When dealing with mechanical systems, especially smaller power units, it’s essential to have a clear understanding of their various elements. These units consist of multiple interconnected parts, each playing a crucial role in ensuring smooth functionality. Recognizing the layout of these elements can greatly aid in maintaining and repairing such systems.

The internal setup of these power devices is often complex, with numerous tiny components working together. For individuals looking to better grasp the construction of these machines, a well-organized illustration can offer valuable insights. Having a detailed overview allows one to quickly identify specific components and their respective roles.

Familiarity with the structure of these units can significantly enhance both troubleshooting and repair tasks. Whether you’re performing routine maintenance or dealing with an unexpected issue, a solid understanding of the unit’s makeup can streamline the process and help ensure longevity.

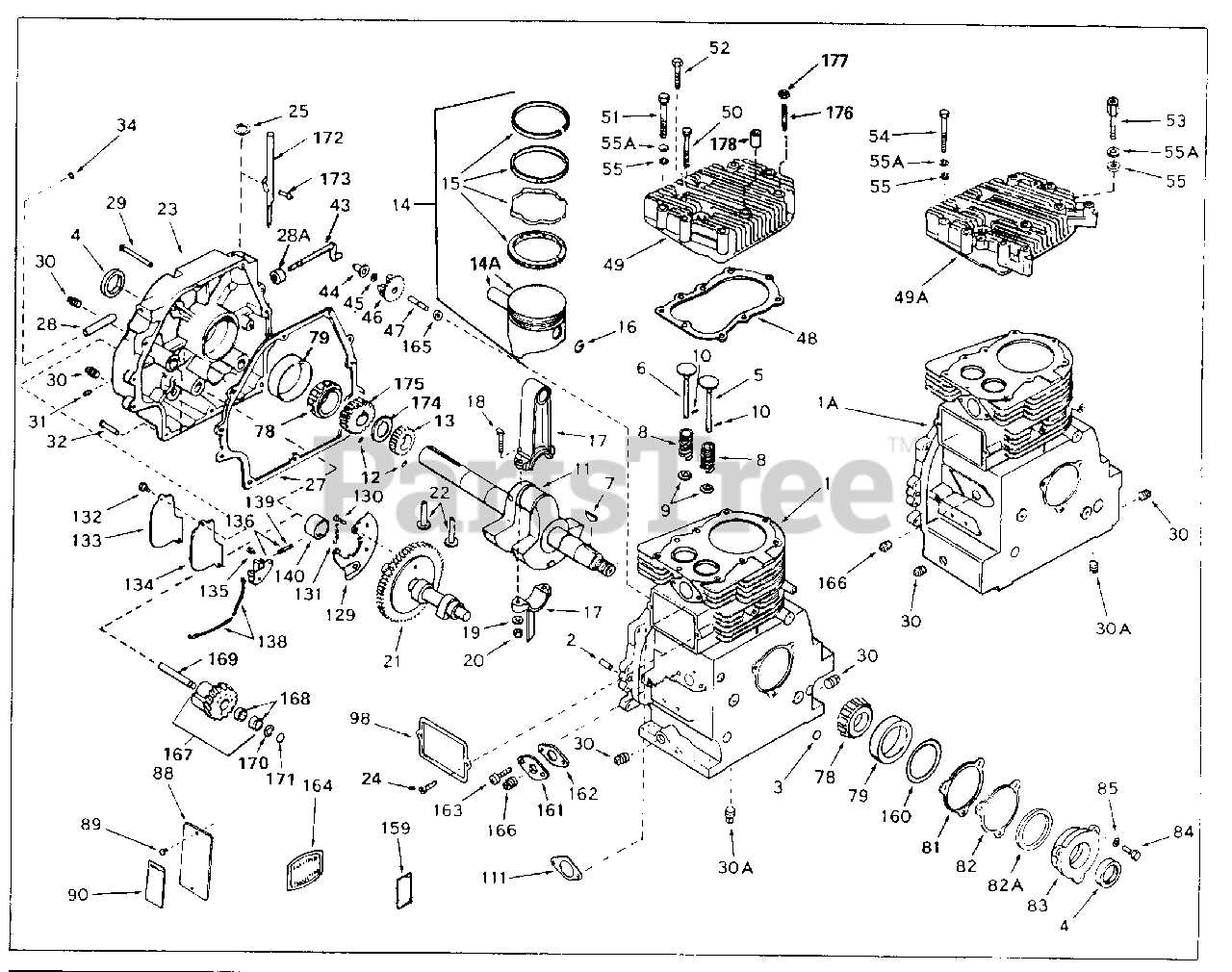

Components Overview of a Small Power Unit

In this section, we explore the essential parts that make up a compact motor system. These components work together to ensure the efficient performance of the machine, contributing to its power output and smooth operation. Understanding how these elements function can help with proper maintenance and troubleshooting.

