In the realm of marine propulsion systems, comprehending the arrangement of various elements is crucial for maintenance and performance optimization. A clear visualization of these components not only aids in identifying potential issues but also enhances the efficiency of repairs and upgrades.

By exploring the intricate relationships among engine elements, enthusiasts and professionals can better appreciate the design and functionality that underpins marine power systems. This knowledge empowers users to make informed decisions, ultimately leading to improved reliability and longevity of their equipment.

Engaging with detailed representations of these mechanical systems can transform the way one approaches engine care. It allows for a deeper dive into the specifics, ensuring that each part operates harmoniously within the larger framework.

Understanding Volvo Penta 3.0 Components

This section aims to illuminate the essential elements that contribute to the functionality of a particular marine engine system. Each component plays a vital role in ensuring optimal performance, efficiency, and longevity. By comprehending these parts, users can better maintain their equipment and troubleshoot issues effectively.

Key Elements of the Engine System

Within any propulsion system, certain primary components are crucial. The engine block serves as the core structure, housing various internal mechanisms that facilitate power generation. Additionally, the fuel delivery system ensures that the necessary energy source reaches the combustion chamber efficiently, impacting overall performance.

Auxiliary Components and Their Functions

Beyond the main structures, numerous auxiliary components contribute to the system’s operation. Cooling systems prevent overheating, maintaining optimal temperatures during operation. Furthermore, the exhaust system manages emissions, ensuring compliance with environmental standards while also enhancing engine efficiency. Understanding these interconnected elements is key to maintaining a high-performing marine engine.

