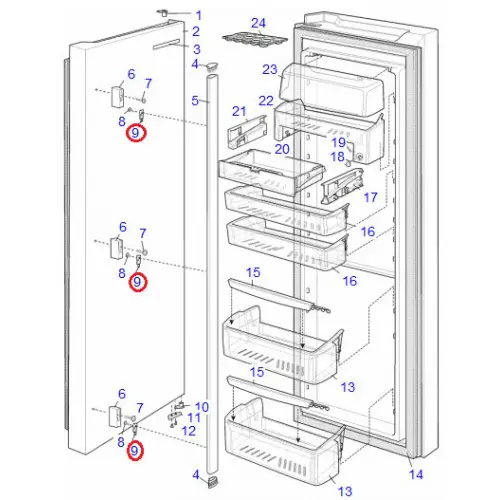

The internal structure of cooling devices consists of various interconnected elements, each designed to perform a specific function within the system. From regulating temperature to ensuring optimal energy consumption, these components work together to create an efficient cooling process. It is essential to recognize how these elements are arranged to understand the functionality of the entire system.

By exploring the assembly of cooling units, one can gain valuable insight into their operation. Each segment, from compressors to temperature sensors, contributes to maintaining the desired environment within the appliance. Knowing how these segments fit together will not only aid in troubleshooting but also provide clarity when looking to upgrade or maintain your equipment.

Overview of Westinghouse Appliance Components

Understanding the structure and functionality of various elements in modern household devices is essential for their maintenance and repair. These components work together to ensure efficient operation, each playing a specific role in the system. In this section, we will explore the primary elements found in common home appliances, highlighting their function and contribution to overall performance.

- Cooling Mechanism: The heart of any appliance responsible for temperature regulation, ensuring that items are stored at the desired conditions.

- Control Unit: This module manages the operation, providing users with the ability to adjust settings and monitor performance.

- Sealing Elements: Vital for maintaining internal conditions, these components help to prevent external air or contaminants from affecting the internal environment.

Main Cooling System Elements

The cooling mechanism is essential for maintaining a steady and safe environment inside. It operates by regulating the flow of cold air and ensuring the right balance of temperature. The components responsible for this function are intricately connected, working in harmony to deliver optimal cooling performance.

Compressor plays a key role in circulating the refrigerant through the system. It compresses the refrigerant, increasing its pressure and enabling the heat exchange process.

Condenser coils are responsible for dissipating the absorbed heat. They allow the refrigerant to cool down by releasing heat to the surrounding air.

Evaporator coils perform the crucial task of cooling the air inside by absorbing heat. As the refrigerant evaporates, it removes heat from the surrounding air, lowering the internal temperature.

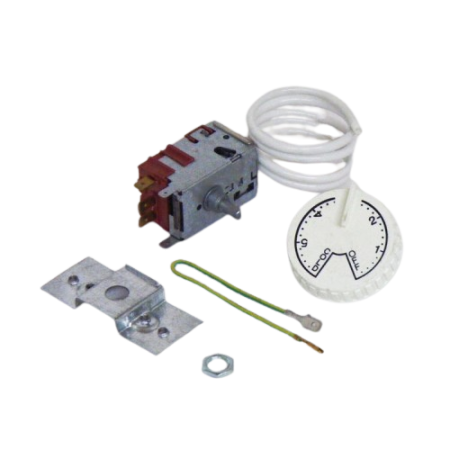

Thermostat

Understanding Electrical Wiring in Refrigerators

The electrical system inside cooling appliances plays a vital role in their operation, ensuring proper power distribution and functionality. Understanding how these circuits are arranged and function can help diagnose issues or maintain the device’s performance over time. Electrical connections link critical components, providing energy to cooling mechanisms, sensors, and control panels.

Power Distribution and Components

At the heart of the wiring network is the power supply, which feeds electricity to the appliance’s motor and compressor. These components drive the cooling cycle, ensuring the interior maintains the right temperature. Electrical paths connect various control systems, which manage the compressor’s cycles, fan operation, and temperature regulation.

Wiring Safety and Maintenance

Maintaining the wiring in good condition is essential for safe operation. Frayed wires or loose connections can lead to malfunctions or even hazards. Regular inspection and ensuring proper insulation around wires help in avoiding any electrical failures. For more intricate repairs, it’s recommended to consult a professional.

Compressor and Its Key Functions

The heart of a cooling system, the compressor plays a vital role in maintaining optimal temperature levels. It is responsible for circulating a special gas within the cooling system, ensuring efficient heat exchange. By compressing and decompressing the gas, this component helps manage thermal conditions, contributing to the overall efficiency of the system.

