In the realm of industrial machinery, specific systems play a crucial role in enhancing efficiency and performance. A thorough comprehension of these systems, especially their internal mechanisms, is vital for optimal operation and maintenance. By examining the individual elements that contribute to the overall functionality, operators and technicians can ensure longevity and reliability in their applications.

Each segment within these systems has a distinct purpose, working harmoniously to achieve desired outcomes. From the main housing to the intricate internal features, understanding how these components interact can shed light on common issues and maintenance practices. Recognizing the significance of each piece not only aids in troubleshooting but also enhances the knowledge base of anyone involved in the management or operation of such technologies.

As we delve deeper into the specifics, it becomes clear that familiarity with the layout and functionality of these essential units is indispensable. By providing a visual representation and detailed description of each element, we can better appreciate the complexities involved and the precision required for successful operation. This exploration is essential for both seasoned professionals and newcomers to the field, promoting a deeper understanding of the intricacies at play.

Understanding Roots Blower Functionality

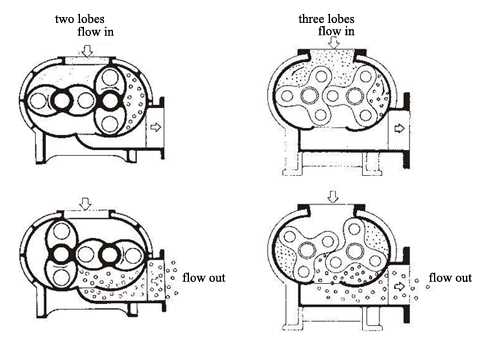

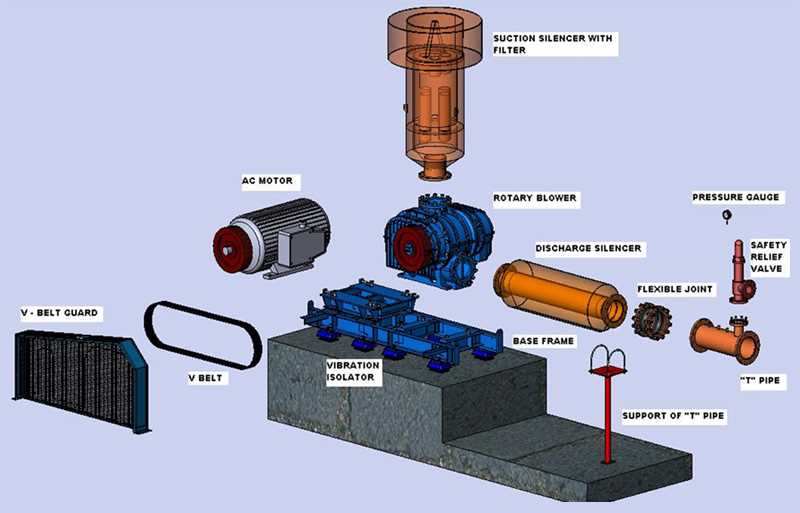

The operation of this specific air-moving device involves the efficient manipulation of gases to achieve optimal performance. By examining its mechanics, one can appreciate how it generates a consistent flow while minimizing energy loss.

At its core, the mechanism employs two rotating lobes that trap and transport air, creating a cycle of compression and discharge. Efficiency is enhanced by precise engineering, ensuring that the unit operates smoothly under varying loads. Key components work in harmony to maintain stability and reliability, making it indispensable in numerous industrial applications.

Understanding the intricacies of this system reveals the ultimate synergy between design and functionality, allowing for effective management of airflow in diverse settings.