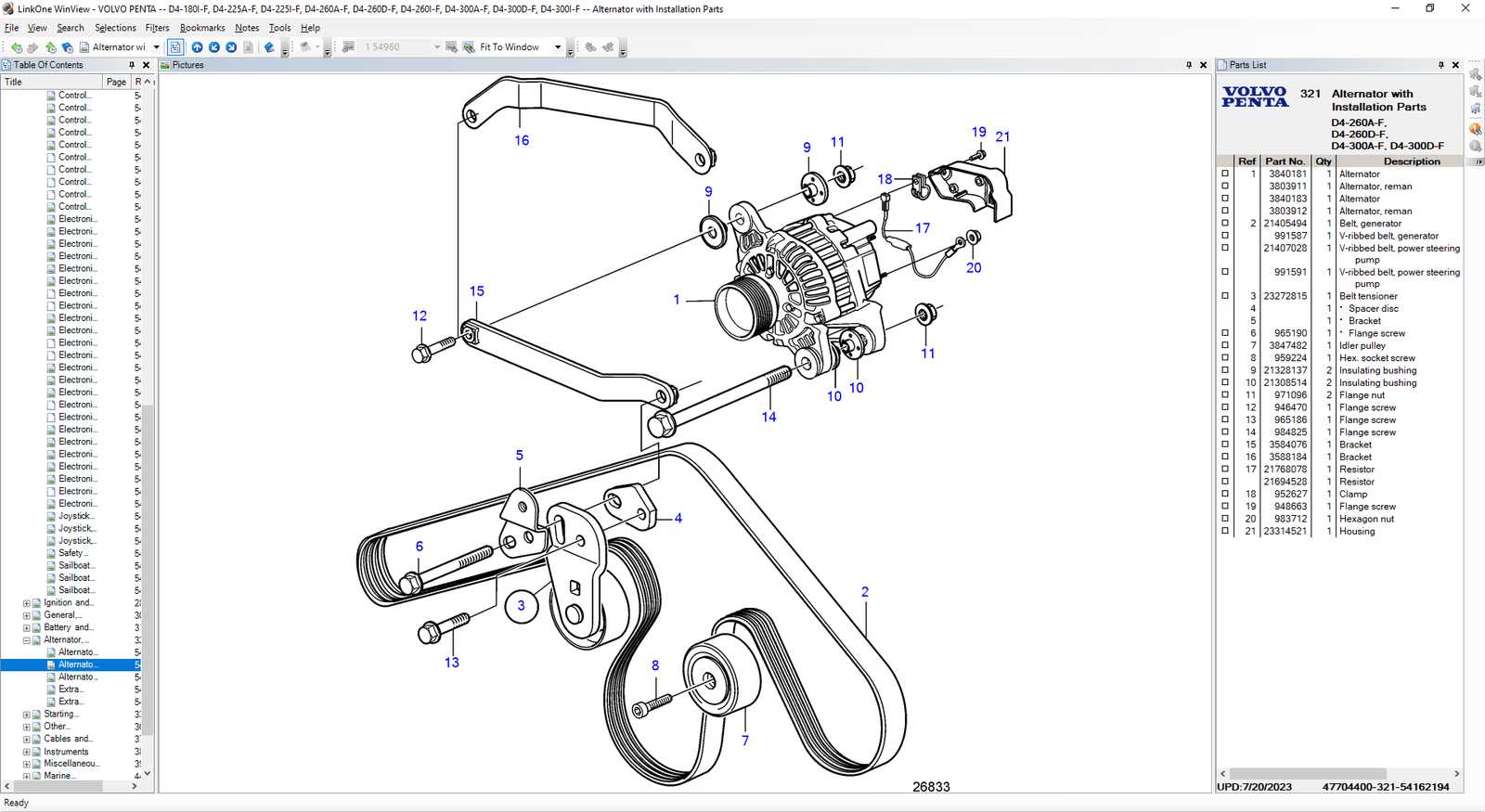

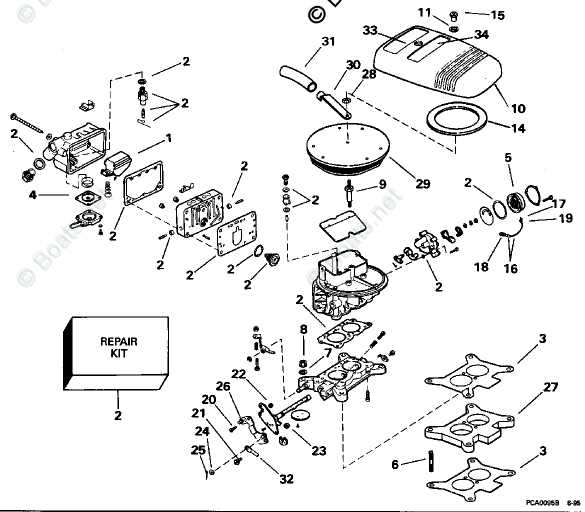

Importance of Parts Diagrams

Understanding the components and their interactions within a system is crucial for effective maintenance and repair. Visual representations of these elements not only simplify the identification process but also enhance overall comprehension of the assembly.

One of the key benefits of utilizing such visual aids includes:

- Clarity: Clear illustrations help in grasping the layout and function of each component.

- Efficiency: Streamlined processes during assembly and disassembly save time and reduce errors.

- Resource Management: Facilitates better planning by highlighting the required elements and potential replacements.

- Training Aid: Serves as a valuable tool for educating new technicians and personnel.

Moreover, the visual representation assists in troubleshooting by allowing users to pinpoint issues more effectively. A comprehensive guide can lead to:

- Reduced downtime during repairs.

- Enhanced safety measures by ensuring correct assembly.

- Improved longevity of equipment through proper maintenance practices.

In conclusion, these visual aids play an integral role in facilitating a deeper understanding and more efficient handling of mechanical systems, ultimately contributing to their optimal performance.

