In modern home appliances, the efficiency of mechanical devices depends largely on how their internal systems are structured. When exploring the internal configuration of such devices, it is essential to understand how each element works in harmony to deliver optimal performance. By breaking down the structure and functionality, we can gain deeper insight into the entire operational process.

One of the key aspects to consider is how these elements are connected and interact with each other. Certain components are responsible for core functionalities, while others contribute to efficiency and user experience. This detailed overview will help clarify the different sections, making it easier to navigate through repairs or maintenance.

Through this guide, we will focus on the essential pieces that form the foundation of the device. From intricate mechanisms to more visible external elements, understanding their layout and purpose will provide a comprehensive perspective on the entire system.

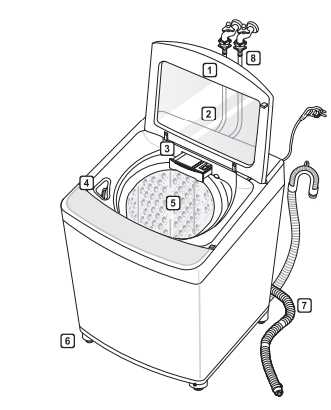

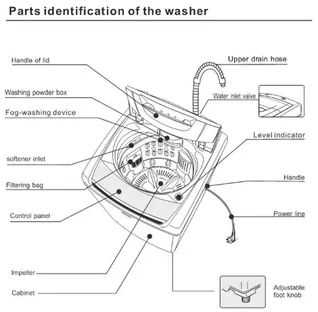

Exploring the Components of a Top Load Washer

Within modern cleaning systems, several key elements work together to ensure optimal performance. These systems feature various internal and external parts that enable the functionality of the unit, making it capable of handling different fabric types and cycles. By understanding how these elements interact, users can gain insight into troubleshooting and improving the efficiency of their device.

Key Mechanical Components

The internal mechanisms are driven by several crucial components. A central motor generates the necessary movement, which is transferred to other elements like the agitator and drum. These elements are responsible for the core operation, allowing fabric to be moved through water and cleaning agents during operation. Additional elements such as pulleys and belts ensure smooth transmission of energy, supporting the overall process.

Water Flow and Control

Managing water levels and flow is essential for any cleaning device. A combination of valves and pumps ensures that the right amount of liquid enters and exits the system at the appropriate times. These components work in coordination with sensors that monitor the

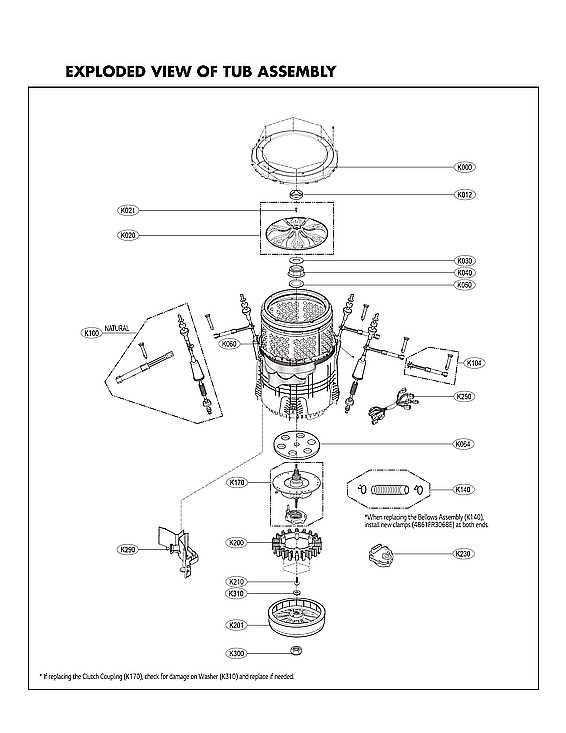

Key Mechanical Elements in a Washing Machine

The core functionality of modern cleaning devices relies on a variety of interconnected components, each designed to ensure effective and efficient operation. These essential elements work together to handle tasks such as water circulation, agitation, and spinning, enabling the entire system to perform its duties with precision.

