Understanding how different elements within a vehicle’s mechanical system are organized is crucial for proper maintenance and repair. A clear and detailed breakdown of these elements helps both professionals and hobbyists identify and manage necessary repairs with confidence. This section provides insights into the layout of key components for various vehicles, allowing users to familiarize themselves with their structure.

When approaching the task of vehicle repair, it’s essential to have a visual reference that outlines each part. This can save time and ensure that nothing is overlooked during disassembly or reassembly. Whether you’re working on the engine, suspension, or electrical systems, having an accurate schematic can make the process much smoother.

In the following sections, we will explore the intricate arrangement of various mechanical elements, helping

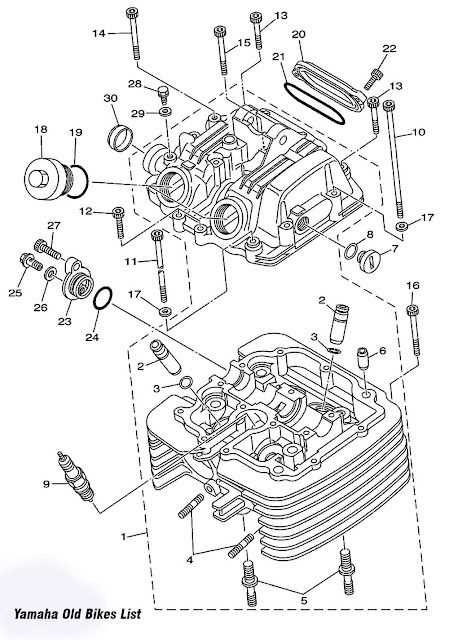

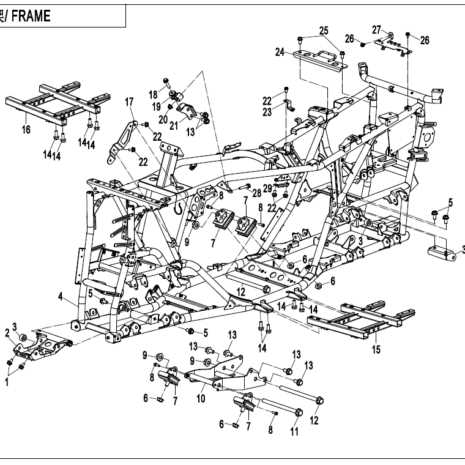

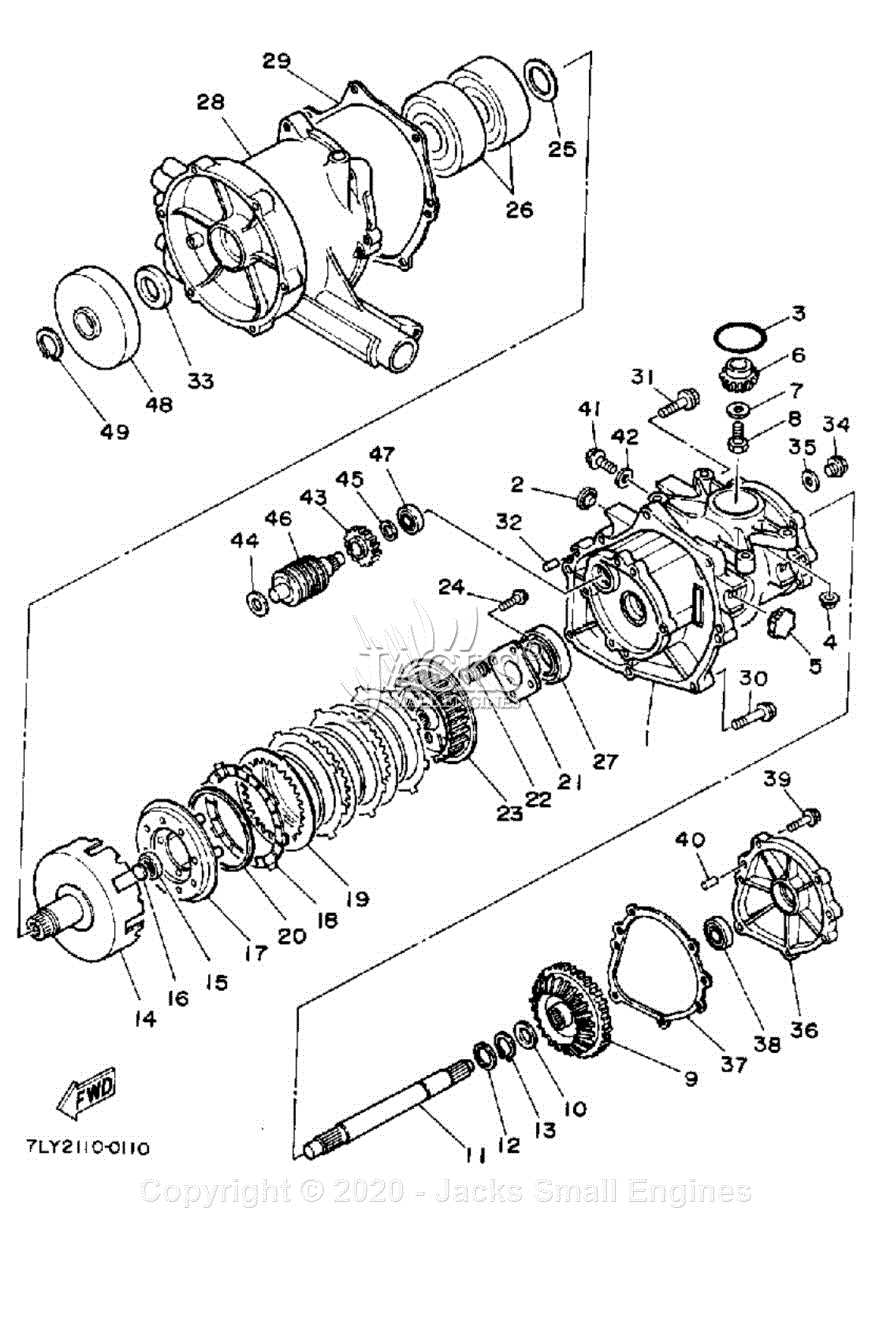

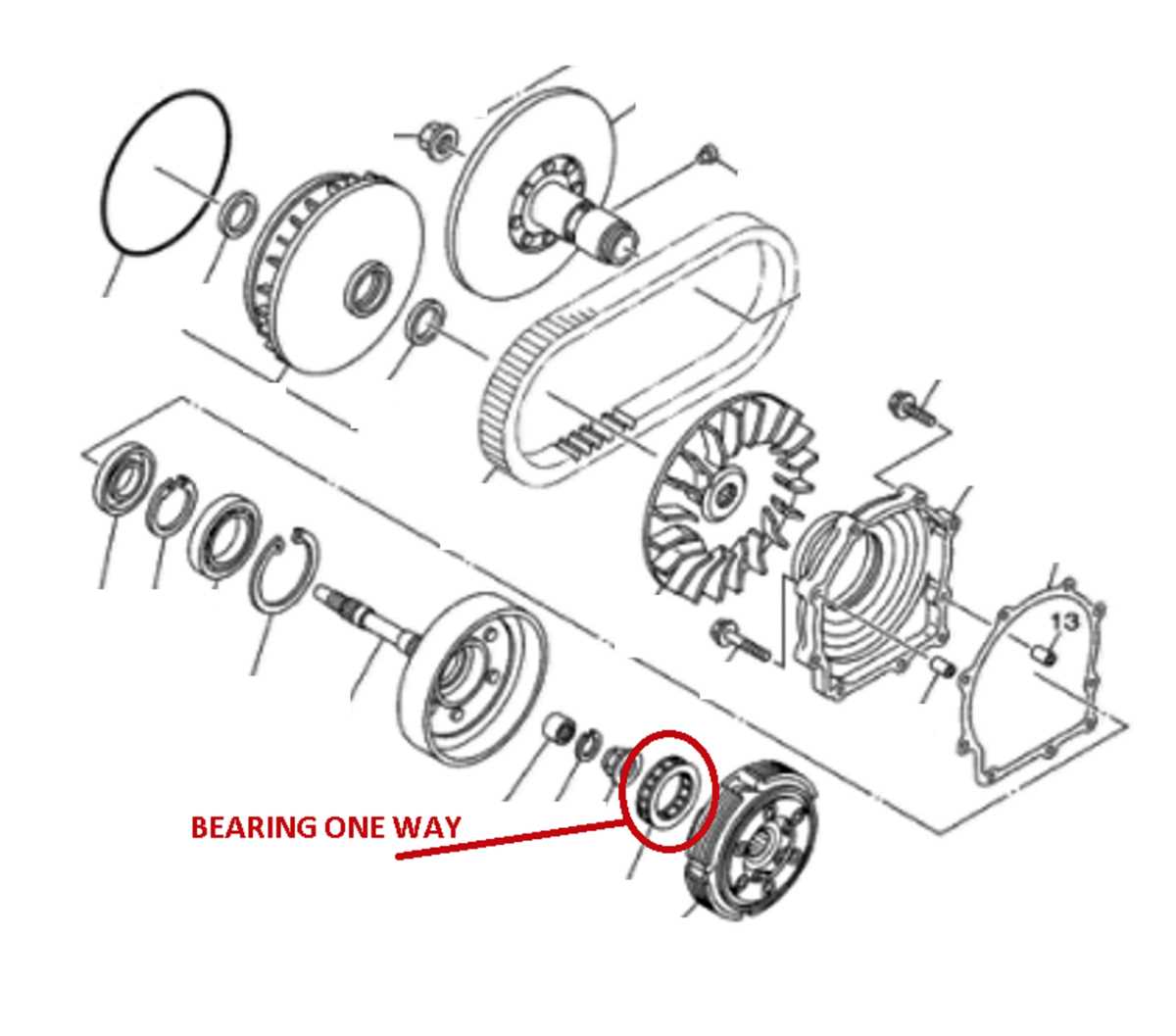

Grizzly 600 Parts Overview

The functionality of any off-road vehicle relies heavily on the integration of various essential components. These elements are crucial for ensuring smooth performance, durability, and safety during operation. Understanding how each segment plays a role can help in maintaining and upgrading the vehicle for optimal use in diverse conditions.

Key mechanical sections like the engine and transmission are at the core of the system, driving both power and efficiency. Supporting elements such as the suspension and braking systems work in unison to provide control and stability, especially on challenging terrains.

Additionally, the electrical system, which powers various accessories and sensors, is vital for modern enhancements. Each mechanical and electrical element plays a role in achieving a balanced and reliable performance. Regular maintenance of these sections is essential to ensure longevity and safety.

Essential Components of the Grizzly 600

The vehicle in question consists of several key elements that ensure its reliable performance and durability in various terrains. Understanding these critical components allows users to maintain the machine effectively, ensuring smooth operation and prolonging its lifespan.

| Component | Function | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | The heart of the machine, providing the necessary power for movement and overall functionality. | |||||||||||||||||||||||||||||||||||||

| Transmission | Facilitates the transfer of power from the motor to the wheels, ensuring efficient movement. | |||||||||||||||||||||||||||||||||||||

