmall 140

Proper upkeep of your agricultural machinery is essential for ensuring optimal performance and longevity. Regular attention to maintenance tasks can help prevent costly repairs and keep your equipment running smoothly. Here are some vital practices to consider.

- Regular Inspections: Frequently examine your machinery for signs of wear and tear. Pay attention to the engine, tires, and other critical components.

- Fluid Levels: Ensure that all fluids, including oil, coolant, and hydraulic fluids, are at appropriate levels. Change them as recommended by the manufacturer.

- Filter Changes: Replace air and fuel filters periodically to maintain engine efficiency. Clogged filters can lead to reduced performance.

- Tire Care: Check tire pressure regularly and inspect for any damage or uneven wear. Properly inflated tires improve handling and fuel efficiency.

- Greasing Points: Lubricate moving parts according to the service manual. This will reduce friction and wear, extending the life of components.

- Battery Maintenance: Clean battery terminals and ensure connections are tight. Regularly check the battery’s charge and replace it as needed.

Implementing these suggestions will contribute to the reliability and efficiency of your agricultural equipment, ensuring it performs effectively during demanding tasks.

Ensuring Longevity of Components

To maintain the functionality and efficiency of machinery, it is crucial to focus on the durability of its individual elements. Implementing preventive measures can significantly extend their lifespan, ensuring reliable performance over time.

Regular maintenance is vital for sustaining optimal working conditions. Adopting a systematic approach can help identify potential issues before they escalate. Below are essential practices to enhance the longevity of equipment components:

| Practice | Description |

|---|---|

| Routine Inspections | Conduct regular checks to identify wear and tear, ensuring early intervention. |

| Proper Lubrication | Maintain appropriate lubrication levels to reduce friction and prevent overheating. |

| Environmental Control | Store equipment in a controlled environment to protect against moisture and extreme temperatures. |

| Quality Replacements | Use high-quality substitutes for any damaged elements to maintain overall integrity. |

By incorporating these strategies, operators can significantly enhance the durability of their machinery, leading to increased efficiency and reduced operational costs.

Repairing Common Farmall 140 Problems

Maintaining agricultural machinery is essential for optimal performance and longevity. Understanding typical issues and their solutions can greatly enhance the operational efficiency of your equipment. This section will discuss common challenges faced by these machines and provide practical repair strategies.

Typical Issues and Their Solutions

- Engine Overheating:

Overheating can be caused by several factors, including low coolant levels, a faulty thermostat, or a clogged radiator. Regularly check and maintain coolant levels, inspect the thermostat for proper functioning, and clean the radiator to prevent overheating.

- Starting Difficulties:

If the machine struggles to start, it could be due to a weak battery, poor connections, or fuel issues. Ensure the battery is fully charged, connections are clean and secure, and that the fuel supply is adequate and free of contaminants.

Preventive Maintenance Tips

- Regularly inspect and change the oil to ensure the engine runs smoothly.

- Keep air filters clean and replace them as necessary to improve engine efficiency.

- Check tire pressure frequently to enhance stability and performance in the field.

- Examine belts and hoses for wear and replace them to avoid unexpected breakdowns.

By addressing these common issues promptly and implementing preventive measures, you can extend the lifespan of your agricultural machinery and maintain its reliability.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your agricultural machinery. By following the outlined steps, you can ensure that the equipment operates efficiently and reliably.

-

Gather Necessary Tools:

- Wrenches

- Screwdrivers

- Pliers

- Replacement components

- Grease and lubricants

-

Review the Manual:

Consult the equipment manual to understand the specific requirements and maintenance recommendations.

-

Disconnect Power Supply:

Before starting any repairs, ensure the machinery is completely powered down to avoid accidents.

-

Inspect the Components:

Examine each part for wear and tear, identifying any elements that need replacement or servicing.

-

Replace Damaged Parts:

Carefully remove the faulty components and install new ones, ensuring a proper fit.

-

Reassemble the Machinery:

Put all parts back together following the order specified in the manual, securing all fasteners tightly.

-

Test the Equipment:

Once reassembled, conduct a test run to ensure everything functions correctly and efficiently.

By following this structured approach, you can effectively restore your machinery to optimal working condition.

Modifications and Upgrades Available

When it comes to enhancing the performance and efficiency of agricultural machinery, various modifications and upgrades can be considered. These improvements not only optimize functionality but also extend the lifespan of the equipment, ensuring it remains reliable for years to come. From engine enhancements to ergonomic adjustments, the possibilities are numerous and tailored to meet specific needs.

Performance Enhancements

One popular avenue for improvement involves boosting engine output. Upgrading to high-performance air filters and exhaust systems can lead to increased horsepower and better fuel efficiency. Additionally, recalibrating the engine management system ensures that the machine operates at peak performance, adapting to various operational demands.

Comfort and Usability Features

Another significant aspect of modifications includes enhancing the operator’s experience. Installing improved seating and ergonomic controls can greatly increase comfort during extended use. Furthermore, adding modern features such as GPS navigation and advanced control systems makes operation easier and more intuitive, allowing for precise and efficient farming practices.