The functionality and durability of outdoor equipment rely on the quality and compatibility of its essential elements. When maintaining such tools, it’s crucial to understand how these components work together to ensure smooth operation. This section delves into the primary elements that make up a robust and efficient cutting tool, offering insights into its structure and mechanics.

Understanding the mechanical framework is vital for users who want to maximize their equipment’s performance. By exploring the core mechanisms, you’ll learn how each piece plays a role in creating a seamless and effective process. Whether you are replacing a specific element or conducting routine maintenance, knowing the essential components can make the task easier and more efficient.

Moreover, proper upkeep of these elements ensures longevity and reliability, allowing the equipment to perform at its peak. This guide will help you navigate through the various parts, providing clarity on how they contribute to the tool’s overall function.

Essential Components of the Husqvarna 460 Rancher

This versatile cutting tool is composed of numerous critical elements that ensure optimal performance and reliability during demanding tasks. Understanding the key components of this machine is crucial for maintenance, repair, and overall efficiency in daily operations.

Main Engine Features

The central power unit drives the tool, providing the force necessary for effective cutting. It consists of several interconnected systems designed for maximum power output while maintaining durability over time.

- Fuel system for steady power delivery

- Ignition mechanism to initiate operation

- Cooling unit to prevent overheating

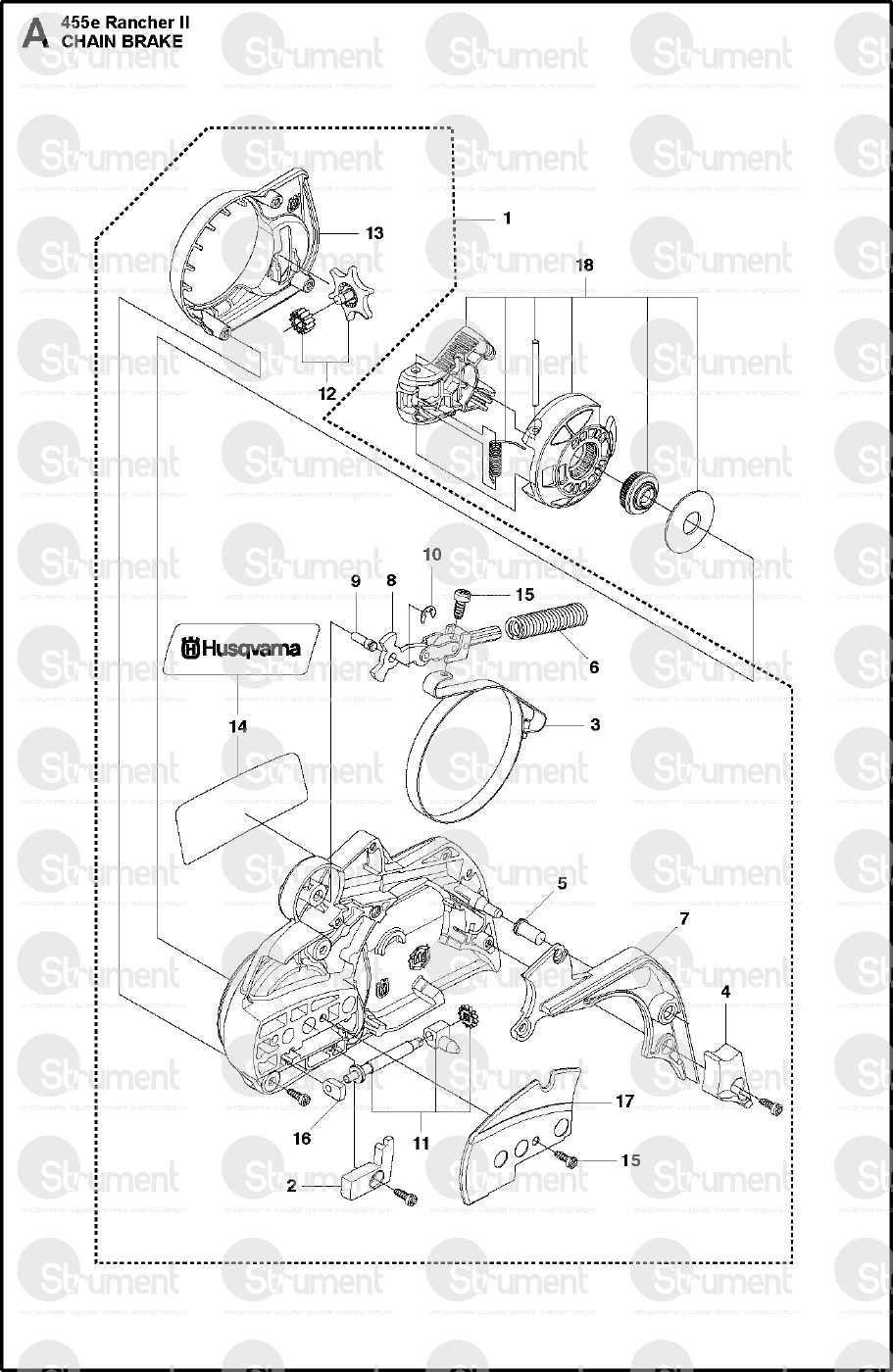

Cutting Mechanism and Drive Components

The cutting mechanism works in tandem with the power unit, ensuring smooth and precise operation. Its sharp elements and durable connections are essential for fast and clean results, even in tough conditions.

- Guide bar for directing the cut

- Sharp cutting element designed for efficiency

- Tensioner system to keep the cutting element taut

Understanding the Chainsaw’s Engine Parts

The internal components of a modern cutting tool’s motor are crucial for its overall performance and longevity. Knowing how these elements interact and function together can greatly improve your ability to maintain the machine and identify potential issues before they escalate.

The engine consists of several key components that work in unison to provide power and efficiency. Below is a breakdown of the essential elements found in most cutting tool motors:

- Cylinder: The chamber where combustion occurs, responsible for generating the force that drives the tool.

