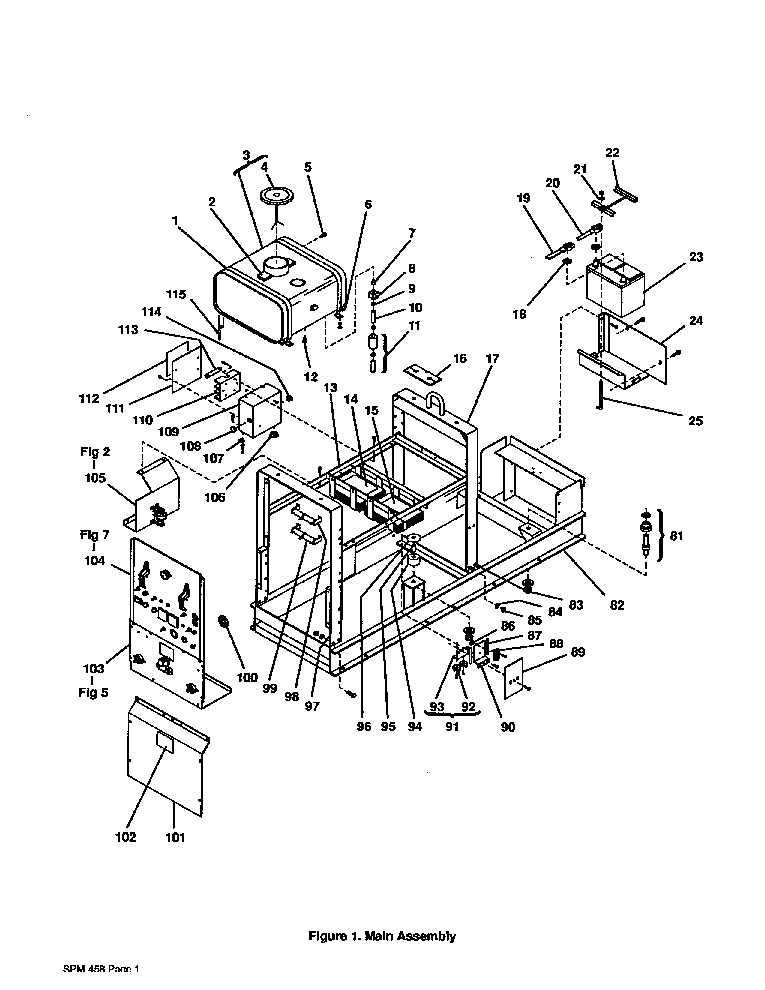

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your equipment. By adhering to a few simple guidelines, you can significantly enhance performance and reliability over time. This section outlines key maintenance practices that will help keep your machine operating smoothly and efficiently.

Regular Cleaning

Keeping your device clean is vital for optimal functionality. Dust, debris, and residue can accumulate, leading to overheating and wear. Make it a habit to regularly inspect and clean the exterior and interior components, ensuring that all parts remain free from contaminants.

Periodic Inspections

Conducting routine inspections can help identify potential issues before they escalate. Check connections, hoses, and other critical elements for signs of wear or damage. Addressing small problems early can prevent more significant repairs and extend the lifespan of your equipment.