| Component | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cylinder | The central chamber where fuel combustion takes place, driving the motion of other parts. | ||||||||

| Carburetor | A mechanism that blends fuel and air in the correct ratio to facilitate combustion. | ||||||||

| Flywheel | A weighted disk that helps regulate engine speed and maintain momentum between power strokes. |

| Component | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Float | Regulates the level of fuel within the chamber, preventing overflow or lack of fuel supply. | ||||||||

| Needle Valve | Controls the flow of fuel into the carburetor, ensuring precise fuel delivery. | ||||||||

| Throttle Plate | Adjusts the amount of air that enters the system, influencing the speed and power output. | ||||||||

| Choke | Restricts air intake during startup to enrich the fuel mixture, aiding in smoother ignition. | ||||||||

| Main Jet | Responsible for delivering fuel to the

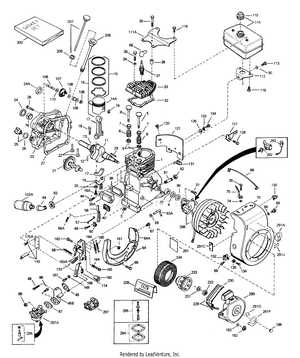

Exploring the Ignition System ElementsThe ignition system is a crucial component responsible for initiating the combustion process in various machinery. It plays a key role in ensuring smooth operation and reliable performance. By understanding its elements, one can maintain or repair the system effectively, preventing potential malfunctions. Spark plugs are essential in igniting the fuel mixture, providing the necessary spark. Wiring connects different parts of the system, ensuring electrical flow. Another important part is the ignition coil, which transforms low voltage into high voltage, essential for creating the spark needed for combustion. Regular inspection and maintenance of these elements can ensure long-lasting functionality and optimal efficiency of the machine’s operation. Air Filter Housing and Function

The air filter housing plays a crucial role in maintaining the overall efficiency of a motor by ensuring clean air intake. This component is designed to shield the filtration system, preventing debris and other particles from entering the airflow, which could negatively impact performance. The structure of the air filter housing is carefully constructed to provide adequate airflow while keeping unwanted elements out. Proper maintenance of this part is vital to ensure long-term reliability and smooth operation of the entire system.

Fuel System Configuration and ComponentsThe fuel system plays a vital role in the overall performance of small combustion machinery. It is responsible for delivering the correct amount of fuel to the combustion chamber, ensuring efficient operation. A well-designed fuel system consists of various elements that work together to optimize the engine’s functionality and longevity. Key Components of the Fuel SystemEssential components of the fuel system include the fuel tank, fuel lines, and carburetor. The fuel tank stores the liquid fuel, while the lines transport it to the carburetor, where it is mixed with air before entering the combustion chamber. Each of these elements must be properly maintained to prevent leaks and ensure a steady flow of fuel. Configuration and OperationUnderstanding the configuration of the fuel system is crucial for troubleshooting and repairs. The arrangement of components affects how fuel is delivered and can influence the overall efficiency of the machinery. Regular inspection and maintenance of these parts can help identify potential issues before they become serious problems. Identifying the Governor Linkage Parts

The governor linkage mechanism plays a crucial role in regulating the speed and performance of small machinery. Understanding its components is essential for effective maintenance and troubleshooting. By familiarizing yourself with the various elements involved in this system, you can ensure optimal functionality and longevity. Typically, the governor assembly includes several key elements, such as the control arm, governor spring, and various connecting rods. Each of these components works in harmony to maintain the desired operational speed. Control arms facilitate the adjustment of throttle position, while governor springs provide the necessary tension to respond to changes in load. Additionally, connecting rods link these parts together, ensuring smooth movement throughout the system. Proper identification and understanding of these components can greatly assist in diagnosing issues related to performance. Regular inspection and replacement of worn or damaged elements will contribute to the reliable operation of the equipment. Exhaust System Components and Diagram

