In this guide, we will delve into the intricate arrangement of essential elements, focusing on the layout and functionality of various sections. By exploring the overall setup, we aim to provide clarity on how each segment connects to form a cohesive system, ensuring a smooth and efficient operation.

The following breakdown will help identify the relationships between these elements, allowing for easier maintenance, repair, or replacement when needed. Understanding this framework can offer valuable insights into the design and purpose of each individual part, making it easier to troubleshoot and enhance performance.

Whether you’re working on improvements or simply looking to understand how everything fits together, this comprehensive overview will guide you through the main areas of interest. With this knowledge, handling any adjustments or replacements will become more intuitive and straightforward.

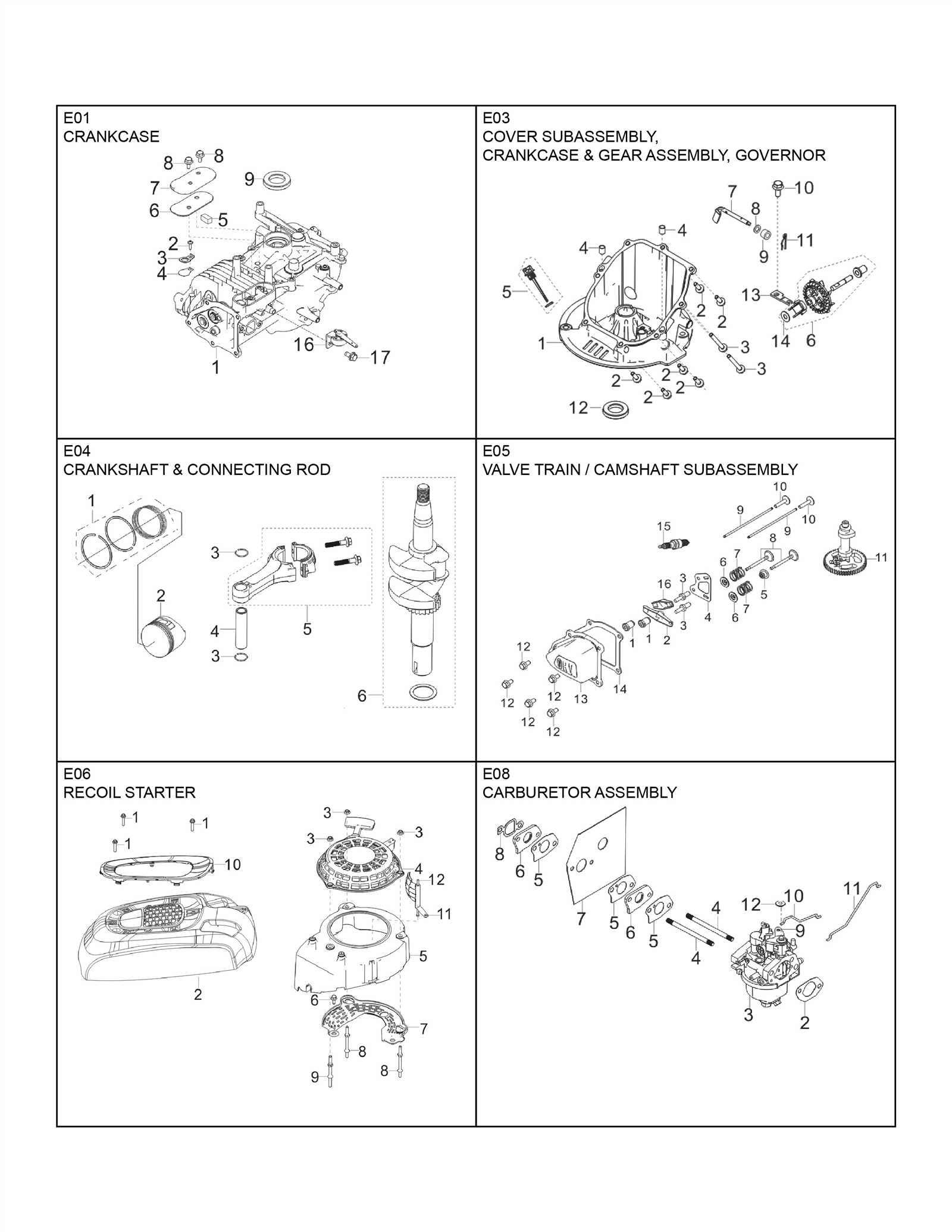

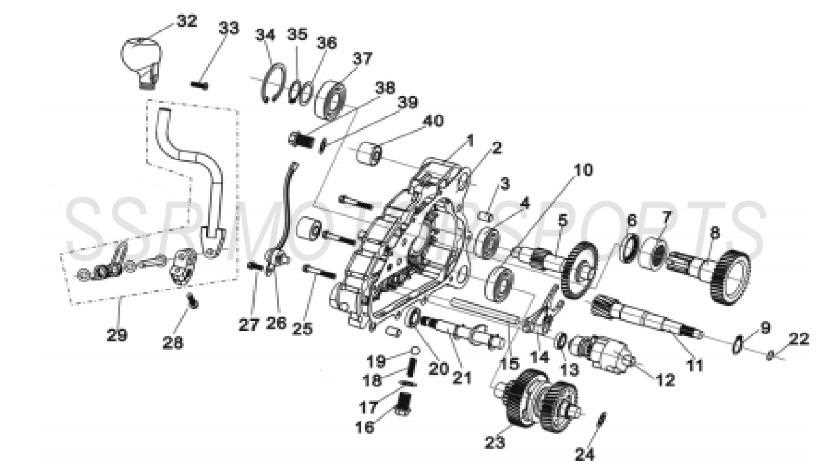

Overview of RV170-S Components

This section provides an in-depth look at the various elements that make up this specific system. Each part plays a crucial role in ensuring optimal performance and seamless operation, working together to deliver reliable functionality. By understanding the core components, users can appreciate how each contributes to the overall efficiency of the setup.

Main Structural Elements

The foundational parts of the system are designed to support and maintain the structure, ensuring durability and long-term stability. These components serve as the backbone, helping to maintain the form and protect sensitive areas from external impact.

Functional Units

Several key modules are responsible for the primary functions of the system. These units work together to control various operations, from power regulation to task execution, enabling the system to perform its intended purpose with precision.

| Component | Description | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Support Frame | Provides structural integrity and protection against external forces. | |||||||||||||||||||

| Key Features of RV170-S Design

