Maintaining machinery effectively requires a clear understanding of its individual elements and how they function together. Each part plays a crucial role in ensuring optimal performance and longevity of your device. A well-organized visual representation can significantly aid in identifying and sourcing replacements when needed.

In this section, we will explore the intricacies of various components commonly found in power tools. By delving into the specifics, users can better appreciate how each segment contributes to the overall efficiency of the machine. This knowledge not only facilitates repairs but also enhances the user experience.

Having access to a detailed illustration of the equipment’s structure is invaluable for both novice and seasoned users alike. It simplifies troubleshooting and encourages proactive maintenance, helping to avoid costly downtime and prolonging the lifespan of the equipment. Let’s uncover the essential parts that keep your tool running smoothly.

Understanding Husqvarna XT722FE Components

Exploring the various elements of a machine can significantly enhance your understanding of its functionality and maintenance. Each component plays a crucial role, contributing to the overall performance and efficiency. By familiarizing yourself with these individual parts, you can identify potential issues, perform timely repairs, and ensure optimal operation.

Engine: At the heart of the device lies the engine, which powers all operations. Its performance directly affects the effectiveness of the entire system. Regular checks and maintenance are essential to keep it running smoothly.

Transmission: The transmission system is vital for power transfer. It allows the operator to control speed and torque, making it essential for different tasks. Understanding how to maintain and troubleshoot this system can prevent operational hiccups.

Cutting Mechanism: This includes blades and associated assemblies, designed to deliver precise cuts. Knowledge of how to sharpen and replace these parts will ensure that the machine performs its best.

Chassis: The frame provides stability and support. It’s important to inspect for wear and tear, as a sturdy chassis is crucial for safe and effective operation.

Wheels and Tires: These components contribute to maneuverability. Ensuring they are properly inflated and free of damage can enhance performance on various terrains.

In conclusion, a comprehensive understanding of these components allows for better maintenance and efficient use. Regular attention to each part can lead to improved longevity and reliability of the machine.

