In the realm of vehicle mechanics, the components that contribute to the slowing and halting of a vehicle play a crucial role in ensuring safety and performance. Each element, though seemingly simple, works in harmony with others to deliver effective deceleration when needed.

To fully grasp the intricacies of these essential elements, one must explore their individual functions and interrelationships. By examining a visual representation of these components, enthusiasts and professionals alike can gain insights into the ultimate efficiency of this stopping mechanism.

Delving into the specifics allows for a deeper appreciation of how various pieces come together, influencing both the reliability and responsiveness of the overall system. Understanding these relationships is vital for effective maintenance and performance optimization.

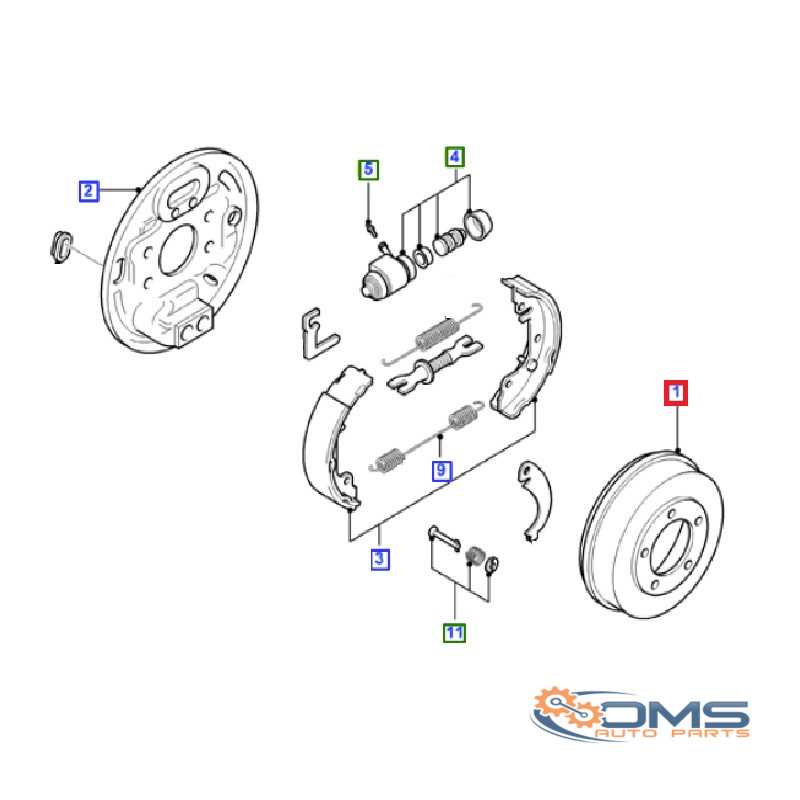

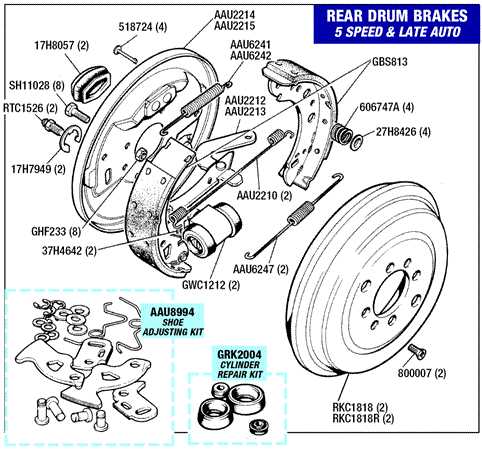

Understanding Rear Drum Brake Components

This section explores the essential elements of a specific stopping mechanism found in many vehicles. Each component plays a crucial role in ensuring effective deceleration and safety. Gaining insight into these elements enhances overall vehicle knowledge and maintenance awareness.

Key Components

- Friction Shoes

- Backing Plate

- Wheel Cylinder

- Adjuster

- Return Springs

Functionality Overview

- The friction shoes expand against the inner surface to create stopping force.

- The backing plate supports and houses other components.

- The wheel cylinder converts hydraulic pressure into mechanical movement.

- The adjuster maintains the correct distance between the shoes and the drum.

- Return springs ensure that the shoes retract after release.

