Understanding the structure and function of various elements in a mechanical device is crucial for effective maintenance and repair. By familiarizing yourself with the key components, you can ensure optimal performance and extend the lifespan of the equipment. Each element plays a specific role in contributing to the overall efficiency and functionality of the machine.

In this guide, we will explore the core units, highlighting their significance and how they interact with each other. This detailed overview will help in identifying potential issues and provide clarity on how different sections work in harmony, ensuring smooth operation.

Whether you’re maintaining your device or conducting repairs, having a clear understanding of its framework is essential. By delving into each segment, you’ll be able to approach any technical task with confidence and precision.

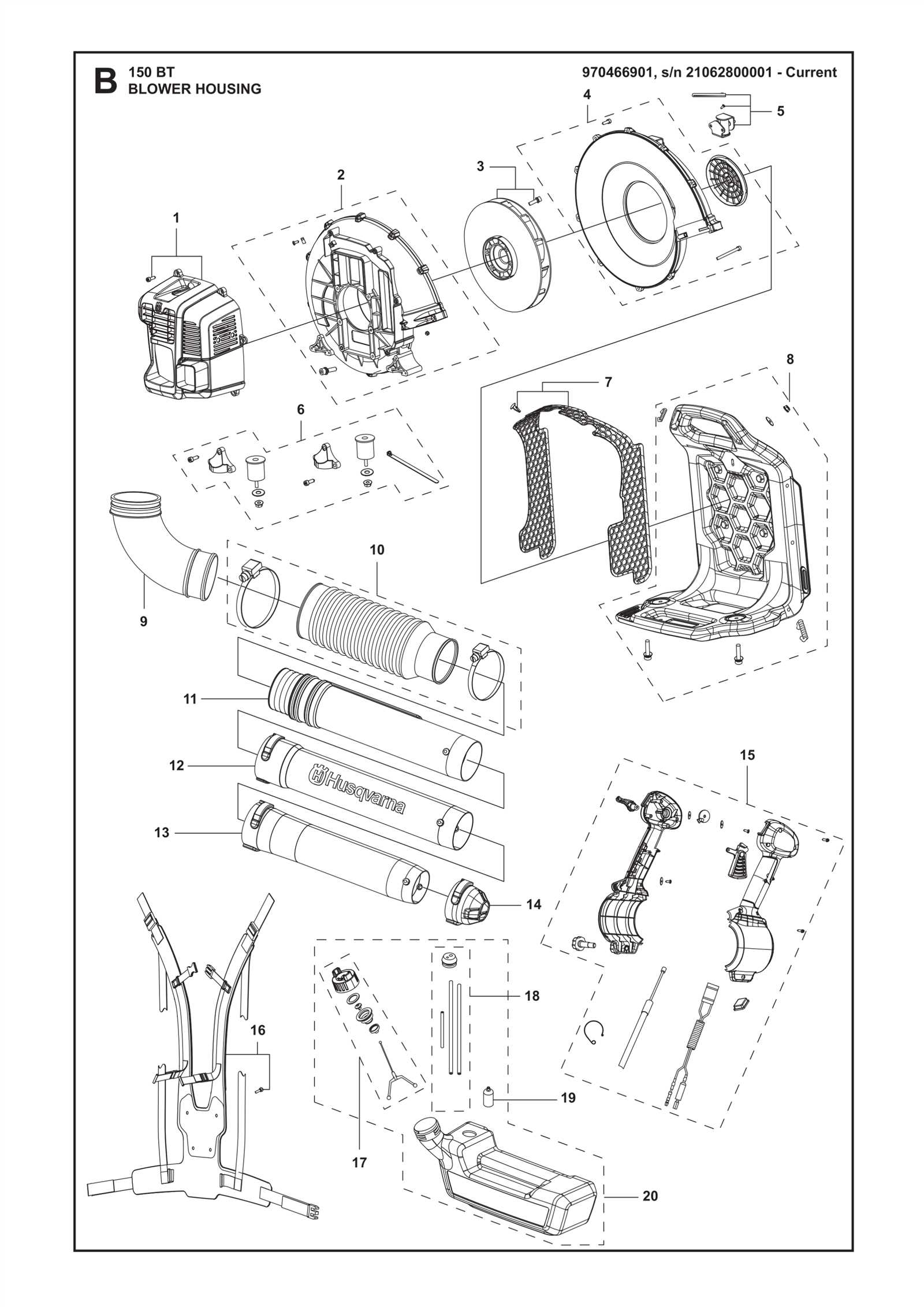

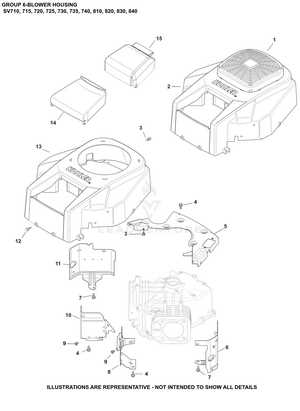

Overview of Husqvarna Blower Components

Understanding the essential elements of outdoor power equipment is crucial for optimal performance and longevity. Each mechanism within the device plays a unique role, working together to provide efficient operation. In this section, we’ll explore the key structures that contribute to the system’s overall functionality.

Engine and Power Source

The core of any outdoor tool lies in its engine. Whether powered by fuel or electricity, the engine is responsible for driving all other components. It generates the necessary force to move air efficiently, ensuring consistent and powerful operation.

- Fuel tank or battery compartment – supplies energy to the engine.

