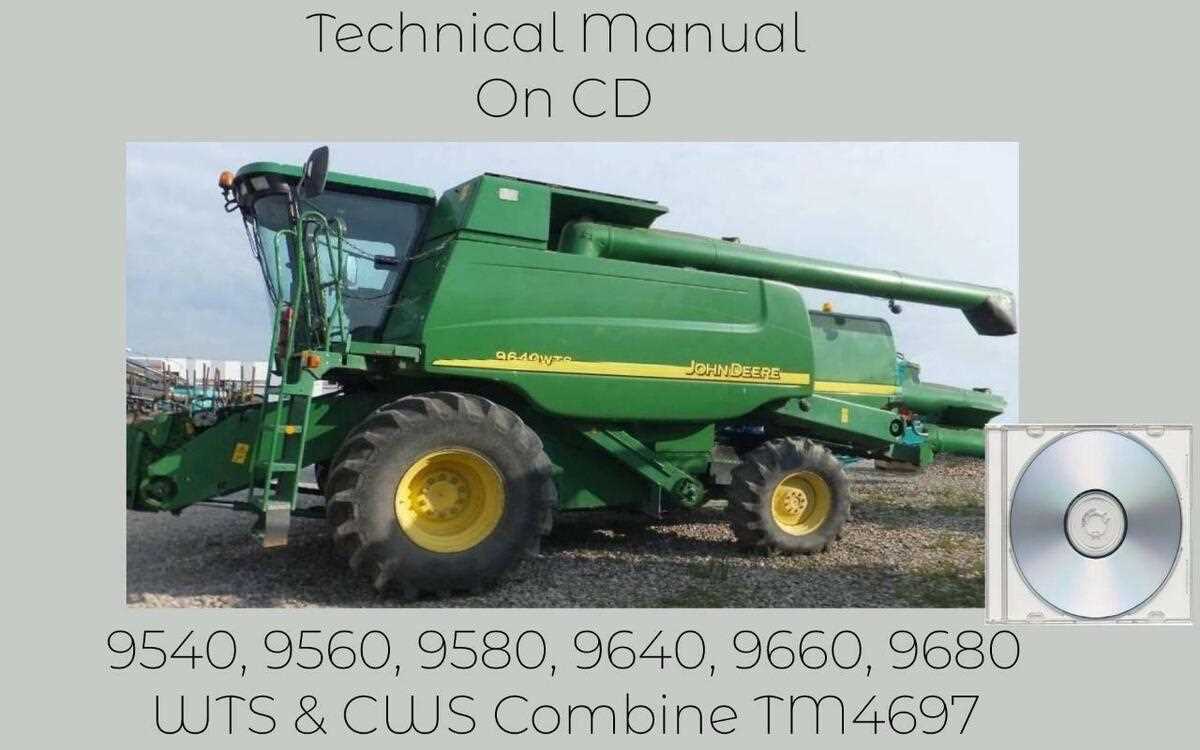

The efficient operation of agricultural machinery is essential for modern farming practices. Understanding the intricate layout of the various elements that comprise these machines allows operators to maintain and troubleshoot effectively. A well-structured layout enhances both performance and longevity, ensuring that each component functions harmoniously within the system.

In this section, we will delve into the specific features and functionalities of the machinery’s structure. By examining the arrangement and roles of individual components, users can gain valuable insights into optimal usage and maintenance practices. Familiarity with these aspects can lead to improved efficiency and reduced downtime during critical farming operations.

With a focus on clarity and precision, we will provide an organized representation of the machinery’s essential components. This resource serves as a valuable guide for operators and technicians alike, facilitating better understanding and management of the equipment.

This section provides a comprehensive look at the various components that make up a modern agricultural harvesting machine. Understanding these elements is essential for effective maintenance and operation, ensuring optimal performance during harvesting seasons.

| Component | Description |

|---|---|

| Header | The front attachment responsible for cutting and gathering crops. |

| Feeding System | Transports the harvested material from the header to the threshing area. |

| Threshing Unit | Separates the grain from the chaff, a critical part of the harvesting process. |

| Cleaning System | Removes debris and ensures the harvested grain is clean and ready for storage. |

| Grain Tank | Stores the harvested grain until it can be unloaded. |

| Engine | Powers the entire machine, providing the necessary energy for operation. |

Key Components of the 9600

The effectiveness of agricultural machinery greatly depends on its essential elements. Understanding the fundamental components enhances operational efficiency and maintenance. Each element plays a pivotal role in the overall functionality and productivity of the equipment.

Engine: The powerhouse of the machinery, responsible for providing the necessary energy for various operations. A well-maintained engine ensures optimal performance and longevity.

Header: This part is crucial for the initial cutting and gathering of crops. Different designs cater to specific crop types, making it vital for productivity.

