Exploring the intricacies of your machinery can significantly enhance its performance and longevity. Knowledge of the various elements and their functions is essential for effective maintenance and repair. This section aims to provide a comprehensive overview, ensuring that users can easily identify and manage the components crucial to their device’s operation.

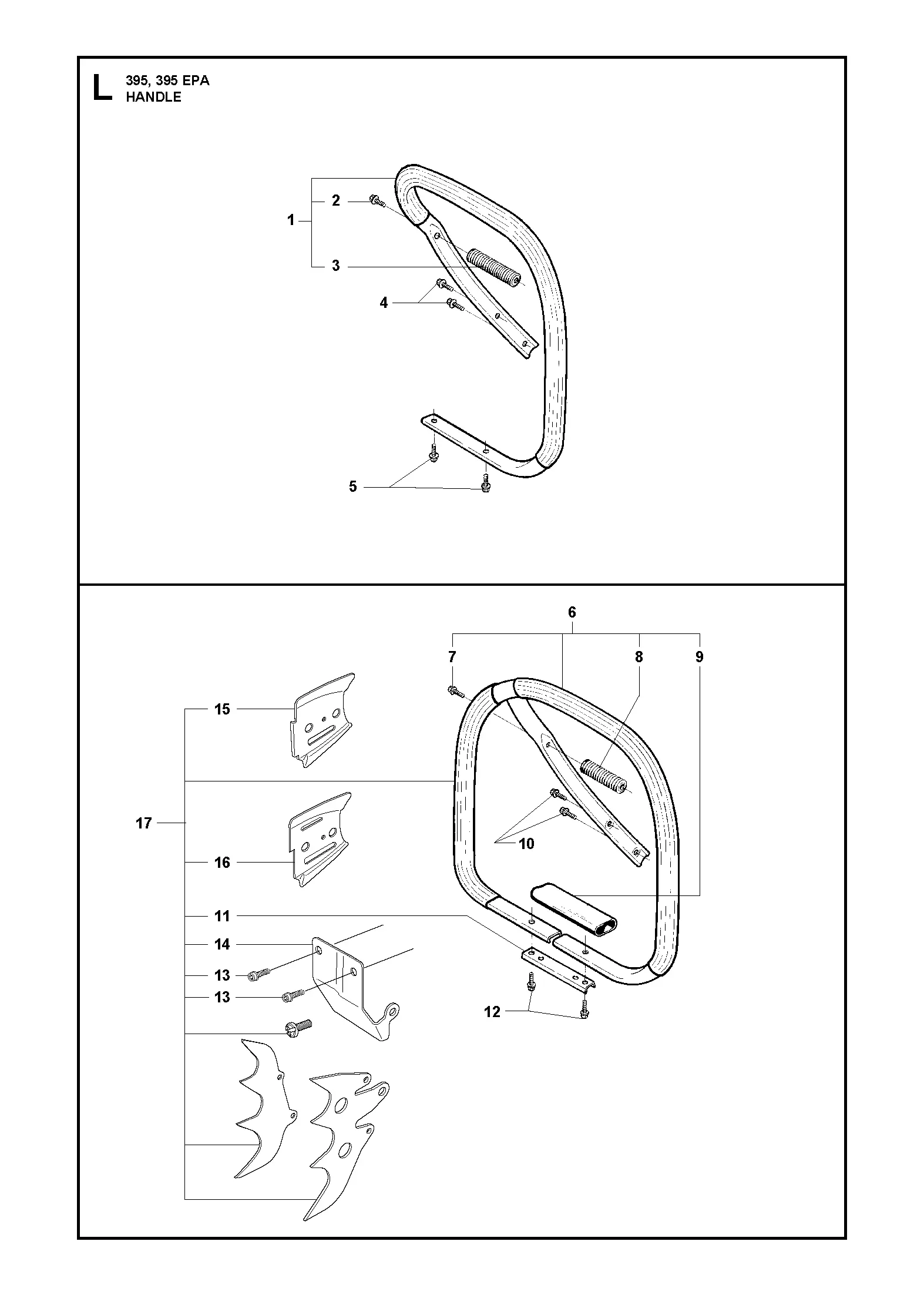

