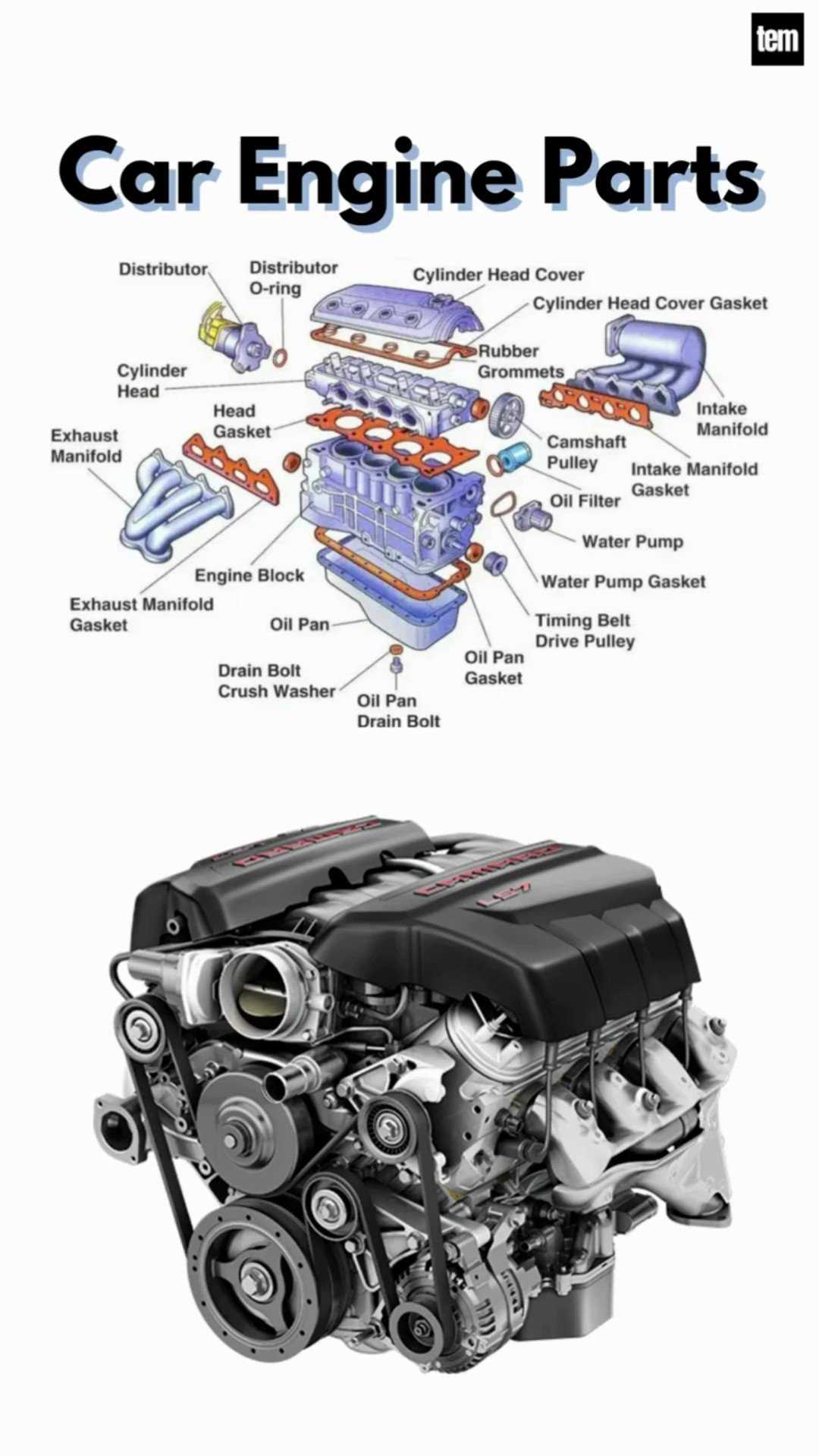

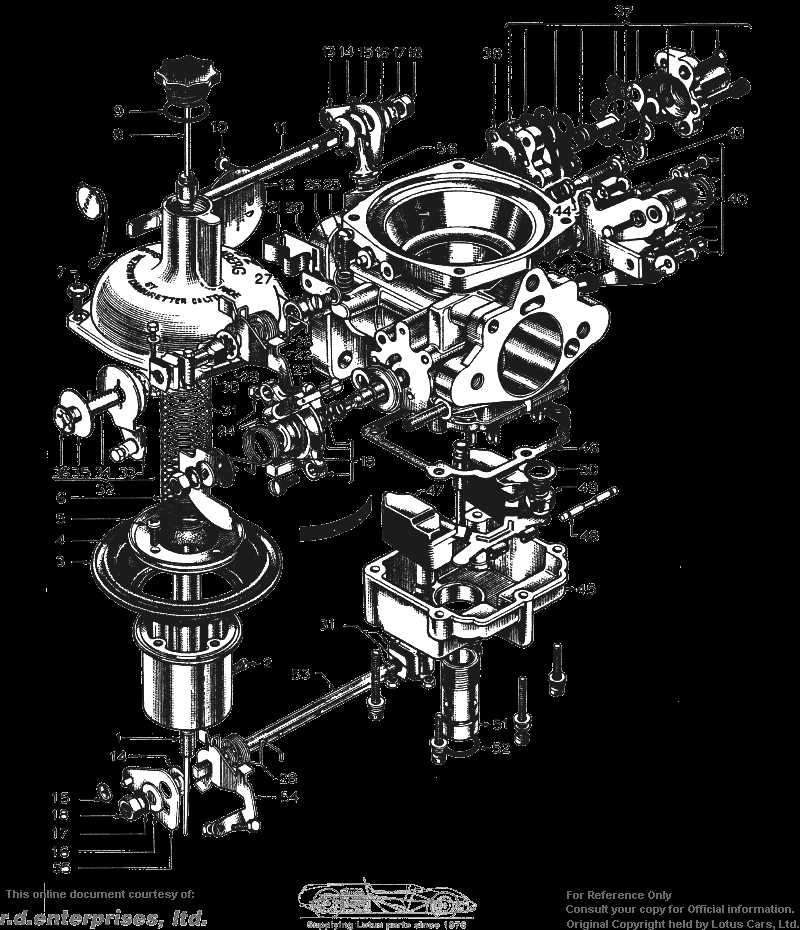

In many vehicles, the system responsible for blending air and fuel plays a critical role in ensuring optimal engine performance. This mechanism carefully regulates the mixture to achieve efficient combustion, impacting both power output and fuel economy. Exploring the inner workings of this system can reveal how different elements contribute to smooth operation.

The intricate assembly involves various elements that work together to control the air-to-fuel ratio. Each piece has a unique function in maintaining the right balance, ensuring that the engine runs smoothly under various conditions. Whether adjusting for high-speed performance or idle settings, the individual components interact seamlessly to support engine functionality.

By delving into the specific elements within this assembly, it becomes possible to gain a clearer understanding of how they influence overall efficiency. Recognizing how each part fits into the larger system can provide valuable insight into maintenance, repairs, and performance tuning.

Understanding the Basics of Carburetors

Mechanical fuel systems play a crucial role in mixing air and fuel efficiently for proper engine performance. These systems, typically found in older engines, utilize a vacuum-based method to control the intake of air, which is then combined with fuel before combustion. Understanding how this process works helps explain how engines can adjust to different driving conditions and maintain efficiency.

The Air-Fuel Mixture

In order to achieve optimal combustion, a precise balance between air and fuel is essential. The device regulating this must ensure that the ratio remains consistent whether the engine is idling, accelerating, or cruising. A well-maintained system helps provide smoother power delivery and efficient fuel usage.

The Role of Valves and Jets

Various components, such as valves and jets, are responsible for controlling airflow and fuel delivery.