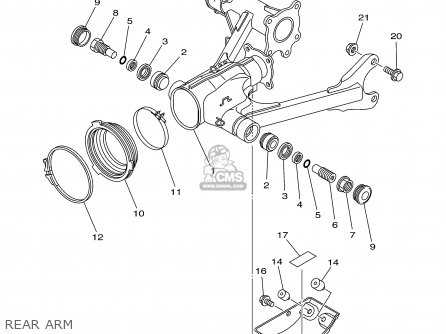

| Suspension | Absorbs shocks from uneven surfaces, ensuring a comfortable ride and protecting other parts from damage. | |||||||||||||||||||||||||||||||||||||

| Brakes | Ensures the vehicle can stop safely and maintain control in different driving conditions. | |||||||||||||||||||||||||||||||||||||

| Component | Function | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gearbox | Converts engine power into torque, adjusting speed and direction. | |||||||||||||||||||||||||||

| Clutch | Engages and disengages the connection between the engine and transmission. | |||||||||||||||||||||||||||

| Driveshaft | Transfers rotational force from the transmission to the wheels. | |||||||||||||||||||||||||||

| Differential | Allows wheels to rotate at different speeds, especially during turns. | |||||||||||||||||||||||||||

| Shifter |

| Component | Function |

|---|---|

| Brake Pads | Friction material that presses against the rotor to slow down or stop the vehicle. |

| Rotors | Discs that rotate with the wheel, providing a surface for the brake pads to grip. |

| Calipers | Housings that hold the brake pads and are activated by hydraulic pressure. |

| Hydraulic Lines | Transport brake fluid from the master cylinder to the calipers, enabling braking action. |

Importance of Regular Maintenance

Regular inspection and maintenance of the braking system are vital to ensure optimal performance and safety. Worn-out components can significantly affect stopping distance and overall vehicle control. Therefore, it is recommended to check these parts periodically and replace them as needed to maintain effective braking capability.

Electrical Wiring and Connections

Understanding the electrical circuitry and connections is crucial for ensuring the proper functioning of machinery. This section provides an overview of essential components and their interrelations, focusing on safety and efficiency in electrical systems.

Key Components

Every electrical system consists of various elements, including switches, connectors, and wiring. Proper installation and maintenance of these components can significantly affect the overall performance. It is vital to ensure that each part is compatible and correctly integrated to avoid malfunctions.

Connection Types

Connections can vary in design, each serving a specific purpose within the electrical framework. Recognizing the different types of connections helps in troubleshooting and enhancing the system’s reliability.

| Component | Description |

|---|---|

| Switches | Devices that control the flow of electricity by opening or closing circuits. |

| Connectors | Elements that join two or more electrical wires, ensuring a stable connection. |

| Wiring | Insulated conductors that carry electrical current between components. |