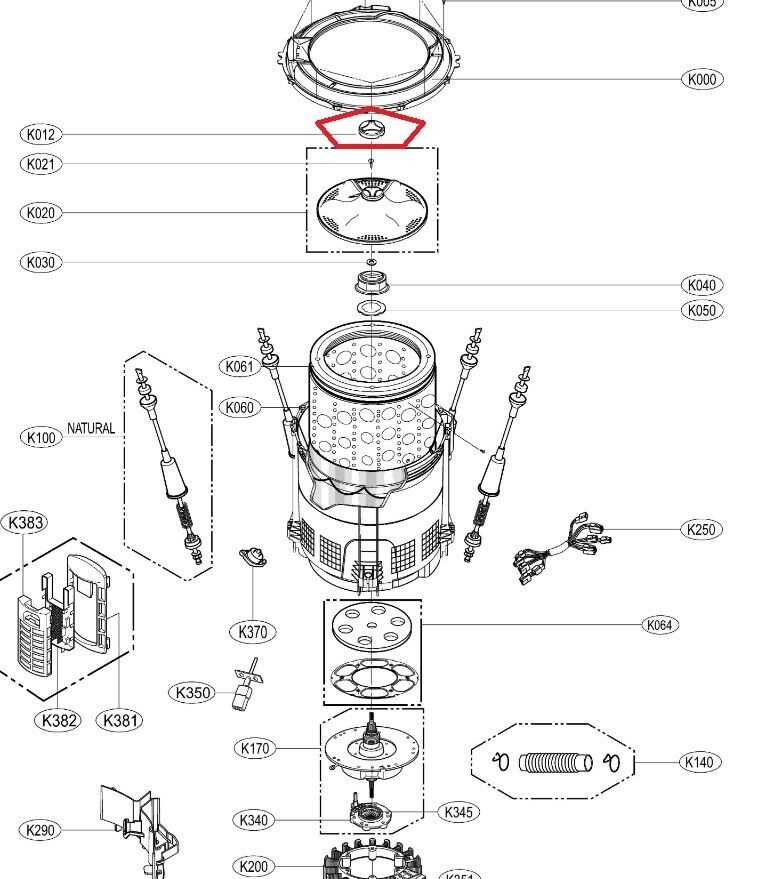

Drum Assembly: The central unit responsible for holding and rotating items during the cleaning cycle. Its construction ensures balanced movement, reducing wear and tear on surrounding parts.

Agitator or Impeller: A crucial part of the cleaning process, this element moves items in a specific pattern to ensure even distribution of cleaning agents and remove dirt effectively.