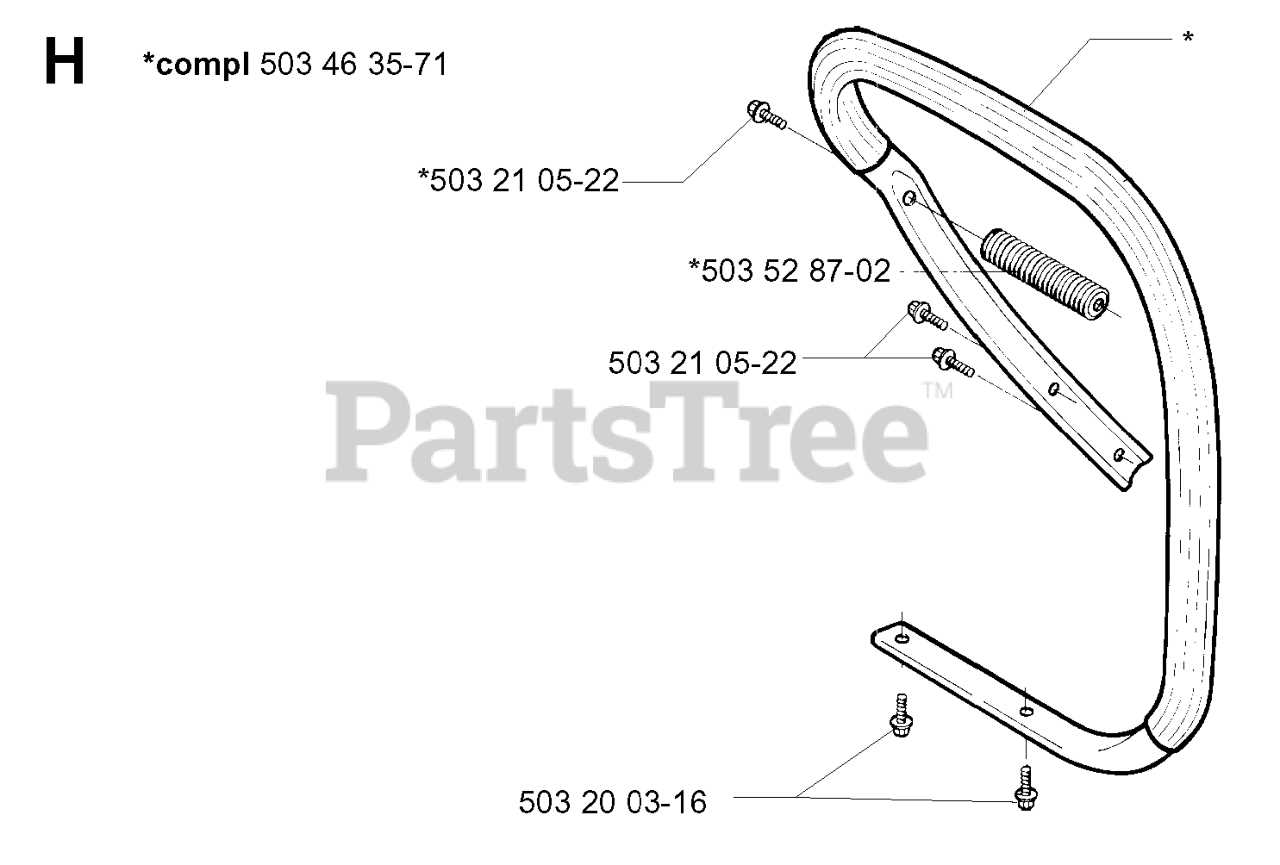

Identifying each piece of your equipment can seem daunting, but a clear representation of its construction can simplify the process. By breaking down the assembly into manageable segments, users gain the ability to troubleshoot issues effectively and optimize functionality. Understanding the layout fosters confidence in handling repairs and adjustments.

