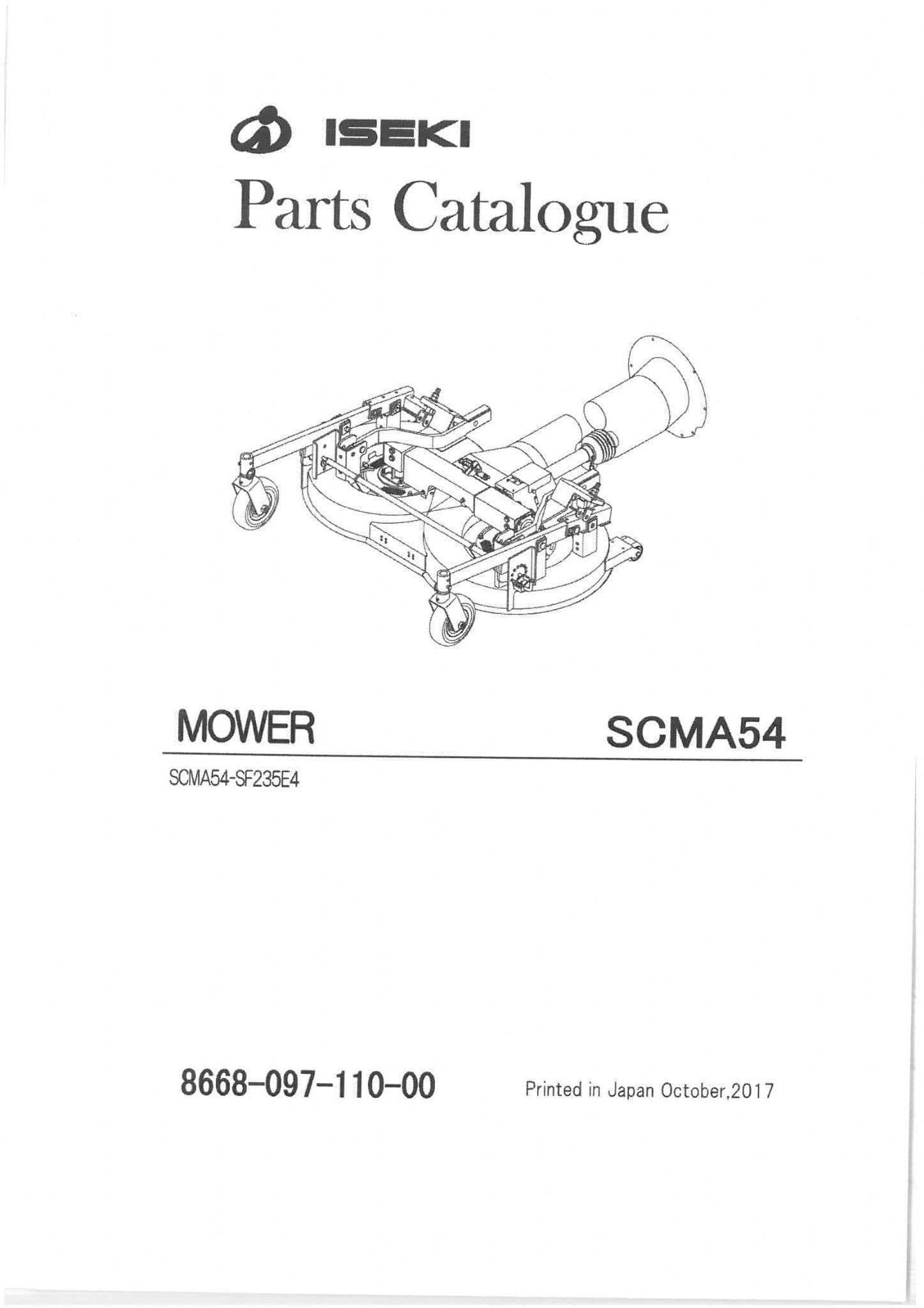

The proper understanding of a zero-turn lawn mower’s structure is essential for effective maintenance and smooth operation. Knowing the individual elements and their arrangement can greatly assist in troubleshooting, upgrades, or simple repairs. Each component plays a critical role in the performance and longevity of the machine.

