In the realm of internal combustion engines, the intricacies of fuel delivery systems play a crucial role in optimizing performance and efficiency. A thorough comprehension of the various elements involved in this process is essential for both enthusiasts and professionals. This section delves into the specific components that contribute to the regulation of the air-fuel mixture, ensuring that engines operate smoothly and effectively.

By exploring the configurations and functions of these essential devices, readers can gain insight into how each component interacts within the system. A well-organized visual representation of these elements can significantly aid in the identification and understanding of their roles, promoting better maintenance and troubleshooting practices. Knowledge of these mechanisms is invaluable for anyone looking to enhance engine performance or restore older models to their former glory.

Whether you are a seasoned mechanic or a curious beginner, familiarizing yourself with the fundamental features and their arrangement will empower you to make informed decisions regarding repairs and upgrades. An in-depth look at these critical elements will not only clarify their significance but also foster a deeper appreciation for the engineering behind fuel management systems.

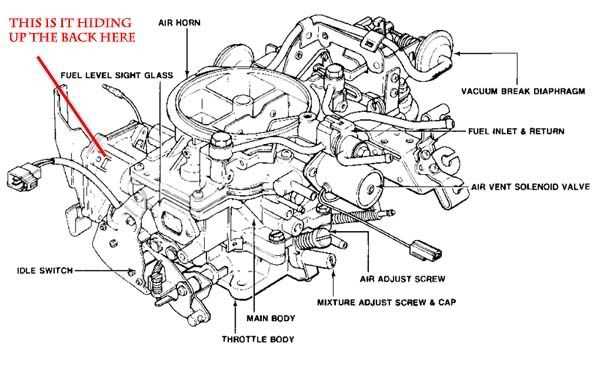

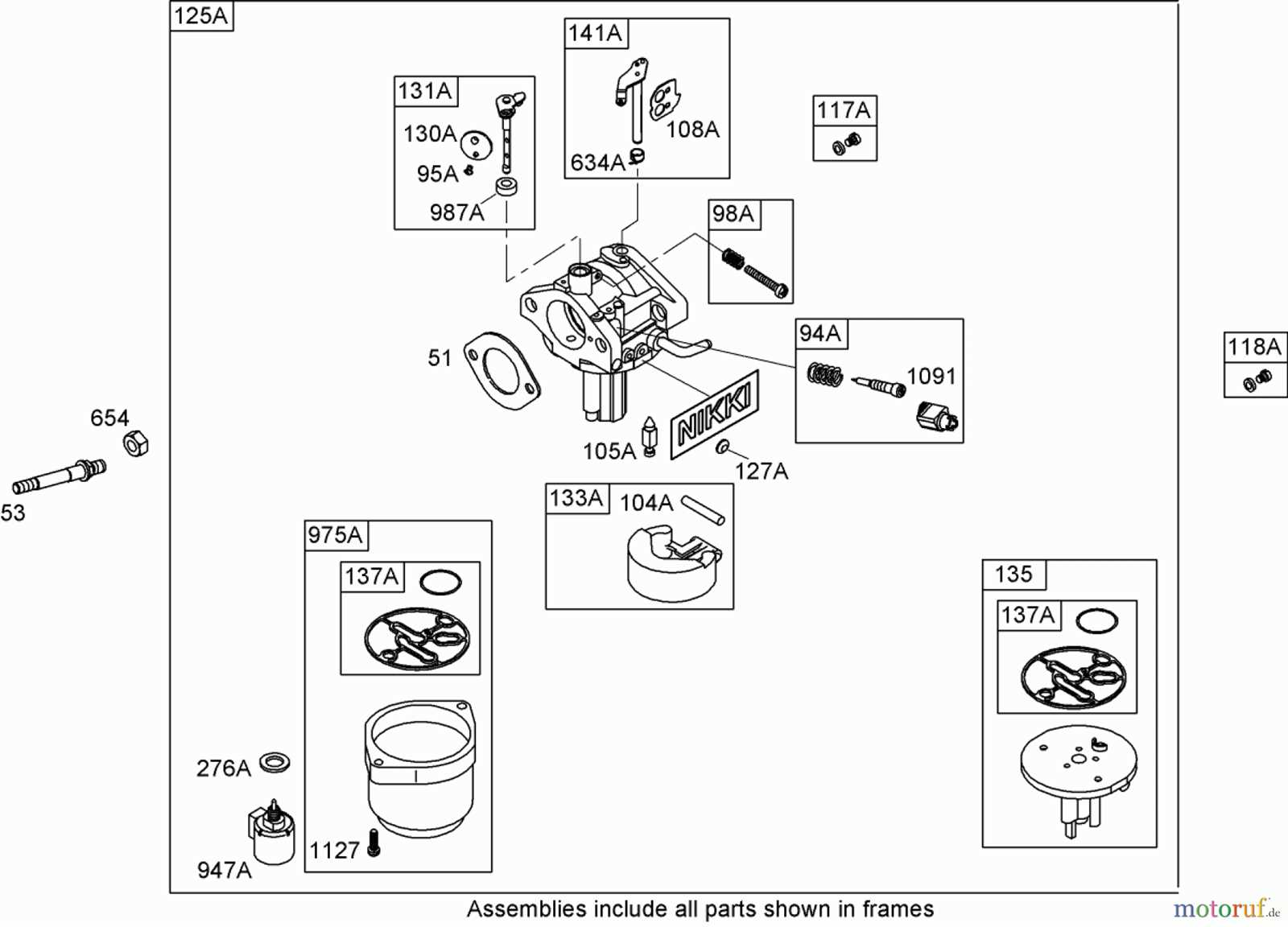

Nikki Carburetor Overview

This section provides a comprehensive insight into a specific type of fuel delivery mechanism commonly used in various engines. These devices play a crucial role in regulating the mixture of air and fuel, ensuring optimal performance and efficiency. Understanding their construction and functionality is essential for maintenance and troubleshooting.

Typically designed with precision, this mechanism consists of several key components that work harmoniously. The elements function together to create the right balance between fuel and air, allowing for smooth engine operation. A thorough knowledge of these components can aid in diagnosing issues and enhancing overall engine performance.

Proper care and regular checks of this essential mechanism can prevent common issues such as poor fuel efficiency or engine misfires. Familiarity with its structure enables users to make informed decisions about repairs or replacements, ultimately leading to a more reliable and efficient engine system.

Common Symptoms of Carburetor Issues

