In the realm of outdoor equipment maintenance, having a clear overview of the individual elements is crucial. This section aims to illuminate the intricate structure of various machinery, providing insights into their organization and functionality. By grasping these layouts, users can better comprehend how each component interacts within the larger system.

Detailed illustrations serve as valuable resources for both enthusiasts and professionals alike. They allow for an enhanced understanding of the mechanisms at play, facilitating more effective troubleshooting and repairs. With this knowledge, individuals can approach their maintenance tasks with confidence and precision.

Moreover, these visuals can significantly streamline the process of acquiring replacement elements, ensuring compatibility and optimal performance. As one navigates the complexities of equipment upkeep, having access to comprehensive layouts is an ultimate advantage, promoting efficiency and effectiveness in all endeavors.

Understanding the layout and components of any equipment is essential for effective maintenance and repairs. Visual representations provide clarity and facilitate a deeper comprehension of how various elements fit together, ensuring smoother operation and troubleshooting.

Here are some key reasons why these visual guides are valuable:

- Enhanced Clarity: Clear illustrations help users quickly identify individual components, making it easier to locate and understand each part’s role.

- Efficient Repairs: With accurate depictions, technicians can swiftly find the necessary elements, reducing downtime during maintenance.

- Improved Learning: For those new to machinery, these visuals serve as educational tools, promoting better understanding and retention of information.

- Accurate Ordering: When replacements are needed, having a clear reference ensures the correct items are ordered, minimizing errors and unnecessary purchases.

- Streamlined Assembly: Step-by-step visuals simplify the reassembly process, reducing the likelihood of mistakes and enhancing overall efficiency.

In summary, these visual representations are crucial for anyone involved in the upkeep or assembly of equipment. They not only aid in immediate tasks but also contribute to a broader understanding of how systems function, ultimately leading to better performance and longevity.

Common Homelite Models Overview

This section provides insight into popular models that are widely recognized for their reliability and performance. Each variant has unique features that cater to different user needs, making them suitable for various tasks.

Popular Variants

- Model A: Known for its lightweight design and ease of use, ideal for homeowners.

- Model B: Offers enhanced power and durability, perfect for more demanding jobs.

- Model C: Features advanced technology, designed for professionals seeking efficiency.

Key Features

- Versatility: Adaptable to a range of applications.

- Maintenance: User-friendly systems for easy upkeep.

- Performance: Engineered for high efficiency and output.

Key Components of Homelite Tools

This section explores the essential elements that contribute to the efficiency and functionality of various power devices. Understanding these components is crucial for both effective usage and maintenance.

| Component | Description |

|---|---|

| Motor | The driving force behind the tool, responsible for generating power. |

| Handle | Provides grip and control, enhancing user comfort and safety. |

| Blade | Critical for cutting, trimming, or shaping materials effectively. |

| Battery | Supplies energy for cordless models, allowing for mobility and convenience. |

| Safety Switch | A vital feature that ensures secure operation, preventing accidental starts. |