Whether you’re a seasoned professional or a novice, having access to detailed visual references enhances your ability to interact with the machinery. This guide serves as a valuable resource, paving the way for informed decisions and ultimately extending the life of your tools. Dive into the details and discover how each element plays a role in the overall performance of your equipment.

Understanding the Husqvarna 395 Parts Diagram

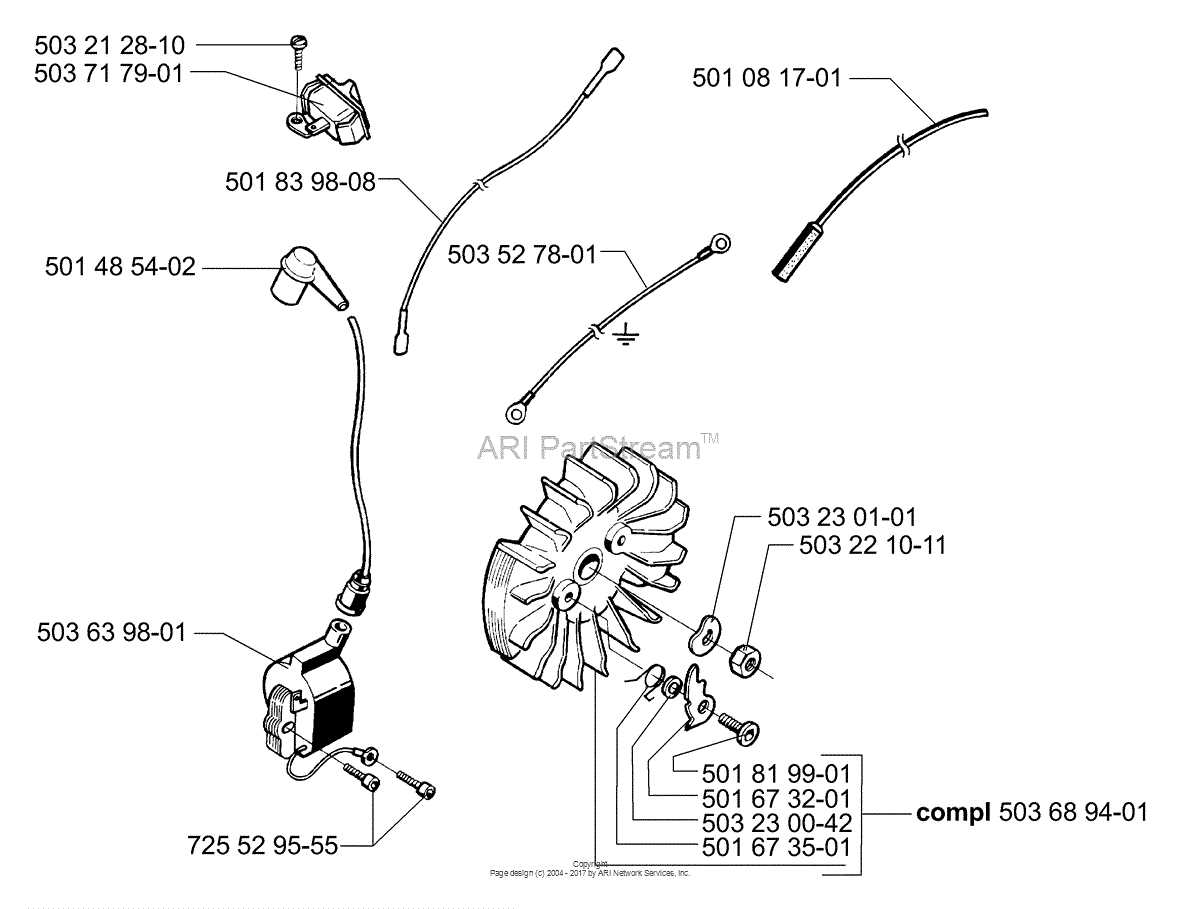

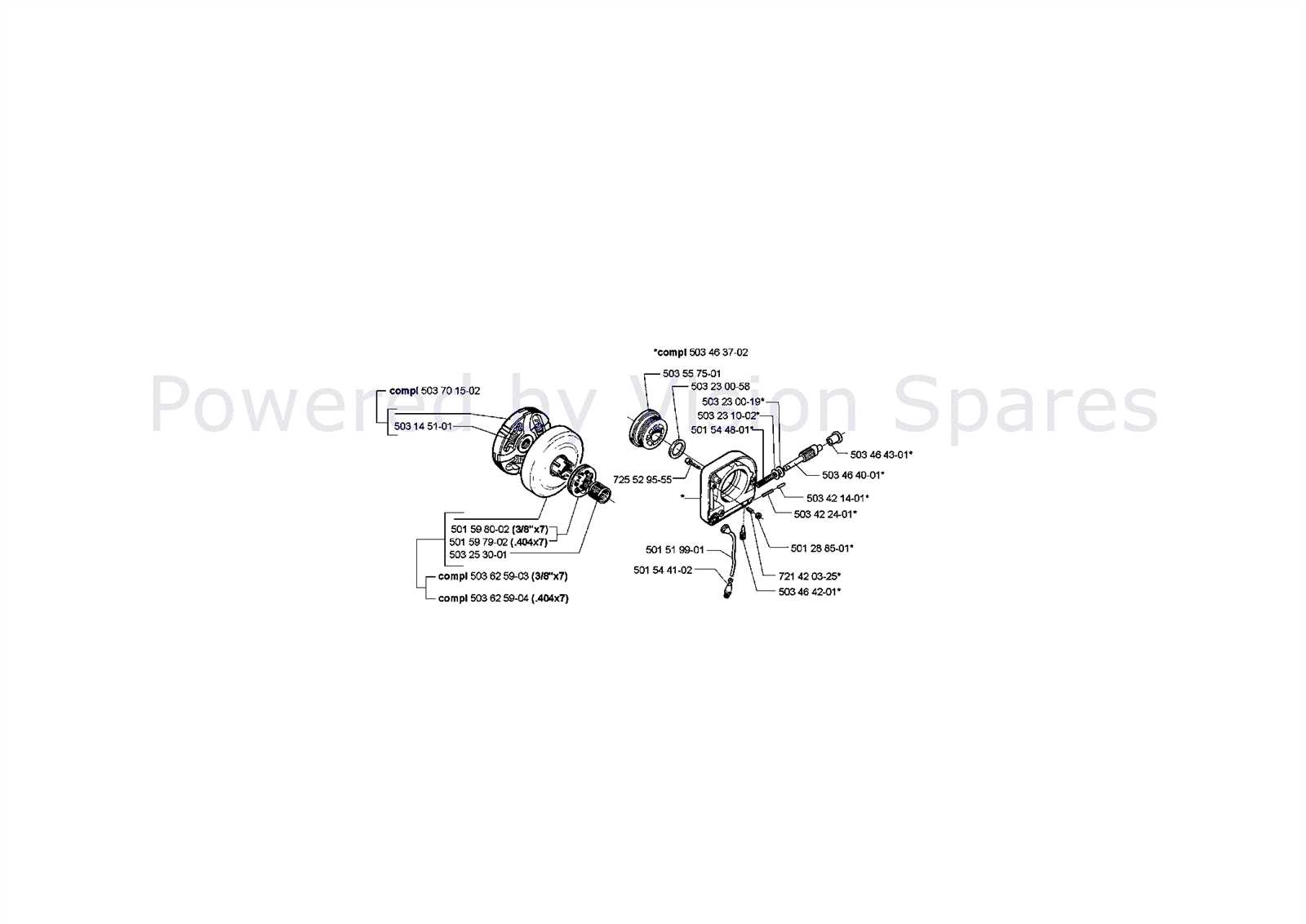

Comprehending the visual representation of components for machinery is crucial for effective maintenance and repairs. This illustration serves as a valuable tool for users, offering insights into how various elements interconnect and function together. Familiarity with these visuals not only enhances repair efficiency but also empowers operators to tackle issues with confidence.

