Exploring the intricacies of a specific lawn tractor model reveals the essential elements that contribute to its performance and functionality. A thorough examination of these components aids in the effective maintenance and repair of the machine, ensuring optimal operation in various conditions.

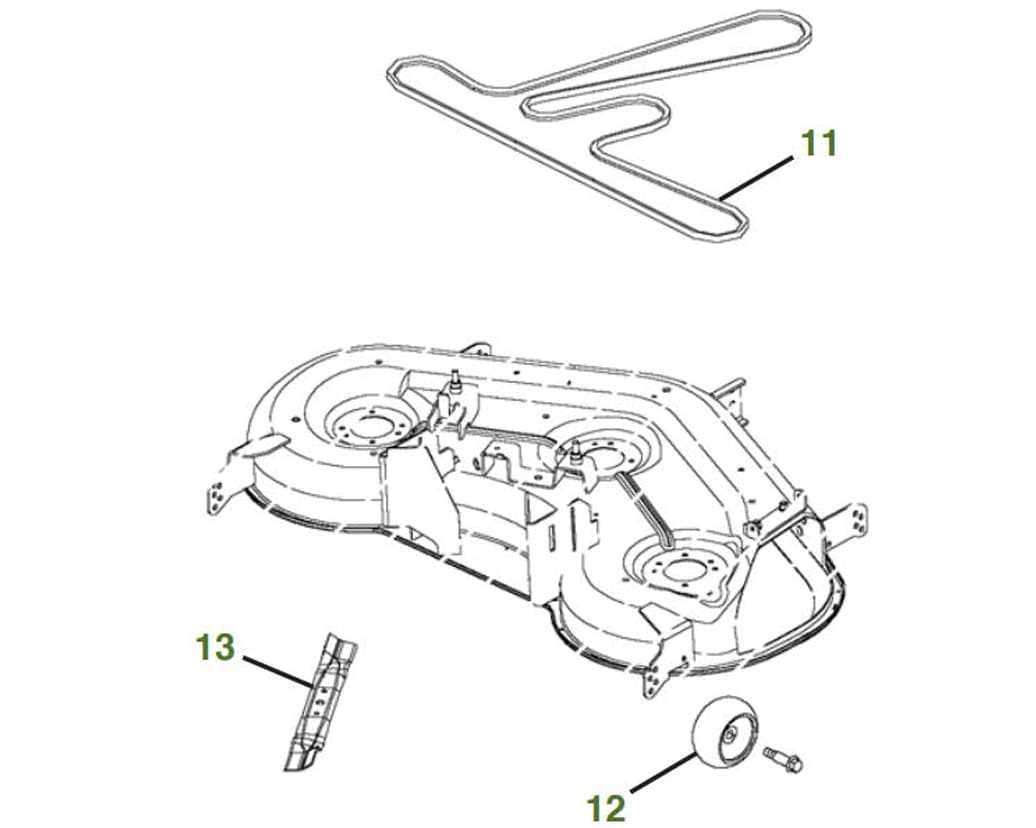

The assembly of a lawn tractor comprises numerous vital elements, each playing a unique role in the overall performance. By familiarizing oneself with the arrangement and interaction of these parts, users can enhance their knowledge, leading to informed decisions during servicing or upgrades.

