In every modern kitchen, efficient waste management systems play a crucial role in maintaining cleanliness and functionality. These mechanisms are designed to streamline the disposal process, ensuring that food remnants are handled with ease and minimal disruption. A comprehensive understanding of their inner workings can significantly enhance user experience and prolong the lifespan of the equipment.

To fully appreciate how these systems operate, it’s vital to explore the various elements that contribute to their efficiency. Each component serves a unique purpose, working harmoniously to break down and eliminate organic materials. By delving into these essential features, users can gain insights that aid in troubleshooting and maintenance.

In the pursuit of ultimate performance, familiarizing oneself with these key features not only empowers users but also instills confidence in their ability to manage kitchen waste effectively. Whether for routine upkeep or addressing specific issues, knowledge of each element is indispensable.

Understanding Badger Disposal Components

This section delves into the essential elements of a kitchen waste management system, focusing on their functions and interactions. A comprehensive understanding of these components enhances the efficiency and longevity of your setup, ensuring smooth operation during daily use.

Core Elements

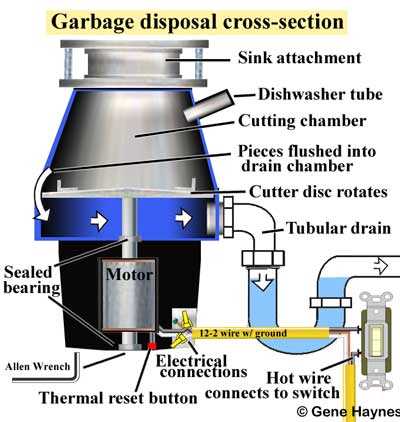

The main components of a kitchen waste management unit include the motor, grinding chamber, and various connection fittings. Each plays a critical role in the overall function, from processing food scraps to ensuring proper drainage.

Component Overview

| Component | Function |

|---|---|

| Motor | Powers the grinding mechanism to break down waste. |

| Grinding Chamber | Houses the blades that shred food remnants into smaller pieces. |

| Mounting Assembly | Secures the unit to the sink and provides stability. |

| Drainage System | Facilitates the safe removal of processed material. |

Understanding these components not only aids in troubleshooting but also empowers users to perform basic maintenance, extending the life of their kitchen waste management unit.

Key Parts of Badger Disposals

Understanding the essential components of these waste management units is crucial for effective operation and maintenance. Each element plays a significant role in ensuring efficiency and longevity.

- Motor: The powerhouse that drives the grinding mechanism.

- Grinding Chamber: The area where food waste is processed into smaller pieces.

- Impeller: A rotating part that helps in breaking down waste.

- Shredder Ring: Works alongside the impeller to further chop food scraps.

- Drain Assembly: Facilitates the exit of waste material after processing.

Each of these components contributes to the ultimate performance of the unit, ensuring that it functions smoothly and efficiently over time.

How to Read Disposal Diagrams

Understanding technical illustrations is crucial for effective maintenance and troubleshooting. These visuals provide a roadmap, helping users identify components and their relationships. Mastering this skill enhances your ability to execute repairs confidently.