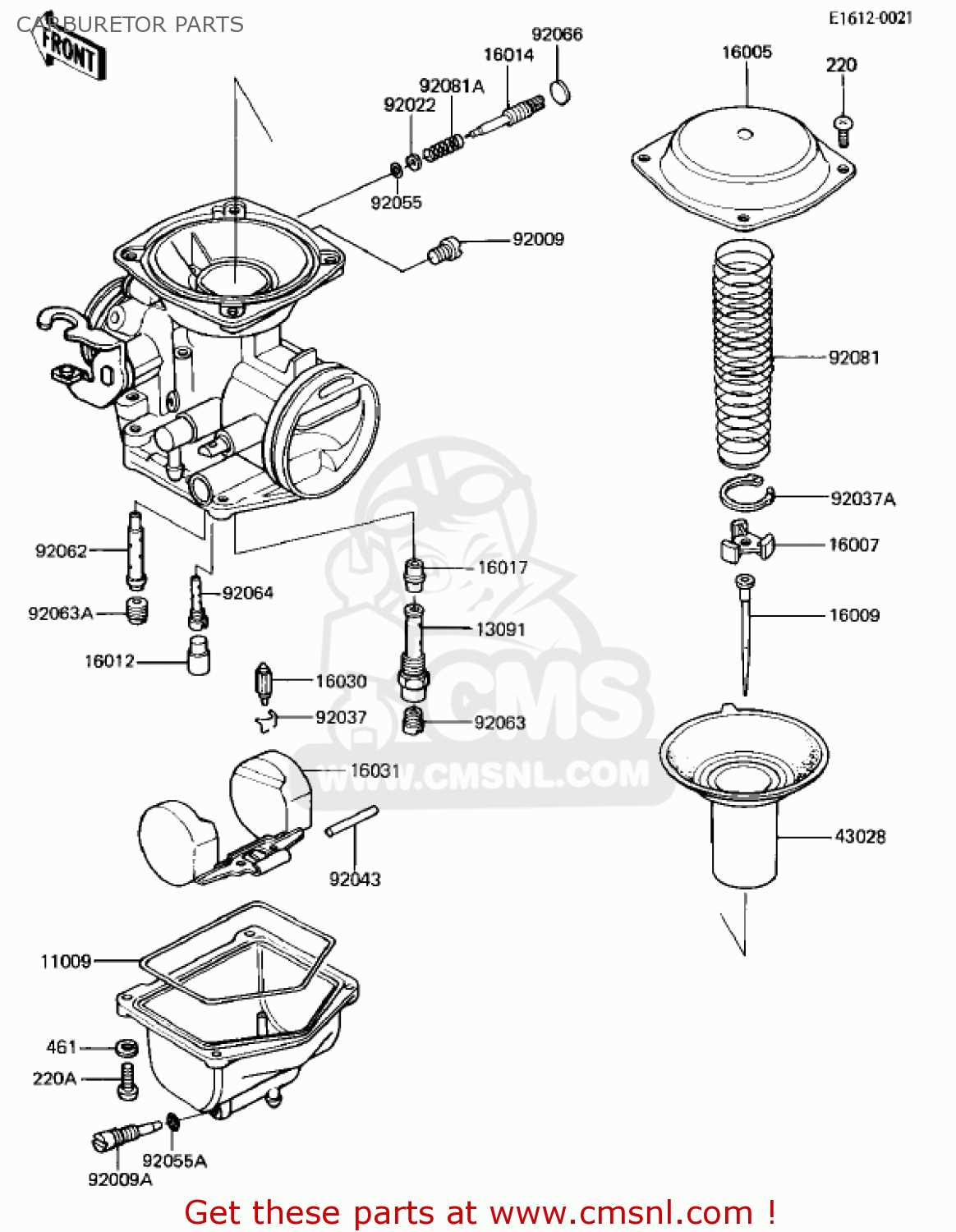

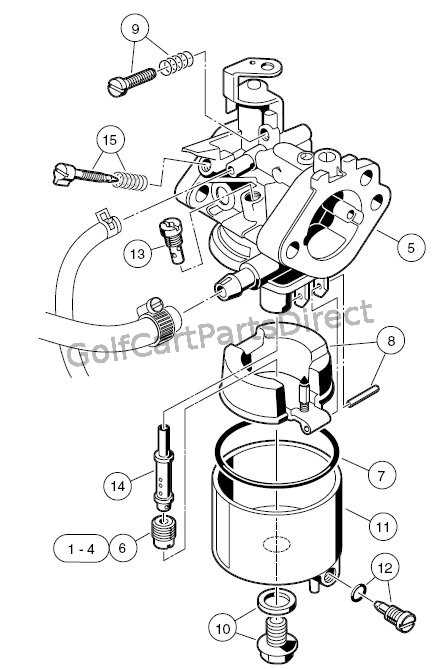

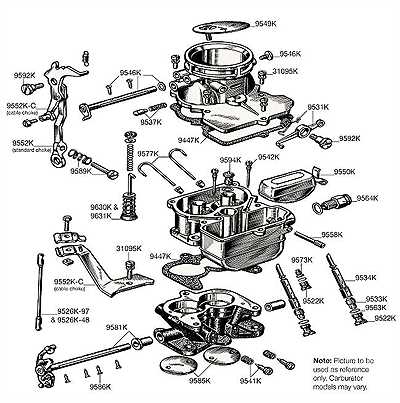

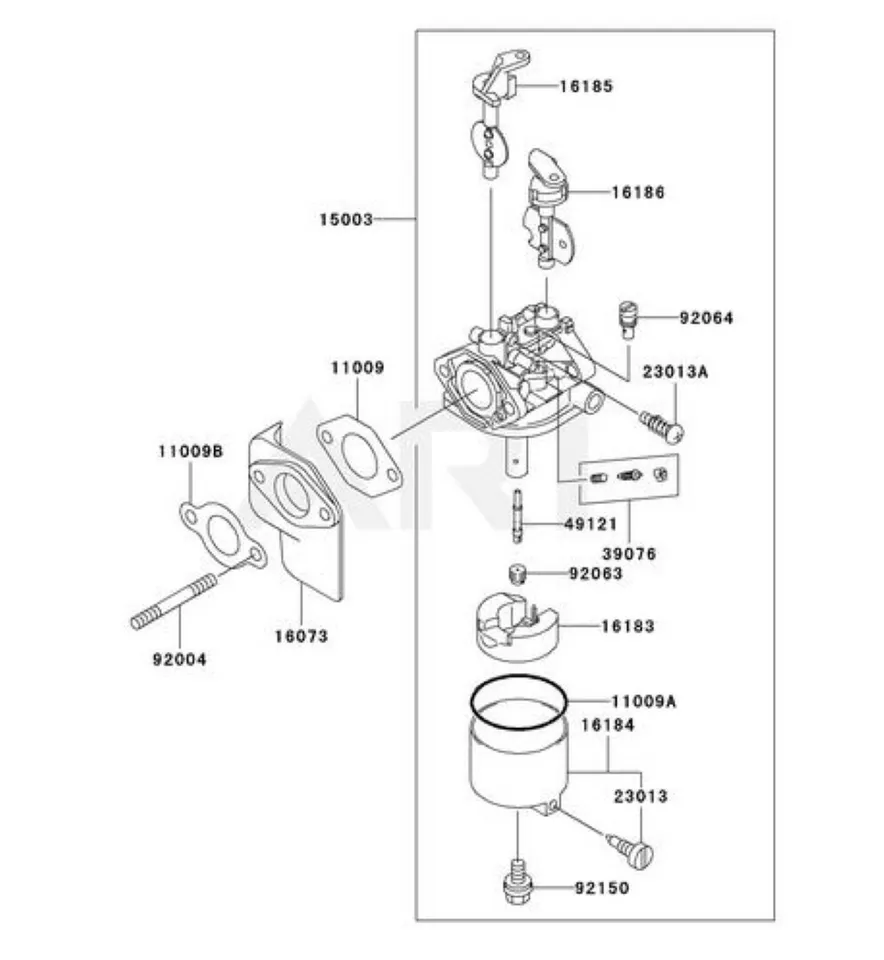

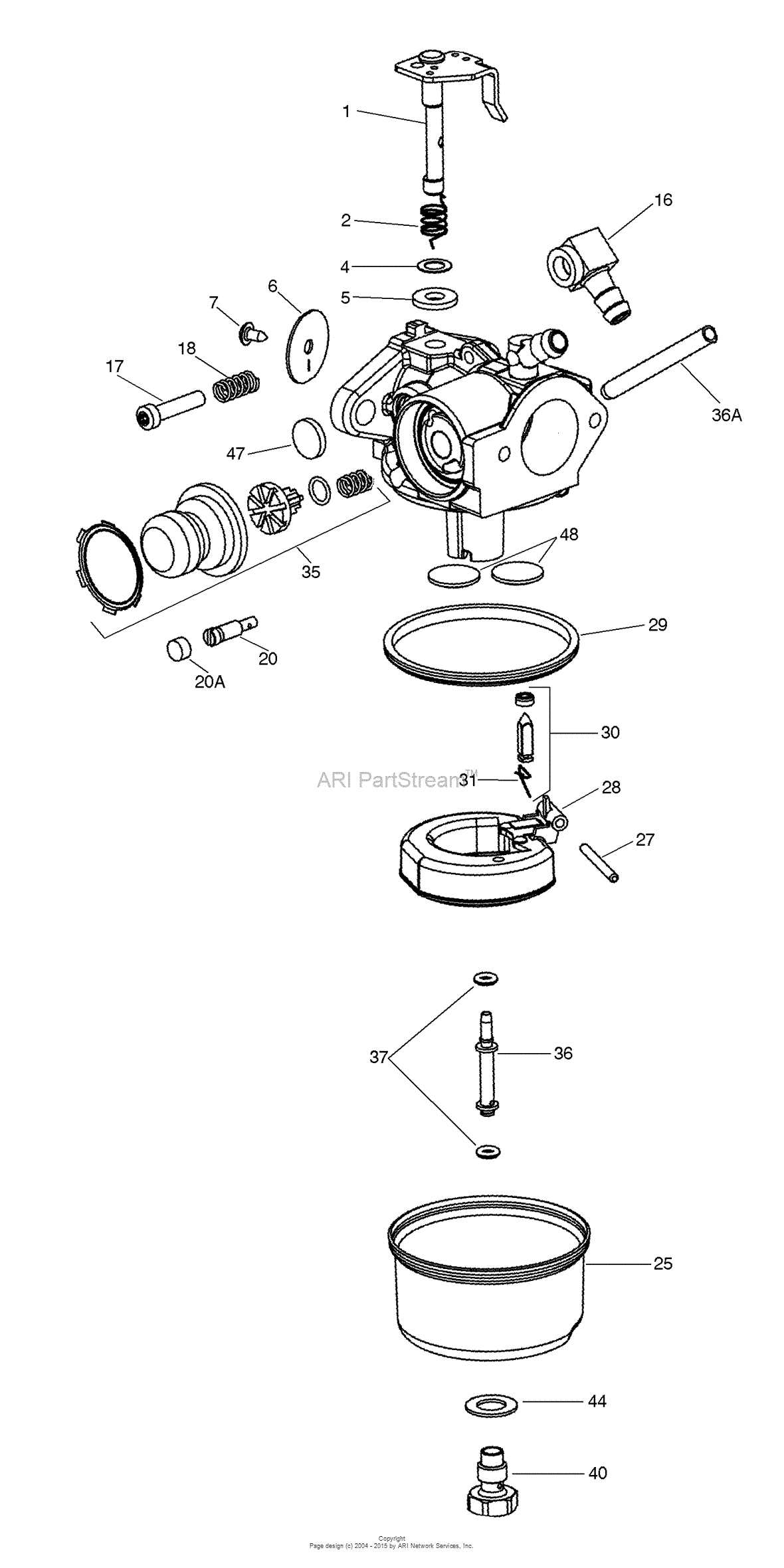

Main Components in a Carburetor System

The fuel-mixing system is made up of several key elements that ensure smooth engine operation. These components work together to regulate the mixture of fuel and air for optimal performance. Understanding the purpose and function of these elements helps in maintaining the engine’s efficiency.

- Fuel Bowl: A chamber that stores fuel before it is mixed with air. It ensures a steady supply of fuel to the engine.

- Float: A device that regulates the fuel level in the bowl, preventing overflow by controlling the flow of fuel.

- Venturi: A narrow section where air speeds up and creates a vacuum to draw fuel into the airflow.

- Throttle Plate: A mechanism that controls the amount of air entering the system, affecting engine speed and power.