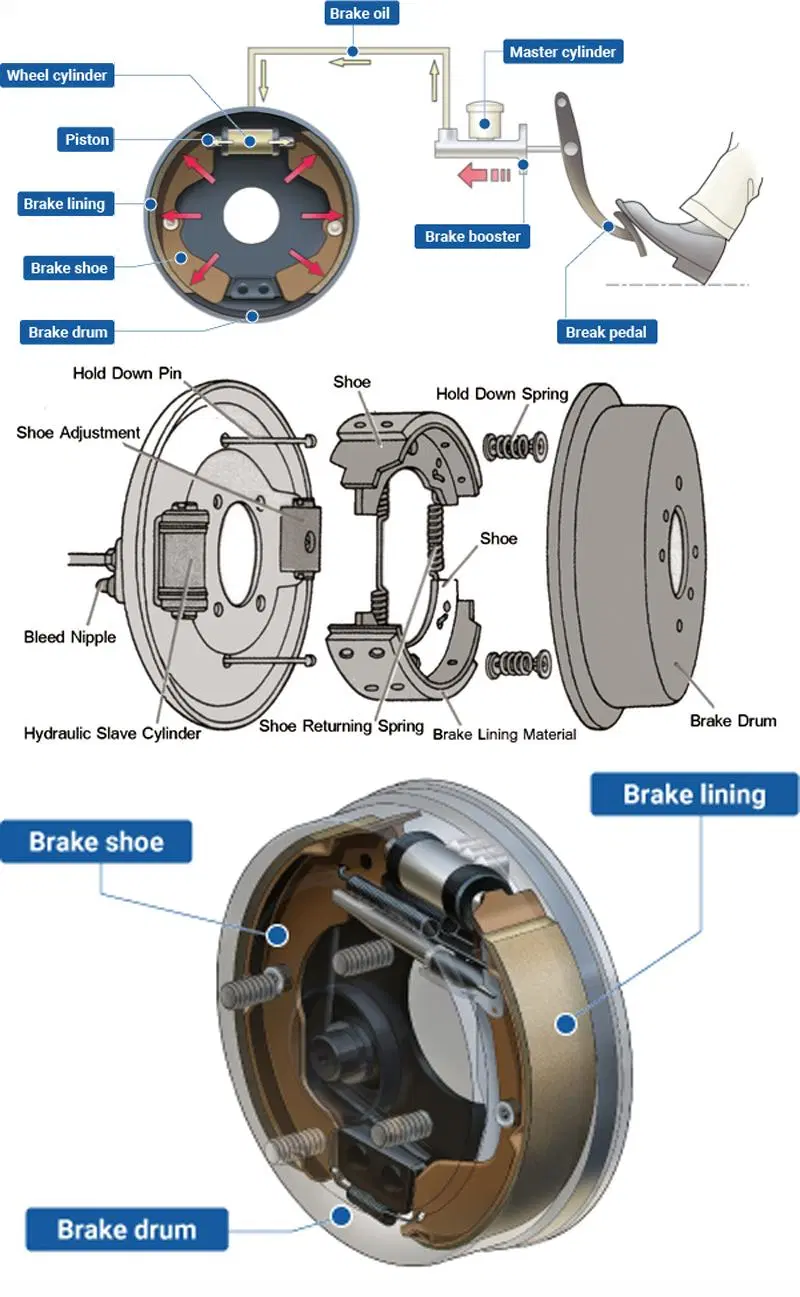

Overview of Brake Drum Assembly

The assembly that facilitates the slowing down and stopping of a vehicle is a critical component in automotive engineering. Understanding its structure and functionality is essential for both maintenance and repair. This assembly comprises several elements that work in unison to ensure optimal performance and safety during operation.

Components and Functionality

Each segment of this assembly plays a specific role, contributing to the overall effectiveness. The primary elements include the circular housing, friction material, and various mechanical linkages. Together, these parts create a system that reliably reduces speed when engaged.