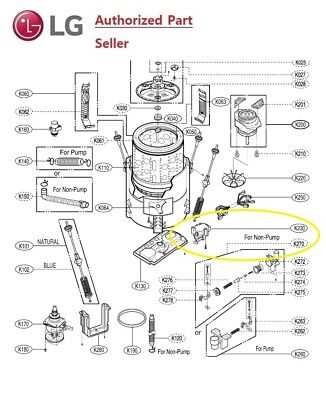

Pump Mechanism: This device manages the flow of water, both into and out

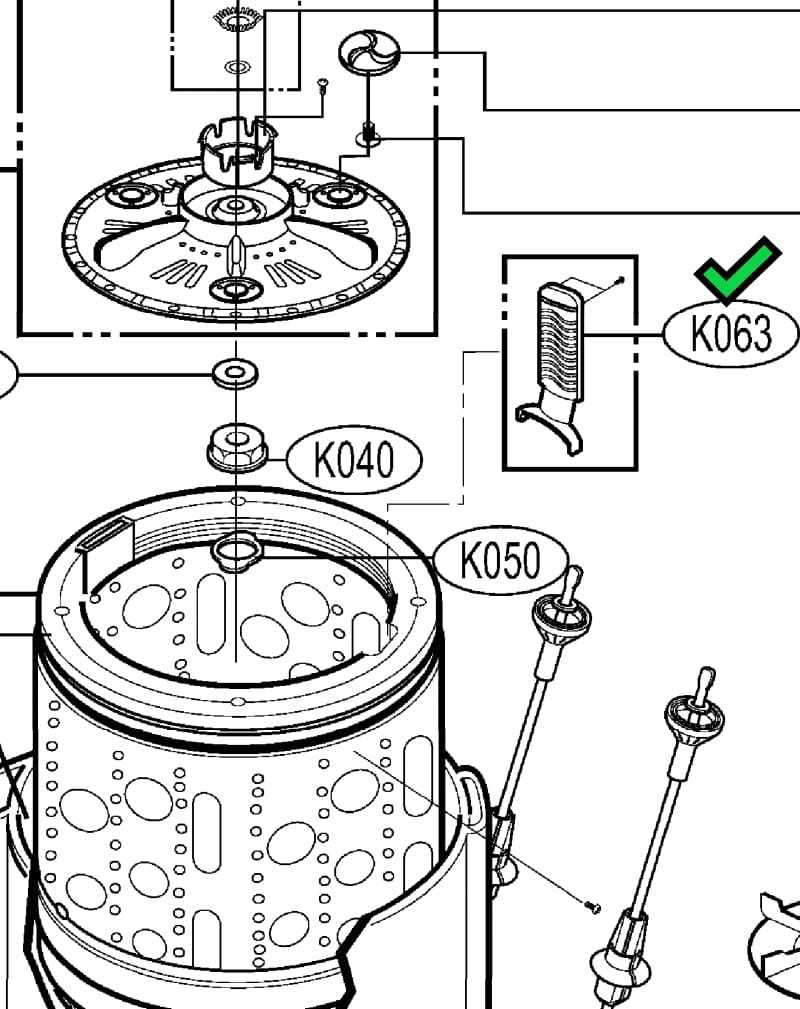

How Agitators and Impellers Function

The efficiency of cleaning in home appliances relies heavily on internal mechanisms designed to move items and ensure thorough distribution of water and detergents. These devices create the necessary motion to enhance the overall process, whether through a rotating action or other types of movement.

Agitators: Traditional Motion Mechanism

An agitator is a central mechanism that employs a vertical spindle to produce rotational movement. This motion is designed to create friction between items, helping to loosen dirt. The consistent action of an agitator enhances the cleansing effect by constantly moving items against each other.

- Rotates back and forth to create scrubbing action.

- Helps mix water with detergent more efficiently.

- Maintains a steady movement to improve results.

Understanding the Role of Drain Pumps

Drain pumps play a crucial role in ensuring that water is efficiently removed during the cleaning process. These components help maintain optimal fluid levels by channeling excess liquid out of the system. Without proper functioning, the overall performance could be compromised, leading to potential issues.

Key Functions of Drain Pumps

- Responsible for extracting liquids after the cycle completes.

- Prevents water from accumulating and causing overflow.

- Facilitates faster drying by ensuring the system remains clear of residual moisture.

Common Issues with Drain Pumps

- Blockages caused by debris or lint, hindering fluid flow.

- Worn-out components that may lead to reduced performance.

- Electrical malfunctions impacting the activation of the pump.