- Ignition system – starts the motor and controls its running condition.

Airflow System

The airflow system is designed to optimize the movement of air through the machine. By channeling air efficiently, this system enables powerful performance, suitable for various outdoor tasks

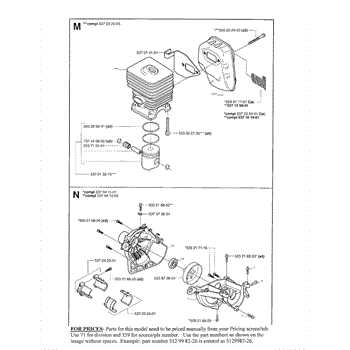

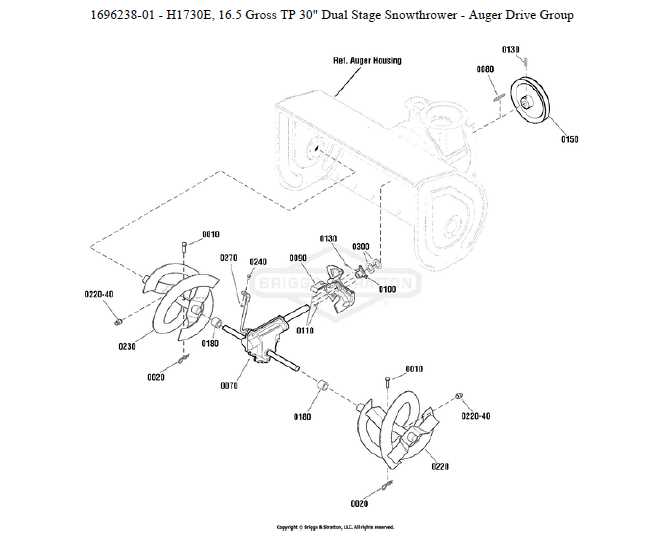

Key Parts in Husqvarna Blowers

Effective outdoor cleaning tools rely on well-designed components that work together to ensure performance and durability. Each element plays a crucial role in maintaining the efficiency and reliability of the device, ensuring smooth airflow and power delivery.

The primary motor assembly provides the driving force, while precision-engineered blades are responsible for creating a strong air current. The housing, typically made of durable materials, protects internal mechanisms and aids in airflow control. Essential filters ensure the machine runs smoothly by preventing debris from clogging the system.

Other important components include the intake and exhaust systems, which manage the flow of air through the device, and ergonomic handles, designed for comfort during extended use. All these elements contribute to the overall functionality and longevity of the equipment.

Common Blower Assembly Issues

Assembly-related malfunctions can often arise due to improper installation or wear of individual components. Identifying these problems early helps avoid larger failures and ensures smooth operation of the device. Below are some of the most frequent concerns observed in this type of equipment assembly.