Maintenance and Inspection

Regular inspection of this assembly is crucial to prevent wear and ensure longevity. Key indicators of potential issues include unusual noises, decreased responsiveness, and visible signs of damage. Timely maintenance not only enhances safety but also improves the driving experience.

| Component | Function |

|---|---|

| Circular Housing | Encases the friction material and provides structural support. |

| Friction Material | Creates the necessary friction to slow down the vehicle. |

| Mechanical Linkages | Transmits force from the pedal to the friction material. |

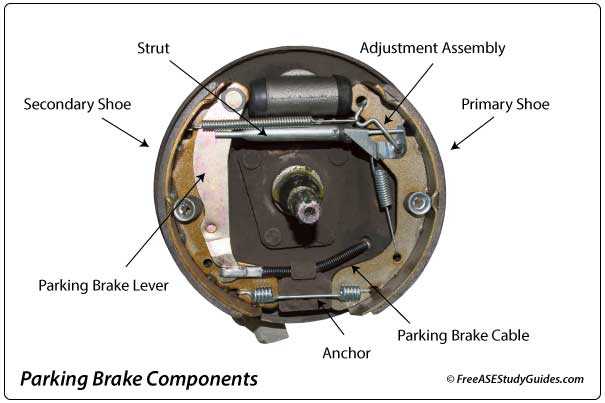

Function of Brake Shoes Explained

The components responsible for slowing down or stopping a vehicle play a crucial role in ensuring safety and control. These elements are vital in transforming kinetic energy into heat energy through friction, allowing for effective deceleration. Understanding their functionality is essential for anyone interested in automotive systems.

Role in Vehicle Stopping Mechanism

When the driver applies pressure to the pedal, the system activates, causing the friction elements to press against a rotating surface. This contact creates resistance, which slows the wheels. The efficiency of this process depends on the material and design of these components, influencing overall performance and responsiveness.

Importance of Maintenance

Regular inspection and maintenance of these components are essential for optimal performance. Over time, wear can diminish their effectiveness, leading to longer stopping distances and increased safety risks. Ensuring they are in good condition helps maintain the vehicle’s performance and enhances safety for all road users.

Role of the Brake Drum

The component in question plays a crucial role in the functionality of a vehicle’s slowing system. It serves as a key element that interacts with various mechanisms to ensure effective deceleration and safe stopping. Its design allows it to withstand significant forces while providing the necessary friction required for optimal performance.

Functionality is at the heart of this component’s importance. When the actuator is engaged, the friction material makes contact with the surface, generating the required resistance. This process transforms kinetic energy into thermal energy, enabling the vehicle to slow down or come to a complete halt.

Additionally, durability is a vital characteristic of this essential element. Constructed from robust materials, it must endure high temperatures and pressures generated during operation. Over time, regular maintenance and inspections are crucial to ensure its integrity and prevent potential failures, which could compromise overall safety.

Importance of Wheel Cylinder

The wheel cylinder plays a crucial role in the overall functionality of a vehicle’s stopping system. It acts as a vital component that ensures effective force transfer, enhancing safety and performance.

Key reasons for its significance include:

- Force Application: It converts hydraulic pressure into mechanical force, pushing the friction elements against the rotating surface.

- Consistency: Ensures even wear and reliable operation, which is essential for consistent stopping power.

- Durability: Designed to withstand high pressures, contributing to the longevity of the entire system.

- Maintenance: Regular checks can prevent costly repairs and ensure optimal functionality.

Understanding the wheel cylinder’s role allows for better maintenance practices and ultimately enhances driving safety.