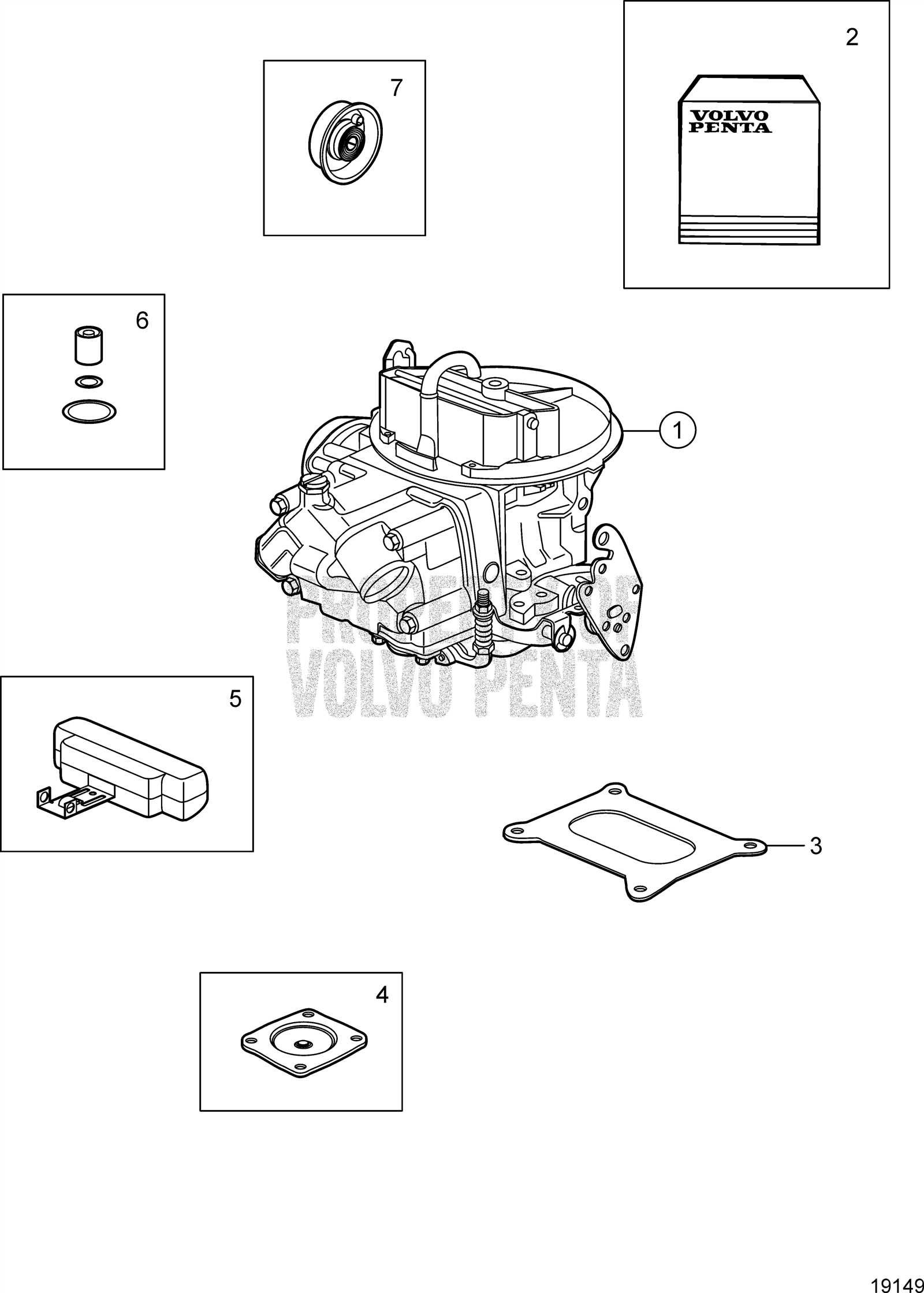

Key Components of Volvo Penta 3.0

Understanding the fundamental elements of marine engines is essential for optimal performance and maintenance. Each component plays a vital role in ensuring smooth operation and reliability on the water. Here, we will explore the critical parts that contribute to the overall functionality of these power systems.

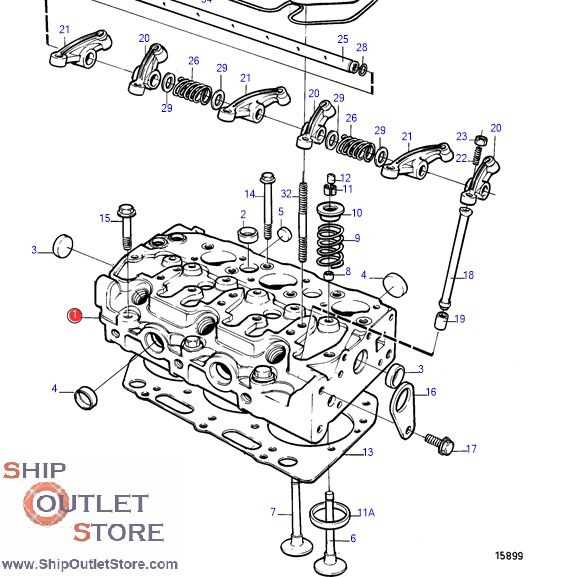

The engine block serves as the core of the unit, housing the cylinders and facilitating combustion. The crankshaft, a crucial piece, converts linear motion into rotational force, driving the propeller. Meanwhile, the camshaft orchestrates the opening and closing of valves, allowing for efficient air and fuel flow.