Loose or Misaligned Components

One common issue is the loosening or misalignment of essential parts within the system. Vibrations during use can cause screws and fasteners to become loose, resulting in poor performance or potential damage to the mechanism. Regular inspection and tightening of these connections can prevent this problem.

Obstructions in Airflow

Blockages in the airflow path can occur due to debris buildup, which significantly impacts the efficiency of the device. Keeping the system clean and ensuring that no foreign objects enter the assembly will help maintain optimal functionality.

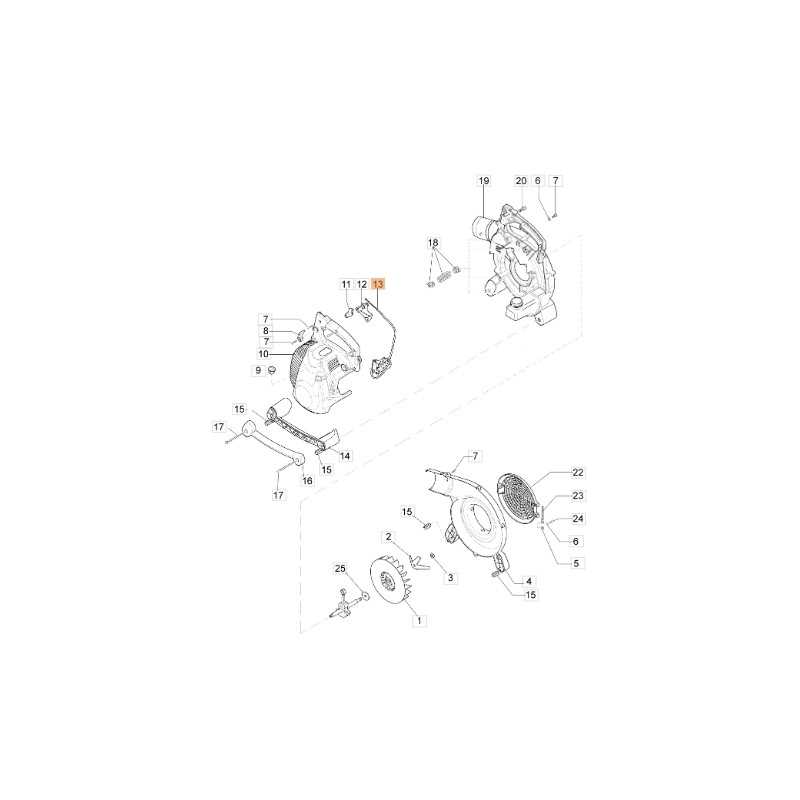

How to Identify Specific Blower Parts

Understanding the various components of your equipment is essential for proper maintenance and efficient repairs. Whether you’re replacing a damaged part or simply checking for wear and tear, being able to recognize the individual pieces is key to ensuring smooth operation.

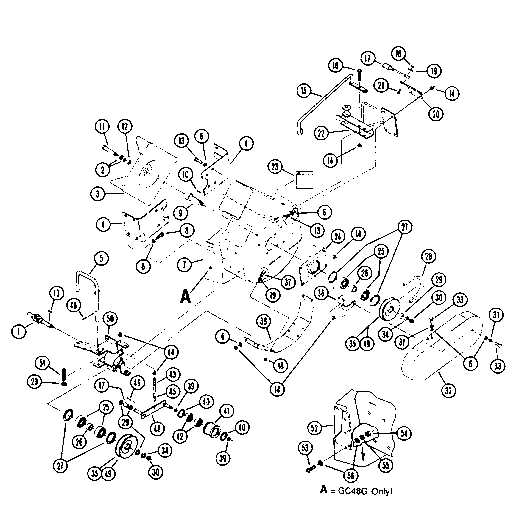

Recognizing the Key Components

Each machine is made up of several critical elements that work together to deliver optimal performance. Start by identifying the primary sections, such as the engine, fan assembly, and control system. Familiarize yourself with the shape, size, and location of these parts, as they are typically the most visible and easily distinguishable.