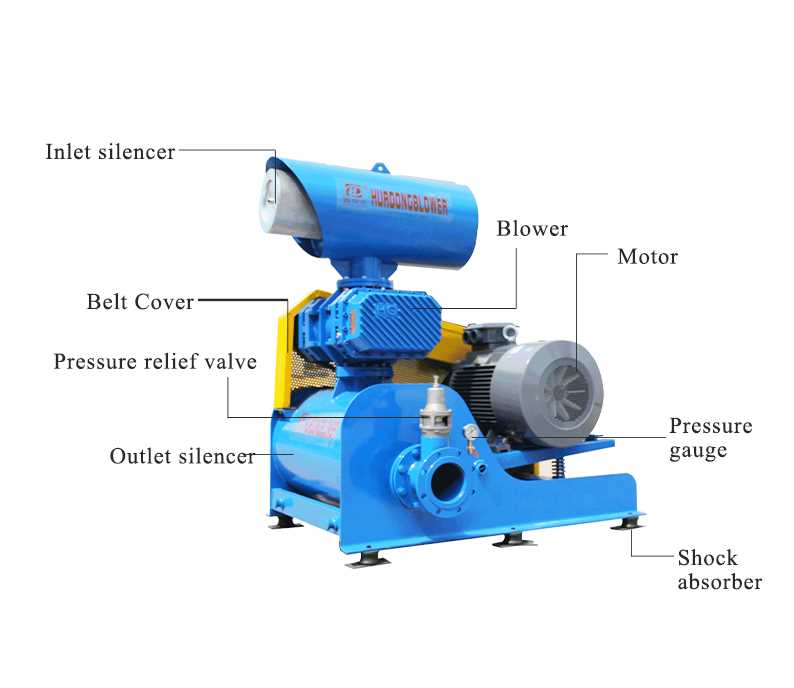

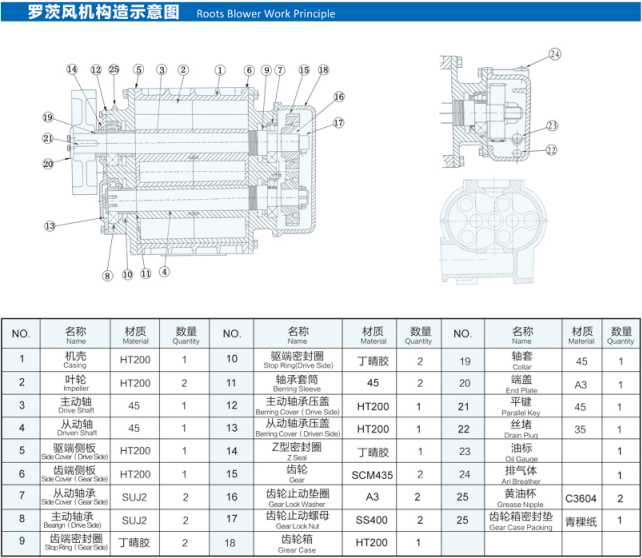

Key Components of Roots Blowers

Understanding the essential elements of this type of mechanical device is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and efficiency, contributing to the overall functionality of the system.

Rotors

The rotors are fundamental to the operation of the machine, responsible for creating the movement of air or gas. Their precise design allows for minimal leakage and maximizes volumetric efficiency. Typically, they operate in a synchronized manner to compress the incoming medium effectively.

Housing

The housing encloses the internal mechanisms and provides structural integrity to the assembly. It is designed to withstand pressure and protect the internal components from external contaminants. Proper sealing and alignment within the housing are critical for preventing loss of efficiency and ensuring longevity.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in understanding complex mechanical systems. They serve as a visual guide, helping individuals grasp the relationships and functions of various components. By utilizing these representations, users can ensure efficient maintenance, troubleshooting, and overall performance of machinery.

Enhancing Understanding

Well-crafted visuals simplify intricate details, allowing users to quickly identify elements and their purposes. This clarity can significantly reduce errors during repairs and adjustments, leading to improved operational efficiency.

Facilitating Communication

Clear representations foster better communication among team members. When everyone can refer to the same visual reference, discussions become more focused, reducing misunderstandings and enhancing collaboration.

| Benefit | Description |

|---|---|

| Clarity | Helps in understanding complex structures and functions. |

| Efficiency | Streamlines maintenance and repair processes. |

| Collaboration | Improves communication and teamwork. |

Common Applications of Roots Blowers

This technology is widely utilized across various industries due to its efficiency and reliability. Its design allows for the movement of air and gases in a consistent manner, making it suitable for numerous applications where a steady flow is crucial.

Wastewater Treatment: In this sector, the equipment is essential for aeration processes, ensuring that microorganisms receive the necessary oxygen for effective decomposition of organic matter.

Pneumatic Conveying: The system is frequently employed for transporting bulk materials in manufacturing settings, providing a reliable method to move powders and granules without damage.

Vacuum Systems: This technology is instrumental in creating vacuum environments for various processes, including packaging and material handling, enhancing operational efficiency.

Food Processing: In the food industry, it is utilized for mixing and aerating ingredients, contributing to the production of high-quality products while maintaining hygiene standards.

Mining Operations: Here, the system assists in dust control by providing a steady airflow, improving working conditions and safety for personnel.