Each section of the illustration highlights specific elements, making it easier to identify and locate parts when necessary. By studying this layout, users can develop a deeper understanding of the machinery’s overall design and operational mechanics, ultimately leading to more informed decisions during upkeep.

Utilizing this representation effectively can significantly reduce downtime and extend the lifespan of the equipment. Engaging with the details allows users to pinpoint potential problems and address them proactively, ensuring optimal performance at all times.

Key Components of the Husqvarna 395

This section highlights the essential elements of a powerful cutting tool designed for professional use. Understanding these components is crucial for maintaining optimal performance and ensuring longevity. Each part plays a specific role in the overall functionality, contributing to the efficiency and effectiveness of the equipment.

Core Elements

Among the primary parts, the engine stands out as the heart of the machine, providing the necessary power to tackle demanding tasks. Additionally, the cutting system is vital for achieving precise results, while the handle and control mechanisms ensure user comfort and safety during operation.

Maintenance and Upkeep

Regular inspection and maintenance of these components are essential for peak performance. Familiarity with each part allows for timely repairs and replacements, minimizing downtime and enhancing productivity.

| Component | Function |

|---|---|

| Engine | Generates power for cutting |

| Cutting System | Facilitates precise cutting |

| Handle | Ensures comfort and control |

| Fuel System | Delivers energy to the engine |

| Air Filter | Maintains clean airflow for combustion |

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair equipment. These illustrations offer a clear view of each element and its placement within the assembly, making it easier to identify what you need for replacements or upgrades.

To effectively interpret these visuals, follow a systematic approach. Start by identifying the main sections that categorize different components. This can often help you narrow down your search to specific areas of interest.

| Step | Description |

|---|---|

| 1 | Locate the key or legend, which explains symbols and numbers used in the illustration. |

| 2 | Examine the layout, noting how parts are arranged and their relationships to one another. |

| 3 | Identify specific components by referencing the key and correlating them with the physical unit. |

| 4 | Use the information to determine what replacements or enhancements are necessary. |

With practice, your ability to navigate these illustrations will become second nature, ultimately leading to more efficient repairs and maintenance.

Common Issues with Husqvarna 395 Parts

Understanding typical challenges associated with essential components can significantly enhance the performance and longevity of your machinery. Identifying these common issues helps in maintaining optimal functionality.

- Wear and Tear: Over time, frequent use can lead to deterioration of critical elements, resulting in reduced efficiency.

- Improper Installation: Incorrect assembly may cause misalignment, leading to operational failures.

- Fuel System Problems: Clogs in the fuel delivery system can result in engine stalling or poor performance.

- Electrical Failures: Wiring issues can hinder the ignition process, causing starting difficulties.

Addressing these issues promptly can prevent further complications and ensure the machine operates at its best.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Numerous resources are available to ensure you can quickly acquire what you need to keep your machinery in optimal condition.

Online Retailers

- Visit specialized websites that focus on outdoor equipment.

- Check major e-commerce platforms for a wide selection.

- Explore manufacturer websites for direct purchases.

Local Suppliers

- Find local hardware stores that stock components.

- Visit authorized dealers for expert advice and quality parts.

- Look into repair shops that may sell individual items.

By exploring these avenues, you can ensure a successful search for the necessary components to maintain your equipment efficiently.

Maintenance Tips for Husqvarna 395

Regular upkeep is essential for ensuring the longevity and performance of your outdoor equipment. Implementing a consistent maintenance routine not only enhances efficiency but also minimizes the risk of unexpected failures. Here are some key practices to keep your machinery in top condition.

Check and Clean Air Filters: Regularly inspect air filters to prevent debris buildup. Clean or replace them as necessary to maintain optimal airflow and engine performance.

Inspect the Spark Plug: Examine the spark plug for wear and carbon buildup. Replacing it periodically can improve ignition and overall operation.

Lubricate Moving Parts: Ensure that all moving components are adequately lubricated to reduce friction and wear. Use the recommended lubricant for best results.