Key elements such as the drive system, blades, and control mechanisms must be easily identifiable and maintained to ensure consistent functionality. Clear visibility of the structural layout empowers owners to keep their equipment in prime condition with minimal effort.

In this section, we will explore how to navigate the detailed arrangement of the mower’s mechanical and electrical components. With an organized overview, you will gain a better understanding of the critical connections and placements that make up this powerful machine.

Essential Components of the Zero-Turn Mower

This section provides an overview of the key elements that make up the advanced lawn tractor. Each part plays a crucial role in ensuring smooth operation, efficiency, and durability, making maintenance and understanding of these components vital for optimal performance.

Engine and Power System

The engine is the powerhouse of the machine, driving the blades and enabling the swift movement of the mower. This component ensures the machine operates with enough power to cut through various grass types efficiently. Along with the engine, the fuel system and battery contribute to consistent and reliable performance.

- Air filter for engine protection

- Fuel tank and lines for power supply

- Ignition system to start the engine

Cutting System

The cutting system is designed to deliver precise and clean grass trimming. Comprising the blades, deck, an

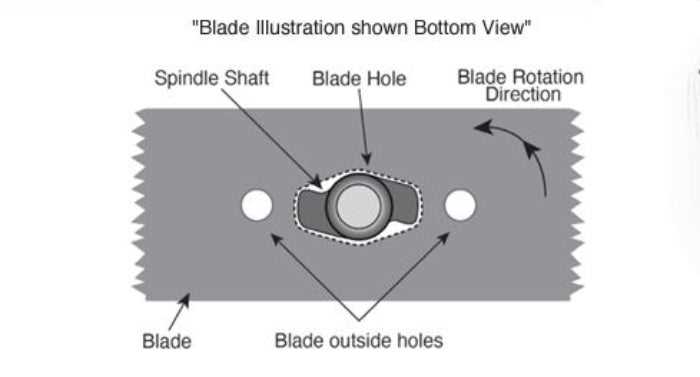

Blades and Deck Assembly Breakdown

The cutting system and deck structure play a crucial role in the overall performance of any lawn tractor. A clear understanding of the components involved in this assembly ensures better maintenance and optimal functionality. This section provides an overview of the essential elements, emphasizing the connection between the cutting blades and the deck mechanism.

Blades are the primary cutting components, responsible for trimming grass efficiently. These sharp, durable parts are mounted beneath the deck and rotate at high speeds. The number and arrangement of these blades can impact cutting precision and coverage.

The deck assembly supports and houses the blades, acting as a protective shield while maintaining the correct cutting height. This assembly includes the deck shell, spindles,

Steering System Overview and Maintenance

The steering mechanism is a critical component for ensuring smooth and precise control of the vehicle. Proper functioning of this system is essential for maneuverability and overall safety. Regular maintenance helps to prevent wear and tear, extending the lifespan of the steering components and ensuring responsive handling.

Main Components of the Steering System

- Steering Wheel: The main control interface for directing the vehicle.

- Steering Linkage: Connects the wheel to the steering mechanism, allowing for directional changes.

- Hydraulic Assist: Helps reduce the effort required to turn the wheel, providing smoother handling.

Maintenance Tips

- Regularly inspect the steering linkage for signs of wear or looseness.

- Ensure that

Engine Components and Performance Insights

The internal mechanisms that drive a modern zero-turn mower are meticulously designed to ensure efficient operation and long-lasting performance. Each part plays a vital role in maintaining balance between power output and fuel consumption, resulting in a smooth and reliable mowing experience.

Pistons are responsible for converting fuel into the mechanical energy needed to power the machine. High-quality pistons ensure a steady flow of power, reducing wear and increasing longevity. Additionally, valves control the intake of air and fuel, as well as the expulsion of exhaust, keeping the engine running at its optimal level.