- Regulates airflow to the intake system

- Maintains the correct air-fuel mixture

- Responds to driver input for speed control

- Essential for smooth engine performance

- Regulates fuel supply to the mixing chamber

- Maintains a stable fuel level for consistent operation

- Prevents fuel overflow and maintains proper air-fuel mixture

Fuel Flow Regulation in Carburetors

The regulation of fuel flow within mechanical systems is essential for ensuring efficient energy conversion. Proper control of fuel delivery directly impacts the system’s performance, maintaining a balanced mix for optimal combustion. Without precise management, issues like inefficiency or instability can arise, affecting the overall operation.

Key Components for Flow Management

Several elements contribute to maintaining the ideal balance of fuel. These include specific valves and chambers designed to adjust the supply based on demand. By dynamically controlling the volume, the system achieves consistent energy output under various conditions.

Balancing Air and Fuel

The interaction between air and fuel is critical. Through specific mechanisms, the ratio can be adjusted to suit different operational states, from idle to peak performance. This balance ensures that the fuel is utilized effectively, preventing wastage and enhancing power delivery.

Role of the Throttle Valve

The throttle valve plays a crucial role in managing airflow within the intake system. Its position directly influences how much air is allowed to enter, which in turn affects the overall performance of the engine. By controlling this air passage, the throttle valve ensures the correct balance between air and fuel for optimal operation.

The mechanics of the throttle valve involve precise movement that adjusts based on input from the driver, whether accelerating or decelerating. This regulation is vital for maintaining steady power output and fuel efficiency.

Air-Fuel Mixture Adjustment

The balance between air and fuel is essential for smooth engine performance. Proper regulation ensures that the right amount of oxygen blends with the fuel, maximizing efficiency and minimizing emissions. Incorrect proportions can lead to performance issues, such as stalling or excessive fuel consumption.

Why Adjustment Matters

Maintaining the correct ratio is crucial for engine longevity and reliability. A mixture that’s too rich or too lean can cause overheating, poor acceleration, or even long-term damage to the internal components. Adjusting the balance prevents these issues, ensuring that everything functions optimally.

Steps to Fine-Tuning

The process involves making slight changes to ensure the right air-to-fuel ratio. This fine-tuning can be achieved through careful manipulation of the system’s mechanisms. Once adjustments are made, it is important to test the engine’s response

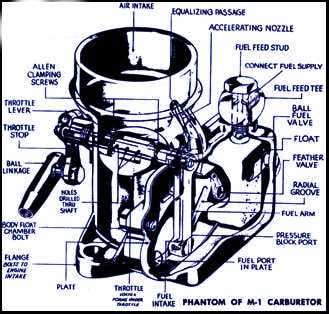

Identifying the Venturi Effect in Carburetors

The Venturi effect is a fundamental principle in fluid dynamics that plays a crucial role in the functioning of specific mechanisms. This phenomenon occurs when a fluid flows through a constricted section of a pathway, resulting in a decrease in pressure and an increase in velocity. Understanding this effect is essential for recognizing how it influences the operation of various devices designed for efficient fuel-air mixing.

When the fluid passes through a narrowed area, the velocity rises, which in turn causes the pressure to drop. This drop in pressure creates a suction effect, drawing in additional fluid from surrounding areas. This mechanism is vital for achieving optimal performance in fuel delivery systems. Observing the Venturi effect can provide insights into the efficiency and responsiveness of the system.

Identifying the signs of this phenomenon can help troubleshoot issues related to performance and efficiency. Key indicators include irregular flow patterns, unexpected pressure readings, and inconsistent mixing ratios. A comprehensive understanding of the Venturi effect allows for improved calibration and fine-tuning of the device, ensuring smooth operation and enhanced performance.

Float Chamber and Its Importance

The float chamber is a crucial component in the fuel delivery system of internal combustion engines. Its primary function is to maintain a consistent level of fuel, ensuring optimal performance during operation. This essential mechanism plays a significant role in the overall efficiency and reliability of the engine.

Key Functions of the Float Chamber

Impact on Engine Performance

When the float chamber operates correctly, it enhances the engine’s responsiveness and efficiency. However, any malfunction can lead to issues such as:

- Inconsistent fuel flow

- Engine flooding or starvation

- Decreased power output

Understanding the function and significance of the float chamber is essential for ensuring the longevity and effectiveness of the engine.

