When it comes to maintaining trees and large shrubs, having a reliable tool is essential. The design and functionality of these elongated implements can significantly impact their efficiency and ease of use. A thorough understanding of the various elements that make up such a tool can enhance the user experience and ensure optimal performance.

In this section, we will explore the essential features that contribute to the effectiveness of these gardening aids. By examining the individual components, we can uncover their roles and how they work in harmony to provide a seamless experience. From cutting mechanisms to extension systems, each part plays a crucial role in achieving the ultimate results.

Furthermore, grasping the interplay of these elements allows users to make informed decisions when selecting or maintaining their tools. Whether you’re a seasoned professional or an enthusiastic hobbyist, delving into the intricacies of these devices can elevate your gardening tasks to new heights.

Pole Pruner Overview

This section provides a comprehensive understanding of the tool designed for reaching and trimming branches high above the ground. It is essential for maintaining trees and shrubs, allowing for precise cutting without the need for ladders or scaffolding.

| Component | Description |

|---|---|

| Handle | Extends reach and provides control during operation. |

| Cutting Mechanism | Enables efficient and effective cutting of branches. |

| Blade | Designed for sharpness and durability to handle various wood types. |

| Safety Features | Includes mechanisms to prevent accidents during use. |

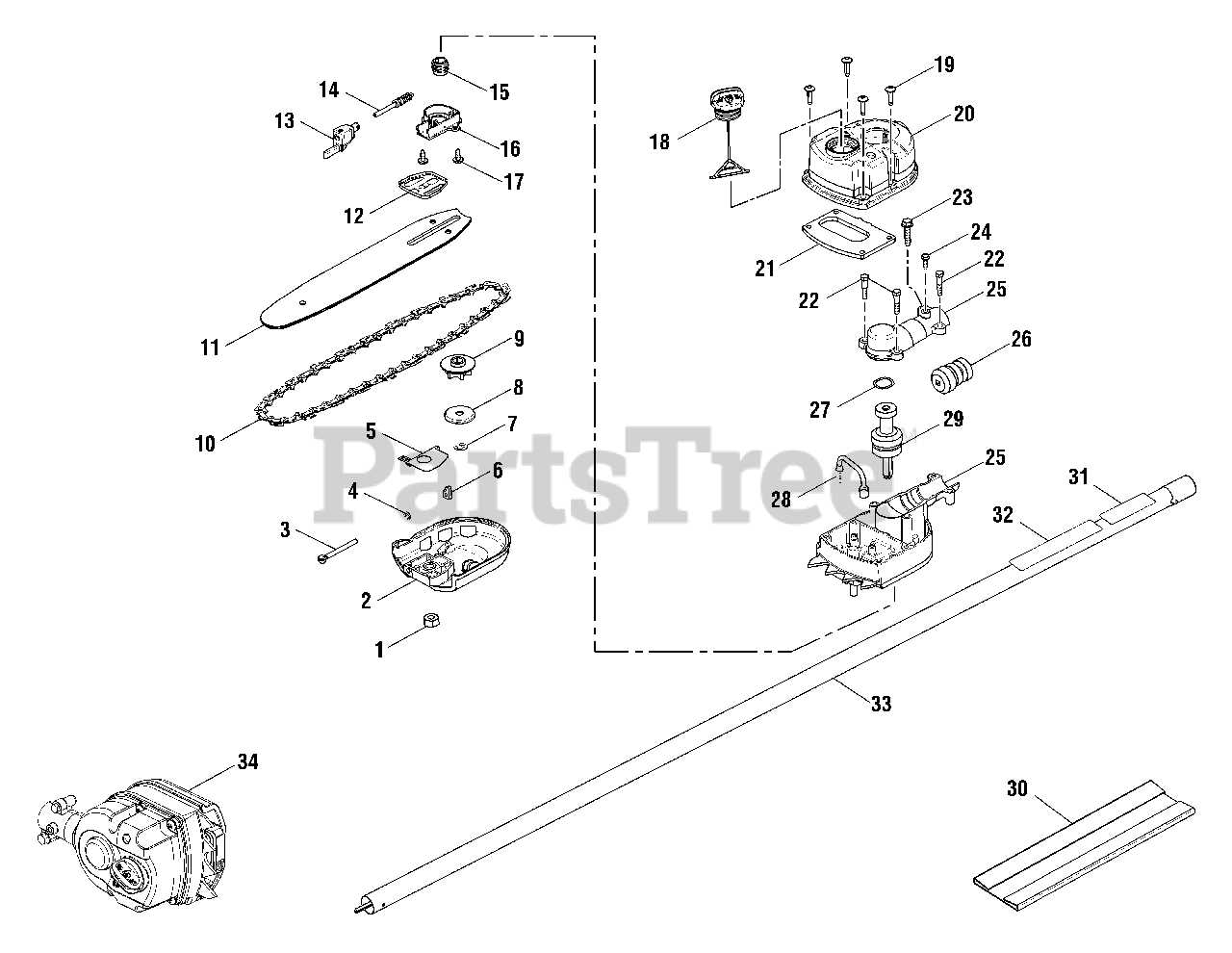

Components of a Pole Pruner

Understanding the key elements of this cutting tool is essential for proper maintenance and effective use. Various mechanical and structural components work together to ensure efficient trimming and cutting of tall branches. Each element plays a crucial role in delivering precision and power to the user.

Handle and Extension

The handle provides the user with a firm grip, ensuring control during use. The extension mechanism allows the tool to reach greater heights, often adjustable to fit the task at hand. This part is designed for stability and ease of operation.