Detailed Inspection Techniques

For a more detailed approach, look closely at the smaller components that might be harder to spot. These include screws, seals, and connectors. By carefully examining their condition and position, you can pinpoint which piece might need attention or replacement, ensuring your machine remains in top working condition.

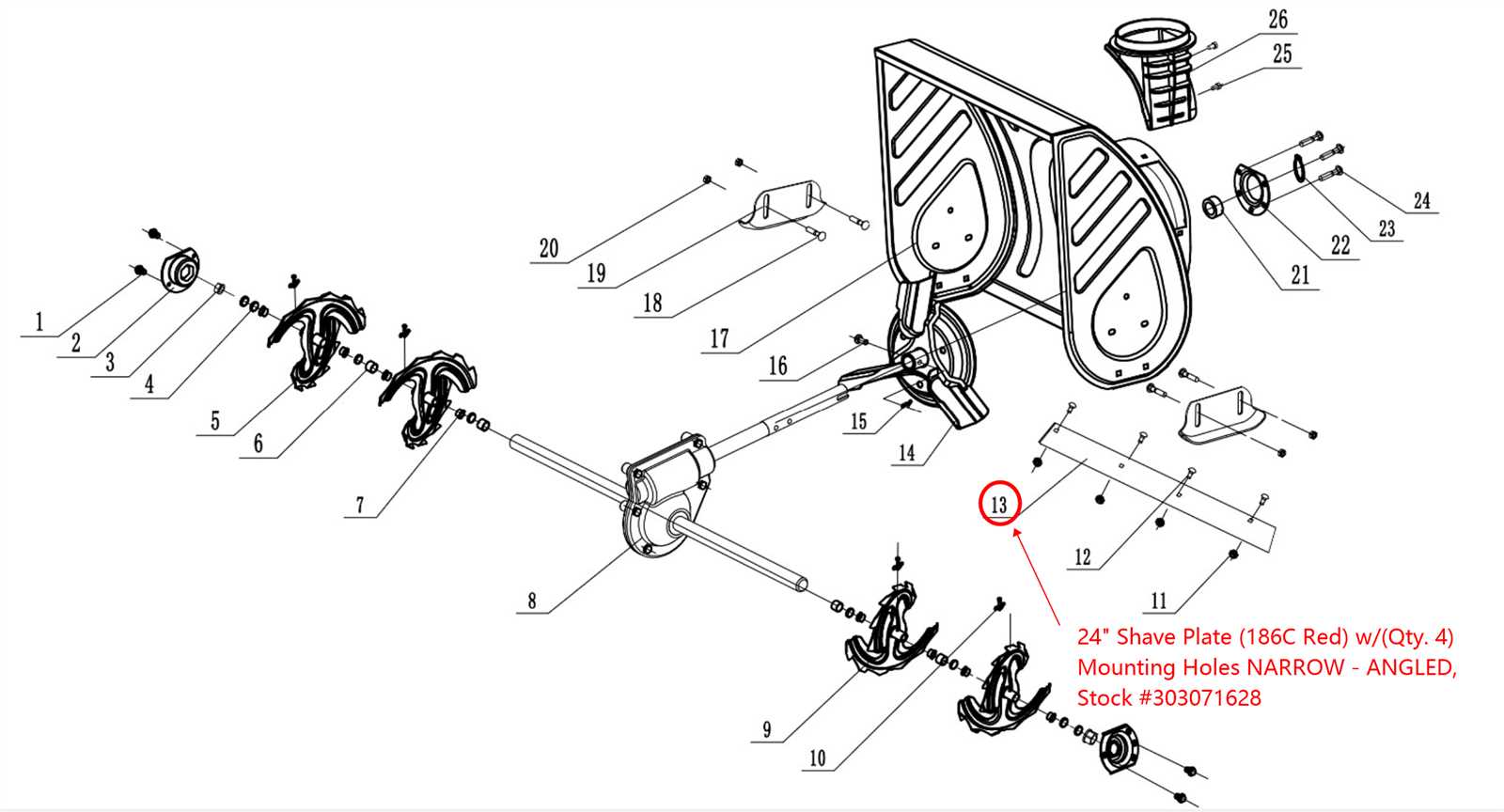

Replacing Worn Blower Components

Over time, various components of the machine experience natural wear and tear. Regular maintenance helps ensure smooth operation and extends the life of the equipment. Identifying and replacing any deteriorated parts in a timely manner is key to maintaining efficiency.