The fuel system, including injectors and pumps, ensures the proper mixture reaches the combustion chamber. An effective cooling system, comprising a water pump and thermostat, maintains optimal temperatures to prevent overheating. Additionally, the electrical system, featuring the starter and alternator, powers essential functions and provides ignition.

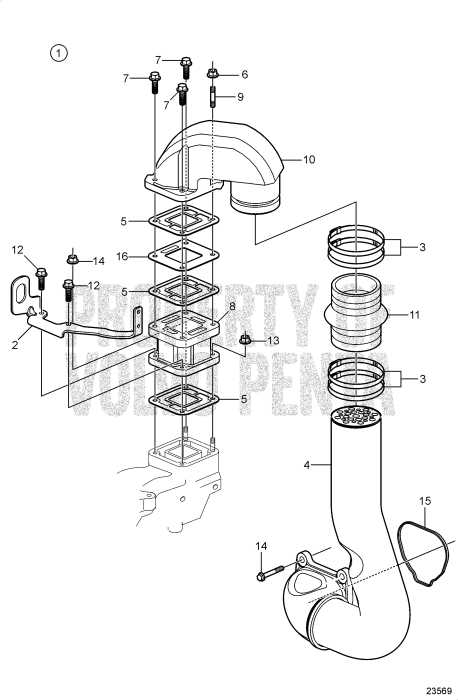

Lastly, the exhaust system plays a pivotal role in expelling gases produced during combustion, ensuring a clean and efficient operation. By delving into these components, one can appreciate the engineering that underpins marine propulsion systems.

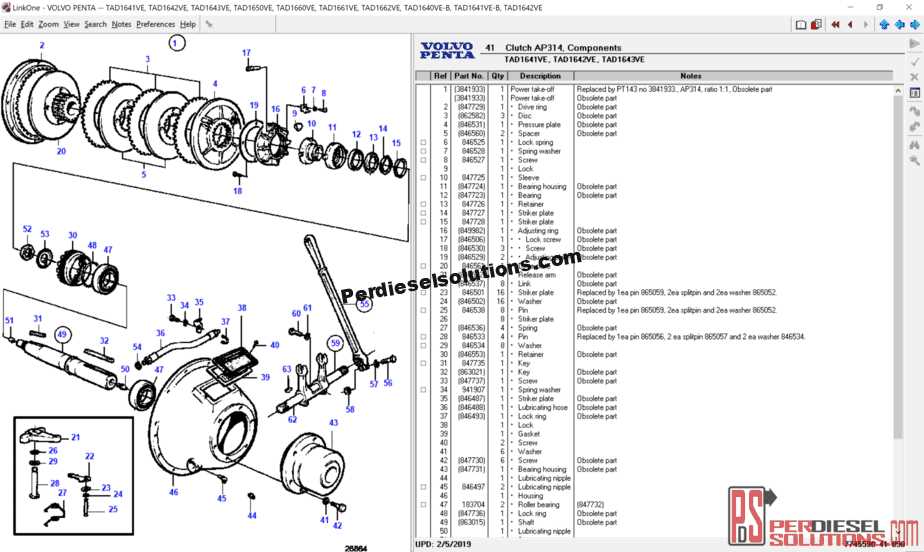

How to Read a Parts Diagram

Understanding an illustration that depicts components can enhance your ability to identify and source necessary items for maintenance or repair. This skill is essential for ensuring your equipment operates smoothly and efficiently.

Key Elements to Note

- Labels: Look for names and numbers associated with each element to easily find replacements.

- Connections: Observe how different parts interact; this helps in understanding assembly and disassembly.

- Legend: Refer to the legend or key for symbols and codes that clarify the function of each component.

