In the realm of modern farming, the efficiency of machinery plays a pivotal role in enhancing productivity. A thorough understanding of the various components that make up these essential tools is crucial for optimal operation and maintenance. Farmers and technicians alike benefit from having access to detailed visual aids that illustrate the intricate relationships between different elements.

Comprehending these components not only simplifies repairs but also empowers operators to troubleshoot issues effectively. By delving into the specifics of each segment, one can ensure that the machinery performs at its ultimate best. Proper maintenance and familiarity with these illustrations can lead to prolonged equipment life and reduced downtime.

As we explore the intricate layouts and schematics related to these agricultural implements, it becomes clear that knowledge is an invaluable asset in the field. Whether you are a seasoned farmer or a newcomer, grasping the mechanics behind these machines will pave the way for greater efficiency and success in your farming endeavors.

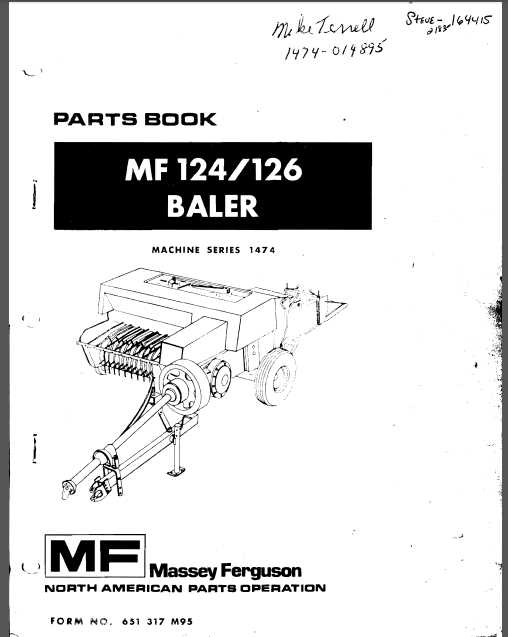

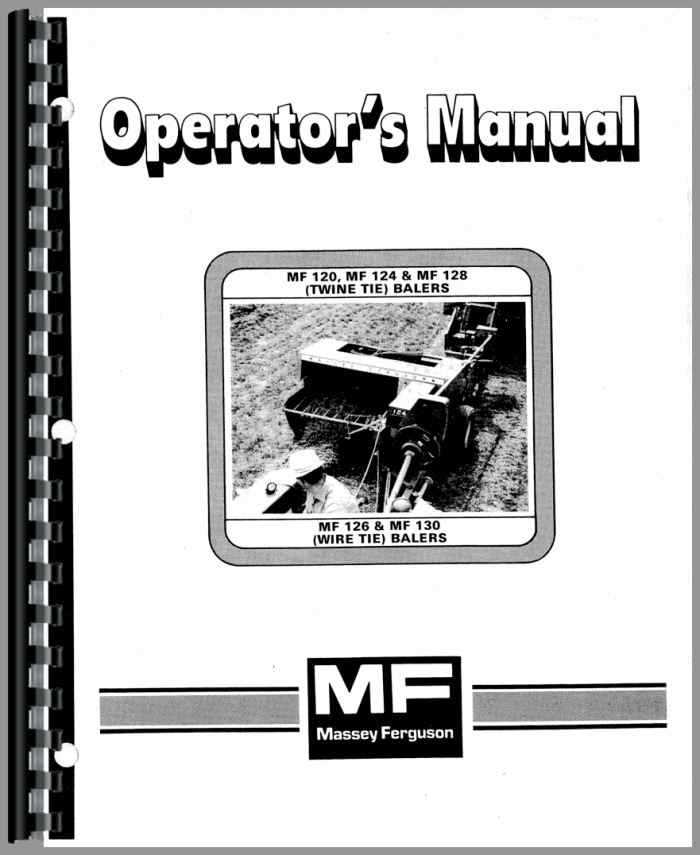

Massey Ferguson 124 Baler Overview

This section provides an insightful look into a widely used agricultural implement designed for hay and straw management. Renowned for its efficiency and reliability, this machinery plays a crucial role in the harvesting process, helping farmers streamline their operations and improve productivity.

The equipment is engineered to create compact and uniform bundles, which facilitate easier handling and storage. With its robust construction and user-friendly features, it caters to the diverse needs of modern farming practices. Its adaptability to various field conditions and crop types enhances its appeal among agricultural professionals.

Key components of this implement are meticulously designed to ensure optimal performance and longevity. Understanding the function of each element is essential for maintaining efficiency and minimizing downtime during operation. Regular maintenance and timely replacement of worn parts are vital for sustaining high productivity levels.

In summary, this agricultural tool stands out as a pivotal asset for farmers, offering a blend of durability, ease of use, and efficiency that significantly contributes to successful harvesting endeavors.

Key Features of the Baler

Understanding the essential characteristics of this agricultural machinery is crucial for optimizing its performance and efficiency in the field. This equipment is designed to streamline the process of collecting and compacting various types of crops, making it an invaluable tool for farmers.