Auger: Serving as a conduit for moving harvested material from the header to the main chamber, this component facilitates efficient processing and minimizes losses during transitions.

Threshing System: Essential for separating the grain from the chaff, this system employs various mechanisms to achieve effective results. Proper calibration is crucial for maximizing yield.

Chassis: The framework that supports all other components, ensuring stability and balance during operation. A robust chassis contributes to the machine’s durability and performance.

Control Systems: Modern machinery features advanced controls that enhance user interaction and precision. These systems monitor performance, allowing for adjustments to optimize operations.

Maintenance Tips for Combine Parts

Regular upkeep is essential for ensuring optimal performance and longevity of agricultural machinery. By following proper care practices, operators can prevent breakdowns, reduce repair costs, and enhance the overall efficiency of their equipment.

Routine Inspections

Conduct frequent checks of all components to identify wear and tear. Look for signs of damage or misalignment and address any issues promptly to maintain smooth operation.

Lubrication and Cleaning

Keep moving parts well-lubricated to minimize friction and prevent rust. Additionally, regular cleaning helps to remove debris and buildup, ensuring that machinery functions at its best.

Common Issues with 9600 Components

Various components of agricultural machinery can encounter frequent challenges that affect their performance and reliability. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity.

- Wear and Tear: Components may experience deterioration over time due to regular use, leading to decreased efficiency.

- Hydraulic System Failures: Leaks or malfunctions in the hydraulic system can cause operational disruptions.

- Electrical Malfunctions: Wiring issues or faulty sensors can result in erratic performance and error codes.

- Clogged Filters: Blockages in air or fuel filters can hinder the machine’s ability to operate smoothly.

- Drive Belt Issues: Wear on drive belts may lead to slippage or complete failure, affecting overall functionality.

Regular inspection and timely maintenance are essential to address these issues proactively and ensure uninterrupted operation.

Replacement Parts Availability

Access to essential components is crucial for maintaining the efficiency of agricultural machinery. Finding reliable sources for these items can significantly reduce downtime and enhance performance.

Various suppliers offer an extensive selection of these components, ensuring that operators can quickly acquire what they need. Online marketplaces, local dealers, and specialized retailers often provide both genuine and aftermarket options, catering to diverse preferences and budgets.

Additionally, some manufacturers maintain a comprehensive inventory, which simplifies the search process. Regular maintenance checks can also help identify which items are frequently needed, facilitating timely ordering and ensuring that equipment remains operational.

Aftermarket vs. OEM Parts

When it comes to replacement components for machinery, buyers often face a critical decision: whether to opt for aftermarket alternatives or original equipment manufacturer (OEM) offerings. Each option presents its own set of advantages and disadvantages, influencing not only performance but also cost and longevity.

Advantages of Aftermarket Options

Aftermarket solutions typically offer several benefits, making them an attractive choice for many users:

- Cost-Effectiveness: Generally, aftermarket products are less expensive than OEM items, providing a budget-friendly alternative.

- Variety: There is often a wider selection available, allowing users to choose from different brands and features.

- Enhanced Features: Some aftermarket components may include improvements or enhancements that OEM versions do not offer.

Benefits of OEM Components

Choosing OEM parts also has its merits, particularly in terms of reliability and compatibility:

- Quality Assurance: OEM products are manufactured to the original specifications, ensuring a high level of quality and performance.

- Guaranteed Fit: These components are designed specifically for the machinery, minimizing the risk of installation issues.

- Warranty Coverage: OEM parts often come with warranties, providing peace of mind regarding durability and performance.