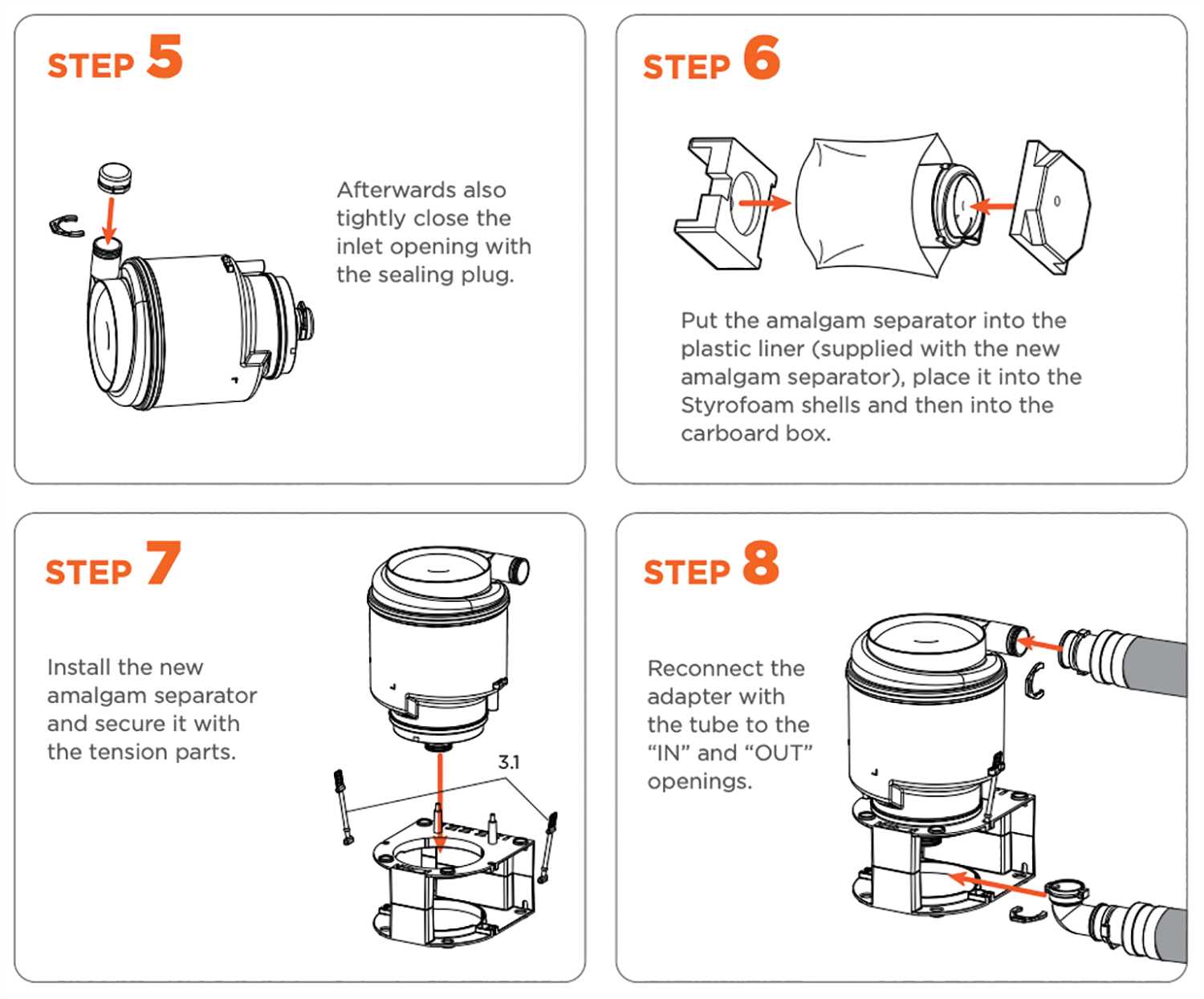

To interpret these visuals effectively, consider the following steps:

- Familiarize Yourself with Symbols:

- Identify common icons used for various elements.

- Learn what each symbol represents to avoid confusion.

- Study the Layout:

- Observe how components are arranged to understand flow.

- Note connections between different parts for clarity.

- Refer to the Legend:

- Always check the accompanying legend for explanations.

- This can reveal important details about functionality.

- Take Your Time:

- Don’t rush; carefully analyze each section.

- Make notes of any areas that need further investigation.

By following these steps, you’ll enhance your comprehension and ability to troubleshoot effectively.

Common Issues with Badger Parts

Many users encounter various challenges with their kitchen units, often stemming from specific components. Understanding these common issues can significantly enhance the longevity and efficiency of the appliance.

Noise Problems: One frequent complaint is excessive noise during operation. This can be attributed to loose or worn-out elements that need inspection or replacement. Ensuring all connections are secure can often mitigate this issue.

Jamming: Another typical concern is the unit becoming stuck, usually caused by foreign objects or food particles that hinder functionality. Regular maintenance and proper usage can help prevent such occurrences.

Leakage: Many users report water leaks around the base or connection points. This can indicate a need for sealing or gasket replacements. Timely attention to leaks can prevent further damage to surrounding areas.

Electrical Issues: Lastly, problems with the motor or electrical connections can lead to complete failure. Checking the wiring and connections regularly can help identify potential hazards before they escalate.

By being aware of these common issues and addressing them proactively, users can ensure their kitchen units operate smoothly and efficiently for years to come.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the extended lifespan and optimal performance of your kitchen apparatus. By following a few straightforward practices, you can prevent issues and maintain efficiency over time.

- Regular Cleaning: Consistently remove food remnants and debris to avoid buildup that can lead to malfunctions.

- Avoid Hard Items: Refrain from disposing of tough materials that can damage the internal components.

- Flush with Water: After use, run cold water for several seconds to help clear out any particles and maintain smooth operation.