Another key component is the crankshaft, which transfers the energy produced by the pistons to the rest of the drivetrain. A well-maint

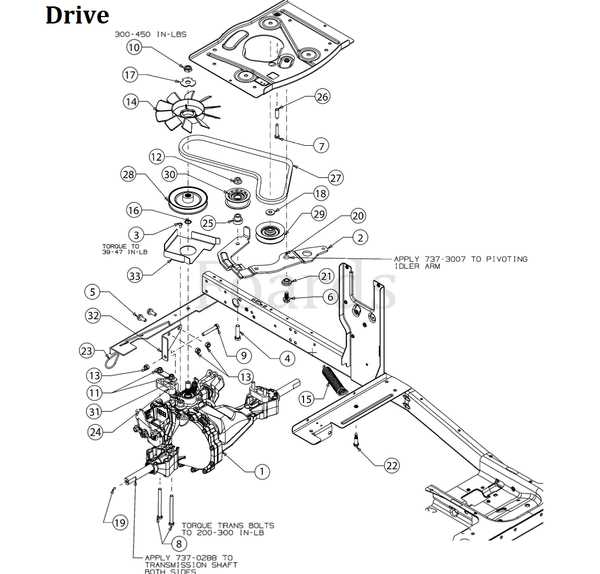

Hydrostatic Transmission Diagram and Parts

The hydrostatic transmission system provides efficient power transfer and smooth operation, making it essential for maintaining optimal performance in various equipment. Understanding the structure and key components of this system ensures better maintenance and troubleshooting capabilities.

The primary components of the transmission system consist of multiple interconnected elements that work together to regulate speed and torque.

- Pump Unit – Responsible for controlling the flow of hydraulic fluid, driving the system effectively.

- Motor Assembly – Converts hydraulic energy back into mechanical energy to power the equipment’s movement.

- Control Valves – Regulate the fluid pressure and ensure

Electrical System Parts and Layout

The electrical system of a riding mower is crucial for its overall functionality and efficiency. This section outlines the components and their arrangement, highlighting how they interact to power the machine effectively. Understanding the layout can assist in troubleshooting issues and performing maintenance tasks.

At the core of the electrical setup is the battery, which supplies the necessary energy to start the engine and power various accessories. The ignition switch is another key element, controlling the power flow from the battery to the engine. Additionally, wiring harnesses connect various electrical components, ensuring a seamless flow of electricity throughout the system.

In this configuration, fuses are employed to protect the electrical circuit from overloads, safeguarding the mower from potential damage. The starter solenoid acts as a relay, allowing the ignition switch to engage the starter motor when activated. Furthermore, safety features like the seat switch and blade engagement switch are integrated into the electrical layout to enhance user protection during operation.

Overall, a comprehensive understanding of the electrical components and their arrangement is essential for maintaining optimal performance and ensuring the longevity of the equipment.

Seat and Comfort Features Breakdown

The seating arrangement and comfort attributes of a riding mower play a crucial role in ensuring an enjoyable and productive experience for the operator. This section delves into the various aspects that contribute to comfort, from ergonomically designed seats to adjustable features that cater to individual preferences.

Ergonomic Design

At the heart of a comfortable riding experience is the ergonomic design of the seat. Contoured seats provide essential support, reducing fatigue during extended use. The materials used often feature cushioning that enhances comfort while ensuring durability against wear and tear.

Adjustable Features

Another significant aspect is the availability of adjustable settings. Many models offer options to modify the seat position, allowing operators to find their ideal riding posture. This feature not only enhances comfort but also promotes better control over the mower, leading to improved efficiency.

In addition, some units include armrests and lumbar support, further enhancing the overall user experience. Such thoughtful design elements demonstrate a commitment to operator well-being, making long hours of mowing a more pleasant endeavor.

Wheels, Tires, and Suspension System

The mobility and stability of a lawn mower heavily rely on its wheel assembly, tire design, and suspension framework. Each component plays a crucial role in ensuring optimal performance and user comfort, especially when navigating uneven terrain. A well-designed system enhances traction, reduces vibrations, and contributes to the overall efficiency of the machine.