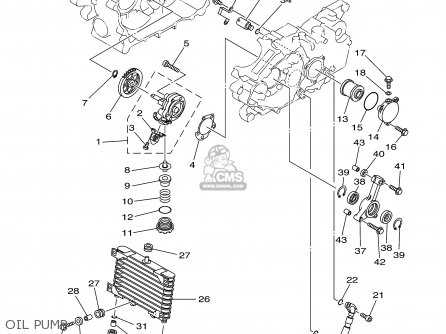

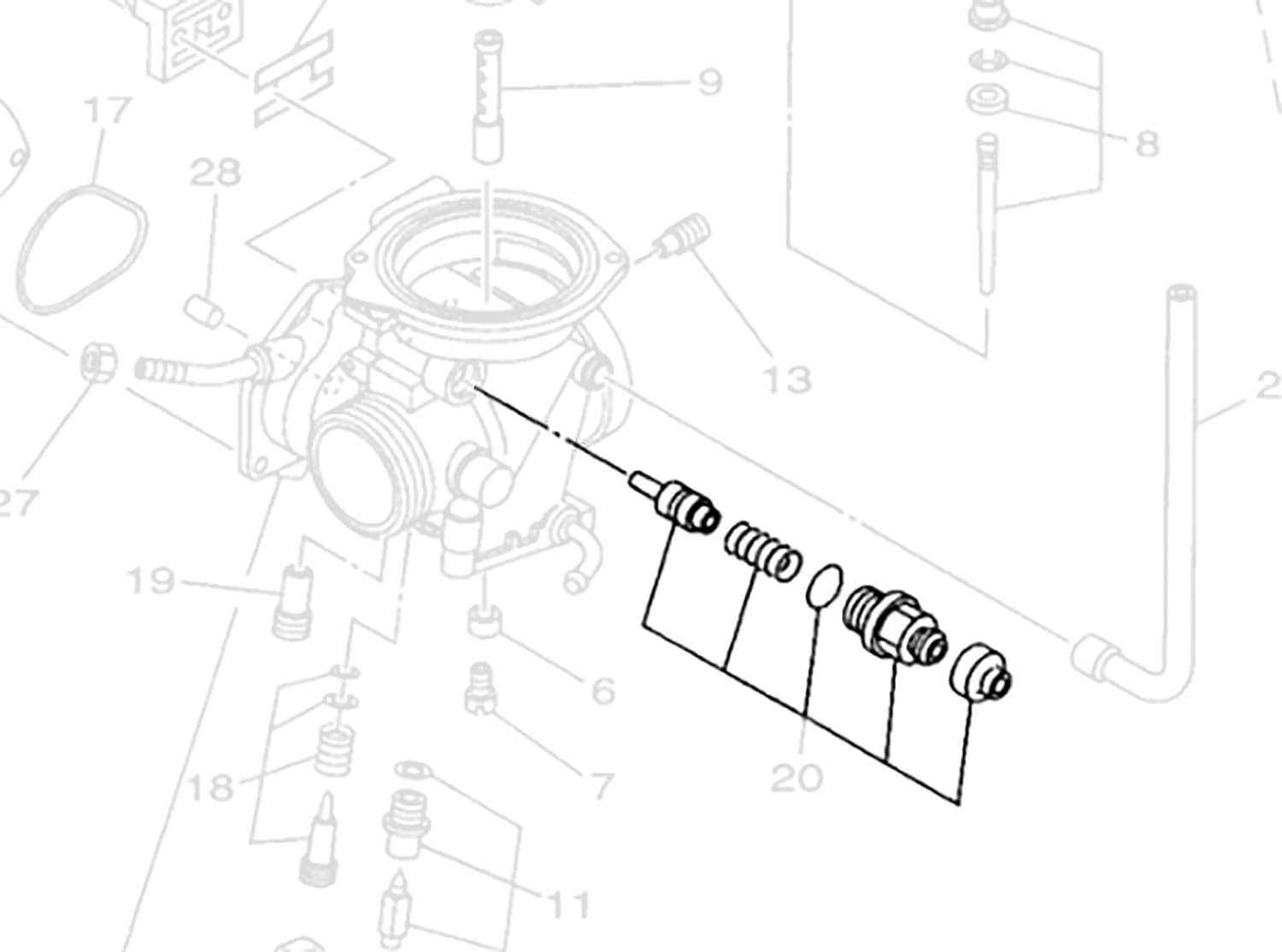

Fuel System Parts and Their Functions

The fuel system is crucial for the efficient operation of any engine, playing a vital role in delivering the necessary energy for performance. Understanding the components involved can enhance maintenance and troubleshooting processes, ensuring optimal functionality and longevity.

Key Components

Essential elements of the fuel system include the fuel tank, fuel pump, and fuel injectors. The tank stores the fuel, while the pump is responsible for transporting it to the engine. Fuel injectors then atomize the fuel, allowing for a precise mixture with air for combustion.

Supporting Elements

Additional components, such as fuel filters and pressure regulators, also contribute to the system’s efficiency. Filters remove impurities, protecting the injectors and engine, while regulators maintain the correct pressure for optimal fuel delivery. Together, these parts ensure smooth operation and performance consistency.

