Maintaining efficient outdoor machinery during the chilly months is crucial for ensuring optimal performance. A comprehensive overview of the individual elements that contribute to the functionality of these machines can greatly assist users in troubleshooting and repairs. This section aims to provide clarity on the various components involved in such equipment, helping to demystify their roles and significance.

Exploring the intricacies of these elements not only enhances the user experience but also empowers operators to take charge of their maintenance needs. By familiarizing oneself with the specific functions of each component, users can effectively diagnose issues and extend the longevity of their equipment. A thorough understanding can lead to improved performance and reliability when faced with winter challenges.

Whether you are a seasoned operator or a newcomer to the world of winter machinery, gaining insights into the various components is beneficial. This knowledge can serve as a foundation for informed decision-making regarding repairs, upgrades, and replacements, ultimately ensuring that your equipment is always ready to tackle the cold.

Understanding frequent problems encountered during winter operations can greatly enhance the performance and longevity of outdoor equipment designed for clearing pathways. Many users face challenges that can stem from a variety of factors, ranging from mechanical failures to operational oversights.

Here are some typical complications that users may experience:

| Issue | Description | Possible Solution |

|---|---|---|

| Difficulty Starting | Equipment fails to ignite or run smoothly. | Check fuel levels, inspect the spark plug, and ensure the battery is charged. |

| Reduced Clearing Efficiency | Material is not being removed effectively. | Examine the blades for damage and clear any blockages in the chute. |

| Excessive Vibrations | Noticeable shaking during operation. | Inspect for loose components and ensure proper assembly of parts. |

| Stalling During Use | Unit stops operating unexpectedly. | Verify fuel quality and ensure air filters are clean. |

How to Identify Replacement Parts

Understanding how to locate and recognize essential components for machinery maintenance is crucial for ensuring optimal functionality. Proper identification aids in acquiring the correct elements needed for repairs and enhances the lifespan of your equipment.

Consult the Owner’s Manual

The owner’s manual serves as a valuable resource for locating specific component details. It typically contains diagrams, part numbers, and descriptions that simplify the identification process.

Utilize Online Resources

Online platforms often provide detailed catalogs and forums where users can seek advice and share experiences. These resources are helpful for confirming part specifications and compatibility.

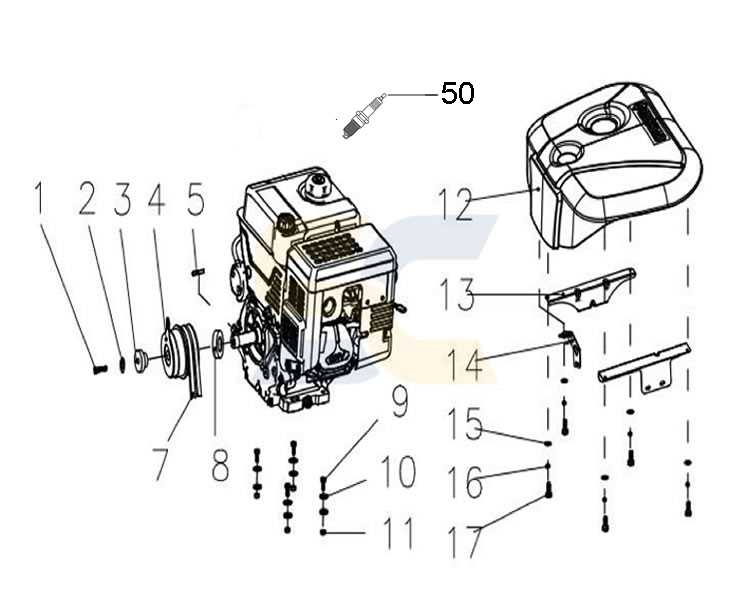

Visual Guide to Snow Blower Parts

This section provides a comprehensive overview of the essential components that make up a powerful winter clearing machine. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance during harsh weather conditions.

| Component | Description |

|---|---|

| Augers | These rotating blades gather and direct the snow into the discharge chute. |

| Impeller | This component helps propel the snow through the chute for effective throwing distance. |

| Chassis | The frame that supports all other components, providing stability and structure. |

| Discharge Chute | This adjustable opening directs the snow away from the clearing area. |

| Skid Shoes | These help regulate the height of the machine above the ground for optimal performance. |

Tools Required for Repairs

Effective maintenance and repair of equipment necessitate a specific set of tools. Having the right instruments not only streamlines the process but also ensures safety and precision in every task. This section outlines the essential implements needed to address common issues and perform necessary adjustments.

