The intricacies of modern cooling solutions involve a myriad of components working in harmony to ensure efficient performance. Understanding the layout and functionality of these elements is crucial for both maintenance and enhancement of their capabilities. This section delves into the essential building blocks that contribute to the overall operation of these systems, providing insights into their arrangement and interconnectivity.

Through a comprehensive examination, readers will gain a clearer perspective on how each element integrates within the broader framework. Identifying these components allows for a better grasp of their roles, paving the way for informed decision-making when it comes to repairs or upgrades. Recognizing the specific functions and placements of these parts can significantly influence the effectiveness and longevity of cooling mechanisms.

By unraveling the complexity of these systems, we aim to equip individuals with the knowledge necessary for optimal utilization. Whether you are a technician, an enthusiast, or simply curious, understanding the intricacies of these mechanisms can enhance your appreciation for the technology at play. Join us as we explore the essential elements that keep cooling systems running smoothly and efficiently.

Overview

This section provides a comprehensive insight into a compact cooling system designed for effective thermal management. Its functionality plays a crucial role in maintaining optimal operating temperatures during demanding tasks, ensuring both efficiency and longevity of connected equipment.

The system is particularly valued in various industries for its portability and user-friendly design. Here are some key features that highlight its significance:

- Compact Design: The unit’s size allows for easy transportation and integration into diverse work environments.

- Efficient Cooling: Engineered to provide consistent temperature regulation, it helps prevent overheating.

- Durability: Constructed with robust materials, it is built to withstand rigorous use.

- User-Friendly Interface: Simplified controls enhance operational ease for users.

In summary, this cooling system serves as an indispensable tool in enhancing productivity and safeguarding equipment performance in various applications.

Key Features of Coolmate 4

This section highlights the essential characteristics of a specific cooling system designed for optimal performance in demanding environments. Understanding these features can help users appreciate the advantages of utilizing this equipment in various applications.

Durability and Reliability

One of the standout attributes of this cooling apparatus is its robust construction. Key aspects include:

- High-quality materials that withstand extreme conditions.

- Reliable performance even under heavy usage.

- Resistance to corrosion and wear over time.

User-Friendly Design

This cooling unit is designed with the end user in mind. The following elements enhance usability:

- Intuitive controls for easy operation.

- Compact size for convenient placement in tight spaces.

- Low maintenance requirements to ensure hassle-free operation.

These features collectively contribute to a high-performance cooling solution that meets the needs of various industrial settings.

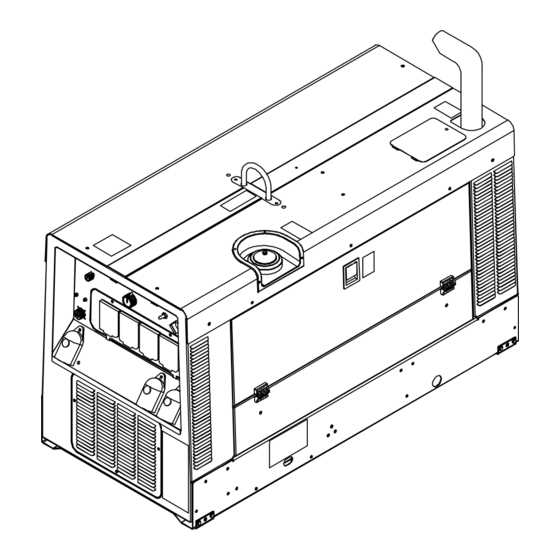

Components of Miller Coolmate 4

This section provides an overview of the essential elements that contribute to the efficient operation of a specific cooling system designed for welding processes. Understanding these components is crucial for maintaining optimal performance and ensuring longevity in a variety of applications.

Key Elements

The cooling system comprises several vital components, each playing a significant role in its functionality. From the circulation of coolant to the management of temperature, these elements work harmoniously to deliver effective cooling solutions.