Regular maintenance and timely inspections of these elements ensure t

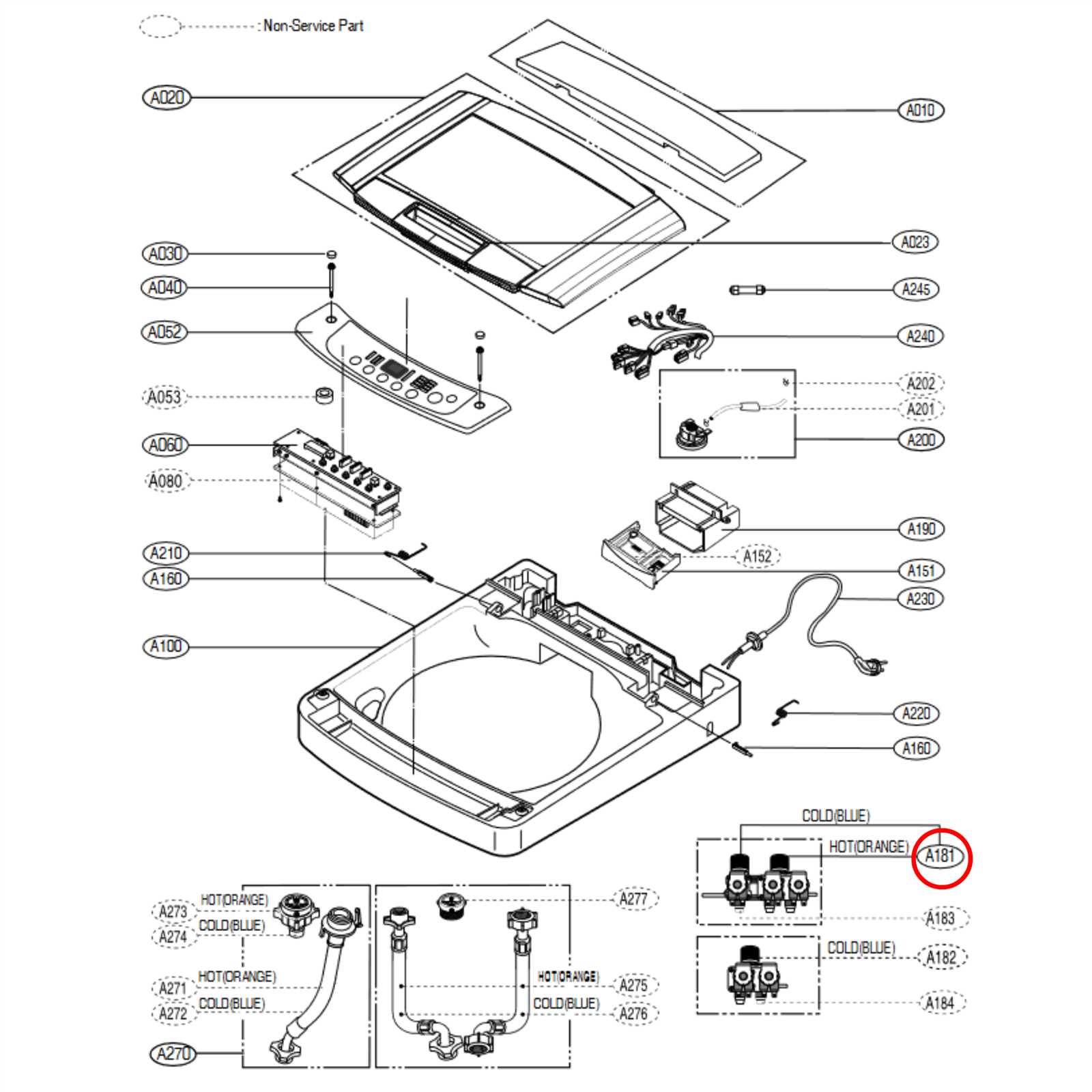

Overview of the Water Inlet Valve System

The water inlet valve plays a crucial role in regulating the flow of liquid into the appliance during specific cycles. This mechanism ensures that the correct volume of water is delivered, contributing to the optimal functioning of various processes. Understanding its components and functionality is key to diagnosing and maintaining the unit’s overall performance.

- Valve Components: The system consists of a solenoid valve that controls the opening and closing to allow water in, based on signals from the control module.

- Water Flow Regulation: The valve is designed to handle varying pressures and ensures that the correct amount is released for different cycles.