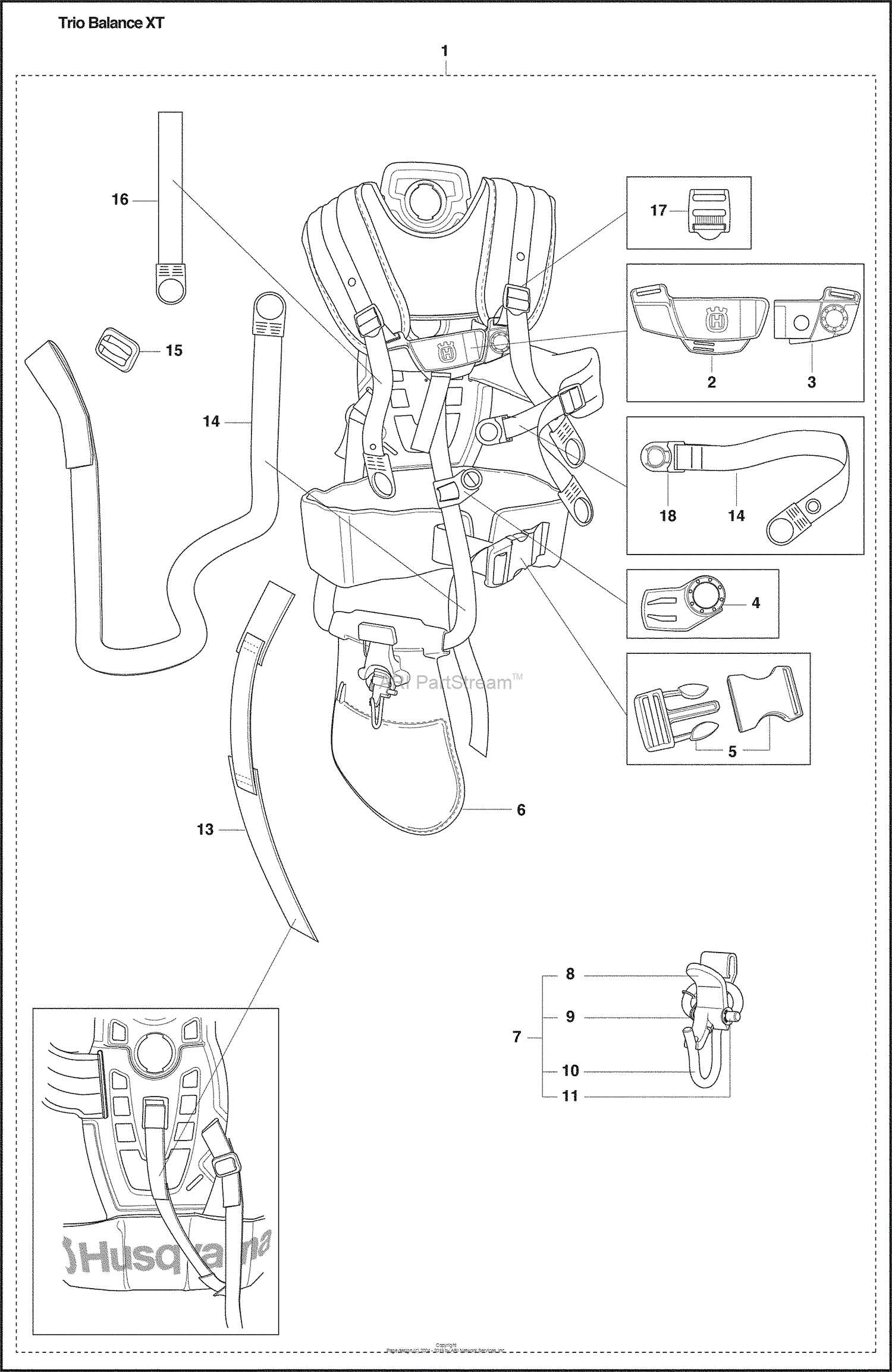

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and function of machinery. They offer a clear overview, allowing users to identify each element and its relation to others within the system. This clarity aids in efficient troubleshooting and maintenance.

Moreover, these illustrations facilitate communication between technicians and engineers, ensuring everyone is on the same page regarding repairs and upgrades. They serve as an ultimate reference tool, helping to prevent errors and improve the accuracy of tasks.

Additionally, access to these visual guides enhances the overall user experience, empowering individuals to confidently navigate the complexities of their equipment. Understanding the arrangement and purpose of each piece ultimately leads to better performance and longevity of the machinery.

Overview of XT722FE Specifications

This section provides an insightful look into the technical characteristics that define the performance and usability of this outdoor equipment. Understanding these specifications is essential for users who wish to optimize their experience and ensure compatibility with various tasks.

Engine Power: The machine is equipped with a robust engine that delivers substantial power, making it suitable for diverse applications, from light-duty to more demanding tasks.

Cutting Width: Featuring a wide cutting deck, this model enables efficient coverage of large areas, reducing the time needed for maintenance and care.

Weight: Designed with a balanced weight, it offers both stability and ease of maneuverability, allowing users to handle it with confidence across various terrains.

Fuel Efficiency: The equipment boasts impressive fuel efficiency, ensuring longer operation times between refuels, which is ideal for extended tasks.

Comfort Features: Ergonomically designed controls and comfortable seating enhance the user experience, making it easier to operate for prolonged periods without fatigue.

Main Components of the Lawn Mower

The efficiency and functionality of a lawn mowing machine depend on several key elements working in harmony. Understanding these core components is essential for both maintenance and optimal performance. Each part plays a specific role, contributing to the overall capability of the machine to achieve a well-manicured lawn.

Engine

The engine is the powerhouse of the mower, providing the necessary energy to drive the blades and propel the machine forward. Different types of engines, including gas and electric, offer varying levels of performance and efficiency. Regular maintenance, such as oil changes and air filter replacements, is crucial for ensuring the engine operates smoothly.

Cutting Deck

The cutting deck houses the blades and is responsible for the actual mowing process. Its design influences the width of the cut and the overall maneuverability of the machine. The materials used in its construction can affect durability and weight. Keeping the cutting deck clean and free from debris enhances the mower’s effectiveness and prolongs its lifespan.

How to Read a Parts Diagram

Understanding an illustration of components can greatly enhance your ability to maintain and repair machinery. These visuals provide a clear representation of various elements and their arrangement, aiding in identifying specific pieces you may need.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself: Begin by understanding common symbols and notations used in the illustration.

- Identify Sections: Look for grouped areas that indicate assemblies or systems within the machinery.

- Reference Numbers: Pay attention to numbers associated with each component, as these often correlate with a list detailing their specifications.

- Color Coding: Observe any color coding, which may indicate different materials or functions.

- Follow Connections: Trace lines and arrows that show how parts interact and connect to one another.

By mastering these techniques, you’ll be better equipped to tackle repairs and order the necessary components with confidence.