The model exhibits a well-thought-out structure that balances functionality and aesthetic appeal, ensuring that every element contributes to overall efficiency. Its layout emphasizes ease of use, durability, and adaptability, making it suitable for various applications. Below, we will explore the defining characteristics that make this design stand out.

Understanding the Internal LayoutWhen exploring the intricate structure of this system, it is crucial to have a clear grasp of how various components are arranged and connected. The internal layout plays a significant role in determining the efficiency and functionality, making it important to understand the relationships between key elements. Main Sections OverviewThe internal setup is organized into several distinct sections, each contributing to the overall performance. By breaking down the arrangement, it becomes easier to identify how each section interacts with others. Key Component InteractionsIn this complex arrangement, understanding the flow of interactions is essential. Each component serves a unique purpose, and together they create a well-balanced system. Breaking Down the Mechanical ElementsUnderstanding the intricate components of a machine requires careful analysis of its individual elements. Each piece plays a crucial role in ensuring the smooth operation and overall performance of the system. By examining these mechanical features, we can uncover the relationships between different parts and how they contribute to the functionality of the whole structure. Core Components and Their RolesAt the heart of the system lie the essential mechanisms that drive its operation. These central pieces, whether moving or stationary, are designed to work in harmony. Key elements such as rotating mechanisms, fasteners, and support structures combine to create a robust and efficient framework. Identifying the purpose of each feature helps us appreciate how they collectively ensure the reliability of the system. Interaction and FunctionalityThe mechanical elements interact in precise ways, with each connection and movement serving a specific purpose. Alignment and timing are crucial to avoid malfunction or inefficiency. Understanding the dynamics of these interactions not only enhances maintenance practices but also provides insights into potential improvements or upgrades. Exploring the Electrical Connections