A key function of this mechanism is to convert low-pressure gas into high-pressure gas, which enhances the cooling cycle. This process is essential in achieving the desired environment within the appliance, as it ensures that warm air is expelled, keeping the system operational and energy-efficient.

In addition, the compressor also regulates the system’s performance by controlling the pressure and temperature. Its proper functioning is crucial for maintaining a consistent

Identifying Temperature Control Mechanisms

Effective regulation of internal cooling systems relies on specific components designed to maintain a stable climate within. These mechanisms ensure that the desired level of cooling is achieved by responding to environmental factors and user settings. Recognizing the key elements responsible for controlling the temperature is essential for both troubleshooting and optimizing performance.

The main control systems typically include sensors and adjustment devices, which work in tandem to monitor and adjust conditions. Understanding their placement and function can help pinpoint any issues and allow for precise modifications when necessary. Learning about these mechanisms can also provide insight into maintaining consistent efficiency over time.

Evaporator Coil Placement and Role

The positioning of the evaporator coil is crucial for the efficient functioning of a cooling system. It serves as a vital component that plays a significant role in the heat exchange process, facilitating the removal of warmth from the interior environment. Understanding its placement helps in maintaining optimal performance and energy efficiency.

Location and Installation

The evaporator coil is typically located within the interior compartment, often concealed behind panels. This strategic placement ensures that air can circulate freely around the coil, enhancing its ability to absorb heat. Proper installation is essential, as incorrect positioning can lead to inefficient cooling and increased energy consumption.

Functionality and Importance

As the main site for heat absorption, the evaporator coil transforms liquid refrigerant into gas, effectively lowering the temperature inside the compartment. This process is crucial for maintaining the desired cooling levels. Additionally, regular maintenance of the coil can prevent frost buildup, ensuring consistent airflow and prolonging the lifespan of the entire cooling system. Understanding this component’s role is key to achieving effective cooling solutions.

Water Dispenser Parts Explained

This section delves into the essential components involved in the operation of a water dispensing system. Understanding these elements can help users maintain functionality and troubleshoot issues effectively.

Below are the key components commonly found in these systems:

- Water Reservoir: This is the chamber that holds the water before it is dispensed. It plays a crucial role in ensuring a steady supply.

- Dispensing Mechanism: This includes levers or buttons that activate the flow of water when pressed, allowing for easy access.

- Water Filter: A vital component that purifies the water, removing impurities and enhancing taste.

- Hoses: Flexible tubes that transport water from the reservoir to the dispensing outlet.

- Control Valve: This regulates the flow of water, ensuring the desired amount is dispensed when needed.

- Ice Maker Connection: In some systems, a linkage to an ice-making unit that uses the same water source for ice production.

Maintaining these components is essential for optimal performance. Regular cleaning and timely replacement of worn parts can prevent malfunctions and enhance the longevity of the system.

How Defrost Systems Operate

Defrost mechanisms are essential components in maintaining optimal conditions within cooling appliances. They prevent the accumulation of frost and ice, ensuring efficient performance and energy consumption. These systems utilize various technologies to regulate temperature and manage moisture, contributing to the longevity and functionality of the unit.

Types of Defrost Mechanisms

- Automatic Defrost: This system activates periodically to melt ice buildup, utilizing heating elements that warm the evaporator coils.

- Manual Defrost: Requires user intervention to remove ice, often through unplugging the unit or using heat sources.

- Frost-Free Technology: Combines fan circulation and temperature control to minimize frost accumulation, promoting even cooling.

Operation Process

- When the temperature within the cooling compartment drops below a specific threshold, the defrost system activates.

- Heating elements warm the evaporator coils, causing any accumulated ice to melt.

- Water from the melted ice drains through a designated outlet, preventing re-freezing.

- Once the temperature stabilizes, the system returns to normal cooling operation.

Door Seal Importance for Efficiency

The integrity of a closure mechanism is crucial for maintaining optimal temperature and energy consumption in any cooling unit. A well-functioning barrier not only prevents warm air from entering but also keeps cold air contained, thereby enhancing performance and efficiency. Understanding the significance of this component can lead to better energy savings and prolonged appliance lifespan.

Impact on Energy Consumption

An effective sealing system reduces the workload on the cooling system by minimizing temperature fluctuations. When the closure is compromised, it forces the unit to operate harder to maintain the desired conditions, leading to increased electricity usage and higher utility bills.