Component Breakdown

| Component | Description |

|---|---|

| Pump | Circulates the coolant throughout the system to regulate temperature. |

| Reservoir | Stores the coolant, ensuring an adequate supply for continuous operation. |

| Cooling Unit | Facilitates heat exchange to maintain optimal temperatures during welding tasks. |

| Control Panel | Allows users to monitor and adjust settings for efficient performance. |

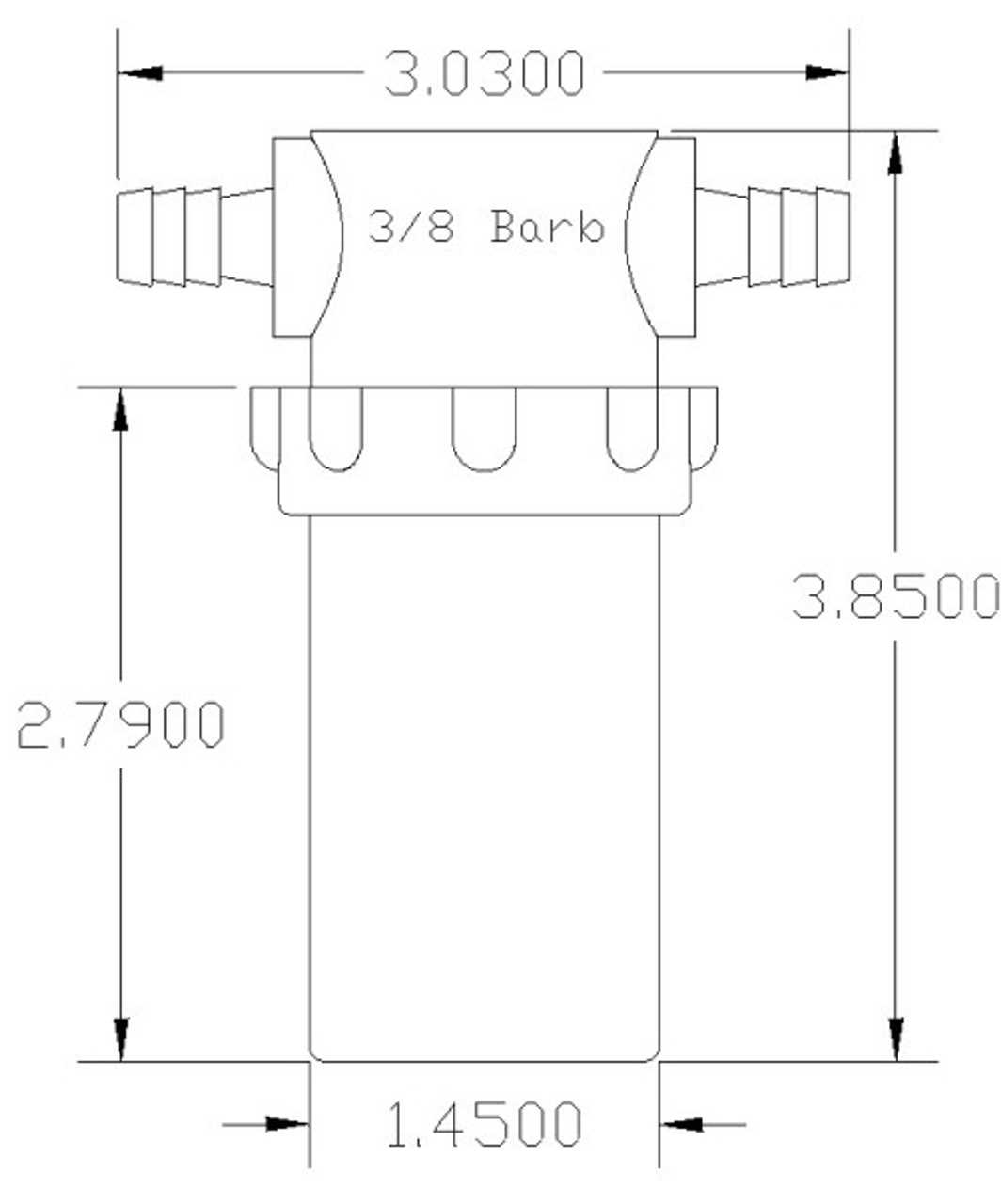

Understanding the Parts Diagram

Comprehending the assembly layout is crucial for effective maintenance and operation of any specialized equipment. By familiarizing oneself with the various components and their interconnections, users can enhance their troubleshooting skills and ensure optimal functionality. This section delves into the intricate details that facilitate a deeper appreciation of the configuration.