Steps for Effective Interpretation

- Start by familiarizing yourself with the overall layout.

- Identify the main components first before delving into smaller details.

- Cross-reference with your manual for additional insights.

- Make notes of any unclear symbols for further research.

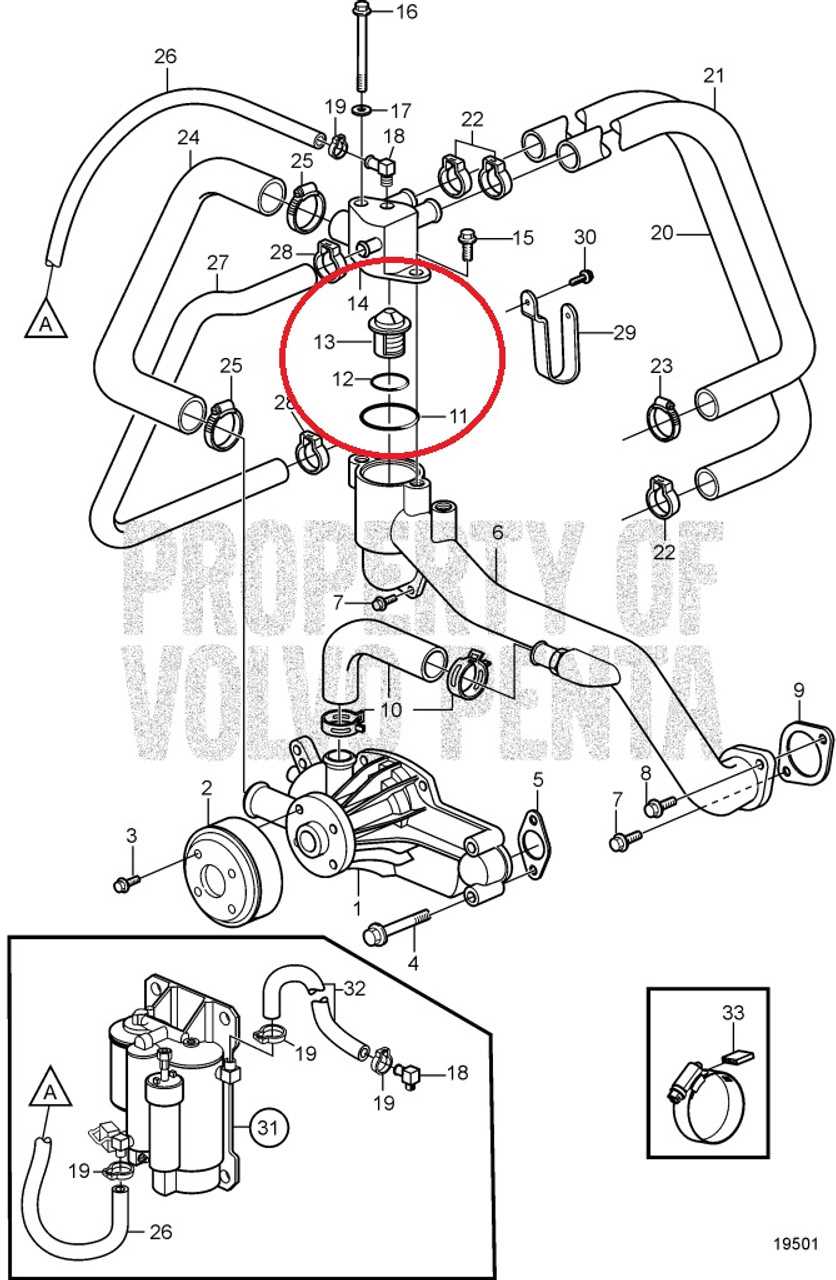

Common Issues and Solutions

Understanding frequent problems associated with marine engines can enhance performance and longevity. Identifying these challenges and implementing effective solutions is crucial for maintaining optimal functionality.

One prevalent issue is overheating, often caused by coolant blockages. Regular maintenance of the cooling system and timely replacement of worn components can mitigate this risk.

Fuel delivery problems can also arise, leading to poor engine performance. Ensuring clean fuel lines and replacing filters regularly can help maintain a steady supply.