- Com

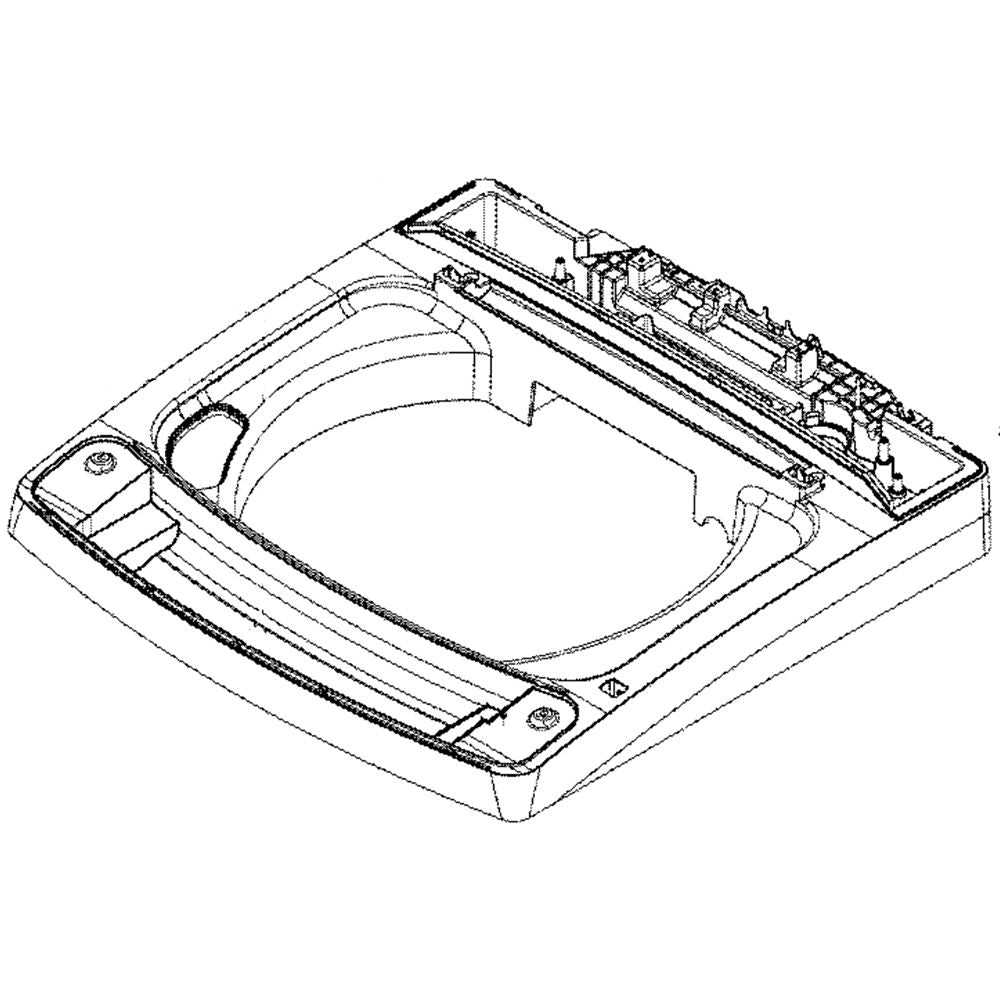

Power and Control Modules Breakdown

This section delves into the essential components that regulate and distribute energy within a home appliance. Understanding these elements is crucial for anyone looking to enhance efficiency or troubleshoot issues effectively.

Primarily, the system consists of several key modules that work in tandem to ensure seamless operation:

- Power Supply Unit: This module converts electrical energy from the outlet into a usable form for other components.

- Main Control Board: Acts as the brain of the appliance, coordinating various functions and responding to user inputs.

- User Interface Module: The interface allows users to select different settings and monitor the operational status.

- Motor Control Unit: Responsible for managing the motor’s speed and direction, this unit plays a vital role in optimizing performance.

Each module features distinct functions, but together they create a harmonious system that enhances the overall user experience. Understanding these components allows for more informed decisions regarding maintenance, upgrades, or repairs.

In conclusion, a thorough comprehension of these critical elements enables users to maximize the potential of their household devices and troubleshoot more effectively when challenges arise.

Detailed Look at Suspension Systems

The suspension system plays a crucial role in ensuring stability and smooth operation of various appliances. It serves to absorb shocks and vibrations, providing a seamless user experience. Understanding its components and functionality can significantly enhance the performance and longevity of the equipment.

Suspension mechanisms are designed to maintain balance and support while in use. They consist of various elements that work together to mitigate the impact of external forces, ensuring that the internal workings remain undisturbed. These components typically include springs, dampers, and linking rods, all of which contribute to the overall effectiveness of the system.

Springs are vital for absorbing shocks and allowing for controlled movement. They enable the structure to flex and adapt to varying conditions, ensuring stability. Meanwhile, dampers play a significant role in controlling oscillations and preventing excessive bouncing. Together, these elements create a cohesive unit that enhances performance.

Understanding the intricacies of suspension systems can lead to better maintenance practices and informed decision-making when addressing potential issues. Proper care and timely intervention can prevent complications, ultimately extending the lifespan of the equipment.

Maintenance Tips for Washer Bearings

Proper upkeep of rotational components is crucial for the longevity and efficiency of your appliance. Bearings play a vital role in minimizing friction and ensuring smooth operation. Regular maintenance can prevent wear and tear, extending the lifespan of these essential elements.

Regular Inspection

Performing routine checks can help you identify any issues early on. Here are some key aspects to focus on:

- Look for unusual noises during operation.

- Check for leaks around the bearing seals.

- Monitor vibrations; excessive movement may indicate a problem.

Cleaning and Lubrication

Keeping bearings clean and properly lubricated is essential. Follow these steps:

- Disconnect power before maintenance.

- Clean the bearing area using a soft cloth to remove debris.

- Apply a suitable lubricant to ensure smooth functionality.

By adhering to these maintenance tips, you can enhance the performance of your appliance and reduce the risk of premature failure.

