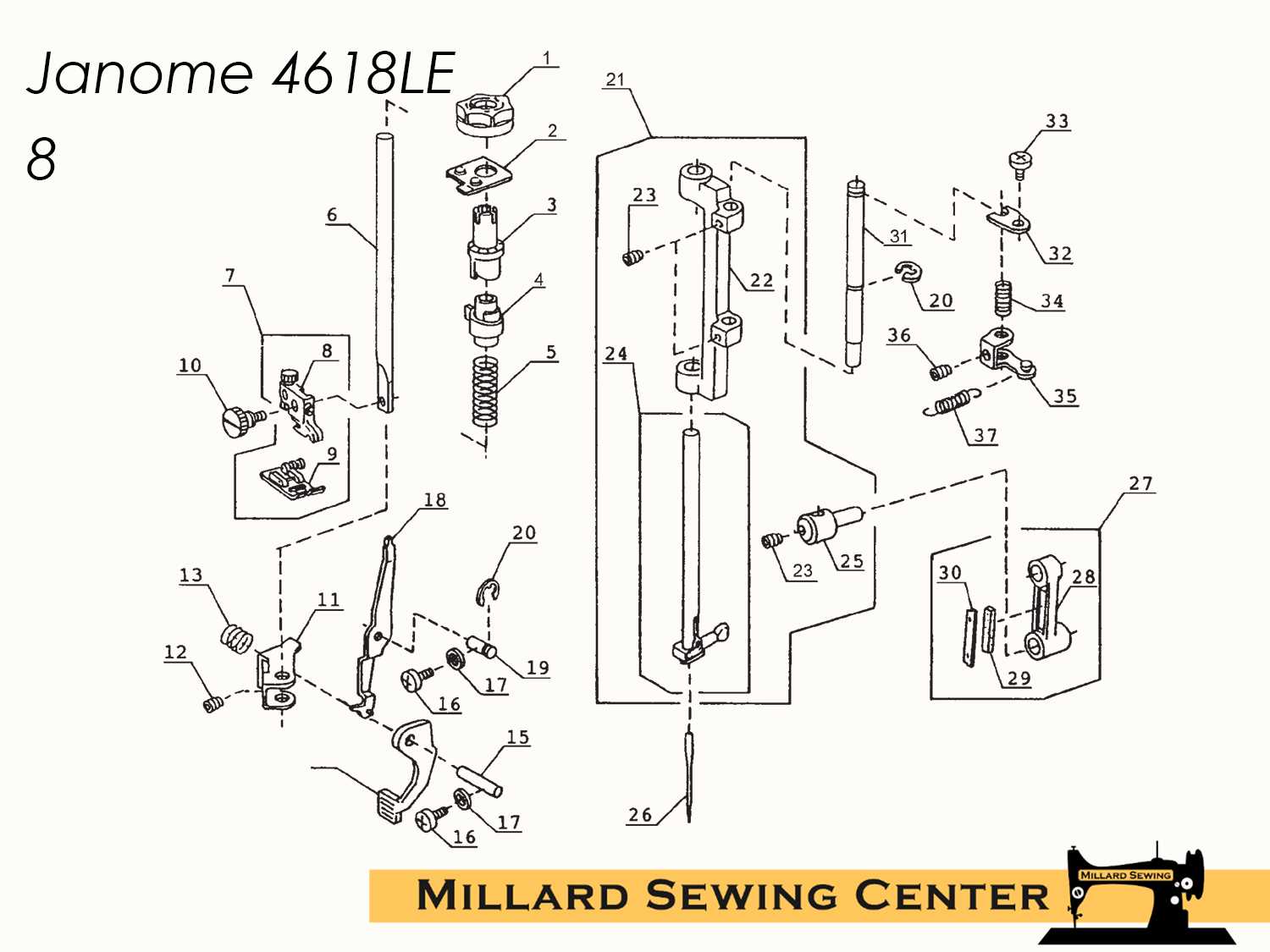

Understanding the intricate relationships between various elements is crucial for effective maintenance and repair. A comprehensive visual representation aids in identifying each component’s function and placement within the overall system. Such resources serve as valuable references for both seasoned professionals and novices alike.

Detailed illustrations not only facilitate the assembly and disassembly processes but also enhance troubleshooting capabilities. By having a clear view of how parts interact, users can more efficiently diagnose issues and implement solutions. Access to these visuals ensures that every aspect of the machinery is considered, promoting longevity and optimal performance.

Moreover, familiarity with these representations fosters confidence when handling machinery. Individuals who can navigate these diagrams are better equipped to make informed decisions during repairs or upgrades. Investing time in understanding these resources ultimately leads to more efficient operations and reduced downtime.

This section focuses on the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these components is crucial for maintenance and optimal operation.