- Use Citrus Peels: Occasionally grinding citrus peels can help deodorize and keep the mechanism fresh.

In addition to these practices, consider the following tips for further enhancing the longevity of your equipment:

- Schedule Professional Inspections: Periodic evaluations by a technician can identify potential issues before they become serious problems.

- Check for Leaks: Regularly inspect connections for any signs of leakage to prevent water damage.

- Monitor Usage: Be mindful of how often the unit is used and adjust your habits to avoid excessive wear.

By adhering to these maintenance strategies, you can significantly extend the life of your kitchen unit and enjoy its benefits for years to come.

Safety Precautions During Repairs

When engaging in repair work, prioritizing safety is crucial to prevent accidents and injuries. Adopting a systematic approach and using the appropriate gear can significantly mitigate risks associated with the task at hand.

Personal Protective Equipment

Utilizing personal protective equipment is essential. Ensure you wear gloves to protect your hands from sharp edges and goggles to shield your eyes from debris. Closed-toe shoes can further safeguard your feet during the process.

Work Area Organization

Maintaining an organized workspace can help avoid mishaps. Clear away any unnecessary items and ensure all tools are within reach. This not only streamlines the repair process but also enhances overall safety.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment on hand can make all the difference. The appropriate tools not only facilitate the process but also ensure that repairs are carried out effectively and safely. Understanding what instruments are essential for your project will save time and enhance your efficiency.

Commonly required tools include wrenches, screwdrivers, and pliers, which are fundamental for loosening or tightening various components. Additionally, a socket set can prove invaluable for more intricate tasks. A utility knife and a pair of safety gloves should also be included in your toolkit for cutting materials and protecting your hands during repairs.

For those who prefer a more organized approach, a tool belt or a storage container can help keep everything within reach. Lastly, having a flashlight on standby can illuminate dark areas, ensuring that no detail is overlooked while you work. Proper preparation with these instruments will streamline your repair experience and contribute to a successful outcome.

Identifying Each Component’s Function

Understanding the various elements within a waste management system is crucial for efficient operation. Each component plays a specific role, contributing to the overall functionality and effectiveness of the unit. By recognizing these roles, users can ensure proper maintenance and troubleshooting when issues arise.

Main Components Overview

The key elements include the motor, grinding chamber, and drain connections, each serving distinct purposes. Familiarity with these components allows for better performance and longevity of the system.

Functionality Table

| Component | Function |

|---|---|

| Motor | Powers the entire mechanism, enabling movement and grinding. |

| Grinding Chamber | Crushes and breaks down waste materials for easier disposal. |

| Drain Connections | Facilitates the smooth flow of waste into the plumbing system. |

Replacement Parts: Where to Buy

When it comes to maintaining your kitchen appliance, knowing where to find suitable components is crucial. Quality replacements ensure optimal performance and longevity. Fortunately, there are several reliable sources for acquiring these essentials.

Online Retailers offer a vast selection, often at competitive prices. Websites like Amazon and eBay provide user reviews and ratings, helping you make informed decisions.

Local Home Improvement Stores are excellent options for immediate needs. Stores such as Home Depot and Lowe’s usually carry a variety of essential components, allowing for quick purchases and advice from knowledgeable staff.

Specialty Supply Shops focus on specific brands and models, ensuring you find exactly what you need. These shops can also offer guidance on installation and maintenance.

Manufacturer Websites often have direct sales or links to authorized dealers, guaranteeing authenticity and quality. This is the ultimate way to ensure compatibility with your appliance.

By exploring these options, you can effectively keep your kitchen functioning smoothly and efficiently.