Signs of Component Wear

Before replacing any elements, it’s crucial to recognize the indicators of wear. Common signs include reduced performance, unusual noises, or visible damage to specific elements. Ignoring these warning signs can lead to more significant issues.

- Decreased airflow or power

- Excessive vibrations or rattling sounds

- Visible cracks or frayed edges on moving parts

Steps for Replacement

Once wear has been detected, the replacement process involves a few straightforward steps. Having the correct tools and replacement parts on hand will streamline the task and ensure safe handling.

Maintenance Tips for Husqvarna Blowers

Regular upkeep is essential for ensuring the longevity and efficient performance of your outdoor equipment. Implementing a consistent maintenance routine can prevent potential issues and enhance the overall functionality of your machine.

Start by routinely checking the air filter to ensure it is clean and free from debris. A blocked filter can hinder airflow, leading to reduced performance. Replace it as needed to maintain optimal operation.

Additionally, inspect the fuel system regularly. Using fresh fuel and checking for leaks will help keep the engine running smoothly. It is advisable to clean the fuel filter periodically to prevent clogging and ensure proper fuel flow.

Don’t forget to sharpen the cutting edges if applicable. Sharp blades are crucial for effective performance, allowing your equipment to operate more efficiently and providing better results.

Lastly, store your equipment in a dry, protected environment when not in use. This practice helps avoid corrosion and damage from the elements, prolonging the life of your machinery.