The layout provides a visual representation of the unit, showcasing the essential elements that contribute to its performance. Each component serves a specific function, and recognizing these roles is vital for both new and experienced users alike. Below is a simplified overview of key features commonly found in similar systems:

| Element | Description |

|---|---|

| Cooling Unit | Responsible for regulating temperature to maintain efficiency. |

| Control Panel | Interface for user adjustments and monitoring operational status. |

| Power Supply | Provides the necessary energy for operation and functionality. |

| Condenser | Facilitates the heat exchange process to maintain ideal conditions. |

| Fan Assembly | Ensures adequate airflow for cooling and efficiency. |

By studying the configuration, users can not only troubleshoot issues more effectively but also optimize the equipment’s performance through informed maintenance practices.

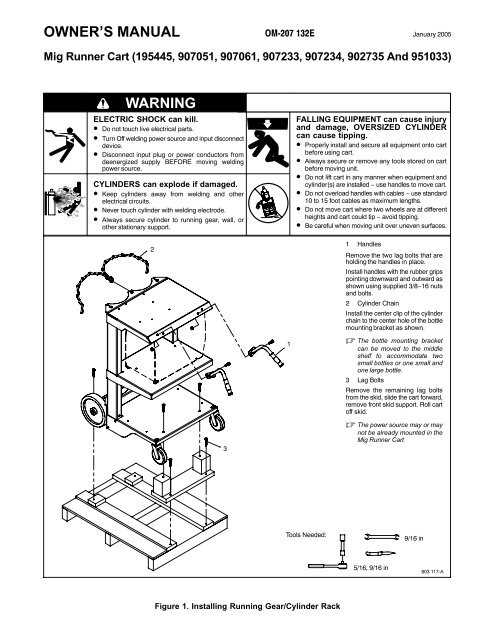

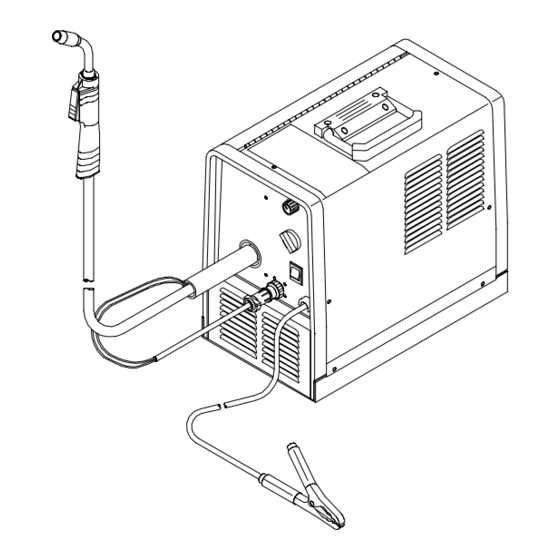

Assembly Instructions for Coolmate 4

The following guide provides step-by-step instructions to put together a cooling system for efficient and reliable operation. By following these directions carefully, you will ensure proper functionality and long-term durability of the system.

Preparation

Before beginning the assembly, make sure you have all the necessary components and tools at hand. Clear your workspace and review the individual elements to familiarize yourself with their placement and role in the system’s structure.

- Ensure all connectors and fittings are clean and free of debris.

- Have a screwdriver set, pliers, and appropriate wrenches available.

- Check the tubing for any bends or damage before installation.