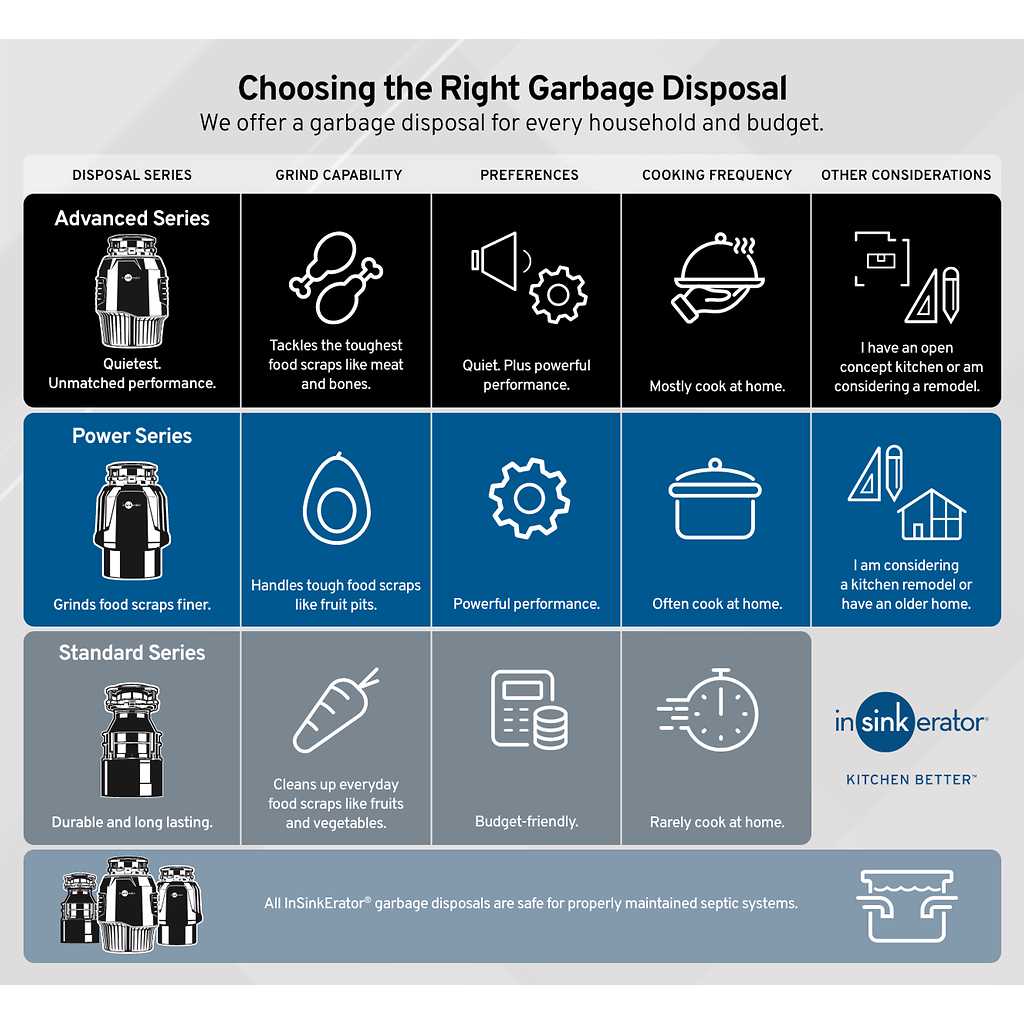

Upgrading Badger Disposal Models

Enhancing the efficiency and performance of your kitchen’s waste management system can significantly improve your culinary experience. Upgrading to newer models often brings advanced features, improved durability, and enhanced energy efficiency. This section will explore the benefits of making such upgrades and what to consider during the process.

Modern Technology has transformed the way these systems operate, offering quieter motors and greater grinding power. These innovations not only facilitate smoother operation but also reduce the likelihood of clogs and jams.

Compatibility with existing plumbing is crucial when considering an upgrade. Ensuring that new models fit seamlessly with your current setup will save time and money on installation.

Additionally, eco-friendly options are increasingly available, allowing consumers to choose systems that minimize environmental impact while maintaining performance. Exploring these choices can lead to both savings and sustainability.

DIY Troubleshooting Techniques

When faced with issues in your waste management unit, understanding basic troubleshooting can save time and money. This guide offers effective methods to identify and resolve common problems, empowering you to tackle challenges confidently.

| Issue | Potential Solution |

|---|---|

| Unit won’t start | Check power supply and reset any tripped breakers. |

| Unusual noises | Inspect for foreign objects and ensure all components are secure. |

| Leaks | Examine seals and connections for wear or damage. |

| Slow drainage | Clear any blockages in the drain line or unit itself. |

Professional Help: When to Call

Understanding the right moment to seek expert assistance can save time and prevent further complications. While many minor issues can be resolved independently, certain situations require the knowledge and skills of a trained professional.

Signs You Need Assistance

If you notice persistent problems that do not improve with basic troubleshooting, it’s essential to consider reaching out for help. Unusual noises, persistent leaks, or complete system failures are strong indicators that your system may require professional intervention.

Benefits of Consulting an Expert

Engaging with a specialist not only ensures a thorough diagnosis but also provides access to advanced tools and techniques. Ultimately, this can lead to a more effective and long-lasting resolution to the issues at hand.