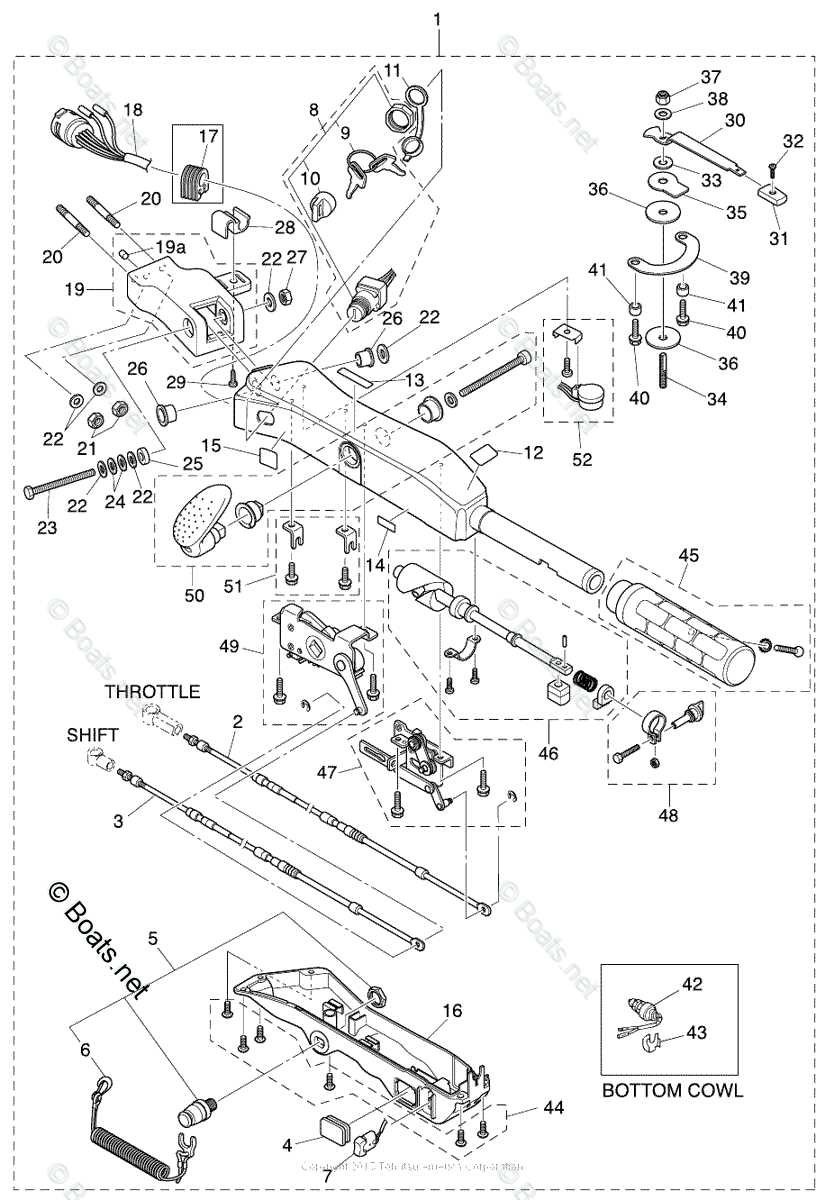

When it comes to maintaining and repairing a vehicle, having a clear understanding of its key components is crucial. The various elements that drive the vehicle forward work together in harmony, allowing for efficient performance and reliable operation. Identifying and visualizing these components can greatly assist in troubleshooting and enhancing overall functionality.

Each component serves a specific purpose in ensuring smooth operation, and being able to identify the intricate connections between these elements allows for better maintenance and repairs. Whether you’re a professional mechanic or an enthusiastic hobbyist, familiarizing yourself with the structure and layout of these elements can make a significant difference.

By delving deeper into the design and placement of these critical components, you can gain insights into how the entire system functions, providing you with a better grasp on improving performance, diagnosing issues, and ensuring longevity.

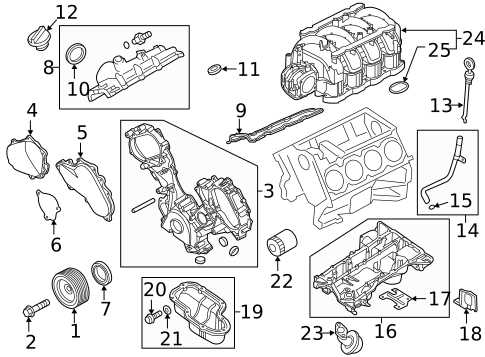

Nissan Engine Components Overview

The internal structure of a modern powertrain system is a highly complex assembly of interconnected parts, each serving a unique function to ensure optimal performance. Understanding the key elements involved can help improve maintenance, troubleshooting, and overall system longevity. This section provides a breakdown of the major components found in most automotive power units.