Signs of Wear and Tear

Regular inspections can help identify issues with the sealing mechanism. Common signs of deterioration include visible cracks, tears, or gaps that can compromise its effectiveness. Addressing these problems promptly can ensure continued efficiency.

Issue Impact Solution Cracks or tears Increased air leakage Replace the seal Gaps in closure Higher energy bills Adjust or realign the door Discoloration Reduced insulation properties Inspect for replacement Fan Motor and Air Circulation Process

The efficiency of cooling systems relies heavily on the functionality of the airflow mechanism. At the heart of this mechanism lies a vital component that plays a significant role in regulating temperature and ensuring consistent circulation throughout the appliance. This section delves into the operation of the airflow generator and its importance in maintaining optimal conditions for stored items.

The fan motor is responsible for generating the necessary airflow within the unit. It operates by drawing air from the interior, passing it over cooling elements, and then redistributing it back into the space. This continuous cycle is crucial for preventing temperature fluctuations and ensuring that every corner receives adequate cool air.

During operation, the fan motor initiates the movement of air, which allows for an even distribution of temperatures. Air circulation not only aids in maintaining a stable environment but also helps in reducing energy consumption, as a well-ventilated interior requires less energy to maintain the desired temperature. Moreover, proper air movement helps to minimize the formation of frost and ice, enhancing overall efficiency.

Understanding the dynamics of the fan motor and air movement is essential for troubleshooting performance issues. Regular maintenance of these components ensures their reliability and longevity, leading to enhanced efficiency and improved performance of the cooling system.

Exploring the Ice Maker Assembly

The ice-making mechanism is a fascinating component within cooling appliances, designed to produce ice cubes efficiently. Understanding its functionality and construction can enhance maintenance and troubleshooting efforts. This assembly plays a crucial role in ensuring a steady supply of ice, making it an essential feature for many users.

Components of the Ice Maker Assembly

The ice-making unit typically consists of several key elements, including a water inlet valve, an ice mold, and a motor. The water inlet valve controls the flow of water into the ice mold, where it freezes and forms cubes. The ice mold is designed to shape the water into cubes, while the motor drives the ejector mechanism, which releases the frozen cubes into the storage bin.

Functionality Overview

Initially, the water fills the mold, and as it freezes, the temperature drops significantly. Once the ice reaches the desired hardness, the motor activates, pushing the ejector arm to release the cubes. This process repeats automatically, ensuring a continuous supply of ice. Regular inspection of the components can prevent issues such as clogs or mechanical failures, thereby maintaining optimal performance.

Maintenance Tips

To ensure the longevity of the ice-making mechanism, routine maintenance is essential. Regularly checking the water inlet valve for clogs, cleaning the mold, and inspecting the motor for any signs of wear can help keep the unit running smoothly. Additionally, ensuring the appliance is kept at the correct temperature will enhance ice production efficiency.

Shelves and Storage Compartments Design

The arrangement and structure of shelving and storage areas play a crucial role in optimizing organization and accessibility within cooling appliances. These elements are designed to maximize usable space while accommodating various container sizes and shapes, enhancing user experience.

Effective design incorporates adjustable shelves that can be tailored to individual needs, allowing users to create custom configurations based on their storage requirements. Removable shelving facilitates easy cleaning and maintenance, ensuring hygiene is maintained effortlessly.

Storage compartments are often strategically placed to provide quick access to frequently used items, while deeper sections can house bulkier products. This thoughtful arrangement not only promotes efficiency but also minimizes food waste by making all items easily visible and accessible.

Materials used in shelf construction should be durable and resistant to spills and stains, contributing to longevity and ease of upkeep. Additionally, transparent or semi-transparent designs enhance visibility, allowing users to see contents at a glance.

In conclusion, well-designed shelving and storage compartments significantly enhance functionality, ensuring a streamlined and organized environment for all stored items.

Common Accessories and Attachments

When it comes to enhancing the functionality and convenience of kitchen appliances, various accessories and attachments play a crucial role. These components not only improve the overall efficiency of the equipment but also offer additional features that can cater to different needs. Understanding the common types available can help users make informed choices for their specific requirements.

Cooling Elements

Cooling elements are essential for maintaining optimal temperatures within the unit. These may include thermostats and temperature sensors, which regulate the internal climate to ensure food preservation. Additionally, various types of shelves can enhance storage capabilities, allowing for better organization of items.

Storage Solutions

Another important category involves storage solutions. This encompasses a variety of baskets and bins designed for different types of items, from fruits and vegetables to smaller packaged goods. Utilizing these accessories effectively can maximize available space and streamline access to frequently used items.