Choke Operation and Its Function

The choke is a vital component within the fuel delivery system, playing a crucial role in regulating the air-fuel mixture. Its primary function is to enhance the engine’s ability to start under cold conditions by reducing the amount of air entering the combustion chamber. This ensures a richer mixture, facilitating ignition and improving performance during initial engine operation.

How the Choke Works

Upon starting, the choke closes partially or fully, limiting airflow. This adjustment enriches the fuel mixture, allowing for easier combustion. As the engine warms up, the choke gradually opens, restoring normal airflow. This transition is critical for smooth operation, as a properly functioning choke helps to prevent stalling and ensures efficient engine performance.

Importance of Proper Functionality

Maintaining the choke in optimal condition is essential for consistent engine performance. A malfunctioning choke can lead to issues such as rough idling, difficulty starting, or poor fuel efficiency. Regular inspection and timely repairs can prevent these problems and ensure reliable operation.

| Choke State | Air-Fuel Mixture | Engine Performance |

|---|---|---|

| Closed | Rich | Improved starting |

| Partially Open | Balanced | Normal operation |

| Fully Open | Lean | Efficient running |

Differences Between Carburetor Jets

The functionality of fuel delivery systems is heavily influenced by the various jets utilized within them. Understanding the distinctions among these components is crucial for optimizing performance and efficiency. Each type of jet plays a unique role in regulating fuel flow, and their specific characteristics can significantly impact the overall operation of the system.

Types of Jets

- Main Jets: These are responsible for providing the primary fuel supply during regular operation, affecting power and acceleration.

- Idle Jets: These control fuel flow at low throttle openings, influencing how the engine runs during idle and low-speed conditions.

- Air Jets: These adjust the amount of air mixed with fuel, playing a vital role in achieving the correct air-fuel ratio.

Key Differences

- Size Variations: Different jets come in various sizes, which determines the volume of fuel or air they allow to pass.

- Application Specificity: Each type is designed for specific operational conditions, impacting performance at different speeds and loads.

- Flow Characteristics: Jets exhibit distinct flow patterns, which influence how fuel is atomized and mixed with air.

Maintenance Tips for Carburetor Parts

Ensuring the optimal functioning of fuel delivery mechanisms is essential for any engine. Regular upkeep can significantly enhance performance and longevity. Here are some practical suggestions to maintain these vital components effectively.

Keep It Clean – Regular cleaning is crucial for smooth operation. Dirt and debris can accumulate, leading to inefficiencies. Utilize appropriate cleaning solutions and tools to remove buildup, ensuring that all surfaces are free from contaminants.

Inspect Regularly – Periodic examinations help identify wear and tear. Look for any signs of damage or corrosion. Early detection can prevent more extensive issues and costly repairs down the line.

Adjust Properly – Calibration is key to achieving the right balance of air and fuel. Make adjustments as needed, based on performance observations. Refer to manufacturer guidelines for the ideal settings.

Store Carefully – If components are removed for maintenance or replacement, store them in a clean, dry environment. This prevents exposure to moisture and other elements that could lead to deterioration.

Consult Experts – When in doubt, seek professional advice. Experienced technicians can provide insights and recommendations tailored to specific models, ensuring that all adjustments and maintenance tasks are carried out correctly.

Troubleshooting Common Carburetor Issues

When dealing with fuel delivery systems, various challenges can arise that affect performance. Understanding these common complications is essential for effective resolution. Proper maintenance and diagnosis can significantly enhance efficiency and extend the lifespan of the system.

Fuel Flow Problems can lead to insufficient power and acceleration. These issues often stem from blockages in the fuel lines or a malfunctioning pump. Checking for clogs and ensuring proper fuel pressure is crucial.

Air-Fuel Mixture Imbalances are another frequent concern. An improper blend can result in poor combustion, causing rough idling and hesitation. Adjusting the mixture settings can help restore optimal performance.

Cleaning and Maintenance are vital for keeping the system functioning correctly. Regular inspection and cleaning of components can prevent the buildup of dirt and deposits that hinder performance. Using appropriate cleaning agents can effectively remove contaminants.

Worn Components can lead to leaks and inefficiencies. Inspecting seals and gaskets for wear is essential, as replacements may be necessary to maintain a tight seal. Addressing these issues promptly can prevent further complications.