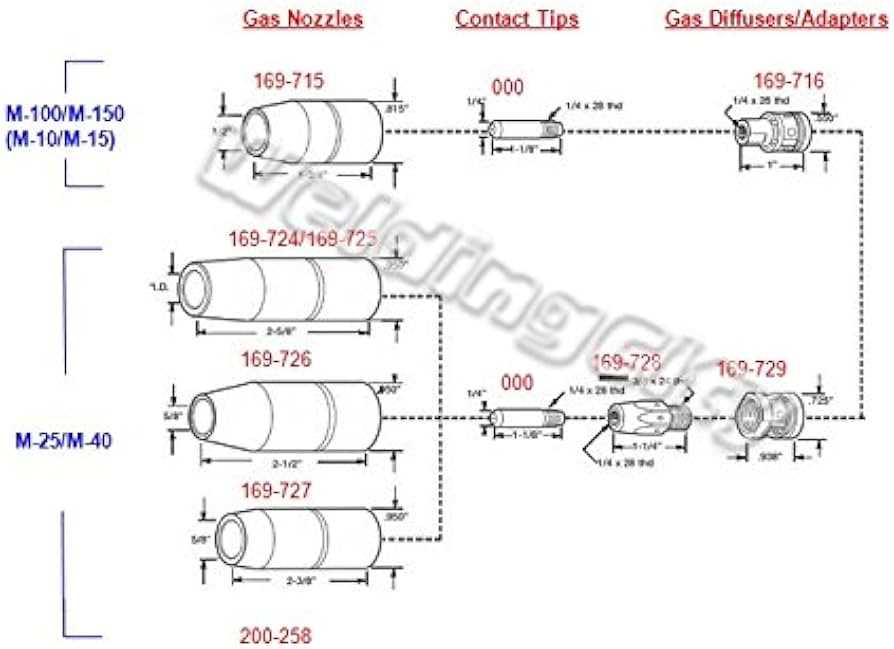

Exploring the Welding Torch Assembly

The welding torch assembly is a crucial component in any welding process, responsible for delivering heat and facilitating the joining of materials. Understanding its structure and function can significantly enhance the efficiency and quality of welding tasks. This section delves into the various elements that constitute the torch assembly, providing insight into their roles and how they work together to achieve optimal performance.

Key Components of the Torch Assembly

The torch assembly typically comprises several essential parts, including the handle, nozzle, and electrode holder. The handle serves as the operator’s grip, allowing for precise maneuverability. The nozzle, on the other hand, directs the flow of gas and heat, ensuring that the welding arc is stable and effective. Lastly, the electrode holder securely holds the electrode in place, enabling the transfer of current to the workpiece.

Maintenance and Best Practices

To ensure the longevity and efficiency of the welding torch assembly, regular maintenance is essential. Inspecting the components for wear and tear, cleaning the nozzle, and ensuring proper gas flow can prevent issues during operation. Additionally, familiarizing oneself with best practices for handling and operating the torch can lead to improved safety and better welding outcomes. Prioritizing maintenance not only extends the life of the equipment but also enhances the overall welding experience.

Understanding Electrical Connections

Electrical connections are essential for ensuring the proper functioning of any machinery. They establish the pathway for electrical currents to flow, allowing components to communicate effectively and perform their designated tasks. A clear understanding of these connections is crucial for troubleshooting, maintenance, and ensuring overall efficiency.

In any system, it is vital to identify the various terminals and connectors involved. Each connection serves a specific purpose, whether it is to power a component or relay signals between different parts of the system. Familiarity with the layout of these connections can prevent errors during repairs and upgrades, enhancing the longevity of the equipment.

Proper wiring techniques play a significant role in the reliability of electrical systems. Utilizing appropriate gauges and types of wires ensures that the connections can handle the required current without overheating or causing damage. Additionally, understanding polarity and grounding is essential to prevent short circuits and electrical failures.

Lastly, regular inspection of electrical connections can help detect wear and tear before it leads to significant issues. Keeping connections clean and secure contributes to the overall safety and performance of the machinery, making it a fundamental aspect of maintenance practices.

Replacing Worn Out Parts

Over time, components within machinery can experience wear and tear, leading to decreased performance and efficiency. Regularly assessing the condition of these elements is crucial to maintain optimal functionality and extend the lifespan of the equipment. Identifying which pieces require replacement is a key aspect of proactive maintenance.

To begin the replacement process, it is essential to consult the manufacturer’s recommendations regarding suitable substitutes. This ensures compatibility and reliability in the machinery’s operation. Carefully removing the worn items and installing new ones can prevent further damage and improve overall performance.

Additionally, keeping a stock of frequently needed replacements can facilitate quick repairs, minimizing downtime. Regular inspections and timely replacements not only enhance efficiency but also contribute to a safer working environment.