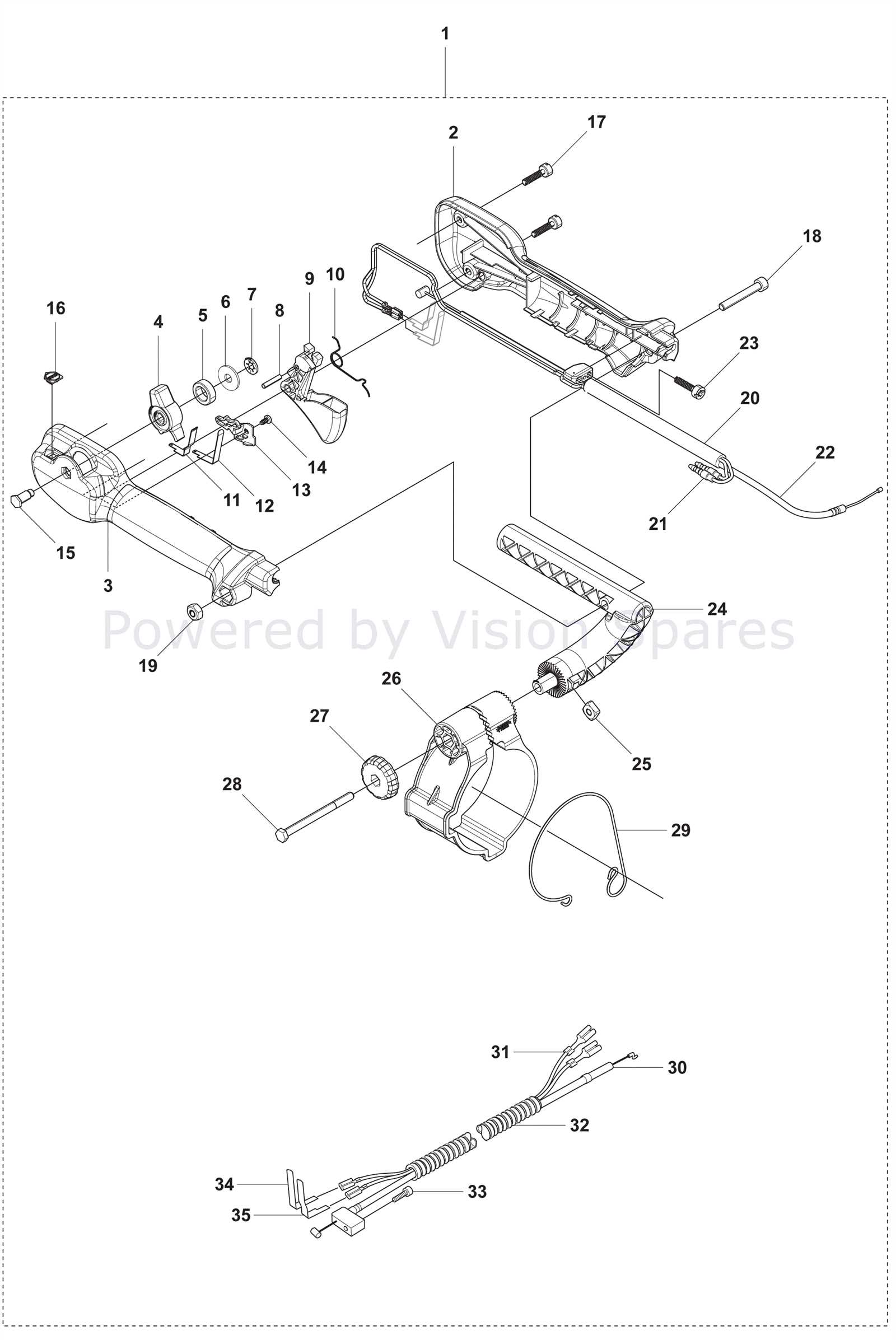

Understanding the Motor System

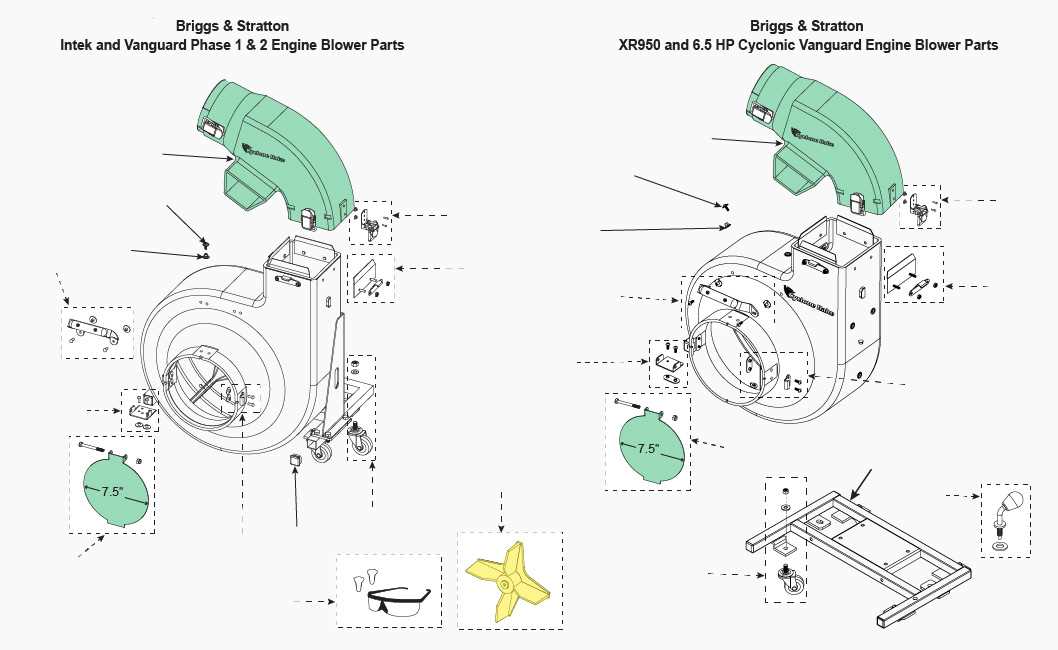

The motor system of a leaf clearing device is a crucial component that ensures optimal performance and efficiency. It comprises various elements that work together to convert electrical energy into mechanical energy, enabling the equipment to operate smoothly. A thorough comprehension of this system can enhance maintenance efforts and prolong the lifespan of the device.