Sharpen Blades Regularly: Keep blades sharp for effective cutting. Dull blades can strain the engine and reduce efficiency, so sharpen them frequently.

Monitor Fuel Quality: Use fresh fuel and store it properly. Stale fuel can lead to starting issues and engine performance problems.

Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance schedules and recommended practices to ensure proper care of your equipment.

Tools Required for Parts Replacement

Replacing components in machinery requires a specific set of instruments to ensure efficiency and safety. Having the right tools at hand not only simplifies the process but also minimizes the risk of damage to the equipment. Below is an overview of essential implements necessary for a successful replacement task.

Essential Tools

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Necessary for removing and securing screws in various components. |

| Socket Set | Provides a variety of socket sizes for different fasteners. |

| Pliers | Useful for gripping and manipulating small parts. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

Additional Considerations

In addition to basic tools, it may be beneficial to have specialized equipment such as a parts cleaner or a multimeter for more complex repairs. Always ensure that your workspace is organized and well-lit to facilitate the replacement process effectively.

Upgrades for Husqvarna 395 Performance

Enhancing the efficiency and power of your cutting tool can significantly improve your experience and productivity. Various modifications can be implemented to maximize output, ensure better handling, and extend the life of your equipment. By focusing on key components and optimizing performance, you can achieve impressive results.