The exhaust system plays a crucial role in the performance and efficiency of a machine. It is responsible for directing harmful gases away from the combustion chamber, ensuring smooth operation and reducing noise. Understanding the various components that make up this system is essential for maintenance and troubleshooting. Typically, the system includes several key elements: the muffler, exhaust pipe, and gaskets. The muffler serves to minimize noise produced during operation, while the exhaust pipe channels the gases safely away from the unit. Gaskets are vital for sealing connections and preventing leaks, contributing to the overall efficiency of the setup. A well-maintained exhaust system not only enhances performance but also prolongs the lifespan of the equipment. Regular inspection and timely replacement of worn-out parts can significantly improve functionality and ensure compliance with safety standards. Crankshaft and Piston Assembly BreakdownThe crankshaft and piston assembly is a crucial component in many small machinery applications, providing the necessary motion to convert fuel energy into mechanical power. This section delves into the intricacies of this assembly, highlighting its various elements and their functions. The crankshaft, typically made from robust materials, is designed to withstand high levels of stress during operation. Its primary role is to transform the linear motion of the piston into rotational motion, which is essential for powering the system. The precise engineering of the crankshaft ensures optimal performance and durability. The piston, a cylindrical component, moves up and down within the cylinder, creating pressure that drives the crankshaft. The interaction between the piston and crankshaft is vital for efficient power generation. Additionally, the assembly may include various seals and bearings that contribute to smooth operation and minimize wear over time. Understanding the components and their interactions within this assembly can help in diagnosing issues and performing maintenance effectively. Regular inspection of these parts can lead to improved efficiency and prolonged lifespan of the machinery. Cooling System and Fan Blades OverviewThe cooling mechanism in small power units plays a crucial role in maintaining optimal operating temperatures. Efficient cooling is essential to prevent overheating, which can lead to performance issues and potential damage. This section explores the components involved in the cooling process and the significance of fan blades in regulating airflow. Components of the Cooling Mechanism

Importance of Fan Blades

Valve Mechanism and Timing ExplanationThe valve mechanism plays a crucial role in regulating the flow of air and fuel into the combustion chamber while allowing exhaust gases to escape. Understanding the timing and operation of this system is essential for maintaining optimal performance in any small power unit. Overview of the Valve Mechanism

This mechanism typically consists of various components that work together to control valve openings and closings. Key elements include:

Timing ConsiderationsThe timing of the valve operation is vital for efficient combustion. Factors affecting timing include:

Throttle Control Linkages and AdjustmentsThe throttle control system plays a crucial role in regulating the speed and performance of small machinery. Understanding the linkages involved and how to properly adjust them can significantly enhance the efficiency and responsiveness of the equipment. This section delves into the various components that make up the throttle control mechanism and outlines the necessary adjustments for optimal operation. Components of the Throttle Control SystemThe throttle control assembly consists of several key components, including the throttle lever, linkage rods, and connecting brackets. Each part interacts to ensure that the throttle opens and closes smoothly in response to user input. Regular inspection of these elements is essential to maintain performance and prevent malfunctions. Adjustment Procedures

Proper adjustment of the throttle linkage is vital for achieving the desired speed settings. Begin by checking the tightness of the connections and ensuring there is no play in the linkages. To adjust the throttle: loosen the retaining screws, reposition the linkage to the desired angle, and then retighten the screws. Testing the throttle response after adjustments is recommended to confirm that the changes have been effective. Spark Plug Location and Related PartsThe spark plug plays a crucial role in the ignition process of small combustion machines. Understanding its placement is essential for proper maintenance and efficient operation. In this section, we will explore where the spark plug is situated and the components associated with it that contribute to the overall functionality. Placement of the Ignition Component

The ignition component is typically found on the upper section of the unit, easily accessible for maintenance tasks. This location allows for straightforward inspection and replacement, ensuring optimal performance. Regular checks can help prevent issues that may arise from improper functioning. Associated ElementsAlongside the ignition element, several related components play vital roles in the operation. These include the ignition coil, which generates the electrical spark, and the connecting wires that facilitate energy transfer. Understanding how these elements interact is key to maintaining the reliability of the machine. |