Core Elements

- Frame: The structural foundation that supports the entire assembly.

- Power Source: Provides the necessary energy for operation, ensuring consistent performance.

- Control System: Manages the various functions and settings, allowing for user customization.

- Hydraulic System: Facilitates movement and operation through fluid power, enhancing efficiency.

Supporting Features

- Safety Mechanisms: Integrated systems designed to prevent accidents and ensure user safety.

- Maintenance Points: Designated areas that simplify servicing and upkeep.

- Connection Interfaces: Points of integration for additional accessories and components.

- Monitoring Systems: Tools that provide real-time feedback on performance and functionality.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and assembly. This guide will help you interpret the schematic effectively, ensuring that you can identify and locate each piece with confidence.

Key Elements to Note

- Labels: Each item in the illustration is typically accompanied by a label indicating its name or number.

- Sections: The layout is often divided into sections for clarity, allowing for easier navigation through different assemblies.

- Reference Numbers: Many diagrams use reference numbers that correspond to a list or catalog, providing further details about specifications and compatibility.

Steps for Effective Interpretation

- Begin by familiarizing yourself with the layout and overall structure of the visual guide.

- Identify the major sections and locate the components relevant to your task.

- Cross-reference the labels and numbers with the accompanying list for detailed information.

- Take note of any special symbols or notations that may indicate important assembly instructions or cautions.

Common Issues and Solutions

This section addresses frequent challenges encountered with machinery and provides effective strategies for resolution. Understanding these issues is crucial for maintaining optimal functionality and extending the lifespan of equipment.

Below are some typical problems and their corresponding solutions:

| Issue | Solution |

|---|---|

| Inconsistent performance | Check for blockages and ensure all components are properly lubricated. |

| Unusual noises during operation | Inspect moving parts for wear and replace if necessary. |

| Overheating | Ensure adequate ventilation and verify that cooling systems are functioning properly. |

| Electrical issues | Examine wiring for damage and secure loose connections. |

| Fluid leaks | Identify the source of the leak and replace faulty seals or gaskets. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any machinery. By implementing systematic care and attention, users can minimize wear and tear, thereby enhancing performance and reliability. Below are some recommended practices to maintain your equipment effectively.

- Regular Cleaning: Keep the machinery clean to prevent dirt buildup. Use a soft cloth and appropriate cleaning agents.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and prevent overheating.

- Inspect Components: Regularly check for any signs of wear or damage. Replace worn components promptly to avoid further issues.

- Follow Usage Guidelines: Adhere to the manufacturer’s recommendations for usage to ensure optimal functioning.

- Store Properly: When not in use, store the machinery in a dry and clean environment to prevent rust and other forms of damage.

By following these guidelines, users can significantly improve the longevity and efficiency of their machinery, ensuring reliable operation for years to come.

Parts Replacement Guidelines

Understanding the procedures for substituting components is crucial for maintaining the efficiency and longevity of equipment. Proper replacement techniques ensure optimal functionality and prevent potential malfunctions. This section outlines essential recommendations to consider when undertaking replacements.

Before starting the substitution process, it is vital to assess the condition of each element. Inspecting for wear or damage allows for informed decisions about which components need to be replaced. Follow these guidelines to ensure a successful replacement:

| Step | Description |

|---|---|

| 1 | Gather the necessary tools and replacement items to ensure a smooth process. |

| 2 | Refer to the manufacturer’s specifications for compatible replacements to maintain efficiency. |

| 3 | Carefully remove the defective component, taking note of its connections and placement. |

| 4 | Install the new element, ensuring all connections are secure and correctly positioned. |

| 5 | Conduct tests to verify the proper function of the newly installed component. |

Adhering to these guidelines will promote effective replacements and enhance overall performance.

Tools Needed for Assembly

When assembling complex equipment, having the right tools is crucial for a smooth and efficient process. Various instruments are necessary to ensure that every component is fitted correctly and functions as intended. Understanding the specific requirements for assembly can greatly enhance the overall experience and outcome.

The following table lists the essential tools required for the assembly process, along with their descriptions and uses:

| Tool | Description | Use |

|---|---|---|

| Screwdriver Set | A collection of various screwdrivers with different sizes and types. | For tightening and loosening screws in different components. |

| Wrench Set | Includes adjustable wrenches and socket wrenches. | Used for gripping and turning nuts and bolts. |

| Pliers | Tools designed for gripping, twisting, and cutting. | Useful for holding small components securely during assembly. |

| Torque Wrench | A specialized wrench that measures the torque applied. | Ensures that bolts and nuts are tightened to the correct specifications. |

| Level | A tool used to check the flatness of surfaces. | Ensures proper alignment of assembled parts. |

Finding Genuine Replacement Parts

Locating authentic components for machinery is essential for maintaining optimal performance and longevity. Utilizing original replacements ensures compatibility and reliability, preventing potential issues that may arise from inferior alternatives. The search for these essential elements can be streamlined by understanding where to look and what to consider during the purchasing process.