Identifying Common Motor Parts in Washers

Understanding the various components associated with the driving mechanism of laundry appliances is crucial for effective maintenance and repair. Each element plays a significant role in ensuring the efficient operation of the device, contributing to its overall performance.

In this section, we will explore some of the most prevalent components that facilitate motion and functionality:

- Stator: This stationary component generates a magnetic field that initiates movement in the rotor.

- Rotor: Attached to the motor shaft, it rotates within the stator’s magnetic field, driving the drum’s motion.

- Drive Belt: This flexible band connects the motor to the drum, transferring power to facilitate spinning and agitation.

- Motor Coupling: A connector that links the motor to the transmission, enabling efficient power transfer.

- Control Board: The electronic component that manages motor functions and adjusts speeds based on the selected cycle.

Familiarizing yourself with these essential components will aid in troubleshooting and enhance the lifespan of the appliance. Regular checks and timely replacements can prevent unexpected malfunctions, ensuring smooth operation.

How Pressure Switches Control Water Levels

In various appliances designed for fabric care, regulating fluid levels is crucial for optimal performance. This regulation is primarily achieved through the use of specific sensors that detect the pressure of the liquid within the system. By monitoring these levels, the sensors communicate with the control unit, ensuring that the correct amount of liquid is utilized during each cycle.

Mechanism of Operation

The functionality of these sensors can be understood through a few key steps:

- When the container begins to fill with fluid, the pressure sensor detects the increasing pressure created by the rising liquid.

- As the pressure reaches a predetermined threshold, the sensor sends a signal to the control unit to stop the flow of liquid.

- If the liquid level drops, the pressure decreases, prompting the sensor to notify the control unit to resume filling.

Importance of Accurate Measurement

Ensuring precise liquid levels is vital for several reasons:

- Efficiency: Maintaining the correct fluid volume prevents wastage and enhances the overall effectiveness of the cycle.

- Safety: Overfilling can lead to leaks or malfunctions, posing risks to both the appliance and the surrounding environment.

- Longevity: Proper water management contributes to the durability of internal components, reducing wear and tear over time.

The Importance of the Lid Lock Mechanism

The locking system of the cover plays a crucial role in the functionality and safety of home appliances. This mechanism ensures that the lid remains securely shut during operation, preventing any accidental openings that could lead to spills or injuries. A reliable locking system enhances user confidence while allowing the device to perform its intended functions without interruptions.

Enhancing Safety Features

One of the primary purposes of the cover locking mechanism is to enhance safety during operation. By keeping the lid firmly closed, it reduces the risk of accidents, such as exposure to moving components or hazardous substances. This feature is especially vital when dealing with high-speed cycles, where the potential for injury is greater. Users can trust that the appliance will not operate if the lid is not properly secured, providing an additional layer of protection.

Ensuring Efficient Performance

In addition to safety, the lid lock mechanism contributes to the overall efficiency of the appliance. A secure cover allows for optimal performance by maintaining the correct pressure and water levels inside the drum. When the lid is locked, the device can execute its functions seamlessly, ensuring effective operation and prolonging the lifespan of its components. Regular maintenance of this mechanism is essential to prevent malfunctions that could disrupt functionality.

Replacing and Repairing Drive Belts

Maintaining the functionality of your appliance is essential for its longevity and performance. One critical component that often requires attention is the drive belt. Over time, these belts can wear out or become damaged, leading to operational issues. Addressing these problems promptly can ensure the smooth operation of the equipment.

Identifying the Need for Replacement is the first step in this process. If you notice unusual noises or a decline in performance, it may indicate that the drive belt is no longer functioning correctly. Inspect the belt for signs of wear, such as cracks or fraying, which can compromise its effectiveness.

To replace the drive belt, begin by disconnecting the power supply to ensure safety. Carefully remove any necessary panels to access the belt. Take note of how the belt is routed around the pulleys before removing it, as this will be helpful when installing the new one. Choose a replacement belt that matches the specifications of your model.

When installing the new belt, ensure proper alignment with the pulleys. After installation, manually rotate the pulleys to check for smooth movement and ensure that the belt is seated correctly. Finally, reassemble any removed components and restore power to the unit. Monitoring the performance after replacement is crucial to confirm that the issue has been resolved.

Regularly inspecting and replacing worn drive belts can significantly enhance the overall efficiency and reliability of your appliance, helping to avoid costly repairs in the future.