Step-by-Step Process

- Start by securing the main unit onto a stable surface. Ensure that it is level to prevent operational issues later on.

- Connect the cooling lines to the designated ports. Make sure the fittings are tight but not over-tightened to avoid damaging the seals.

- Install the fan assembly by attaching it to the unit’s mounting points. Double-check the alignment to ensure it is centered and secure.

- Attach the power supply cable and verify that it is connected to the correct input port. The power cord should have some slack to

Common Issues and Solutions

Over time, equipment designed for cooling can face several challenges due to wear, improper maintenance, or external factors. Identifying the most frequent issues and addressing them promptly can ensure optimal performance and extend the system’s lifespan.

1. Reduced Cooling Efficiency

One of the most common issues is a noticeable decrease in cooling performance. This could be caused by blockages, insufficient fluid levels, or malfunctioning components within the system.

- Check for any obstructions or buildup in the lines and clean them if necessary.

- Ensure the coolant levels are adequate and refill when needed.

- If a component seems faulty, consider replacing it to restore functionality.

2. Overheating

Overheating can result from several causes, such as inadequate ventilation or malfunctioning fans. If left unresolved, this can cause further damage to the cooling system.

- Verify that the cooling area is well-ventilated and free from dust or debris.

- Inspect the fans for proper operation and clean or replace them if necessary.

- If overheating persists, it may indicate a deeper mechanical issue requiring professional inspection.

By addressing these issues early, you can prevent costly repairs and maintain reliable performance.

Maintenance Tips for Coolmate 4

To ensure the longevity and efficiency of your equipment, regular upkeep is essential. By following a few key practices, you can prevent unnecessary downtime and extend the life of the system.

Regular Cleaning

- Clean external surfaces to remove dust and debris.

- Inspect the coolant tank and clear out any contaminants.

- Check for leaks or signs of wear on all visible hoses and connections.

Fluid Replacement

- Monitor fluid levels regularly to ensure proper function.

- Replace the coolant at recommended intervals or sooner if the fluid appears dirty or degraded.

- Always use the recommended type of fluid to prevent corrosion or system damage.

By keeping up with these simple maintenance tasks, you can significantly improve the performance and reliability of your system.

Replacement Parts and Compatibility

When it comes to ensuring the longevity of your cooling equipment, understanding the various components and their interchangeability is essential. Identifying the right substitutes can prevent operational disruptions and improve overall efficiency. Whether you are dealing with older models or new systems, choosing compatible elements is crucial for maintaining optimal performance.

Compatibility plays a key role in the selection process. Many systems are designed to work seamlessly with a range of components, but it’s important to verify that the specifications align correctly. This will ensure smooth integration and minimize the risk of malfunctions.

Replacement items vary based on system design, and it’s important to know the exact specifications required for a successful fit. Always consult the equipment’s manual or a professional to confirm which elements are best suited for your setup.

Benefits of Using Coolmate 4

Efficient cooling systems play a vital role in maintaining the performance and longevity of equipment. By ensuring optimal temperature regulation, these solutions help prevent overheating and increase overall reliability, particularly during extended periods of operation. This section highlights the key advantages of utilizing a modern cooling unit designed for heavy-duty applications.

One of the primary benefits is the enhanced lifespan of your machinery. Consistent and effective cooling reduces wear and tear, lowering the risk of malfunction and the need for frequent repairs. As a result, operational efficiency is significantly improved, leading to cost savings over time.

Another advantage is the unit’s energy efficiency. Modern cooling systems are designed to consume less power while still providing powerful temperature control, helping to minimize energy expenses without sacrificing performance. This not only makes operations more sustainable but also helps reduce your overall environmental footprint.