One of the standout attributes is its robust construction, which ensures durability and reliability under challenging conditions. The machine’s high-capacity intake system allows for rapid collection of materials, significantly reducing operational time. Additionally, advanced compression mechanisms contribute to producing tightly packed bales, enhancing ease of handling and transport.

Another important feature is the adjustable settings, which enable operators to customize the density and size of the output based on specific requirements. This versatility makes it suitable for a wide range of agricultural applications. Furthermore, the inclusion of user-friendly controls and monitoring systems facilitates seamless operation, allowing for quick adjustments while on the move.

Finally, the incorporation of safety mechanisms is paramount, protecting both the operator and the machinery. With these features combined, this piece of equipment plays a pivotal role in modern farming practices, promoting efficiency and productivity.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations of components serve as invaluable resources, providing clarity and organization when addressing mechanical issues.

- Facilitates quick identification of components

- Enhances communication among technicians

- Streamlines the ordering process for replacements

- Improves efficiency during repairs and maintenance

Utilizing these illustrations helps ensure that every piece is correctly accounted for, ultimately reducing downtime and increasing productivity.

Common Parts and Their Functions

This section explores essential components commonly found in agricultural machinery, highlighting their roles and significance in ensuring optimal performance. Understanding these elements can enhance maintenance and troubleshooting efforts.

Feeding Mechanism: This system is crucial for guiding materials into the machine. It ensures a consistent flow, preventing jams and facilitating efficient processing.

Cutting Blade: The cutting blade is responsible for chopping crops to the desired length. Its sharpness directly influences the quality of the final output.

Compression Chamber: This area compacts the material into bales. Its design and capacity determine the size and density of the final product.

Wrapping System: The wrapping mechanism secures the bales with twine or netting, ensuring they remain intact during handling and transport.

Drive System: This component powers the machine’s various functions. A robust drive system is essential for reliable operation and longevity.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for efficient maintenance and repair. These illustrations provide detailed insights into how various elements interconnect and function together. Familiarizing oneself with these visuals can greatly enhance the ability to identify and procure necessary components for any machinery.

Start with the Overview: Begin by examining the entire illustration to grasp the general layout and organization of components. This will help you to visualize how parts relate to one another and where they are situated within the machine.

Identify Key Symbols: Each representation often employs specific icons or labels to denote different components. Take time to familiarize yourself with these symbols, as they provide essential information about each part’s function and position.

Follow the Legend: Most visuals include a legend or key that explains the symbols used. Consulting this section is vital for accurate interpretation, allowing you to decode the information effectively.

Refer to the Numbers: Components are typically numbered in sequential order. Cross-referencing these numbers with the accompanying parts list can clarify which items are required for repairs or replacements.

Pay Attention to Groupings: Components may be grouped according to their function or location within the assembly. Recognizing these clusters can streamline your understanding of how systems interact and facilitate troubleshooting processes.

By mastering these techniques, anyone can enhance their ability to read and interpret complex component representations, leading to more informed maintenance decisions and efficient repairs.

Maintenance Tips for Baler Components

Proper upkeep of agricultural machinery is essential for optimal performance and longevity. Regular maintenance not only ensures efficient operation but also minimizes downtime and costly repairs. Here are some vital tips to keep your equipment in top condition.

Regular Inspections

- Conduct thorough inspections before and after each use.

- Check for signs of wear, damage, or misalignment in the moving parts.

- Examine belts and chains for proper tension and wear patterns.

Lubrication and Cleaning

- Apply appropriate lubricants to all moving components regularly.

- Keep the machinery clean by removing debris and buildup that could hinder performance.

- Inspect and clean filters to ensure optimal airflow and function.

By following these guidelines, you can significantly extend the lifespan of your equipment and ensure it operates at peak efficiency.

Identifying Worn Out Parts

Recognizing the signs of deterioration in machinery components is crucial for maintaining optimal performance and longevity. Regular inspections can help detect issues before they escalate, ensuring that equipment operates efficiently and safely. Knowing what to look for can save time and prevent costly repairs.

Common Indicators of Wear

Several key signs indicate that a component may need replacement. Look for visual damage, unusual sounds during operation, or decreased efficiency. Here are some typical symptoms to observe:

| Indicator | Description |

|---|---|

| Cracks | Visible fractures on surfaces that may compromise integrity. |

| Excessive Play | Looseness in moving parts, indicating worn bearings or mounts. |

| Overheating | Increased temperature in components suggesting friction or inefficiency. |

| Strange Noises | Unusual sounds like grinding or rattling during operation. |

Preventive Maintenance Tips

Implementing regular maintenance routines can significantly extend the lifespan of your equipment. Schedule routine checks, lubricate moving parts, and replace worn components promptly to ensure seamless operation and minimize downtime.

Finding Replacement Parts Easily

Locating components for agricultural machinery can often feel overwhelming, but with the right approach, the process can become streamlined and efficient. Understanding where to seek assistance and how to navigate available resources is essential for maintaining optimal performance.