Reading Parts Diagrams Effectively

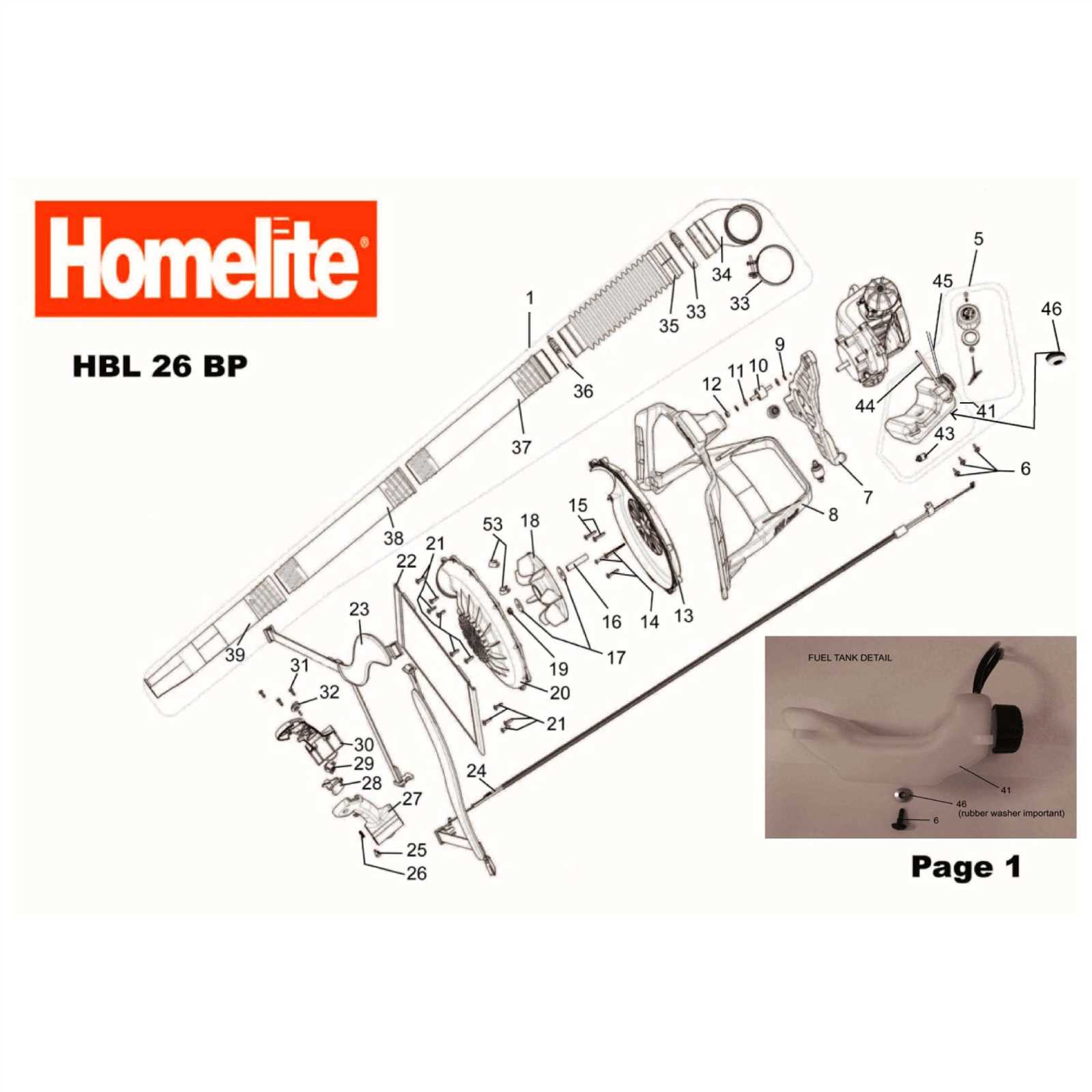

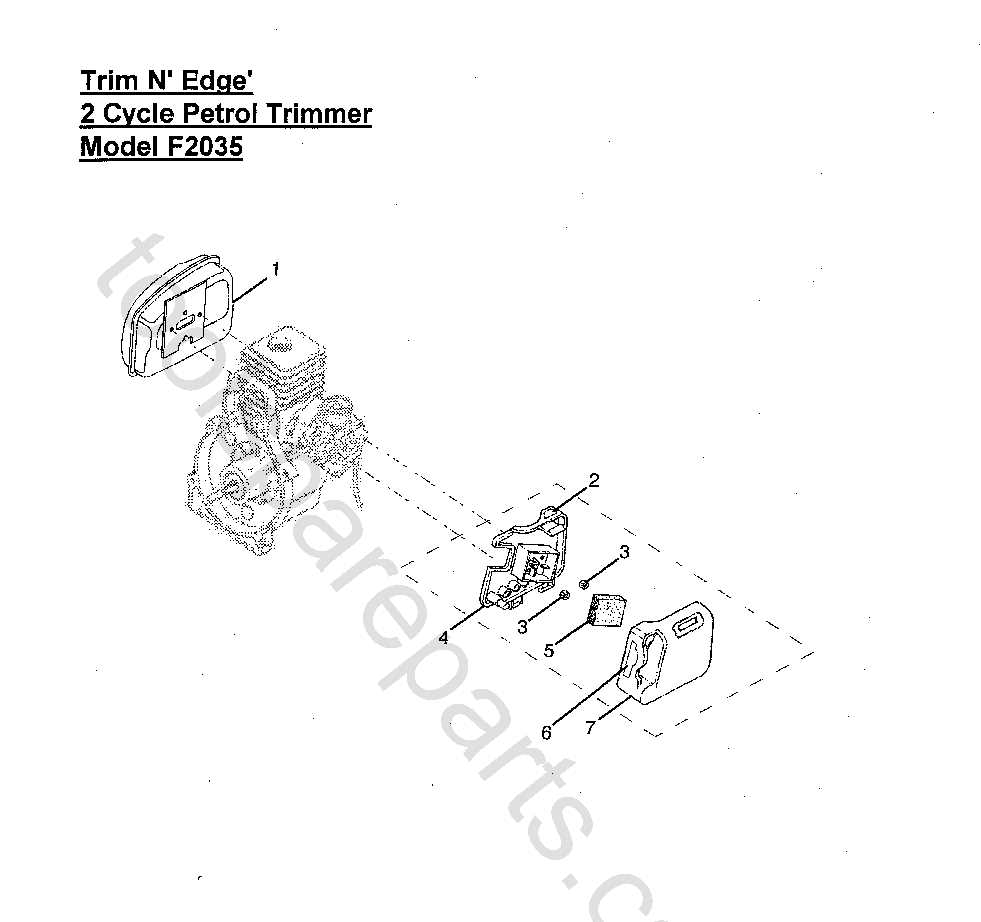

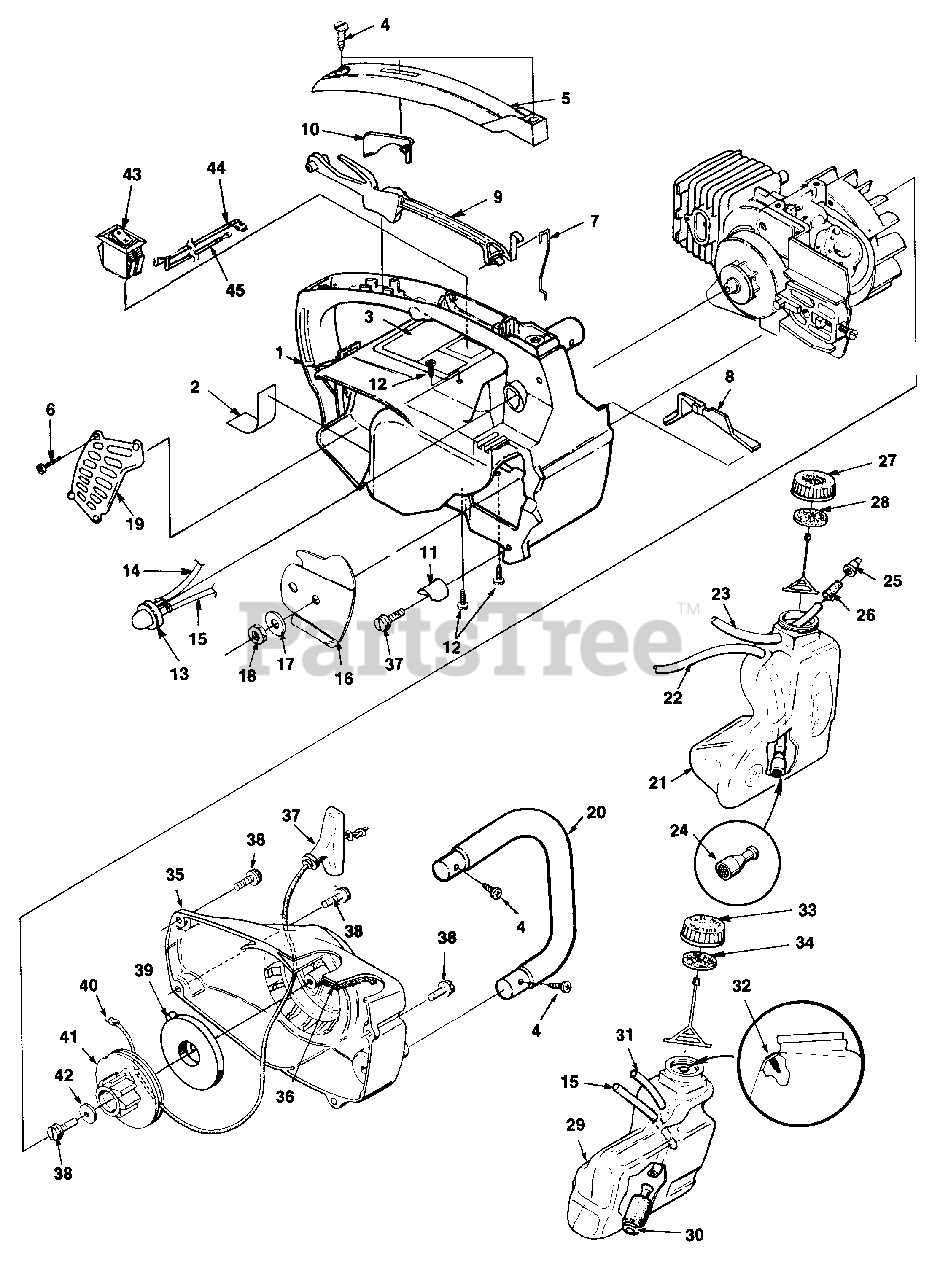

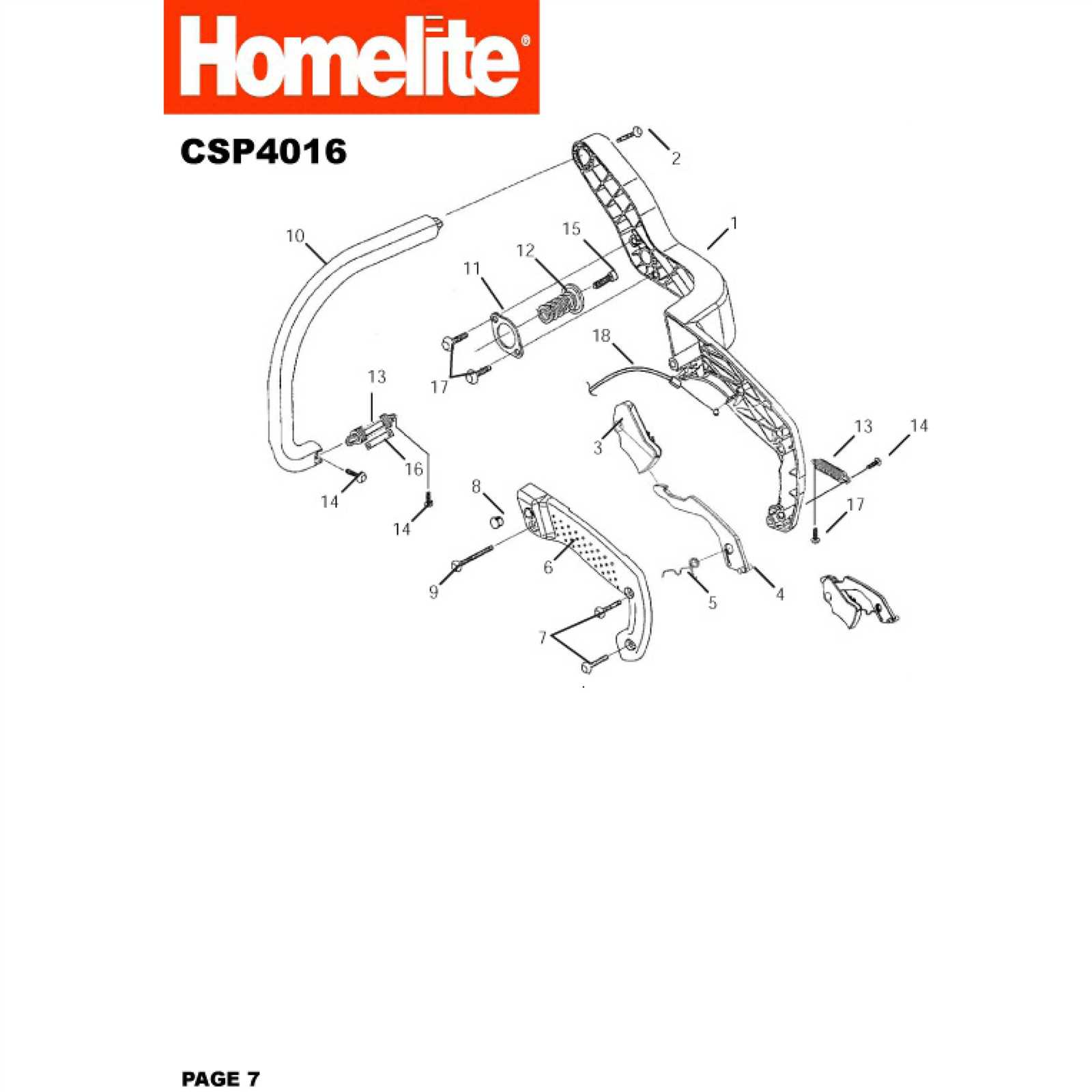

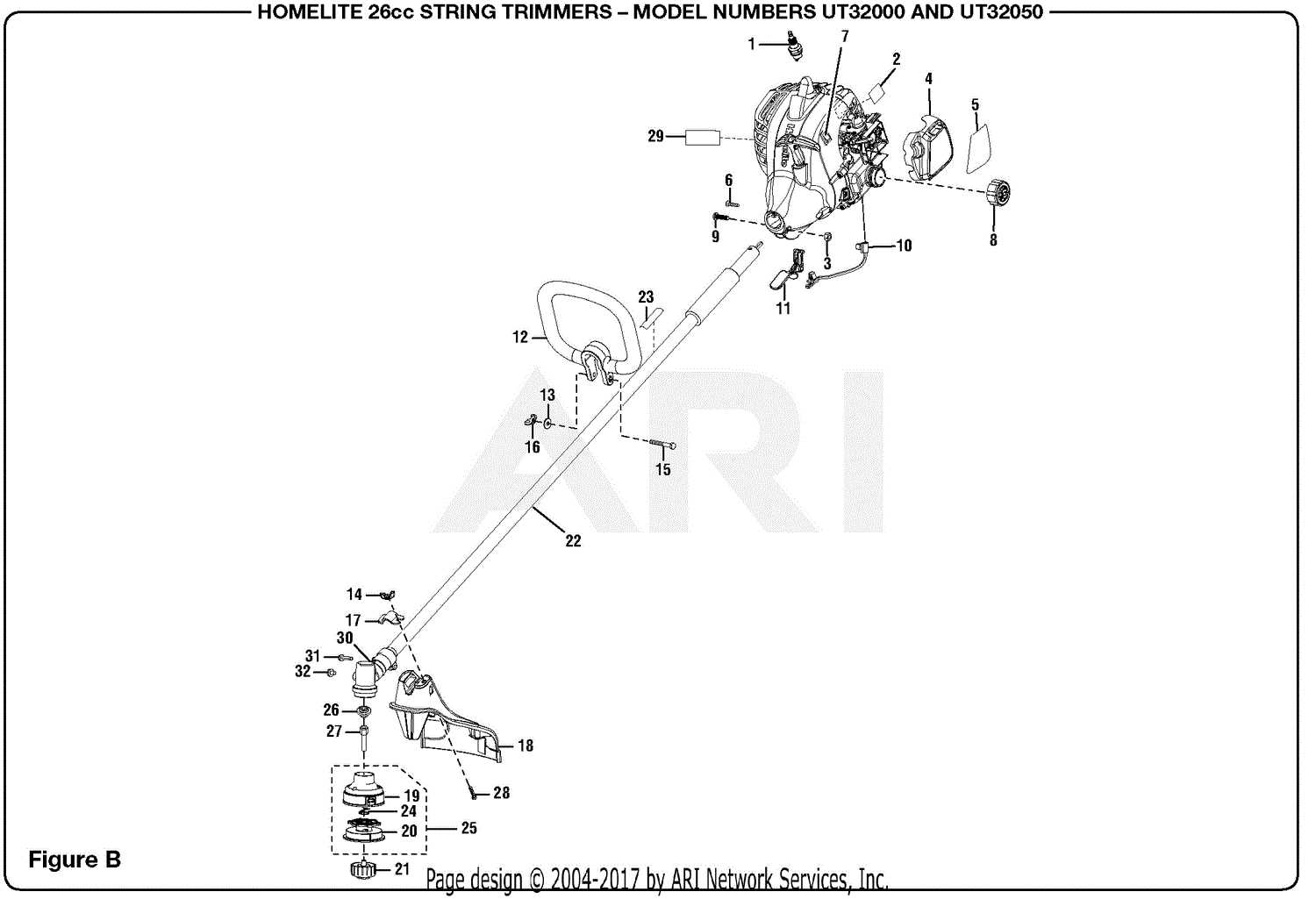

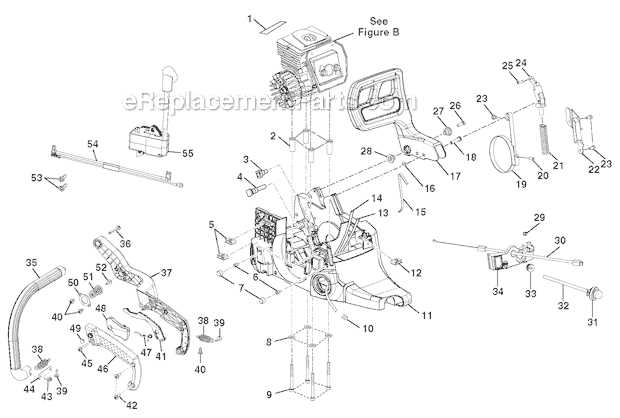

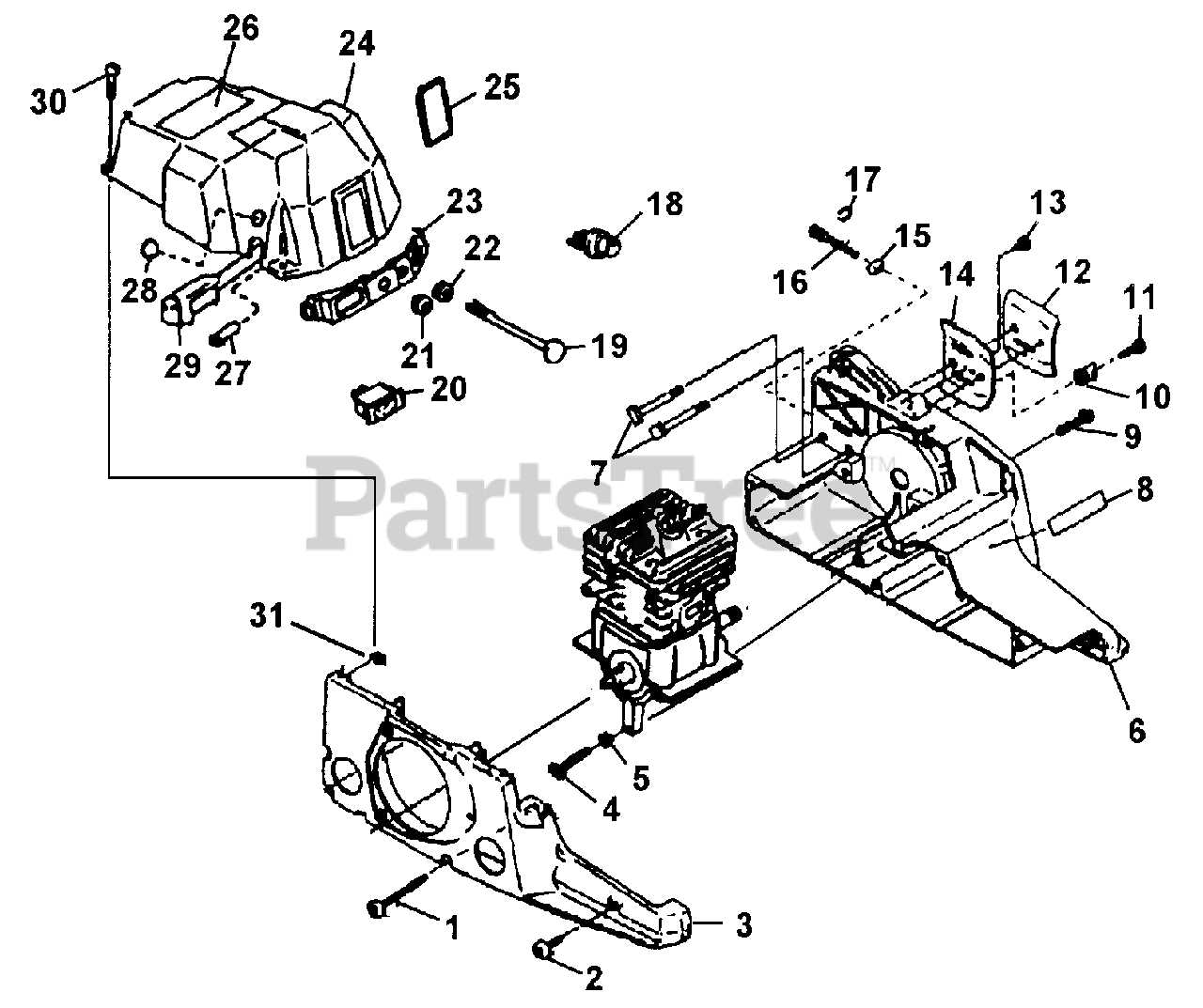