Understanding the layout and flow of electrical pathways is crucial for maintaining and optimizing any system’s functionality. By investigating how each circuit interacts, we can gain insights into the overall performance and reliability. Proper organization of these links ensures efficient power distribution and communication between different elements. Below is a simplified breakdown of key electrical pathways and their corresponding roles:

Detailed View of the Control PanelThe control interface serves as the central hub for managing various functionalities and monitoring essential parameters. It is designed to provide users with an intuitive experience, ensuring that all necessary information is readily accessible. Each component within this interface plays a vital role in the overall operation and efficiency of the system. Layout and Design: The arrangement of controls is meticulously planned to facilitate ease of use. Buttons, switches, and indicators are strategically placed for quick access, allowing users to interact seamlessly with the system. This thoughtful design enhances user engagement and minimizes the chances of errors during operation. Functional Elements: Key features include display panels that convey real-time data, as well as control switches that regulate various settings. The combination of visual and tactile feedback ensures users can operate the system with confidence. Each element is crafted to withstand regular use, providing durability and reliability in demanding environments. Maintenance Considerations: Regular checks of the control interface are essential for optimal performance. Users are encouraged to familiarize themselves with each component to ensure timely troubleshooting. A proactive approach to maintenance can prevent minor issues from escalating into significant disruptions. Maintenance Tips for Critical PartsEnsuring the longevity and efficiency of essential components in machinery is crucial for optimal performance. Regular upkeep not only enhances functionality but also minimizes the risk of unexpected failures. This section will delve into effective strategies for maintaining key elements that play a vital role in overall operation. Regular InspectionsRoutine examinations are essential for identifying wear and tear before it escalates into significant issues. Establish a schedule to inspect critical components, looking for signs of damage, corrosion, or misalignment. Early detection can save time and resources by addressing minor problems promptly. Proper LubricationMaintaining adequate lubrication is vital for reducing friction and wear on moving parts. Use high-quality lubricants as recommended by the manufacturer, and ensure that you apply them at the specified intervals. Consistent lubrication not only extends the lifespan of components but also enhances operational efficiency. Identifying Common Wear and Tear AreasUnderstanding the typical regions of deterioration in machinery is essential for maintaining optimal performance and longevity. By recognizing these areas, users can proactively address issues before they escalate, ensuring that equipment remains in top condition. Some common areas to inspect include: Regular maintenance should include:

By focusing on these areas and incorporating preventive measures, users can enhance the reliability and lifespan of their equipment. Replacement Guidelines for Essential ComponentsMaintaining the functionality of your equipment often requires timely updates to crucial elements. Following appropriate guidelines for replacing these components ensures optimal performance and longevity. Below are essential recommendations for making effective replacements. Identifying Components for Replacement

Replacement Process Steps

By adhering to these guidelines, you can effectively manage component updates, ensuring reliability and efficiency in operation. Upgrading and Enhancing RV170-S FunctionalityImproving and augmenting the performance of your vehicle can lead to a more enjoyable experience and increased efficiency. By focusing on specific components, you can significantly boost capabilities, making it easier to adapt to various situations and preferences. Key Areas for Enhancement

Recommended Upgrades

Troubleshooting Issues Related to Specific PartsAddressing problems associated with individual components can significantly enhance the overall performance of machinery. Identifying the symptoms and understanding the potential causes of malfunction are crucial steps in resolving issues effectively. This section provides insights into common challenges encountered with various elements and offers practical solutions to facilitate efficient repairs. Common Issues and Solutions

Preventive MeasuresRegular maintenance plays a vital role in preventing issues before they escalate. Establishing a routine inspection schedule for critical components ensures that potential problems are detected early. Keeping detailed records of past repairs can also assist in recognizing patterns and addressing recurrent challenges effectively. |