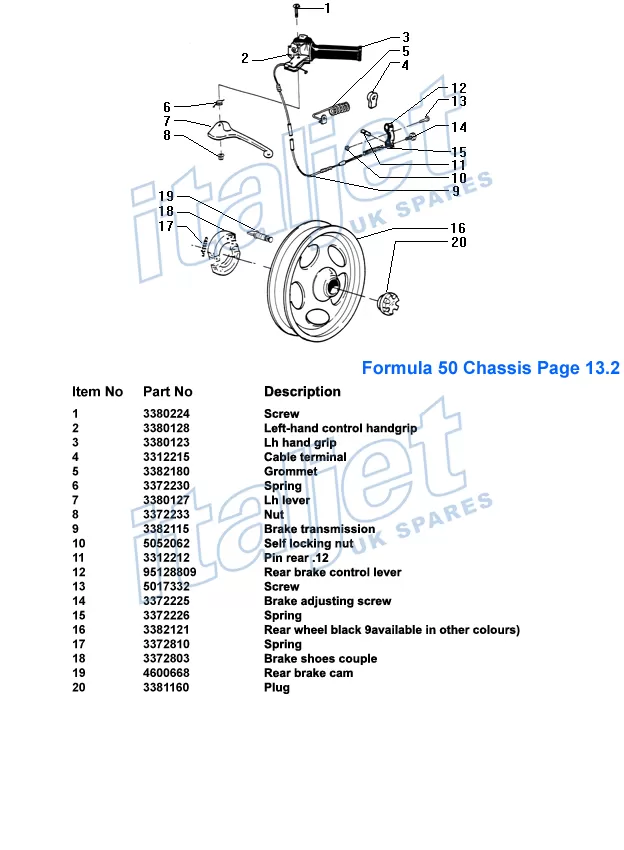

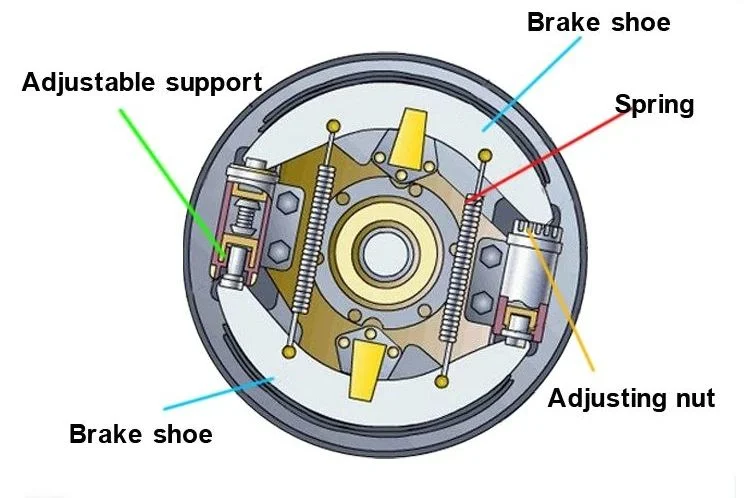

Brake Spring Types and Uses

Understanding the various types of springs used in stopping mechanisms is essential for optimal performance and safety. Each type serves a unique function, contributing to the overall efficiency of the system. This section explores the common varieties and their specific applications.

Types of Springs

Several spring types are prevalent in stopping mechanisms, including coil springs, tension springs, and compression springs. Each type is designed to accommodate different operational demands and stress conditions.

Applications

| Spring Type | Use |

|---|---|

| Coil Springs | Provides support and stability in various components. |

| Tension Springs | Maintains tension in cables and links, ensuring smooth operation. |

| Compression Springs | Absorbs impact and provides resistance, enhancing durability. |

Choosing the right type is crucial for maintaining efficiency and reliability in the system’s functionality.