Understanding illustrations of components is crucial for anyone involved in maintenance or repair tasks. These visual representations offer insights into the relationships and functions of various elements within a device, enhancing comprehension and aiding in troubleshooting. By familiarizing oneself with these images, individuals can streamline their approach to repairs and ensure accurate assembly.

Identifying Key Elements

Begin by focusing on the main features highlighted in the illustrations. Look for labels that indicate specific components, as these will guide you in recognizing their locations and functions. Pay attention to the symbols and lines connecting different parts, as they often denote interactions and dependencies, providing a clearer picture of how everything fits together.

Utilizing Annotations for Clarity

Annotations accompanying the visuals can significantly enhance understanding. These notes often provide essential details, such as part numbers or specifications, which are invaluable during the ordering process. Make a habit of cross-referencing these annotations with the device’s manual to gain a comprehensive grasp of each element’s role and compatibility.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if approached correctly. Many resources are available to help identify the exact items you need for efficient repairs or upgrades. Understanding where to search and what to look for can save time and effort.

Begin by consulting the manufacturer’s website, which often offers comprehensive lists of available components along with their specifications. Online retailers and marketplaces can also provide a vast selection, frequently featuring user reviews to guide your choices. Don’t overlook local hardware stores or repair shops, as they may stock the necessary items or be able to order them for you.