- Piston: Moves within the cylinder, compressing the air-fuel mixture before ignition, which ultimately drives the motor.

- Crankshaft: Converts the linear motion of the piston into rotational motion, transferring power to the cutting mechanism.

- Carburetor: Regulates the air-fuel ratio, ensuring the motor receives the right mixture for combustion.

- Flywheel: Helps to stabilize the engine’s speed and assists in cooling the motor during operation.

Each

Guide to Chain and Bar Setup

Setting up the chain and bar properly is essential for maintaining efficiency and safety when operating your equipment. A well-fitted bar and chain allow the machine to run smoothly, offering better precision and less wear on the components. This guide outlines the steps required to install, adjust, and maintain these key parts of your cutting tool, ensuring optimal performance and longevity.

| Step | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Check the bar and chain for correct size and fitment. | ||||||||||

| 2 | Secure the bar in place and ensure proper alignment. | ||||||||||

| 3 | Install the chain by carefully positioning it around the bar, making sure it fits into the guide slots. | ||||||||||

| 4 | Adjust the chain tension to ensure it’s snug

Replacing the Air Filter for Peak PerformanceThe air filter plays a crucial role in maintaining optimal engine function by preventing dirt and debris from entering the engine. Over time, this essential component can become clogged, reducing airflow and lowering overall efficiency. To ensure maximum performance and longevity of your equipment, it’s important to regularly inspect and replace the filter when necessary. Identifying When to Replace the FilterIt’s important to recognize the signs of a dirty or clogged air filter. A noticeable drop in power output, uneven running, or visible dirt on the filter itself are key indicators that it’s time for a replacement. Regular inspections after heavy use will help keep your engine running smoothly. Steps to Properly Replace the Air FilterBegin by locating the filter cover, which can usually be accessed with minimal tools. Remove the cover, taking care to clean the surrounding area to prevent any debris from falling into the engine. Take out the old filter, and carefully insert a new one. Once installed, secure the cover tightly and ensure everything is properly fitted before restarting your equipment. Maintaining the Fuel System in Husqvarna 460

Proper care of the fuel system is essential to ensure the longevity and performance of any outdoor power tool. Regular attention to the fuel components can prevent common issues, ensuring smooth operation and optimal efficiency. Below are some key steps to keep the system functioning properly.