Research Authorized Dealers

One of the most effective ways to find genuine components is through authorized dealers. These vendors typically offer products that meet strict quality standards and are backed by warranties. It’s important to verify the dealer’s reputation and read customer reviews to ensure a positive experience.

Utilize Manufacturer Resources

Another valuable approach is to consult the manufacturer’s website. Many companies provide lists of certified retailers, along with detailed information about their offerings. This can be an excellent resource for identifying specific requirements and ensuring that any replacement is a perfect match for your machinery.

Assembly Process Explained

The assembly process involves a series of systematic steps aimed at bringing various components together to form a functional unit. Understanding these stages is crucial for achieving efficiency and ensuring the final product operates as intended.

Initially, all necessary components must be gathered and inspected for quality assurance. This ensures that each piece meets the required standards and is free from defects. The following steps outline the assembly procedure:

- Preparation: Organize all components and tools required for the assembly.

- Subassembly: Begin by assembling smaller sections or modules that will later integrate into the main unit.

- Main Assembly: Combine the subassemblies into the final structure, ensuring proper alignment and fitting.

- Testing: Once assembled, conduct functionality tests to confirm that the unit operates correctly.

- Final Inspection: Perform a thorough check for any loose parts, ensuring everything is secured properly.

Following these steps will lead to a well-assembled unit, ready for use or distribution. Proper attention to detail during each phase is essential for optimal performance and longevity.

Safety Precautions During Repair

When undertaking maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with mechanical work. Proper preparation and awareness of potential hazards contribute to a safer working environment.

Before beginning any repair, consider the following safety measures:

- Wear Appropriate Protective Gear: Always use safety goggles, gloves, and sturdy footwear to protect against injuries.

- Ensure Proper Ventilation: Work in well-ventilated areas to avoid inhaling harmful fumes or dust.

- Disconnect Power Sources: Before starting repairs, ensure that all power sources are disconnected to prevent accidental activation.

- Use the Right Tools: Utilize tools designed for specific tasks to reduce the risk of accidents and improve efficiency.

- Read Manuals Carefully: Familiarize yourself with the equipment and its components to understand potential risks and appropriate handling methods.

- Maintain a Clean Workspace: Keep your work area organized and free of clutter to minimize trip hazards.

By implementing these precautions, individuals can significantly enhance their safety while working on mechanical systems, ensuring that repairs are completed effectively and without unnecessary risk.

Frequently Asked Questions

This section aims to address common inquiries regarding the various components and their configurations associated with the device in question. Understanding the common concerns can significantly enhance user experience and ensure optimal functionality.

1. What are the essential components of the system?

The primary elements include the main body, various attachments, and control mechanisms that work together to ensure seamless operation.

2. How can I identify specific parts for replacement?

Refer to the official documentation that outlines the components and their respective functions, helping you identify the necessary replacements easily.

3. Where can I find troubleshooting guides?

Comprehensive troubleshooting guides are often available through the manufacturer’s website or authorized service centers, providing detailed solutions to common issues.

4. Is there a warranty on the components?

Most manufacturers offer a warranty on their products, covering defects and malfunctions within a specified period after purchase. Always check the warranty details when acquiring new parts.

5. How can I ensure proper maintenance of the system?

Regular maintenance involves cleaning, inspection, and timely replacement of worn components to prolong the lifespan and efficiency of the equipment.

Resources for Further Information

Accessing additional materials can significantly enhance your understanding and mastery of the subject. Numerous avenues exist for acquiring valuable insights and support related to various components and their functionality.

Online Forums and Communities: Engaging with online platforms where enthusiasts and experts gather can provide practical advice and shared experiences. Participating in discussions can offer unique perspectives and solutions to common challenges.

Manufacturer Websites: Official sites often contain comprehensive resources, including manuals, guides, and FAQs. These materials are tailored to assist users in navigating the intricacies of their equipment effectively.

Instructional Videos: Visual aids can be particularly beneficial. Numerous video tutorials available on platforms such as YouTube can guide users through processes step-by-step, making complex tasks more manageable.

Technical Support Services: Reaching out to customer service or technical support can provide direct assistance from knowledgeable professionals. They can address specific inquiries and offer tailored solutions.

Books and Publications: Various literature sources, including manuals and reference books, can serve as valuable assets for in-depth learning. These materials often compile extensive information and best practices for efficient operation.

Utilizing these resources will empower individuals to deepen their understanding and improve their practical skills effectively.