Utilizing community forums and discussion groups dedicated to your equipment can be invaluable. Fellow enthusiasts often share insights, recommendations, and even direct links to trusted suppliers. Taking the time to gather information from various sources ensures you find the right replacements swiftly and effectively.

Tips for Maintaining Your Equipment

Proper upkeep of your tools is essential for ensuring their longevity and optimal performance. Regular attention to maintenance can prevent issues and enhance efficiency, saving you time and money in the long run.

Regular Cleaning

Keeping your tools clean is crucial. Dirt and debris can lead to wear and tear. Follow these steps:

- Wipe down surfaces after each use.

- Use a brush or compressed air to remove dust from hard-to-reach areas.

- Store equipment in a dry place to avoid rust.

Routine Inspections

Conducting periodic checks can help identify potential problems early. Consider the following:

- Examine moving parts for signs of damage or wear.

- Ensure all connections are secure and intact.

- Test functionality before and after use.

Where to Source Genuine Parts

Finding authentic components for your equipment is crucial for optimal performance and longevity. Whether you’re looking to replace a worn-out element or enhance your device, knowing where to acquire these items ensures reliability and peace of mind.

Authorized Retailers

One of the most reliable sources for genuine components is through authorized dealers. These establishments provide:

- Verified quality and authenticity

- Expert advice and assistance

- Warranty coverage on purchases

Online Marketplaces

Many consumers turn to online platforms for convenience. Consider these options:

- Reputable e-commerce websites

- Manufacturer’s official website

- Specialized online retailers dedicated to equipment components

Identifying Parts by Model Number

Understanding how to recognize components based on their model numbers is crucial for effective maintenance and repairs. This approach not only simplifies the identification process but also ensures compatibility when sourcing replacements.

Importance of Model Number Recognition

Each unit is assigned a unique identifier that provides essential information about its specifications and compatible accessories. By referencing this number, users can quickly access detailed information, making the repair process more efficient.

Finding Relevant Information

Once the model number is located, individuals can refer to various resources such as user manuals or online databases. These resources often include detailed descriptions and illustrations, enabling users to accurately identify and acquire necessary components.

Exploring Accessories for Your Tools

Enhancing the functionality of your equipment often involves integrating various supplementary items. These enhancements can greatly improve efficiency and overall performance, allowing for a more versatile approach to tasks.

When considering additional components, it’s essential to identify the types that best suit your needs. Here are some common categories:

- Attachments: These can extend the capabilities of your tools, making them suitable for a wider range of applications.

- Storage Solutions: Proper organization aids in quick access and protection of your equipment, contributing to a smoother workflow.

- Maintenance Supplies: Regular upkeep is crucial for longevity, so investing in oils, filters, and other maintenance items is beneficial.

Incorporating these accessories can transform your experience and optimize the use of your devices. Consider exploring these options to fully utilize your equipment’s potential.

Common Repair Techniques Explained

When it comes to restoring equipment, understanding various methods can significantly enhance efficiency and effectiveness. This section outlines several widely-used techniques that can help tackle typical issues encountered during maintenance.

Identifying and Troubleshooting Issues

Effective repair starts with pinpointing the root of the problem. Observing symptoms carefully allows for a systematic approach to addressing malfunctions. Utilizing basic diagnostic tools can aid in confirming suspicions about specific components that may need attention.

Replacement and Assembly Techniques

Once the problematic areas are identified, the next step often involves replacing defective parts. Careful disassembly is crucial to avoid causing further damage. Following manufacturer guidelines or utilizing visual aids can ensure that reassembly is done correctly, promoting longevity and performance.

Safety Precautions During Repairs

Ensuring safety during maintenance is essential to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with repair tasks.

- Wear appropriate protective gear, including gloves and goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep a first aid kit readily available in case of emergencies.

Before starting any repair work, it is crucial to follow these steps:

- Disconnect the equipment from power sources.

- Ensure tools are in good condition and appropriate for the job.

- Read manuals and instructions carefully to understand procedures.

By prioritizing these safety measures, individuals can effectively safeguard themselves and enhance the overall repair experience.