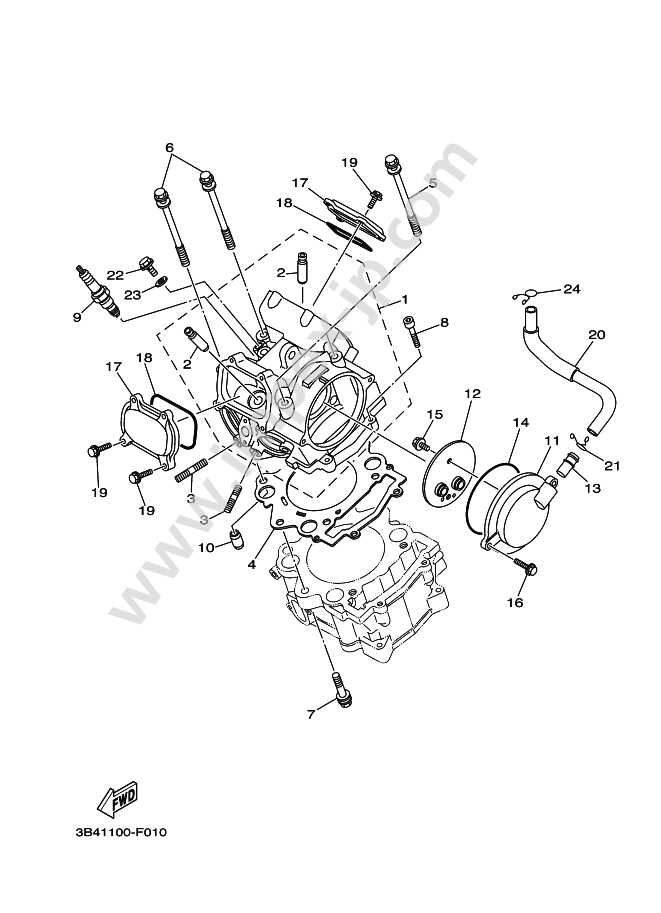

Cooling System and Radiator Layout

The efficiency of an engine’s cooling mechanism is crucial for maintaining optimal performance and longevity. A well-designed cooling system ensures that the engine operates within a safe temperature range, preventing overheating and potential damage. This section delves into the layout of the cooling apparatus, highlighting the arrangement and function of various components that contribute to effective heat dissipation.

Key Components of the Cooling System

Understanding the primary elements of the cooling mechanism is essential for troubleshooting and maintenance. The main components include the radiator, water pump, thermostat, and coolant. Each plays a vital role in regulating engine temperature and ensuring smooth operation.

Radiator Configuration

The radiator serves as a heat exchanger, allowing coolant to dissipate heat effectively. Its configuration impacts the overall efficiency of the cooling system. The layout typically consists of a core, tanks, and inlet/outlet ports that facilitate the flow of coolant.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant. |

| Water Pump | Circulates coolant through the engine. |

| Thermostat | Regulates coolant flow based on temperature. |

| Coolant | Absorbs and transfers heat away from the engine. |

Steering Mechanism Parts Overview

The steering system is a crucial component that enables precise control and direction of the vehicle. It consists of various elements that work in harmony to ensure smooth navigation and responsiveness to driver input. Understanding these components is essential for effective maintenance and troubleshooting.

Main Components of the Steering System

The primary elements include the steering wheel, column, and gearbox, which collaborate to transmit the driver’s movements to the wheels. Each part plays a vital role in enhancing the overall maneuverability of the vehicle.

Importance of Regular Inspection

Regular examination of the steering mechanism is essential for optimal performance. Wear and tear can lead to decreased responsiveness and handling issues. Timely maintenance helps ensure safety and prolongs the lifespan of the entire steering assembly.

Exhaust System Components Diagram

The exhaust system plays a vital role in the overall performance of an engine, ensuring the efficient removal of gases produced during combustion. Understanding its components is essential for maintenance and troubleshooting.

Key elements of this system include:

- Exhaust Manifold: This part collects gases from the engine cylinders and directs them into the exhaust system.

- Catalytic Converter: This component reduces harmful emissions by converting toxic gases into less harmful substances.

- Muffler: It dampens the noise produced by the engine’s exhaust gases, providing a quieter operation.

- Exhaust Pipe: This pathway carries the exhaust gases from the manifold to the outside atmosphere.

- O2 Sensor: This device monitors the level of oxygen in the exhaust gases, helping optimize fuel efficiency.

Each component plays a significant role in enhancing engine efficiency and reducing environmental impact, making it crucial to keep them in optimal condition.