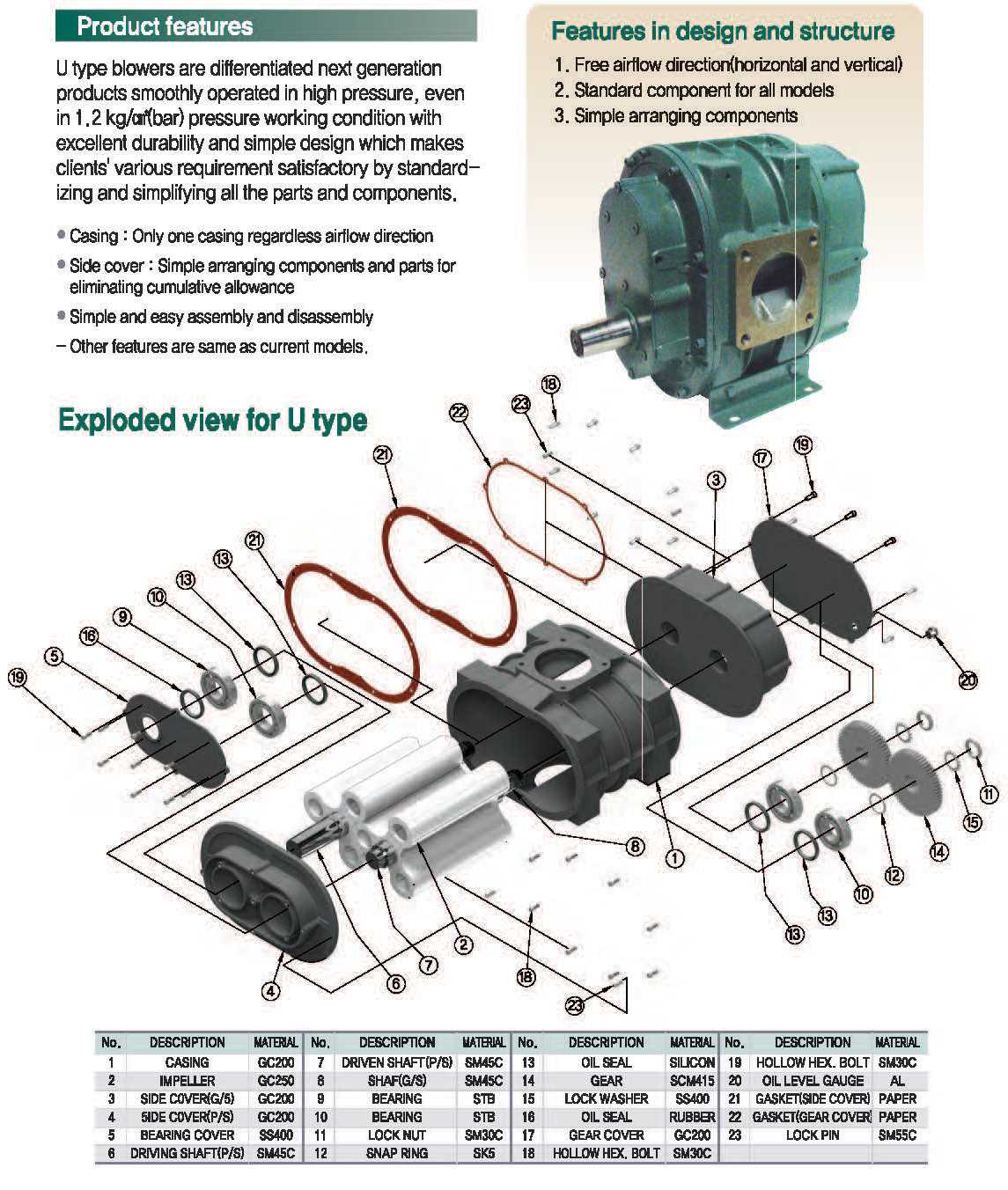

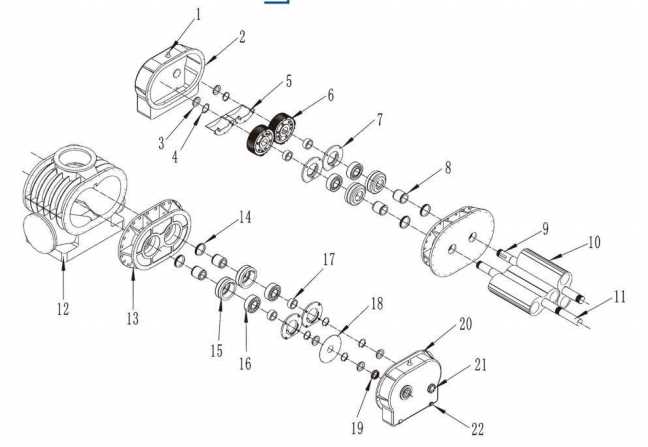

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair. By familiarizing yourself with the visual representation, you can easily identify each component and its role within the system.

- Familiarize with Symbols: Different shapes and lines indicate various elements. Take time to learn what each symbol represents.