Identifying problems with fuel delivery systems is crucial for maintaining optimal engine performance. Several indicators can suggest that these systems are not functioning correctly, leading to various operational issues.

| Symptom | Description |

|---|---|

| Engine Stalling | Frequent stalling or difficulty starting the engine often indicates issues with fuel flow or air-fuel mixture. |

| Poor Acceleration | When the engine struggles to accelerate, it may be a sign of improper fuel delivery or blockage within the system. |

| Increased Fuel Consumption | A sudden rise in fuel usage can point to a rich mixture caused by a malfunctioning system. |

| Backfiring | Unexpected backfiring noises may indicate that the air-fuel mixture is off, often linked to delivery problems. |

| Engine Misfiring | Misfires during operation can result from inconsistencies in fuel supply or inadequate mixture ratios. |

Understanding Nikki Carburetor Functionality

This section explores the essential mechanisms that drive the operation of fuel delivery systems in small engines. These systems play a crucial role in ensuring optimal performance by effectively mixing air and fuel for combustion. A thorough comprehension of their functioning is vital for maintenance and troubleshooting.

Key Components and Their Roles

Several key elements work together to create a balanced mixture for efficient engine performance:

- Throttle Valve: Regulates airflow, controlling engine speed.

- Float Chamber: Maintains a consistent fuel level for stable operation.

- Jet Assembly: Precisely meters fuel into the airflow, ensuring the correct mixture.

- Choke Mechanism: Enriches the mixture during cold starts for easier ignition.

Operational Principles

The functionality of these systems hinges on several principles:

- Air enters through the intake, creating a vacuum that draws fuel into the airstream.

- The throttle position determines how much air enters, influencing engine speed.

- As the engine runs, the float chamber maintains the fuel supply at a steady level.

- The choke assists in adjusting the mixture during varying temperatures and conditions.

Key Components of Nikki Models

The essential elements of various engine fuel delivery systems play a critical role in their overall functionality and performance. Understanding these fundamental components is vital for anyone involved in maintenance or repair tasks, ensuring optimal operation and longevity of the equipment.

Main Functional Elements

- Float Chamber: Maintains a consistent fuel level, allowing for reliable operation.