Components of the Motor System

The motor system includes several key components such as the rotor, stator, and bearings. The rotor is responsible for rotating and generating airflow, while the stator provides the magnetic field necessary for the motor to function. Additionally, bearings facilitate smooth movement, reducing friction and wear over time.

Importance of Regular Maintenance

Regular maintenance of the motor system is essential for optimal performance. This includes checking for wear and tear, ensuring proper lubrication, and cleaning any debris that may obstruct airflow. By keeping these components in good condition, users can ensure efficient operation and avoid potential breakdowns.

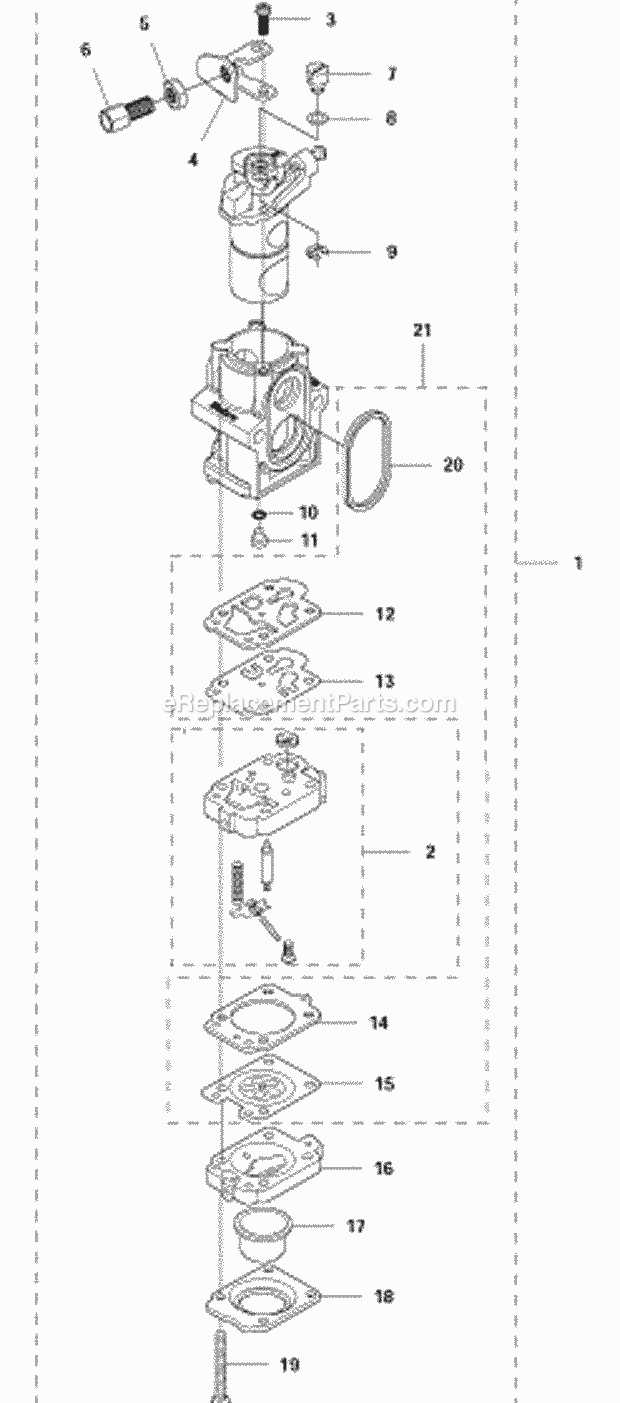

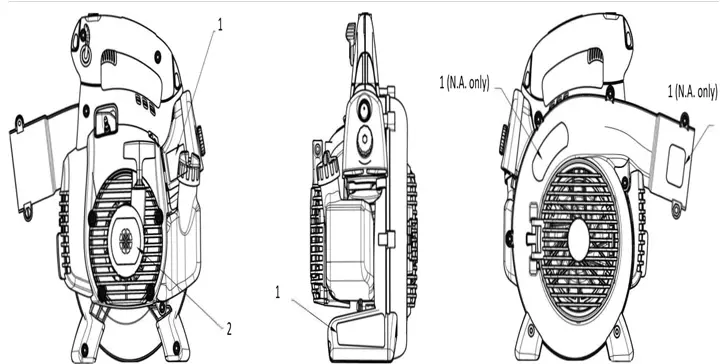

Efficient Airflow Mechanism in Blowers

The design and functionality of air circulation devices are pivotal in enhancing performance and ensuring optimal operation. Understanding the underlying mechanisms that facilitate effective airflow can significantly improve the efficiency and longevity of these tools.