- Identify Components: Start by locating key parts. Look for labels that indicate names or numbers associated with each piece.

- Study Connections: Observe how components are interconnected. Arrows and lines often denote relationships and flow direction.

By mastering these aspects, you’ll be well-equipped to navigate the illustration effectively and execute repairs or replacements with confidence.

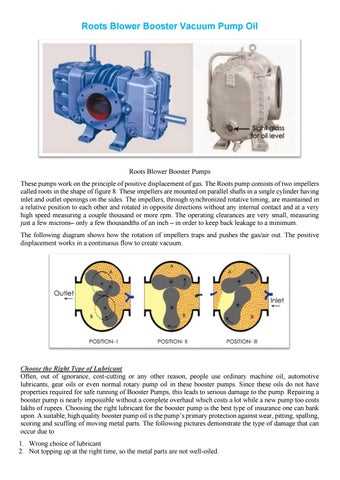

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and proactive measures. Implementing a consistent maintenance routine can significantly enhance performance and extend its operational life. Here are essential practices to keep your machinery in peak condition.

Regular Inspections

Conduct frequent checks to identify wear and tear early. Look for any signs of leaks, unusual noises, or vibrations. Addressing minor issues promptly can prevent more significant problems down the line.

Lubrication and Cleaning

Keep all moving components well-lubricated to reduce friction and wear. Regular cleaning of filters and external surfaces is crucial to maintain efficiency. Neglecting these tasks can lead to operational failures.

Differences Between Roots Blowers

In the realm of positive displacement machines, various models showcase distinct characteristics that cater to specific industrial needs. Understanding these differences is crucial for selecting the right equipment for optimal performance.

Design Variations: The fundamental design elements can vary significantly among different models. Some configurations prioritize efficiency, while others focus on maximizing airflow. This divergence influences their suitability for various applications.

Performance Metrics: Each type exhibits unique performance parameters, such as pressure capabilities and flow rates. Some units excel in high-pressure environments, while others are better suited for large volume transfers. Evaluating these metrics helps determine the ideal choice for specific tasks.

Material Composition: The materials used in construction can impact durability and maintenance requirements. High-performance variants often utilize advanced alloys or coatings to withstand harsh conditions, enhancing longevity and reliability.

Operational Noise: Noise levels during operation can differ widely. Certain designs are engineered to minimize sound emissions, making them more appropriate for environments where quiet operation is essential.

Maintenance Needs: Variations in maintenance requirements can also affect the decision-making process. Some models are designed for easy access to components, allowing for straightforward servicing, while others may require more intensive upkeep.

By considering these distinctions, users can make informed decisions that align with their operational goals and ensure the selection of the most effective solution for their needs.

Identifying Wear and Tear

Recognizing signs of degradation in machinery components is crucial for maintaining optimal performance and preventing costly breakdowns. Regular inspection can reveal subtle changes that may indicate the onset of issues. Early detection allows for timely interventions, ensuring longevity and efficiency in operations.

Common Indicators

Several symptoms can signal the presence of wear. Unusual noises, vibrations, and changes in operational efficiency are primary indicators. Additionally, visual inspections may reveal signs such as discoloration, cracking, or unusual wear patterns. Monitoring these factors can help operators make informed decisions regarding maintenance or replacement.

Assessment Techniques

Utilizing both manual inspections and advanced diagnostic tools can enhance the evaluation process. Regularly scheduled maintenance checks, along with employing techniques such as vibration analysis and thermal imaging, can provide deeper insights into the condition of components. These assessments play a vital role in preventing unexpected failures and ensuring seamless operation.