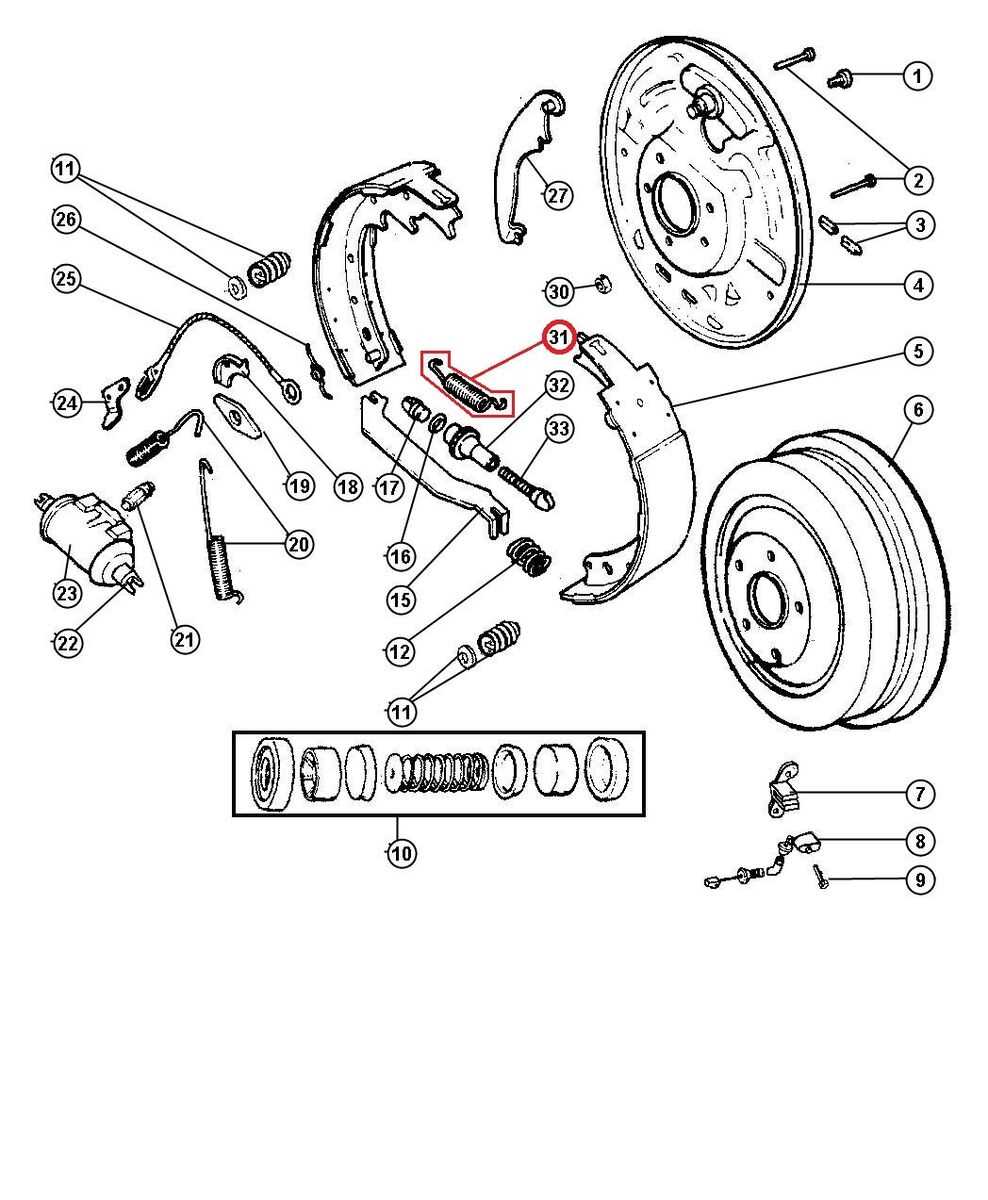

How Adjusters Work in Drum Brakes

Adjusters play a crucial role in maintaining optimal performance and safety in the braking system. These components are designed to automatically compensate for wear over time, ensuring that the friction materials remain in close contact with the rotating elements. By doing so, they help maintain consistent stopping power and prevent excessive pedal travel.

When the friction materials wear down, the distance between them and the rotating surface increases. This is where the adjuster comes into play. It works through a simple yet effective mechanism that senses this increase and automatically brings the components back into alignment. Typically, the adjuster uses a screw or ratchet system to adjust the spacing, allowing for a precise fit that enhances efficiency.

Moreover, the adjuster not only improves performance but also contributes to the longevity of the system. By preventing excessive wear on the friction materials, it ensures that they remain effective for a longer period, reducing the need for frequent replacements. This efficiency ultimately translates to cost savings for the vehicle owner.

In summary, the function of adjusters is vital for the overall effectiveness of the braking system. Their ability to adapt to wear and tear ensures safety and reliability, making them an essential component in modern vehicle design.

Identifying Backing Plate Parts

This section focuses on recognizing various components associated with the backing structure of a braking system. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal functionality and safety.

Key Components

The following table outlines essential elements found on the backing structure, highlighting their functions and significance.

| Component | Function |

|---|---|

| Backing Plate | Serves as the foundation for other components, providing stability. |

| Anchor Pin | Secures the backing plate in place, allowing for effective operation. |

| Adjuster Mechanism | Facilitates adjustment of component spacing for optimal performance. |

Visual Identification

Familiarizing oneself with these components enhances the ability to troubleshoot issues effectively. Recognizing the layout and function of each part will ultimately lead to better maintenance practices.

Common Issues with Drum Brakes

Many vehicles utilize a specific type of stopping mechanism that can experience a range of problems over time. Understanding these issues is essential for maintaining safety and performance. Below are some of the most frequent challenges associated with this braking system.

Frequent Problems

- Uneven Wear: Components may wear unevenly due to misalignment or poor installation, leading to reduced effectiveness.