Online Resources play a crucial role in simplifying the search. Numerous websites offer extensive catalogs, making it easy to browse through a wide selection of items tailored for various machines. Utilizing filters can help pinpoint the exact components needed.

Local Dealers are invaluable as well. Establishing a relationship with nearby suppliers can lead to quicker access to essential items. They often have knowledgeable staff who can provide insights and recommendations for specific needs.

Community Forums and discussion groups can be a treasure trove of information. Engaging with other enthusiasts allows for shared experiences and tips on sourcing hard-to-find elements. Such platforms often feature advice on troubleshooting, enhancing the overall understanding of the equipment.

In summary, combining online searches, local expertise, and community insights creates an effective strategy for swiftly acquiring necessary components, ensuring machinery remains in peak condition.

Popular Accessories for the Baler

Enhancing efficiency and performance is essential for any agricultural equipment. Various add-ons can significantly improve functionality, making tasks easier and more effective. Here, we explore some of the most sought-after enhancements that operators often consider.

Wrap Film Dispenser: This accessory allows for quick and efficient application of wrapping materials, ensuring bales are securely packaged for storage.

Twine Storage System: An organized storage solution for twine can streamline operations, preventing tangles and saving time during baling.

Auto-Lube Systems: Implementing an automatic lubrication system minimizes maintenance effort, prolonging the lifespan of critical components.

LED Work Lights: These lights improve visibility during early morning or late evening operations, enhancing safety and productivity.

Rear View Cameras: Adding a camera system can provide better situational awareness, particularly in tight spaces, reducing the risk of accidents.

Compatibility with Other Equipment

Understanding how various machinery interacts is essential for maximizing efficiency in agricultural operations. Proper compatibility ensures seamless integration, enhancing performance and reducing downtime. Various implements and tools can often complement each other, leading to improved productivity and reduced operational costs.

When considering equipment alignment, it’s important to assess dimensions, connection types, and functionality. Many implements are designed to work together, facilitating tasks such as cutting, gathering, and processing. Ensuring that your machinery is compatible not only optimizes workflow but also prolongs the lifespan of all equipment involved.

Additionally, consulting manufacturers’ specifications and recommendations can provide valuable insights into which models work best in conjunction. This approach helps to achieve the ultimate effectiveness and reliability, ensuring that all components operate harmoniously.

Cost Considerations for Parts Replacement

When it comes to maintaining agricultural machinery, understanding the financial implications of component replacement is essential. Making informed decisions can prevent unexpected expenses and extend the lifespan of the equipment.

Several factors influence the cost of replacing components, including:

- Quality of Components: Original equipment manufacturer (OEM) parts typically come at a higher price but often guarantee better fit and longevity compared to aftermarket alternatives.

- Supplier Reliability: Choosing reputable suppliers can affect pricing and availability. Establishing relationships may lead to better deals and faster service.

- Labor Costs: Consider whether to handle replacements in-house or hire professionals. Labor rates can significantly impact overall costs.

- Frequency of Replacement: Components that wear out quickly may require more frequent investment, affecting long-term budgeting.

To optimize expenses, it’s advisable to:

- Conduct regular maintenance checks to identify potential issues early.

- Compare prices across different suppliers to ensure competitive rates.

- Consider purchasing parts in bulk if possible to take advantage of discounts.

- Invest in training for staff to perform minor repairs and replacements, reducing labor costs.

By carefully evaluating these factors, operators can make strategic decisions that enhance efficiency while managing costs effectively.

Where to Purchase Genuine Parts

Finding authentic components for your agricultural machinery is crucial for maintaining optimal performance and reliability. Whether you require replacement elements or enhancements, sourcing from trusted suppliers ensures quality and compatibility. It’s essential to identify reputable distributors who specialize in original equipment to safeguard your investment.

Online marketplaces often feature a range of options, but verifying the authenticity of the seller is key. Look for certified dealers or manufacturers’ websites, as they typically provide the most reliable selections. Additionally, local agricultural supply stores may stock genuine items, allowing for immediate acquisition and personal assistance.

Joining farming communities or forums can also be advantageous. Members often share valuable insights on where to find legitimate resources and may even offer recommendations based on their experiences. Prioritize purchasing from established vendors to ensure that your machinery operates at its ultimate efficiency.

Service and Repair Resources Available

Accessing reliable resources for maintenance and repairs is crucial for ensuring the longevity and efficiency of agricultural machinery. Various options exist to help users understand the complexities of their equipment, from manuals to online forums and professional services.

Technical Manuals provide detailed instructions and schematics that can guide operators through repairs and maintenance tasks. These documents are essential for troubleshooting issues effectively.

Online Communities and forums offer platforms where users can share experiences, seek advice, and delve into discussions about common challenges faced with their machines. Engaging with fellow enthusiasts can lead to valuable insights and solutions.

Professional Services are available for those who prefer hands-on assistance. Certified technicians can provide expert repairs and routine check-ups, ensuring that equipment operates at its ultimate performance.

Utilizing these resources will empower users to maintain their machinery efficiently, ultimately enhancing productivity and reducing downtime.