Common Replacement Parts for XT722FE

When maintaining outdoor power equipment, understanding the frequently needed components can enhance longevity and performance. Regular wear and tear necessitates the replacement of specific items to ensure optimal functionality.

| Component | Description |

|---|---|

| Air Filter | Essential for maintaining engine performance by ensuring clean air intake. |

| Spark Plug | Crucial for ignition; should be replaced periodically to prevent starting issues. |

| Fuel Filter | Helps keep fuel clean and free from contaminants, ensuring efficient operation. |

| Blades | Worn blades can lead to poor cutting performance; regular replacement is advisable. |

| Belt | Transfers power from the engine to the blades; check for signs of wear or damage. |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of outdoor equipment requires regular attention and care. Adopting effective maintenance practices not only prolongs the lifespan of your machinery but also enhances its efficiency. Here are some essential tips to keep your equipment in top condition.

Routine Checks

- Inspect all components for wear and tear regularly.

- Ensure that all fasteners are secure and not corroded.

- Check fluid levels and replenish as needed.

- Look for signs of leakage in hoses and seals.

Cleaning and Storage

- Clean the equipment after each use to remove dirt and debris.

- Store in a dry, sheltered location to prevent rust and damage.

- Cover equipment with protective tarps when not in use.

By following these simple yet effective maintenance strategies, you can ensure that your machinery remains reliable and efficient for years to come.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining optimal performance and longevity. Using original items ensures compatibility and reliability, reducing the risk of damage and inefficiency.

Authorized Dealers

One of the best options is to visit authorized dealers. They offer a wide selection of genuine items and can provide expert advice tailored to your needs.

Online Retailers

Many reputable online platforms specialize in authentic replacements. Ensure that you verify the seller’s credibility and check customer reviews to guarantee a satisfactory purchase experience.

Aftermarket Parts vs. OEM Parts

The choice between alternative components and original manufacturer offerings can significantly impact performance and longevity. Understanding the distinctions helps consumers make informed decisions, balancing cost, quality, and compatibility.

Quality and Performance

Original parts are crafted to meet specific standards, ensuring optimal functionality. In contrast, alternatives can vary widely in quality, with some providing comparable performance while others may fall short. Investing in reliable alternatives can yield substantial savings without sacrificing efficiency.

Cost Considerations

While original components often come at a premium, alternatives typically offer a budget-friendly solution. However, the lower price of aftermarket options may sometimes lead to increased maintenance costs if quality is compromised. Evaluating the long-term value is essential for making the ultimate choice.

Troubleshooting Common Issues

When operating machinery, encountering problems is not uncommon. Understanding the frequent challenges can help users quickly identify and resolve them, ensuring smooth performance and longevity of the equipment.

Starting Difficulties

If your machine refuses to start, check the fuel level and ensure the spark plug is functioning properly. A clogged air filter may also hinder ignition, so regular maintenance is essential.

Uneven Performance

For issues related to inconsistent operation, inspect the cutting blade for damage or dullness. Additionally, ensure that the drive system is clear of debris, as this can affect overall efficiency. Regular inspections can help prevent these problems from escalating.

Safety Precautions During Repairs

When undertaking maintenance or repair work, prioritizing safety is essential to prevent accidents and injuries. Ensuring a secure environment and using appropriate protective measures can make a significant difference in the overall experience. This section outlines key precautions to consider while performing any mechanical tasks.

Personal Protective Equipment

Utilizing the right personal protective equipment (PPE) is crucial. Always wear gloves to protect your hands from sharp edges and hazardous materials. Safety goggles should be worn to shield your eyes from debris and dust. Additionally, employing sturdy footwear can prevent injuries from falling objects or heavy tools.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Ensure that your area is free of clutter and that tools are stored safely when not in use. Adequate lighting can also reduce the risk of accidents. Be aware of your surroundings and avoid distractions to stay focused on the task at hand. In case of any hazardous materials, proper ventilation and storage are necessary to ensure a safe working atmosphere.

Resources for Husqvarna Enthusiasts

For those passionate about outdoor power equipment, finding reliable information and tools can enhance your experience significantly. This section provides a curated list of valuable resources to support maintenance, repairs, and community engagement.

- Official Manuals: Access comprehensive guides to understand your machine better.

- Online Forums: Join discussions with fellow enthusiasts to share tips and tricks.

- YouTube Channels: Explore tutorials for hands-on guidance on various models.

- Parts Retailers: Discover trusted suppliers for high-quality replacements.

- Local Clubs: Engage with nearby communities for events and meetups.

Utilizing these resources can ultimately deepen your knowledge and enjoyment of your equipment.