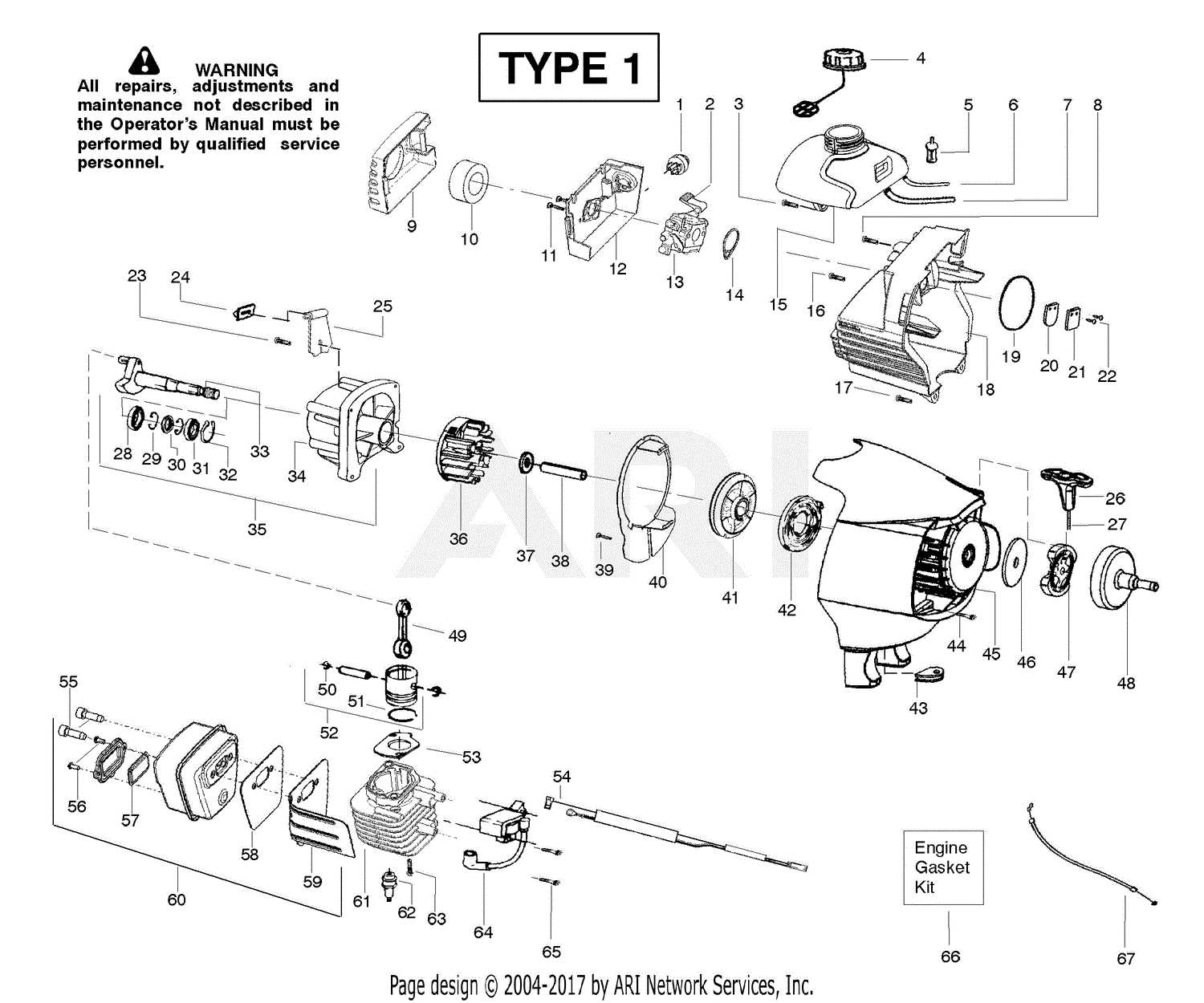

Cutting Mechanism

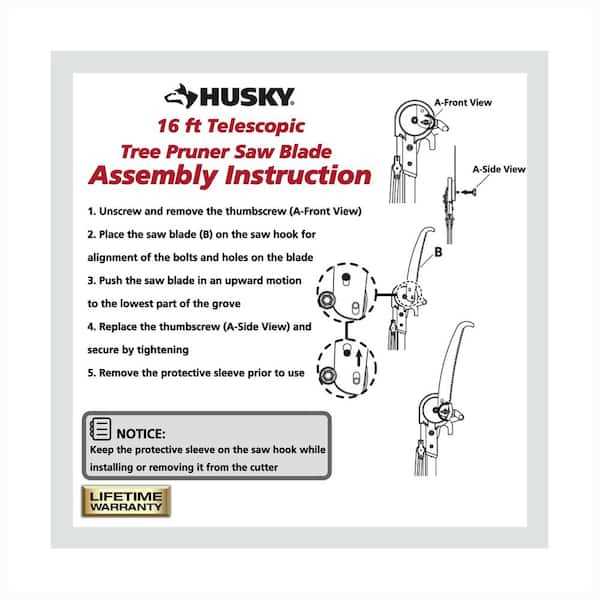

The cutting head includes sharp blades designed to prune branches with minimal effort. Whether manual or powered, the blades are made from durable materials, ensuring longevity and smooth cutting performance. Regular maintenance of this component is crucial for optimal efficiency.

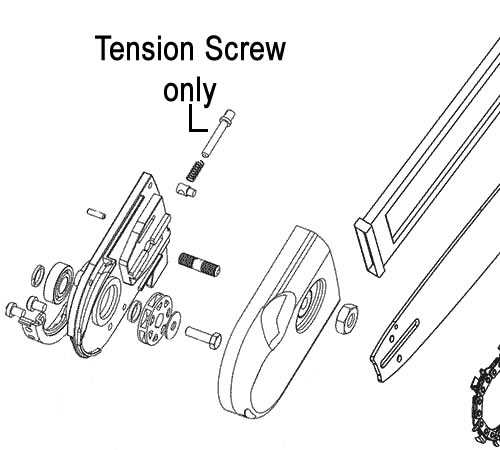

Understanding the Cutting Mechanism

The cutting system of these tools relies on a precise combination of components designed to trim branches with minimal effort. It operates through a synchronized action that ensures clean and efficient cuts, enabling users to maintain control and achieve desired results.

The cutting section consists of several important elements working together:

- Blade Assembly: The primary element responsible for slicing through the wood. It features sharp, durable edges capable of cutting through various types of branches.

- Lever System: This component transfers the user’s input into mechanical force, guiding the blade with optimal pressure for a smooth operation.

- Tension Adjustment: A mechanism that maintains the correct tension in the cutting system, ensuring consistent performance during extended use.

- Safety Lock: An additional feature designed to prevent accidental operation by securing the cutting mechanism when not in use.

By maintaining these key parts, the entire cutting process remains reliable and effective, ensuring longevity and ease of use.

Types of Pole Pruner Blades

When it comes to cutting tools designed for elevated branches, various blade options are available. The choice of blade directly affects the performance, efficiency, and precision of the task. Each type is crafted for specific functions and materials, ensuring clean cuts and longevity.