Gas Regulator and Hose Guide

The gas regulator and hose assembly are crucial components in any welding setup, ensuring a safe and efficient flow of shielding gas to the welding process. Proper management of these elements contributes significantly to the overall performance and safety of the welding operation.

Understanding the Gas Regulator

A gas regulator plays a vital role in controlling the pressure and flow of gas from the tank to the welding torch. Here are key aspects to consider:

- Pressure Adjustment: It allows users to set the desired pressure for optimal welding performance.

- Safety Features: Many regulators include built-in safety mechanisms to prevent over-pressurization.

- Connection Types: Ensure compatibility with your gas supply by choosing the right connection type.

Hose Specifications and Maintenance

Hoses are essential for transporting gas from the regulator to the welding torch. Proper selection and maintenance are necessary for effective operation:

- Material Quality: Select hoses made from durable materials that resist wear and pressure.

- Length Considerations: Choose a length that allows flexibility without excessive slack, which could lead to damage.

- Regular Inspections: Routinely check hoses for leaks, cracks, or other damage to ensure safe operation.

By understanding the functions and maintenance of the gas regulator and hose assembly, users can enhance the efficiency and safety of their welding tasks.

Proper Setup for Welding Efficiency

Achieving optimal performance in welding requires careful preparation and configuration of equipment. Proper alignment and adjustments can significantly enhance the quality of the welds while minimizing material waste and rework. Understanding the essential components and their functions is crucial for effective operation.

Start by ensuring that the welding apparatus is clean and well-maintained. Regular inspection of the equipment will help identify any wear or damage that could affect its functionality. Calibrating the settings based on the specific material and thickness being worked on is vital. This includes adjusting the voltage, amperage, and wire feed speed to match the requirements of the task at hand.

Additionally, the workspace layout plays a significant role in overall efficiency. Organize tools and materials within easy reach to reduce unnecessary movement during the welding process. Proper lighting and ventilation are also essential to create a safe and comfortable working environment, allowing for better focus and precision.

Finally, practice is key. Regular training and familiarization with different welding techniques will build proficiency and confidence. An experienced operator can adapt quickly to varying conditions, ensuring consistent results and high-quality workmanship.

Safety Features and Precautions

Ensuring safety during the operation of welding equipment is paramount for preventing accidents and injuries. This section highlights essential safety mechanisms and recommended practices that enhance user protection while working with advanced welding systems.

Essential Safety Mechanisms

Modern welding devices are equipped with several crucial safety features designed to minimize risks. These mechanisms include automatic shut-off systems that engage during prolonged inactivity, as well as overheat protection to prevent equipment damage and user harm. Additionally, integrated ventilation systems help dissipate harmful fumes, ensuring a safer working environment.

Recommended Safety Practices

To complement the built-in safety features, users should adhere to specific precautions to enhance personal safety. Wearing appropriate protective gear such as gloves, helmets, and protective clothing is vital. It is also essential to maintain a clutter-free workspace, ensuring that emergency exits are accessible and that fire extinguishing equipment is readily available.

| Safety Feature |

Description |

| Automatic Shut-off |

Turns off the device after a set period of inactivity. |

| Overheat Protection |

Prevents equipment damage by shutting down when overheating occurs. |

| Ventilation System |

Enhances air circulation to reduce the accumulation of harmful fumes. |

Using the Control Panel Effectively

Maximizing the potential of your equipment largely depends on how well you understand and utilize the control interface. This section focuses on various techniques and tips to ensure that users can operate the panel confidently, enhancing overall functionality and performance.

To begin with, familiarize yourself with the key components of the interface:

- Power Settings: Adjust the output to suit your specific needs.

- Feed Speed: Control the wire feed rate for optimal results.

- Voltage Adjustment: Fine-tune voltage levels for different materials.

Here are some effective strategies to consider:

- Read the Manual: Understanding the specifications and features will guide you in making informed adjustments.

- Practice Settings: Experiment with different settings on scrap material to learn how changes affect performance.

- Use Visual Indicators: Pay attention to the panel’s feedback, which can provide insight into your current settings and any necessary adjustments.

By employing these practices, you can optimize the operation of your machinery and achieve better results in your projects.