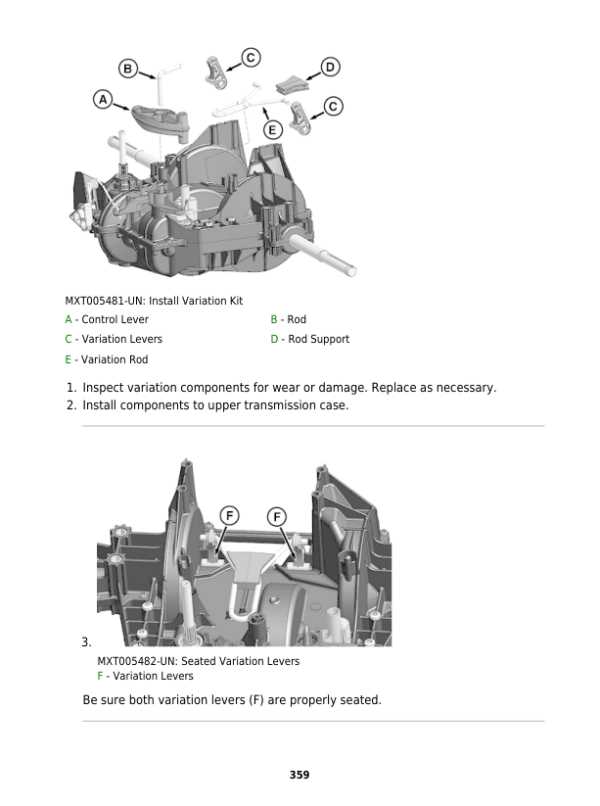

For those engaged in maintenance or troubleshooting, visual aids showcasing the configuration of these components can prove invaluable. Such resources provide clarity, allowing for a more profound understanding of how each piece contributes to the machinery’s effectiveness.

When undertaking maintenance tasks on a mechanical system, having the right tools is essential for ensuring efficiency and precision. Proper equipment not only facilitates smoother operations but also enhances safety during repairs.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Needed for various fastening tasks.

- Pliers: Useful for gripping and manipulating components.

- Socket Set: Provides versatility for different bolt sizes.

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Oil Filter Wrench: Specifically designed for removing filters.

- Compression Tester: Assesses the performance of the system.

- Multimeter: Measures electrical properties for troubleshooting.

Having these tools readily available will significantly streamline the repair process and contribute to effective troubleshooting.

Step-by-Step Assembly Instructions

This section provides a detailed guide for the assembly process, ensuring that each component is correctly fitted for optimal performance. Following these instructions will help maintain efficiency and longevity.

Required Tools

- Socket wrench set

- Torque wrench

- Flathead screwdriver

- Phillips screwdriver

- Lubricant

Assembly Process

- Start by gathering all necessary components and tools in a clean workspace.

- Refer to the component layout for an overview of where each piece fits.

- Begin with the foundation and secure it firmly.

- Attach the next set of components, ensuring alignment with pre-drilled holes.

- Use the torque wrench to fasten screws to the specified tightness.

- Check each connection for stability before proceeding to the next step.

- Finally, apply lubricant to moving parts to ensure smooth operation.

How to Replace Engine Parts

Replacing components within a motor requires careful planning and precise execution. Understanding the basic steps involved can ensure a smooth process and optimal performance of the machine.

Preparation Steps

Before commencing, gather all necessary tools and new components. Ensure that the workspace is clean and organized to facilitate an efficient workflow. Safety gear should be worn at all times to prevent accidents.

Replacement Process

Begin by disconnecting the power source to avoid any electrical hazards. Carefully remove the old components, noting their positions and connections. Install the new items by following the reverse order, ensuring all connections are secure. Double-check your work to confirm everything is in place before reactivating the power supply.

Understanding the Wiring Diagram

This section focuses on comprehending the electrical layout essential for the operation of the machinery. Grasping the connections and components will facilitate better maintenance and troubleshooting.

Key Components

- Battery: Supplies power for starting and operation.

- Ignition System: Initiates combustion within the power unit.

- Starter Motor: Engages the flywheel to start the unit.

- Wiring Harness: Connects various electrical elements.

Importance of Understanding

Recognizing the layout helps in diagnosing issues and ensuring the reliability of the system. A clear grasp of the connections allows for efficient repairs and enhances overall performance.

Cost Analysis of Replacement Parts

Understanding the financial implications of component replacement is essential for maintaining operational efficiency. Various factors influence the overall expense, including the quality of materials and market availability.

Initial Costs: The upfront investment can vary significantly based on the manufacturer and the specific nature of the item required. Often, premium options offer greater longevity but come at a higher price.

Long-term Considerations: While cheaper alternatives might be appealing, they may result in more frequent replacements, leading to increased expenses over time. Analyzing the total cost of ownership is crucial for making informed decisions.

Market Trends: Prices fluctuate based on demand and supply dynamics. Staying informed about market trends can help in strategizing purchases and potentially reducing costs.

Where to Buy Genuine Components

Finding authentic components for machinery is essential for maintaining optimal performance and longevity. Quality assurance and reliability are key factors when selecting suppliers.

Authorized Retailers

Purchasing from authorized dealers ensures that you receive genuine items. These retailers often provide:

- Warranty on products

- Expert assistance and support

- Access to the latest inventory

Online Marketplaces

Reputable online platforms also offer a wide selection of authentic components. Consider the following tips:

- Check seller ratings and reviews

- Verify return policies

- Ensure product authenticity guarantees