- Noise: Unusual sounds during operation often indicate that components need attention, possibly due to debris or lack of lubrication.

- Overheating: Excessive heat can cause parts to warp, impacting the overall functionality of the stopping mechanism.

- Fluid Leaks: Leaks from seals can lead to a loss of hydraulic pressure, compromising performance.

- Corrosion: Environmental factors can cause rust and deterioration, affecting the integrity of the system.

Maintenance Tips

- Regularly inspect components for signs of wear or damage.

- Keep the system clean and free from debris.

- Ensure proper installation and alignment during repairs.

- Use high-quality materials to minimize the risk of failure.

- Address any noises or performance issues promptly to prevent further damage.

Maintenance Tips for Drum Brakes

Proper upkeep of your vehicle’s stopping mechanism is crucial for optimal performance and safety. Regular inspections and maintenance can help identify issues early, ensuring reliability and longevity.

Regular Inspections

Routine checks are essential to catch wear and tear before it escalates. Look for signs of deterioration and listen for unusual noises during operation.

Cleaning and Lubrication

Keeping the components clean enhances efficiency. Ensure that moving parts are adequately lubricated to prevent rust and friction-related issues.

| Maintenance Task | Frequency |

|---|---|

| Inspect components | Every 6 months |

| Clean surfaces | As needed |

| Check fluid levels | Monthly |

| Replace worn parts | As needed |

Signs of Worn Brake Components

Maintaining optimal performance in a vehicle is crucial for safety and reliability. Over time, various components responsible for stopping the vehicle can experience wear and tear, leading to potential hazards. Recognizing the signs of degradation early can prevent more serious issues and ensure a smoother ride.

- Unusual Noises: Listen for grinding, squeaking, or rattling sounds when engaging the stopping mechanism.

- Poor Response: If the vehicle takes longer to stop or feels less responsive, it may indicate that elements are deteriorating.

- Vibrations: Noticeable vibrations in the steering wheel or floor when slowing down can signal issues with the components.

- Pulling to One Side: If the vehicle drifts left or right during deceleration, it could point to uneven wear or malfunctioning parts.

- Warning Lights: Pay attention to dashboard alerts that indicate potential problems with the stopping system.

Addressing these warning signs promptly can enhance safety and extend the lifespan of your vehicle’s stopping mechanism. Regular inspections and maintenance are essential to ensure all components function effectively.

Replacing Rear Drum Brake Parts

Ensuring the optimal functioning of your vehicle’s stopping mechanism is crucial for safety. This section outlines the essential steps for the replacement of key components in this system, allowing for a smoother and more reliable operation.

Before beginning the replacement process, consider the following:

- Gather necessary tools and equipment.

- Ensure the vehicle is securely lifted and supported.

- Identify the specific components needing replacement.

Follow these steps for effective replacement:

- Remove the wheel to access the assembly.

- Detach the retaining mechanisms of the components.

- Carefully take out the worn items and inspect surrounding areas.

- Install new components, ensuring proper alignment and fit.

- Reassemble all parts and double-check connections.

Finally, perform a test to confirm functionality and safety. Regular maintenance can help prolong the lifespan of these vital elements, ensuring your vehicle remains dependable on the road.

Choosing Quality Brake Components

Selecting high-grade components for your vehicle’s stopping system is essential for ensuring optimal performance and safety. Quality materials and craftsmanship directly impact how effectively your automobile responds during deceleration. Investing time in understanding the various options available can significantly enhance your driving experience.

Durability is a key factor to consider. Components made from robust materials will withstand wear and tear over time, providing consistent performance under varying conditions. Look for items that have been tested for longevity and resilience to ensure they can handle everyday demands.

Another important aspect is compatibility. It’s crucial to choose components that are specifically designed for your vehicle model. Mismatched items can lead to subpar performance and may compromise your safety on the road.

Performance should also be a priority. Quality components contribute to better responsiveness and shorter stopping distances, enhancing overall driving confidence. When evaluating options, consider those with positive reviews from other users regarding their effectiveness.

Finally, don’t overlook the manufacturer’s reputation. Reputable brands typically invest in research and development, ensuring their products meet or exceed industry standards. Selecting components from trusted sources can lead to better reliability and peace of mind.