Key Mechanical Elements

Several critical mechanical components work together to convert fuel into motion. Below is a list of the main structural elements and their functions:

| Component | Function | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block | The core framework where other essential elements are mounted and aligned. | |||||||||||||||||||||||||||||||||||||

| Piston | Responsible for transferring the force of combustion

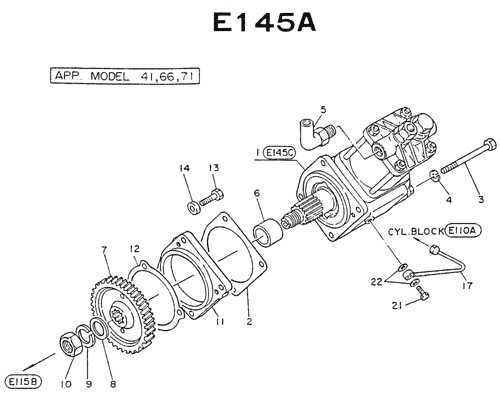

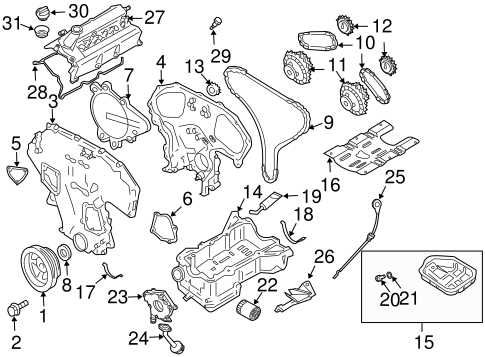

Key Elements in Nissan Engine Diagrams

Understanding the components within a vehicle’s core mechanical system is essential for maintaining and optimizing performance. Diagrams offer a visual breakdown of crucial elements, helping to identify and locate important components. Each part plays a significant role in ensuring the smooth operation of the system, and a clear representation allows for easier troubleshooting and repairs. Below is an overview of the major components often highlighted in mechanical system schematics, detailing their function and importance:

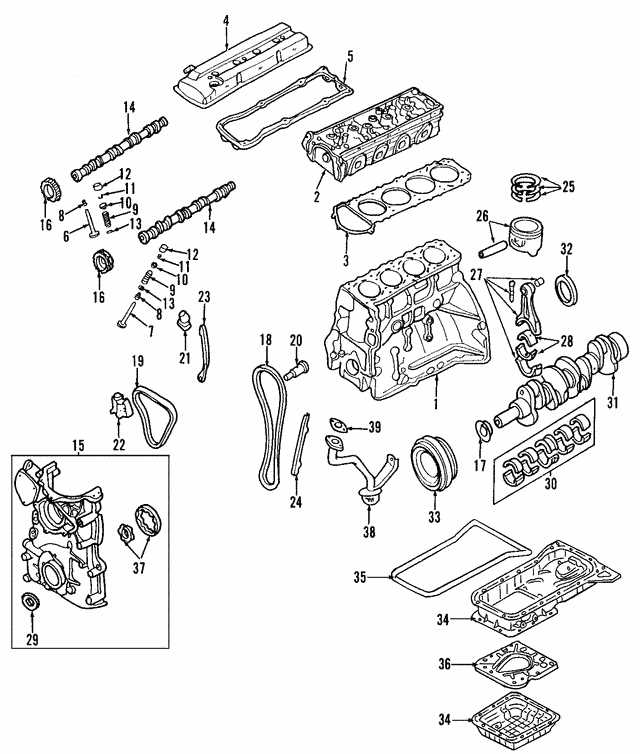

Valve Arrangement and Mechanisms

The arrangement and functioning of the valve system play a crucial role in optimizing the performance of a vehicle’s power unit. This intricate setup regulates the flow of air and fuel into the combustion chamber while also allowing exhaust gases to escape. Understanding how these mechanisms operate is essential for ensuring efficiency and longevity in automotive applications. Types of Valve ArrangementsVarious configurations exist for these components, each designed to enhance specific performance characteristics. Common types include overhead valves (OHV), overhead cam (OHC), and dual overhead cam (DOHC) setups. The choice of arrangement impacts not only the efficiency of airflow but also the overall responsiveness and power output of the power unit. Mechanisms in ActionThe operational mechanisms of the valve system include various components such as lifters, pushrods, and rocker arms. These elements work in unison to open and close the valves at precise intervals, synchronized with the crankshaft’s rotation. Advanced designs may incorporate variable valve timing (VVT) systems, which further optimize performance by adjusting the timing of valve events based on engine conditions, thereby enhancing fuel efficiency and reducing emissions. In summary, the arrangement and mechanisms governing the valve system are pivotal for achieving optimal performance and efficiency in modern vehicles. A comprehensive understanding of these elements allows for better diagnostics and improvements in vehicular technology. Oil Pump and Lubrication System in Nissan EnginesThe efficiency of a vehicle’s performance heavily relies on its ability to maintain proper lubrication throughout its components. The mechanism responsible for circulating oil plays a crucial role in ensuring smooth operation, minimizing wear and tear, and enhancing overall reliability. This system works seamlessly to provide adequate lubrication to various moving elements, thus preventing friction and overheating. The oil pump serves as the heart of the lubrication system, drawing oil from the reservoir and pushing it through the channels to critical areas. Its design typically features a positive displacement mechanism, ensuring a consistent flow of lubricant under various operating conditions. This ensures that all moving parts receive the necessary amount of oil, regardless of the speed or load conditions. Additionally, the lubrication system includes components such as filters and coolers, which contribute to maintaining the quality and temperature of the oil. The filters remove contaminants that may accumulate, while coolers help in dissipating excess heat, thereby preserving the lubricant’s effectiveness. Overall, a well-functioning lubrication system is essential for the longevity and performance of any automotive mechanism. Regular maintenance, including oil changes and inspections, can significantly enhance the durability and efficiency of this critical system. Nissan Fuel Injection System Components

The fuel injection system plays a crucial role in optimizing the performance and efficiency of modern vehicles. It is designed to deliver the right amount of fuel to the combustion chamber, ensuring that the air-fuel mixture is precise for effective combustion. Understanding the key components involved in this system can help in diagnosing issues and enhancing overall vehicle performance.

Each of these components works together seamlessly to ensure optimal combustion and efficiency. Regular maintenance and understanding of these elements can significantly impact the longevity and performance of the vehicle. Exploring the Cooling System in Nissan EnginesThe cooling mechanism is a crucial component of any vehicle’s performance and longevity. It plays an essential role in maintaining optimal operating temperatures, preventing overheating, and ensuring efficient functionality. Understanding this system is vital for any automotive enthusiast or technician aiming to enhance vehicle reliability and performance. Key Components of the Cooling Mechanism

Importance of MaintenanceRegular upkeep of the cooling system is essential for preventing malfunctions. Neglecting this aspect can lead to overheating, which may cause severe damage to critical components. Key maintenance practices include:

Timing Chain and Belt Assembly in Nissan MotorsThe timing mechanism plays a crucial role in ensuring the synchronized operation of various components within the power unit. This assembly, consisting of either a chain or a belt, is vital for maintaining the precise timing necessary for optimal performance. Understanding its functionality and construction can help in diagnosing issues and performing maintenance effectively. There are two primary types of timing mechanisms commonly used: chains and belts. Each type has its advantages and disadvantages:

Regular maintenance of this assembly is essential to prevent severe mechanical failures. It is advisable to follow the manufacturer’s recommended service intervals and perform inspections periodically. Key signs of wear or failure may include:

In conclusion, understanding the construction and maintenance of the timing chain and belt assembly is crucial for ensuring longevity and performance. Whether utilizing a chain or a belt, timely servicing can prevent extensive damage and enhance overall reliability. Nissan Exhaust System Parts and DiagramThe exhaust system plays a crucial role in vehicle performance by channeling harmful gases away from the combustion chamber and minimizing emissions. Understanding the components involved is essential for effective maintenance and upgrades. Key components of the exhaust system include:

Each of these elements is interconnected, ensuring that exhaust gases are managed effectively and efficiently. Proper understanding and maintenance of these components can lead to improved vehicle performance and longevity. Common Issues with Nissan Engine Parts

Various challenges can arise in the mechanical components of vehicles, often leading to performance degradation or complete failure. Understanding these frequent complications can aid in timely maintenance and repair, ultimately extending the lifespan of the vehicle. Frequent ComplicationsCommon problems include wear and tear, oil leaks, and overheating. These issues can stem from a variety of factors such as age, lack of maintenance, and manufacturing defects. Recognizing the signs of these complications early can prevent further damage and costly repairs. Identifying ProblemsIt is crucial to be aware of symptoms that may indicate underlying issues. Regular inspections and proper care can help maintain optimal functioning and reliability.

|