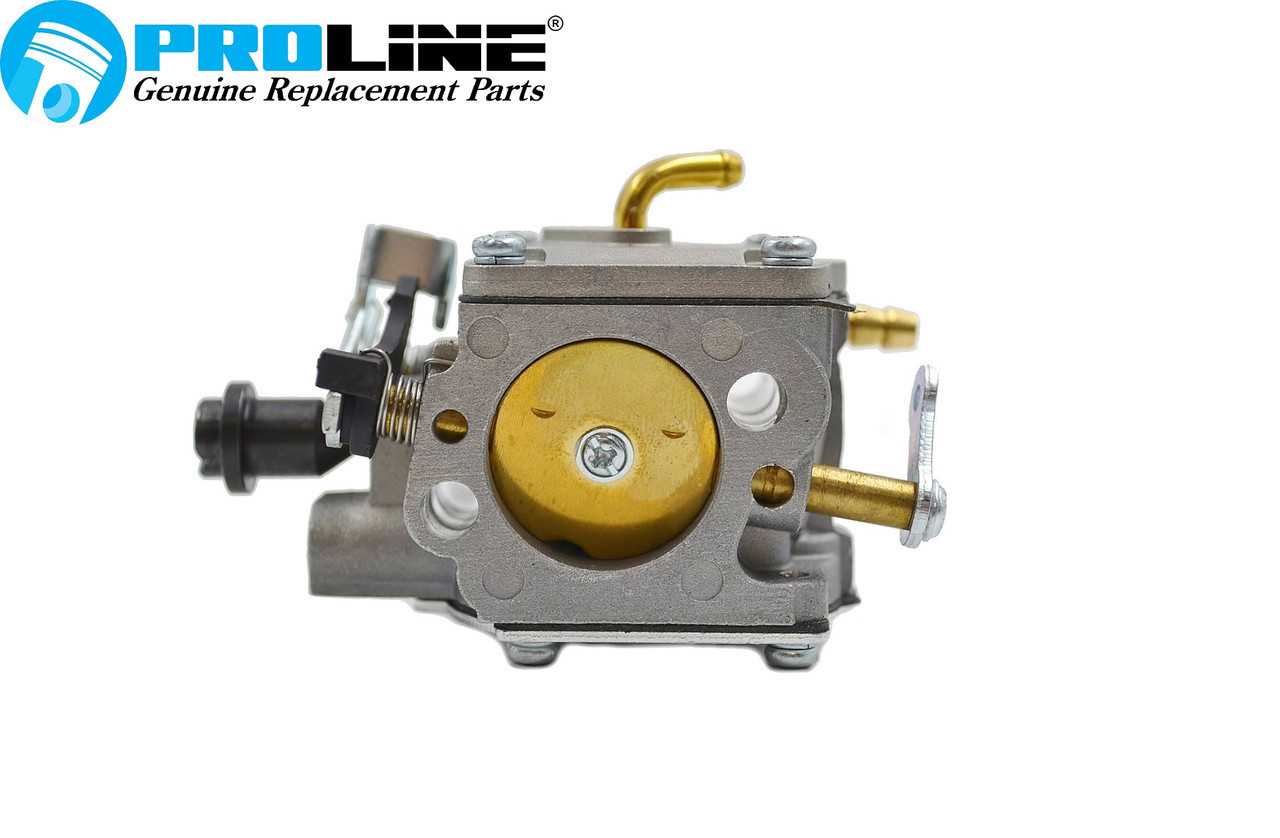

Engine Modifications

One of the most effective ways to boost performance is through engine enhancements. Consider upgrading the carburetor for better fuel delivery, or installing a high-performance air filter to increase airflow. Additionally, fine-tuning the ignition system can lead to improved combustion efficiency, resulting in more power and better fuel economy.

Cutting Equipment Improvements

Investing in quality cutting equipment can also yield noticeable benefits. Upgrading to a sharper, more durable chain can enhance cutting speed and precision. Furthermore, adjusting the bar length to suit your specific tasks can improve maneuverability and efficiency in various cutting scenarios.

Implementing these upgrades can transform your tool, making it more effective and enjoyable to use, while ultimately delivering superior results in your projects.

Exploring Aftermarket Parts Options

When it comes to enhancing the performance and longevity of your outdoor equipment, considering alternatives to original components can provide numerous benefits. Aftermarket solutions often offer a blend of affordability, availability, and quality, allowing users to customize their tools according to specific needs.

Benefits of Aftermarket Components

Opting for alternative parts can result in significant savings while maintaining, or even improving, functionality. Many aftermarket manufacturers focus on producing durable and high-performance replacements, making them a viable choice for enthusiasts and professionals alike.

Factors to Consider

Before purchasing alternative components, it’s essential to evaluate compatibility, quality, and warranty options. Ensuring that the replacements fit properly and meet performance standards will ultimately enhance your experience.

| Criteria | Aftermarket Option | OEM Option |

|---|---|---|

| Cost | Generally lower | Higher |

| Availability | Widely available | Limited |

| Performance | Variable, often improved | Consistent |

| Warranty | May vary | Standard warranty |

Benefits of Using Genuine Parts

Opting for authentic components significantly enhances the longevity and performance of your equipment. These original items are designed specifically for your machinery, ensuring a perfect fit and optimal functionality. While substitutes may seem appealing due to lower costs, they often lack the reliability and quality that genuine alternatives provide.

Quality Assurance

Original components undergo rigorous testing to meet high standards, ensuring that they function seamlessly with your machinery. This quality assurance reduces the risk of breakdowns and enhances overall efficiency.

Long-Term Savings

Investing in authentic parts can lead to substantial savings over time. While the initial cost may be higher, the durability and reliability of genuine components minimize the need for frequent replacements, ultimately proving to be more economical.

| Aspect | Genuine Components | Aftermarket Alternatives |

|---|---|---|

| Quality | High | Variable |

| Fit | Perfect | Often Inaccurate |

| Longevity | Extended | Shorter |

| Warranty | Included | Limited |

Frequently Asked Questions About Husqvarna 395

This section addresses common inquiries regarding a specific model of chainsaw, offering insights into its functionality, maintenance, and accessories. Users often seek clarity on various aspects to ensure optimal performance and longevity of their equipment.

| Question | Answer |

|---|---|

| What is the recommended fuel mixture for this chainsaw? | A mixture of 50:1 with high-quality two-stroke oil is advised for peak performance. |

| How often should I replace the air filter? | It’s best to check and replace the air filter every 10 to 20 hours of operation, depending on usage. |

| What are the signs that the chain needs sharpening? | Signs include slower cutting speed and increased effort to make cuts, indicating a dull chain. |

| Can I use aftermarket accessories? | While compatible aftermarket accessories can be used, it’s advisable to ensure they meet quality standards. |