In addition, advanced cooling technology allows for greater flexibility in managing different operational conditions. Whether dealing with varying workloads or environmental factors, the system adapts to ensure optimal temperature levels, pr

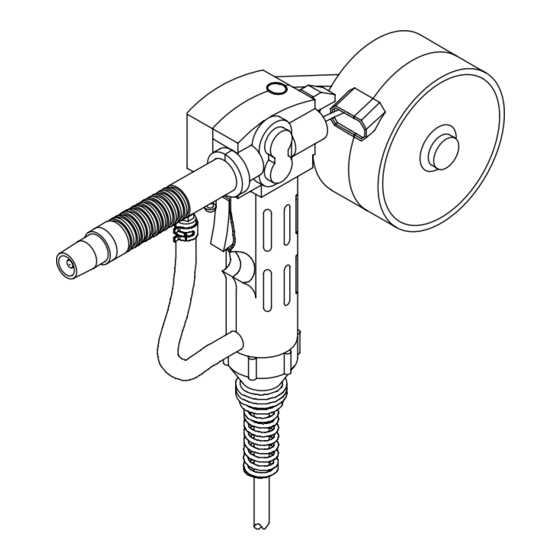

Applications in Welding Processes

Effective cooling systems are essential in welding to ensure the longevity and performance of both equipment and materials. These systems help manage heat during intensive operations, preventing damage and ensuring stable working conditions for various components. Proper temperature control plays a crucial role in maintaining the integrity of welds, especially during prolonged use.

Importance of Cooling in Welding

In welding, controlling heat is critical to prevent overheating of torches and other sensitive equipment. This ensures smoother operations, enhances safety, and reduces the chances of material deformation. Whether in light-duty or heavy-duty welding tasks, an efficient cooling system allows for uninterrupted work, reducing downtime due to equipment failure.

- Prevents overheating of components

- Ensures consistent performance during prolonged operations

- Reduces wear and tear on equipment

Common Welding Applications

Cooling systems are widely used across different welding processes, supporting the integrity of both manual and automated techniques. Their applications include:

- TIG Welding: Ensuring precise heat control during intricate welds, critical for metals sensitive to high temperatures.

- MIG Welding: Facilitating smoother wire feeding and reducing spatter by maintaining consistent temperatures.

- Plasma Cutting: Supporting high-speed cutting tasks where excessive heat can damage both tools and materials.

With proper cooling, welders can maintain high-quality work while

Safety Considerations When Operating

Ensuring safe operation is paramount when working with advanced equipment that involves liquid cooling systems. Awareness and adherence to safety protocols are crucial to avoid potential hazards. Proper handling and maintenance can significantly reduce the risk of accidents, ensuring the longevity of both the equipment and the operator’s health.

Electrical Safety

- Always disconnect the power source before performing any maintenance or adjustments.

- Ensure the equipment is properly grounded to prevent electrical shocks.

- Inspect all wiring and connections for wear or damage before each use.

Handling Coolant

- Wear protective gloves and safety glasses when handling the coolant to avoid skin and eye irritation.

- Ensure the coolant is stored and disposed of according to local environmental regulations.

- Check for leaks regularly and repair any damage immediately to prevent exposure to hazardous substances.

- Follow the manufacturer’s guidelines for fluid levels and replacement intervals.

- Keep the system free of debris to maintain optimal cooling efficiency.

By following these safety precautions, operators can minimize risks and maintain a safe working environment, ensuring efficient and secure equipment performance.

Customer Reviews and Feedback

Understanding user experiences provides valuable insights into the functionality and reliability of the product. Feedback from various users helps identify strengths, highlight areas for improvement, and guide potential buyers in making informed decisions.

Many users have expressed satisfaction with the performance and durability, emphasizing its efficiency in various applications. Positive reviews often mention ease of use and reliability, making it a trusted choice for a range of tasks. Additionally, users appreciate its consistent performance under different conditions, ensuring dependable results over time.

However, some customers have shared suggestions for enhancements. Common feedback includes requests for minor adjustments to improve specific features or increase overall convenience. Such constructive criticism plays an essential role in product evolution and customer satisfaction.

In summary, customer reviews reflect a generally positive experience, with a few thoughtful recommendations for further improvement. This feedback ensures that the product continues to meet the diverse needs of its users.