Another common concern is electrical failures, typically linked to corroded connections. Routine inspection and cleaning of electrical systems can prevent disruptions in power.

Lastly, unusual noises may indicate internal wear or damage. Conducting periodic checks and addressing any abnormalities early can save time and costs in repairs.

Where to Find Genuine Parts

Locating authentic components for your marine engine is crucial for maintaining optimal performance and longevity. This section will explore various reliable sources to ensure you acquire the highest quality items tailored for your needs.

Authorized Dealers

Visiting certified distributors is one of the best ways to guarantee that you receive genuine items. These establishments offer a wide selection and often provide expert guidance, ensuring you choose the correct components for your specific requirements.

Online Retailers

Reputable e-commerce platforms specialize in marine engine supplies. When shopping online, ensure you verify the seller’s credibility and look for customer reviews. This can help you find the ultimate source for authentic items without the hassle.

Maintenance Tips for Longevity

Ensuring the durability and performance of your marine engine requires regular attention and care. Implementing consistent maintenance routines can significantly extend the lifespan of your equipment, allowing for optimal functionality and reliability during use.

First, routinely check and replace fluids, including oil and coolant, to prevent overheating and ensure smooth operation. Clean or replace filters as needed to maintain efficiency and reduce wear. Additionally, inspect belts and hoses for signs of wear or damage, as these components are vital for proper function.

Another crucial aspect is the electrical system. Regularly inspect connections and terminals for corrosion, ensuring reliable power supply. Furthermore, keep the exterior clean and free from salt and debris, which can cause deterioration over time.

Finally, consult your manufacturer’s guidelines for specific maintenance schedules and recommendations. Following these tips will help safeguard your equipment, providing peace of mind and enhancing overall performance.

Upgrades for Enhanced Performance

Improving the efficiency and output of your marine engine can significantly enhance your boating experience. Various modifications and enhancements can be applied to increase power, fuel efficiency, and overall reliability. Exploring these options can lead to a more enjoyable and seamless time on the water.

Engine Tuning and Optimization

One of the most effective ways to boost performance is through engine tuning. Adjusting fuel-air mixtures, ignition timing, and other parameters can optimize engine output. Custom tuning chips or software can be employed to achieve tailored settings that suit specific usage requirements, providing noticeable improvements in acceleration and top speed.

Exhaust System Upgrades

Upgrading the exhaust system can greatly enhance engine performance. A high-flow exhaust not only reduces back pressure but also improves exhaust gas flow, which can result in increased horsepower. Additionally, modern materials can provide durability and resistance to corrosion, ensuring longevity and consistent performance under marine conditions.

Tools Needed for Assembly

When assembling a marine engine, having the right instruments at your disposal is crucial for a successful outcome. The assembly process requires precision and care, and the appropriate tools can significantly enhance efficiency and accuracy.

Essential items include wrenches, screwdrivers, and pliers, which are fundamental for securing components. Additionally, a torque wrench is vital for ensuring that all fasteners are tightened to the manufacturer’s specifications.

Don’t forget about specialized tools, such as a gasket scraper and a sealant applicator, which can aid in achieving a leak-free assembly. Lastly, having a good quality workbench and ample lighting will help create an optimal workspace.

Comparing Volvo Penta 3.0 Models

This section explores the distinctions among various engine variants, highlighting their unique characteristics and performance metrics. Understanding these differences is essential for making informed decisions about compatibility and functionality.

- Engine Specifications:

- Power output variations

- Torque delivery differences

- Fuel Efficiency:

- Comparative consumption rates

- Impact of engine size on mileage

- Applications:

- Best uses for each model

- Suitability for different types of vessels

When selecting an engine, consider your specific needs and the environment in which you’ll operate. Each variant offers distinct advantages that can enhance performance and reliability.

FAQs About Parts and Maintenance

This section aims to address common queries related to components and upkeep for various marine engines. Understanding these aspects can enhance performance and longevity.

Common Questions

- What should I check regularly to ensure optimal performance?

- How often should I replace essential components?

- What are the signs of wear that I should look for?

Maintenance Tips

- Perform routine inspections of all key elements.

- Always use high-quality replacements for worn parts.

- Keep the engine clean to prevent debris buildup.