Bypass Blades

These blades operate similarly to scissors, providing a smooth, clean cut. Ideal for fresh and green wood, they are designed to minimize damage to the tree while offering excellent precision. The sharp edge slices through the branch, allowing for healthy growth.

Anvil Blades

Perfect for tougher, dead branches, this type of blade crushes through dry wood with ease. The design consists of a sharp edge meeting a flat surface, ensuring maximum force is applied to break harder materials. While not as precise as bypass options, they excel in heavy-duty tasks.

Adjustable Length Features Explained

Tools with adjustable extensions provide flexibility and convenience during various tasks. The ability to modify the size allows users to adapt to different heights and reach areas that would otherwise be difficult.

These extensions are designed with specific mechanisms that ensure easy adjustment while maintaining stability during use. Below are some key aspects of these features:

- Locking Mechanisms: Secure locks ensure that once the tool is extended, it remains firm and stable.

- Incremental Adjustments: Users can extend the tool to various lengths, offering precise control over reach.

- Lightweight Materials: Despite the added extension, these tools remain easy to handle due to the materials used in their construction.

- Compact Storage: Adjustable designs allow for easy storage when the tool is retracted to its shortest form.

These features enhance efficiency, making these tools suitable for a wide range of environments and applications.

Safety Mechanisms in Pole Pruners

Ensuring user protection is a key priority in the design of long-handled cutting tools. Modern equipment integrates multiple systems to prevent accidents and reduce potential hazards during operation. These features help maintain control and minimize the risk of injury while trimming high branches.

- Automatic chain brake: This system halts the cutting action immediately if sudden movement or force is detected, preventing further damage or injury.

- Anti-kickback guard: Reduces the likelihood of the tool being pushed back towards the user, especially when cutting dense or difficult wood.

- Grip-enhancing handles: Ergonomically designed grips allow for better control and reduce slippage during use, especially in wet conditions.

- Blade cover: When not in use, a protective sheath can be applied to the blade to prevent accidental cuts or contact.

- Lock-off button: This mechanism prevents the tool from being unintentionally started, adding an extra layer of security.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure your equipment functions smoothly over time. Consistent care helps prevent unnecessary wear and prolongs its lifespan. Keeping components clean, well-lubricated, and free from debris can make a significant difference in how long your tool remains in optimal condition.

Lubrication

One of the most crucial aspects of maintenance is ensuring that all moving parts are properly lubricated. This reduces friction, which in turn minimizes wear and tear on the internal mechanisms. Using the right oil or grease for your tool is key, and it should be applied regularly according to the manufacturer’s guidelines.

Inspection and Cleaning

Frequently inspecting your equipment for any signs of damage or wear is vital. Remove any dirt, sap, or debris that may accumulate after use, as this can negatively affect performance. If necessary, replace any worn-out components to maintain efficiency and safety.

Choosing the Right Tool for Tree Maintenance

Selecting the best equipment for maintaining trees and shrubs depends on several factors. The correct tool not only makes trimming easier but also ensures safety and efficiency during the process. Understanding your needs and the type of vegetation you’ll be working with is essential for making the right choice.

Key Features to Consider

- Blade quality: Opt for high-quality steel that remains sharp even after multiple uses.

- Length and reach: Choose the proper length for your height and the height of the branches you’ll be trimming.

- Weight and balance: Ensure the tool is lightweight enough for extended use without causing strain.

Additional Considerations

- Look for a tool with adjustable handles for better control and precision.

- Consider ergonomic designs that reduce the risk of fatigue and improve comfort during long tasks.

- Ensure replacement parts are easily accessible to prolong the lifespan of your equipment.

Common Problems and Solutions

When maintaining outdoor cutting equipment, various issues can arise during use, often related to the device’s functionality. Understanding the root causes and applying practical solutions can help ensure long-lasting performance and reduce downtime. Below are some common problems encountered and effective ways to resolve them.

| Problem | Possible Cause | Solution |

|---|---|---|

| Equipment not starting | Empty fuel tank or clogged air filter | Check fuel level and refill if necessary. Clean or replace the air filter. |

| Difficulty in cutting | Dull or damaged blade | Sharpen or replace the blade to ensure smooth operation. |

| Engine overheating | Insufficient lubrication or debris buildup | Ensure proper oil levels and remove any debris obstructing airflow. |

| Excessive vibration | Loose or unbalanced components | Tighten all fasteners and check for wear or damage in key components. |