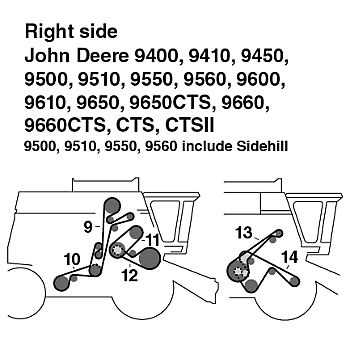

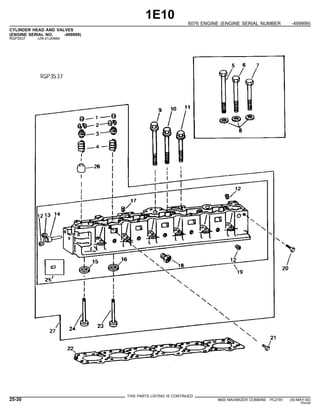

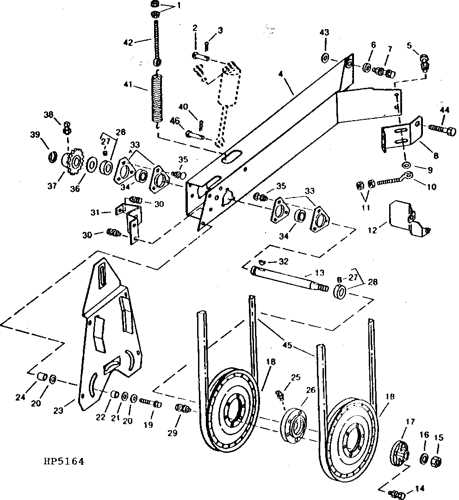

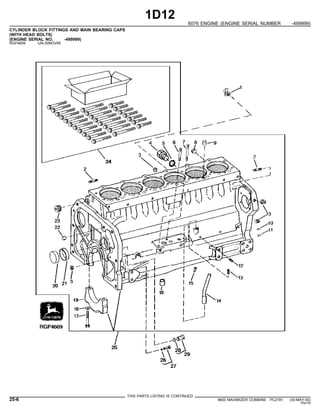

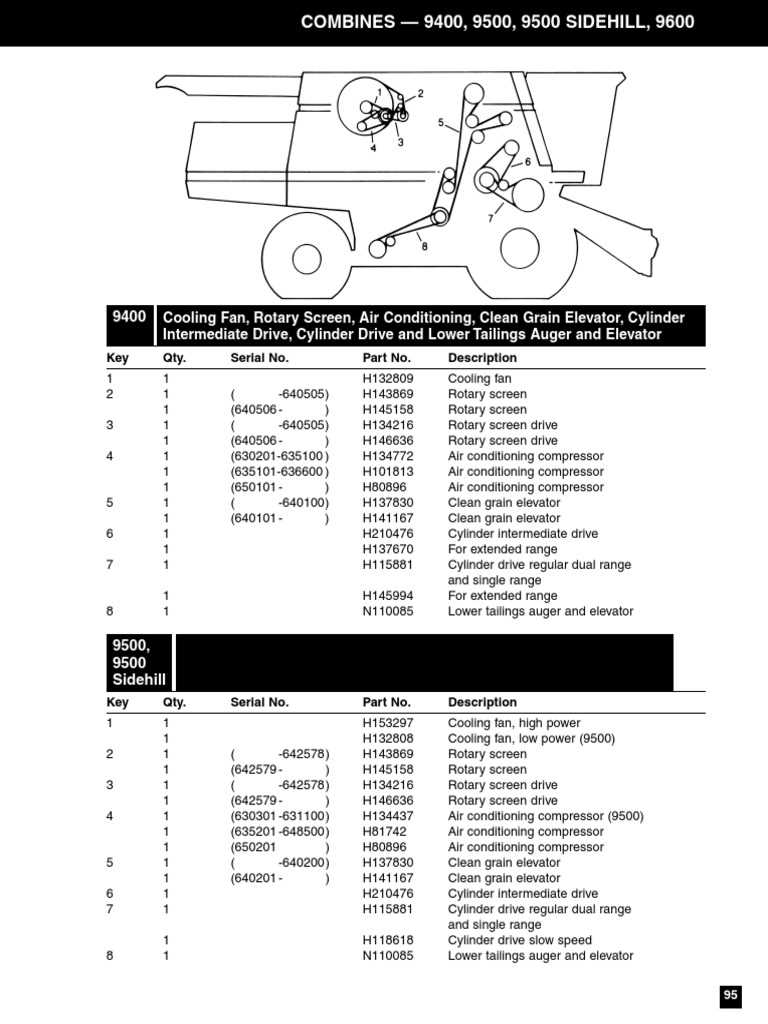

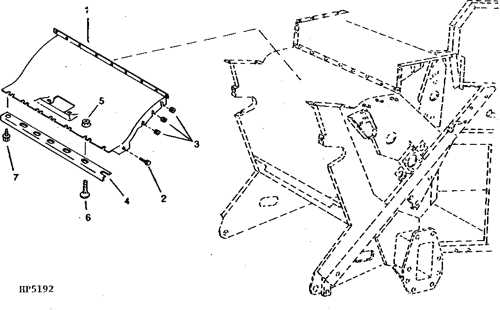

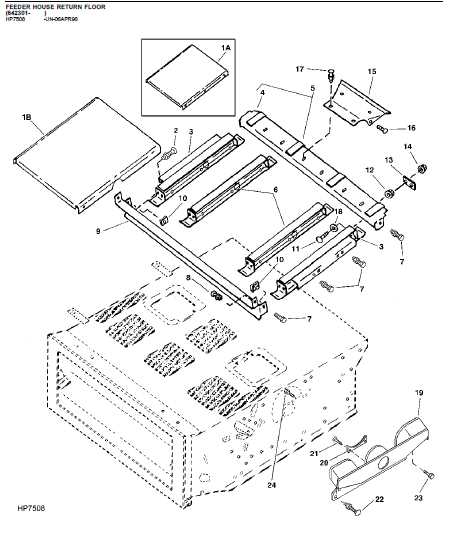

Understanding the Parts Diagram

This section provides insight into the layout and organization of components within a complex agricultural machine. A visual representation serves as an essential tool for identifying and comprehending various elements that contribute to the equipment’s overall functionality.