Wheels and Tires

The choice of wheels and tires significantly impacts the maneuverability of the equipment. Durable tires are essential for providing adequate grip and traction on various surfaces. Options may include turf-friendly designs that minimize damage to grass and maximize control during operation. Additionally, the size and width of the wheels can affect stability, making it vital to select the appropriate specifications for the intended use.

Suspension Mechanism

A robust suspension mechanism is critical for enhancing the ride quality of the mower. This system absorbs shocks from uneven surfaces, ensuring a smoother experience for the operator. Adjustable suspension systems allow users to customize the ride height and stiffness based on personal preference and terrain conditions, ultimately improving handling and reducing operator fatigue during extended use.

Fuel System Components and Connections

The fuel system plays a crucial role in the overall performance of any outdoor equipment, ensuring efficient delivery of fuel to the engine for optimal operation. Understanding the key components and their interconnections is essential for maintenance and troubleshooting purposes.

Main Components

- Fuel Tank: Stores the fuel needed for operation.

- Fuel Pump: Responsible for transferring fuel from the tank to the engine.

- Fuel Filter: Removes impurities and debris from the fuel before it reaches the engine.

- Fuel Lines: Connect various components, allowing the fuel to flow from the tank to the engine.

- Carburetor or Fuel Injector: Mixes fuel with air for combustion in the engine.

Connections Overview

- Fuel is drawn from the tank through the fuel lines to the pump.

- The pump then pushes the fuel to the filter to ensure cleanliness.

- After filtration, the fuel travels through the lines to the carburetor or injector.

- The mixture of fuel and air is then sent to the combustion chamber for ignition.

Proper understanding of these components and their connections is vital for effective troubleshooting and maintenance of the fuel system, ensuring reliable operation of the machinery.

Safety Features and Mechanisms

Ensuring operator safety is a paramount consideration in the design of modern outdoor power equipment. Various protective mechanisms are integrated into machines to mitigate risks and enhance user security. Understanding these features is essential for safe operation and maintenance.

Key Safety Mechanisms

- Emergency Stop Switch: This critical feature allows for immediate cessation of operation, minimizing potential hazards.

- Seat Safety Switch: Designed to prevent operation when the operator is not seated, this mechanism reduces the risk of accidents.

- Blade Brake: Engaging automatically when the operator disengages from the control, this feature ensures blades stop quickly to prevent injury.

- Anti-Tip System: This system helps maintain stability on uneven terrain, reducing the risk of overturning.

Operator Awareness Features

- Warning Labels: Clear and concise labels provide critical information regarding safe operation and potential hazards.

- Operational Lights: Indicators for engine status and blade engagement alert operators to machine readiness, enhancing safety during use.

- Manuals and Guides: Comprehensive user manuals outline safe practices and maintenance tips, ensuring informed operation.

Frame and Chassis Parts Layout

The framework and chassis of a mower are crucial components that provide stability and support for various operational elements. Understanding the arrangement and function of these structural elements is essential for maintenance and troubleshooting. This section delves into the configuration of these components, highlighting their significance in the overall functionality of the machine.

Key Elements: The primary structure consists of the base frame, which serves as the foundation for mounting the engine, transmission, and other vital systems. Reinforced sections enhance durability, ensuring the equipment withstands the rigors of frequent use.

Support Features: Additional support components such as brackets and mounts are strategically placed to secure various attachments, ensuring optimal performance. Each element plays a specific role in maintaining the integrity and balance of the entire assembly.

In conclusion, a thorough comprehension of the framework and chassis layout is essential for effective maintenance and repair. Proper identification and understanding of these structural elements can significantly extend the lifespan of the equipment.