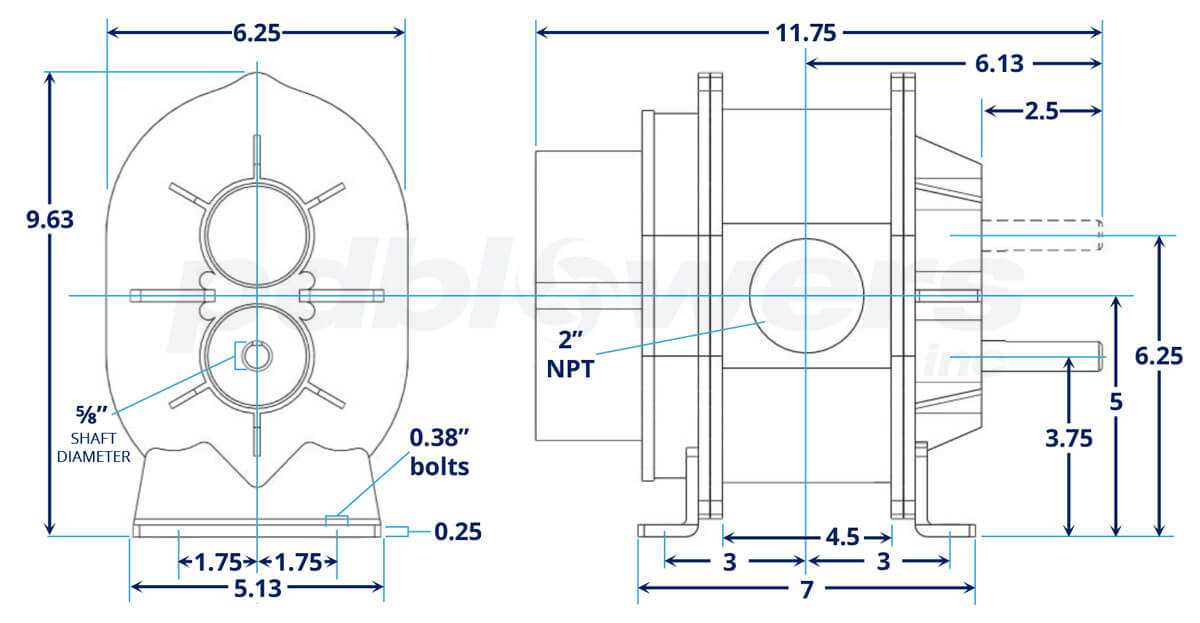

Replacement Parts and Compatibility

Ensuring the longevity and efficiency of mechanical systems often necessitates the timely replacement of various components. Understanding the compatibility of these elements is crucial for maintaining optimal performance and preventing potential operational issues. This section delves into the significance of selecting the correct substitutes and the factors that influence their interchangeability.

Understanding Compatibility Factors

When seeking substitutes for any mechanical device, several factors must be considered. These include dimensional specifications, material composition, and performance characteristics. It’s essential to assess whether a replacement component meets the required standards for fit and functionality, ensuring seamless integration into the existing system.

Finding Quality Replacements

Quality plays a vital role in the selection process. Opting for components from reputable manufacturers can mitigate risks associated with subpar replacements. Furthermore, consulting compatibility charts and manufacturer guidelines can aid in identifying suitable alternatives, ultimately contributing to the reliability and efficiency of the overall system.

Upgrades for Enhanced Performance

Improving efficiency and output in mechanical systems can significantly enhance overall functionality. By incorporating advanced components and technology, operators can achieve optimal results while reducing wear and tear on machinery.

Key Areas for Enhancement

- Material Quality: Upgrading to high-strength alloys can improve durability and performance.

- Sealing Solutions: Implementing advanced sealing systems can reduce leakage and increase pressure stability.

- Lubrication Technology: Utilizing synthetic oils can lower friction and extend operational life.

Implementation Strategies

- Assess current system performance and identify weaknesses.

- Research compatible upgrades that align with operational goals.

- Consult with experts for installation and maintenance recommendations.

Safety Precautions During Repairs

When undertaking maintenance tasks on complex machinery, it is crucial to prioritize safety. Adhering to appropriate guidelines helps prevent accidents and ensures a smooth repair process. Below are essential precautions to consider.

- Always wear personal protective equipment (PPE), including gloves, goggles, and helmets, to shield against potential hazards.

- Ensure that the equipment is powered down and properly locked out before beginning any disassembly.

- Keep the workspace clean and organized to reduce the risk of slips and falls.

Moreover, following proper protocols enhances overall efficiency during repairs:

- Read the manufacturer’s manual thoroughly to understand the specific requirements for safe handling.

- Utilize the correct tools and ensure they are in good condition to avoid malfunction during repairs.

- Work in pairs whenever possible, as having an extra set of hands can provide assistance in case of an emergency.

By implementing these safety measures, individuals can contribute to a safer working environment while effectively addressing the necessary repairs.

Resources for Further Learning

Expanding your knowledge in the field of industrial machinery is essential for mastering its intricacies. A variety of resources can enhance your understanding, from technical manuals to online courses. These materials can provide valuable insights into the mechanisms and components involved, facilitating a deeper comprehension of their functionality and maintenance.

Books and Manuals

Consider exploring comprehensive textbooks that cover the fundamentals of air movement technologies. Manuals from manufacturers often contain detailed explanations and diagrams, allowing you to delve into specific elements effectively.

Online Courses and Webinars

Platforms offering online courses provide an ultimate opportunity to learn from experts. Participating in webinars can also help you stay updated with the latest advancements and practical applications in this field.