Basic Hand Tools

Essential hand tools form the foundation of any repair job. A selection of screwdrivers, wrenches, and pliers will be crucial for disassembling components and tightening connections. Socket sets are particularly useful for accessing tight spaces, while adjustable wrenches provide versatility in handling various fasteners.

Specialized Equipment

In addition to basic hand tools, specialized equipment may be required for more complex repairs. Torque wrenches ensure that bolts are tightened to the manufacturer’s specifications, preventing damage or failure during operation. Lubrication tools such as grease guns are important for maintaining smooth functionality and prolonging the lifespan of moving parts.

Maintenance Tips for Longevity

Proper upkeep is essential to extend the lifespan of your outdoor equipment. Regular attention to key components not only enhances performance but also prevents costly repairs. Following a structured maintenance routine can ensure optimal functionality and durability over time.

Routine Inspections

Conducting frequent checks on vital elements is crucial. Look for signs of wear and tear, such as frayed belts or loose screws. Addressing minor issues promptly can prevent more significant problems later on.

Seasonal Care

Adjust your maintenance practices according to the seasons. Clean any debris after use, and store the equipment in a dry, sheltered space. This proactive approach minimizes exposure to harsh weather, contributing to the ultimate longevity of your machinery.

Ordering Parts from Authorized Dealers

Acquiring components from certified retailers ensures quality and compatibility for your machinery. When seeking replacements or upgrades, it’s crucial to rely on trusted sources to avoid issues that may arise from inferior alternatives. Authorized dealers provide not only genuine items but also expert assistance, enhancing your overall experience.

Steps to Order

Start by identifying the specific components you require. Consult your user manual or parts list to pinpoint the exact items needed. Once you have this information, visit the dealer’s website or contact them directly. Many authorized retailers offer online ordering systems, making it convenient to browse inventory and place orders from the comfort of your home.

Benefits of Authorized Retailers

Choosing authorized retailers comes with several advantages. First, you are guaranteed to receive authentic items that meet manufacturer standards. Additionally, these dealers often provide warranties on their products, giving you peace of mind. Should you encounter any issues during installation or operation, their knowledgeable staff is readily available to assist you.

Final Considerations

Always compare prices and check for available promotions. While genuine components may cost more than aftermarket options, the long-term reliability and performance typically justify the investment. Prioritize your equipment’s longevity and efficiency by sourcing components from authorized suppliers.

DIY Repairs: Step-by-Step Guide

Taking on repairs yourself can save both time and money, while also giving you a sense of accomplishment. This guide will walk you through essential steps to tackle common issues with your outdoor equipment effectively and confidently.

Before you begin, it’s important to gather the necessary tools and materials. Here’s what you’ll need:

- Screwdriver set

- Wrench set

- Replacement components

- Lubricating oil

- Safety gloves and goggles

Now, let’s break down the repair process into manageable steps:

- Identify the Problem: Carefully assess the equipment to determine the exact issue. Look for unusual sounds, leaks, or visible wear and tear.

- Refer to the Manual: Consult the user manual for specific troubleshooting tips and part numbers. This will guide you in the right direction.

- Disassemble the Unit: Use the appropriate tools to take apart the equipment, noting the order of disassembly for easier reassembly.

- Inspect Components: Examine each part for damage or wear. Replace any broken or worn items with new ones.

- Clean Thoroughly: Remove dirt and debris from all components to ensure optimal performance.

- Reassemble: Carefully put the equipment back together, following the order you noted during disassembly.

- Test Functionality: Once reassembled, run the equipment to ensure everything is working as intended.

By following these steps, you can effectively manage repairs on your outdoor tools, keeping them in good working condition for years to come.

Resources for Snow Blower Users

Having access to reliable information and tools is essential for maintaining your winter equipment. Whether you are seeking guidance on repairs, looking for user manuals, or trying to find compatible accessories, various resources can enhance your experience and ensure your machinery operates efficiently during the cold months.

Online Communities and Forums

Joining online communities can provide invaluable support. Enthusiasts and experts share tips, troubleshooting advice, and personal experiences. Engaging in these platforms not only helps solve issues but also fosters a sense of camaraderie among users.

Manufacturer Resources

Official websites often offer extensive resources, including user manuals and maintenance guidelines. Product manuals provide essential information about operations and safety, while maintenance schedules help you keep your equipment in top shape.