Key elements that contribute to the efficient airflow include:

- Impeller Design: A well-designed impeller is crucial for generating high air velocity. Its shape and angle influence the volume of air moved and the speed at which it is expelled.

- Aerodynamic Ducting: Smooth and streamlined ducts minimize resistance, allowing for unimpeded airflow. The path that air takes through the device can affect performance greatly.

- Intake Vents: Properly placed intake vents ensure a steady flow of air into the system, preventing blockages and enhancing overall efficiency.

Maintaining these components in optimal condition is essential for preserving the device’s functionality:

- Regular cleaning of the intake vents to avoid dirt accumulation.

- Periodic inspection of the impeller for any signs of wear or damage.

- Ensuring that the ducting is free from obstructions that could hinder airflow.

By focusing on these aspects, users can ensure that their air circulation devices operate efficiently, providing reliable performance for various tasks.

Guide to Husqvarna Blower Accessories

Understanding the various attachments and enhancements available for outdoor equipment can significantly enhance its functionality and performance. This section will explore essential accessories that complement your gardening tool, making it more versatile and effective for different tasks.

- Replacement Nozzles: Different nozzles can alter airflow and direction, allowing for more precise cleaning. Consider options such as wide or concentrated nozzles based on your specific needs.

- Vacuum Kits: These kits enable the user to convert their equipment into a vacuum, perfect for collecting leaves and debris efficiently.

- Shoulder Straps: Comfortable straps can help distribute weight evenly, reducing fatigue during extended use and improving overall handling.

- Protective Gear: Investing in safety equipment such as goggles and ear protection is essential to ensure a safe working environment while using powerful tools.

- Replacement Filters: Regularly changing filters will maintain optimal performance and extend the life of your equipment.

Incorporating these accessories into your toolkit can enhance your outdoor experience, making tasks more manageable and enjoyable.

Diagnosing Problems in Blower Systems

Identifying issues within air circulation mechanisms is crucial for maintaining optimal performance. Understanding common symptoms can aid in pinpointing the underlying causes of malfunctions. A systematic approach to troubleshooting can save time and prevent further damage.

Common Symptoms and Their Causes

| Symptom | Possible Cause |

|---|---|

| Inconsistent airflow | Clogged filters or ducts |

| Excessive noise | Loose components or debris |

| Overheating | Blocked vents or motor issues |

| Unusual vibrations | Imbalanced or damaged blades |

Troubleshooting Steps

To effectively address identified issues, follow these basic troubleshooting steps. Begin by inspecting the system for visible obstructions. Next, check the components for wear and tear, ensuring everything is properly secured. Regular maintenance, including cleaning and replacing filters, can significantly enhance the longevity and efficiency of the device.

Choosing the Right Parts for Repairs

When it comes to maintaining outdoor equipment, selecting suitable components is crucial for ensuring optimal performance and longevity. Identifying the correct replacements not only enhances functionality but also contributes to overall safety during operation.

To make informed decisions, consider the following aspects:

- Compatibility: Ensure that the replacements are designed for your specific equipment model to avoid any fitting issues.

- Quality: Opt for high-quality alternatives to guarantee durability and reliability during use.

- Manufacturer Recommendations: Refer to guidelines provided by the manufacturer to find suggested components.

- Reviews and Ratings: Investigate user feedback and ratings to assess the performance of various options.

- Warranty and Support: Check if the components come with a warranty, as this can provide peace of mind in case of defects.

By considering these factors, you can ensure that your repairs are effective and that your equipment remains in top condition for all your outdoor tasks.