Key Components Overview

Familiarity with the essential elements is crucial for effective maintenance and troubleshooting. Here are the primary categories of components:

- Engine and Power Transmission

- Harvesting Mechanisms

- Control Systems

- Chassis and Structural Parts

Benefits of Understanding the Layout

Comprehending the structure offers several advantages:

- Facilitates efficient repairs and replacements.

- Enhances the ability to diagnose issues accurately.

- Improves maintenance scheduling by recognizing wear patterns.

How to Read the Diagram

Understanding visual representations of machinery components is essential for effective maintenance and repairs. These illustrations provide valuable insights into the structure and arrangement of various elements, allowing for easier identification and troubleshooting.

To interpret the visual guide effectively, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the symbols used, as they indicate different components and their functions. |

| 2 | Identify the main sections of the illustration, which often group related components together for clarity. |

| 3 | Follow the flow lines or connections that demonstrate how different parts interact within the system. |

| 4 | Use accompanying legends or notes that provide additional information about specific components. |

Diagram Legend and Symbols

The key to understanding any technical illustration lies in its legend and symbols. This section aims to elucidate the various representations used in the visual guides, helping users decode the information presented effectively. Recognizing these symbols is crucial for interpreting the operational components and functionalities accurately.

Common Symbols and Their Meanings

Various icons are utilized to depict different elements and functionalities within the visual aids. For instance, a triangle often signifies a critical alert or warning, while a circle may represent a standard operating procedure. Familiarity with these symbols enhances comprehension and ensures proper operation and maintenance.

Color Coding in Visual Guides

In addition to symbols, color coding plays a significant role in differentiating between parts and functions. Each color typically represents a specific category, such as electrical systems or hydraulic components. Understanding this color scheme aids in quickly locating relevant information and facilitating efficient troubleshooting.

Parts Identification Using Diagrams

Understanding the layout and functionality of machinery components is essential for effective maintenance and repairs. Visual representations serve as valuable tools for recognizing various elements, ensuring that each component is correctly identified and utilized during servicing.

Benefits of Visual Aids

- Enhanced clarity in identifying components

- Streamlined troubleshooting and repair processes

- Facilitation of training for new operators

Utilizing Reference Images

Reference images can greatly assist in locating specific elements. By following visual guides, users can:

- Quickly find the required component for replacement.

- Ensure proper assembly during reinstallation.

- Minimize errors and enhance efficiency in repairs.

Benefits of Using Parts Diagrams

Utilizing visual representations of components can significantly enhance the understanding of complex machinery. These illustrations serve as essential tools for identifying individual elements, facilitating effective maintenance and repairs. By providing a clear view of the assembly, they enable users to navigate through intricate systems with greater ease.

Enhanced Clarity

Visual aids reduce ambiguity when addressing mechanical issues. Technicians can quickly pinpoint the necessary elements, minimizing the risk of miscommunication or errors during repairs. This clarity ensures that all involved parties are on the same page, promoting efficiency in problem-solving.

Efficient Maintenance

Having a comprehensive visual guide simplifies routine upkeep. Operators can easily refer to the illustrations to locate parts that require attention, ensuring that machinery remains in optimal condition. This proactive approach not only extends the lifespan of the equipment but also improves overall productivity.

| Advantage | Description |

|---|---|

| Improved Understanding | Facilitates easier identification of components. |

| Time-Saving | Reduces time spent on locating and fixing issues. |

| Increased Safety | Helps avoid errors that could lead to accidents. |

Improving Repair Efficiency

Enhancing the effectiveness of maintenance procedures can significantly reduce downtime and costs associated with equipment repairs. By adopting systematic approaches, operators can ensure swift and accurate interventions, leading to prolonged machinery lifespan and improved overall productivity.

Utilizing Comprehensive Documentation

Having access to thorough manuals and schematics is essential for efficient troubleshooting and repairs. These resources provide valuable insights into components and assembly, enabling technicians to quickly identify issues and implement solutions without unnecessary delays.

Implementing Regular Maintenance Practices

Establishing a routine maintenance schedule helps in early detection of potential failures. By monitoring the performance and condition of machinery regularly, operators can address minor issues before they escalate, thereby minimizing the need for extensive repairs and ensuring operational continuity.