By following these steps, you can ensure that your machine remains reliable and performs well throughout its lifespan. How to Adjust the Carburetor Correctly

Proper tuning of the fuel delivery system is essential for optimal engine performance. Adjusting this component ensures efficient fuel consumption and smooth operation, preventing issues such as stalling or excessive exhaust emissions. By following a few straightforward steps, you can achieve the perfect balance for your machine. Understanding the Adjustment ScrewsTypically, there are three screws that control the air and fuel mixture: the low-speed, high-speed, and idle adjustments. The low-speed screw manages fuel delivery at idle and low RPMs, while the high-speed screw regulates fuel flow during full-throttle operation. The idle screw adjusts the engine’s idle speed, ensuring it runs smoothly when not under load. Steps for Accurate AdjustmentTo begin, start the engine and allow it to warm up. Once warm, turn the low-speed screw clockwise until the engine starts to run rough, then slowly turn it counterclockwise until you find the optimal setting where it runs smoothly. Next, repeat this process for the high-speed screw, ensuring the engine responds well under full throttle. Lastly, fine-tune the idle screw to achieve a steady idle without stalling. Regular adjustments may be necessary to maintain peak performance. Exploring the Ignition System of the ChainsawThe ignition system plays a crucial role in the overall functionality of a cutting tool. It is responsible for generating the spark that ignites the fuel-air mixture, leading to the engine’s operation. Understanding this system is essential for proper maintenance and troubleshooting, ensuring optimal performance. Key Components of the Ignition System

Common Issues and Solutions

Understanding the Oil Pump and Chain Lubrication

The oil pump plays a crucial role in the maintenance of optimal performance for cutting equipment. It ensures that the cutting mechanism remains properly lubricated, preventing excessive wear and enhancing efficiency during operation. Effective lubrication is essential for reducing friction, minimizing heat buildup, and prolonging the lifespan of the components involved. The lubrication system typically consists of various components that work together to deliver oil to the necessary areas. Understanding how this system operates can aid users in maintaining their equipment effectively.

Regular inspection and maintenance of the oil pump and its components can significantly impact the overall performance of the equipment. Ensuring that the lubrication system functions correctly will enhance cutting efficiency and durability. Replacing the Recoil Starter AssemblyReplacing the recoil starter assembly is a crucial task that ensures the reliable operation of your equipment. This component is responsible for initiating the engine’s starting process, and a malfunction can lead to difficulty in starting the machine. Regular maintenance and timely replacement of this assembly can help prevent further issues and enhance overall performance. To begin the replacement, first, ensure that the equipment is turned off and disconnected from any power source. Carefully remove the screws securing the starter assembly to access the internal components. Once exposed, detach the old starter assembly by carefully disconnecting any attached cables or springs. It is essential to keep track of all parts to ensure a smooth reinstallation process. Next, take the new recoil starter assembly and align it with the mounting points. Secure it in place by tightening the screws appropriately. After the assembly is fixed, reconnect any cables or springs that were previously detached. Finally, perform a test to ensure that the starter engages properly and the engine starts smoothly. Regular checks after installation will help maintain its efficiency. Troubleshooting Common Husqvarna 460 IssuesWhen operating a powerful cutting tool, users may encounter various challenges that hinder its performance. Identifying these issues is essential for maintaining efficiency and ensuring safety during use. Common problems can stem from several factors, including fuel system malfunctions, ignition failures, or mechanical wear. By systematically addressing these potential concerns, one can restore optimal functionality. A frequent issue involves difficulty in starting the machine. This could result from stale fuel, a clogged filter, or a malfunctioning spark plug. To resolve this, inspect the fuel quality and replace it if necessary, ensuring that all filters are clean and the ignition system is functioning properly. Another common concern is inadequate power during operation. This can often be attributed to a dirty air filter or a blocked exhaust. Regularly cleaning or replacing the air filter and ensuring the exhaust is clear can significantly enhance performance. Additionally, checking the tension of the cutting mechanism may also prove beneficial. Lastly, unusual noises during operation may indicate underlying mechanical issues. If strange sounds occur, it’s advisable to halt usage immediately and inspect the components for any signs of damage or wear. Regular maintenance checks can help prevent these problems and extend the lifespan of the tool. Upgrading the Muffler for Better Efficiency

Enhancing the exhaust system of a power tool can lead to significant improvements in performance. By optimizing the muffler, users can achieve better airflow, resulting in increased power and efficiency. This modification is essential for those looking to maximize the potential of their equipment while also ensuring a quieter operation. Benefits of Upgrading

Considerations for Selection

Best Practices for Chainsaw Maintenance

Proper upkeep of cutting tools is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. Adopting a few fundamental practices can significantly improve the reliability and effectiveness of your equipment.

By implementing these maintenance practices, you can extend the life of your equipment and ensure its efficient operation. Regular checks and proper care lead to improved performance and safer usage. |