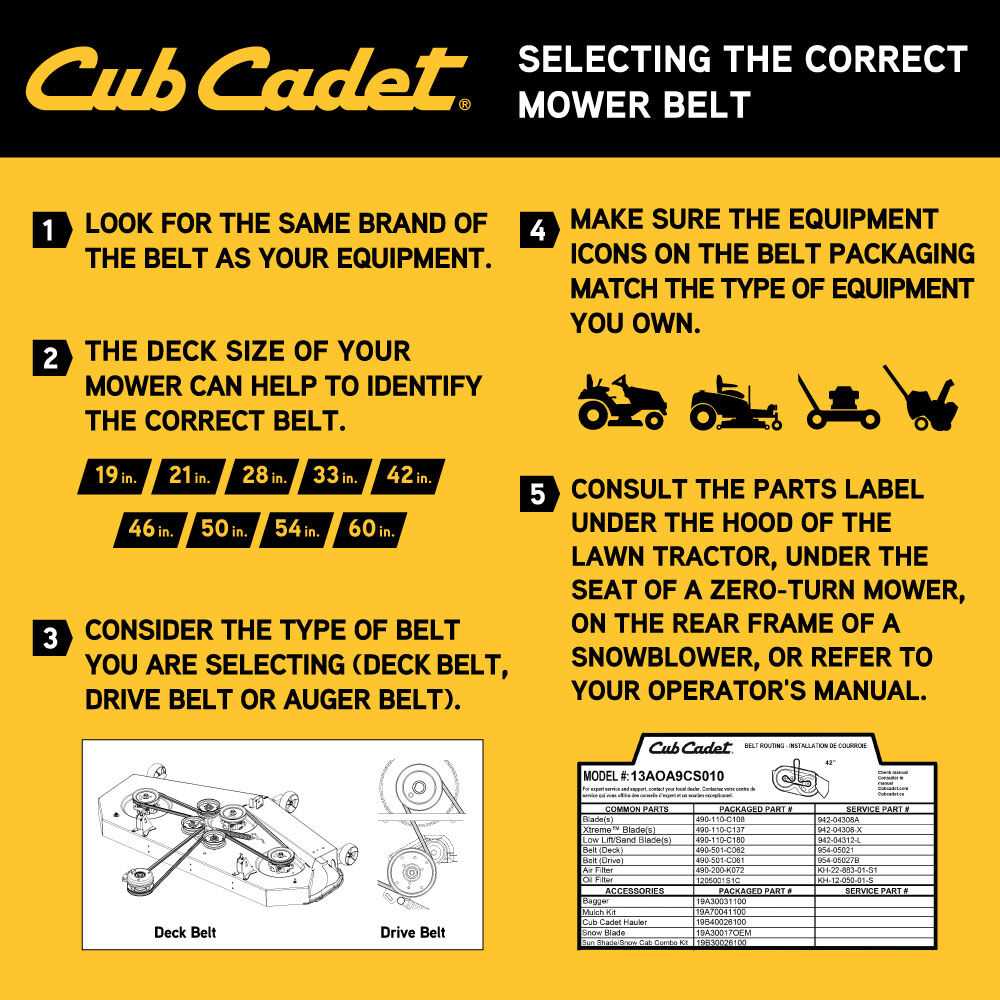

Maintenance Parts and Service Intervals

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. This section focuses on the necessary components and recommended service schedules that can help maintain peak efficiency and reliability.

Essential Components

To keep your machine running smoothly, consider the following key elements:

- Air Filter: Helps maintain clean airflow to the engine.

- Oil Filter: Ensures proper lubrication by filtering contaminants from the oil.

- Blades: Sharp, well-maintained blades enhance cutting performance.

- Battery: A fully charged and well-maintained battery is crucial for reliable operation.

- Tires: Properly inflated tires contribute to stability and traction.

Recommended Service Schedule

Adhering to a regular maintenance schedule will help prevent unexpected issues. Below are the suggested intervals for servicing:

- Every 25 hours of operation:

- Inspect and clean the air filter.

- Check oil levels and change if necessary.

- Every 50 hours of operation:

- Sharpen or replace blades.

- Inspect and clean the battery terminals.

- Every 100 hours of operation:

- Change the oil filter.

- Inspect tires for wear and proper inflation.

Following these guidelines will help you maintain your equipment effectively and ensure its longevity.