- Throttle Valve: Controls the amount of air-fuel mixture entering the engine, impacting power output.

- Jet System: Regulates fuel flow, ensuring the correct mixture for different operating conditions.

- Choke Mechanism: Aids in starting the engine by enriching the fuel mixture during cold starts.

Supportive Components

- Accelerator Pump: Provides an additional fuel surge for quick acceleration.

- Idle Adjustment Screw: Allows fine-tuning of the idle speed for smooth operation.

- Fuel Inlet Valve: Prevents overflow by closing when the chamber reaches a specific level.

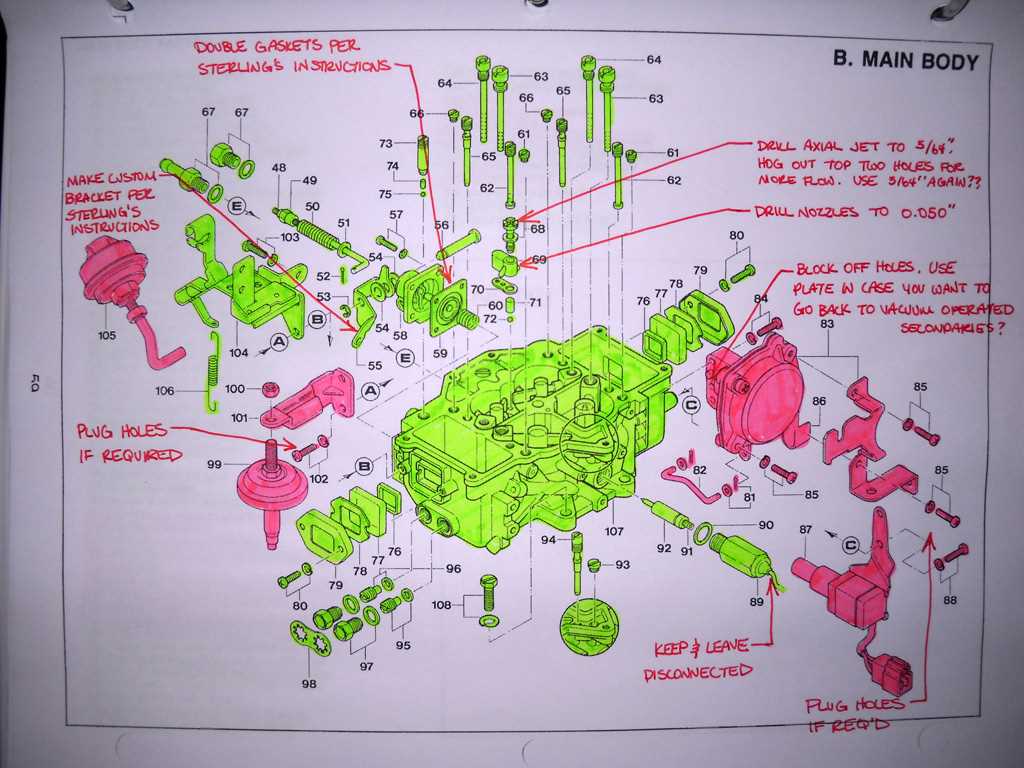

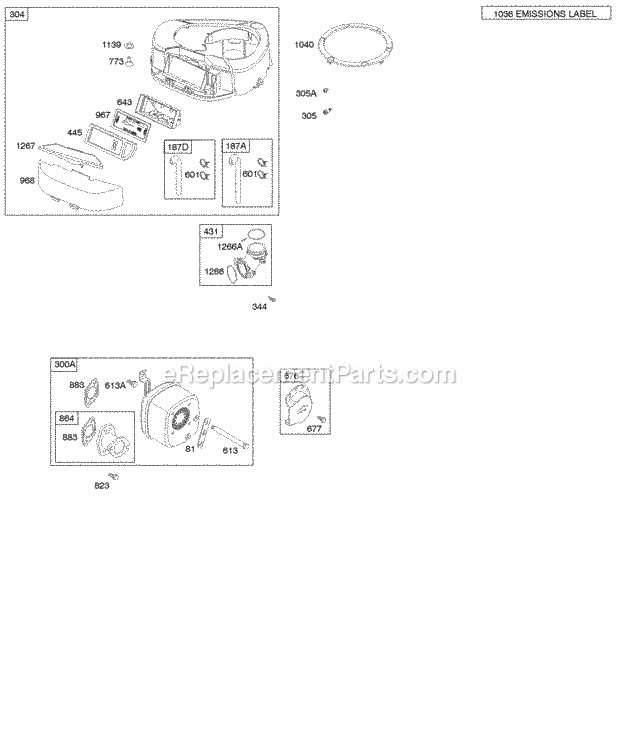

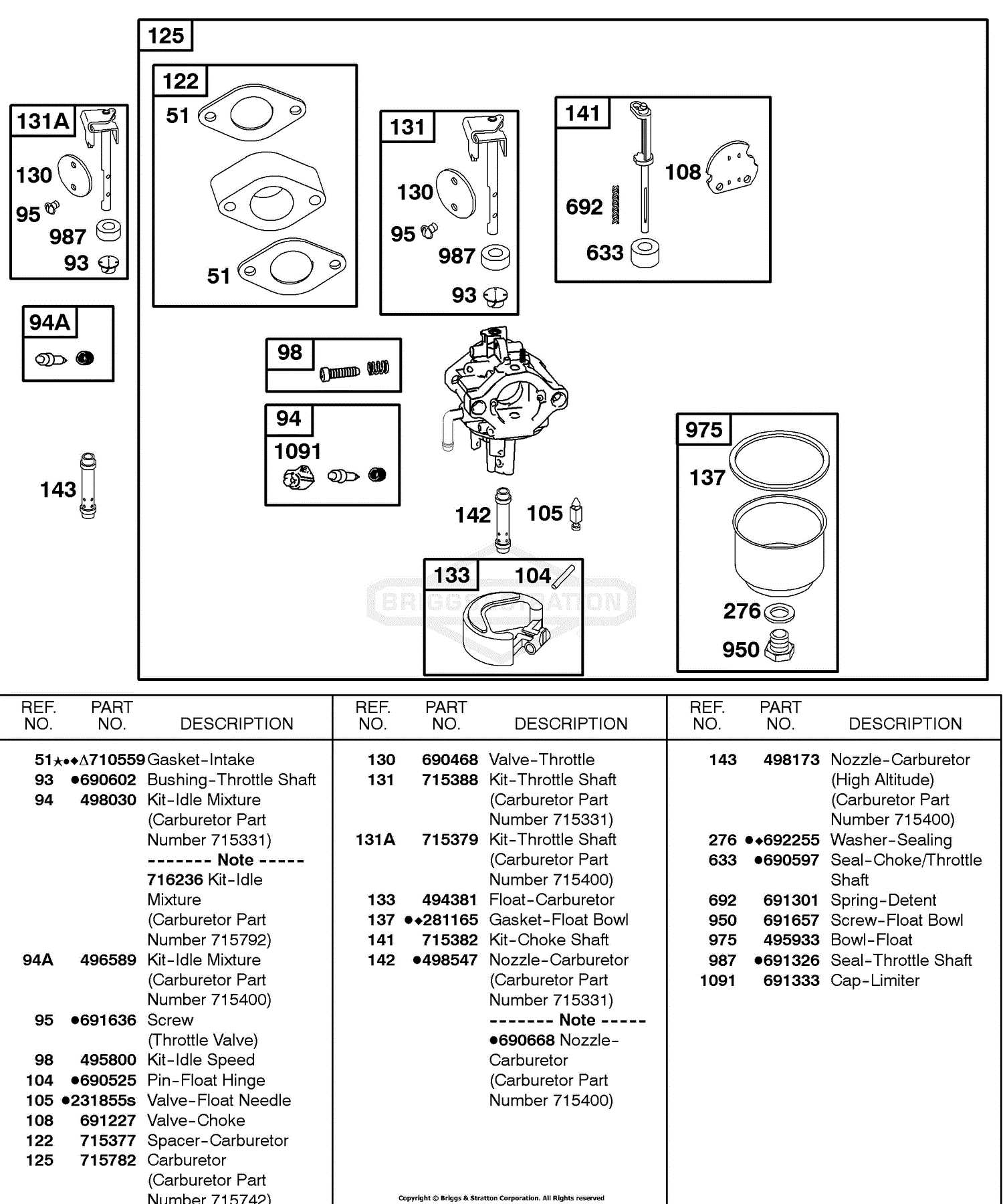

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair. These visual guides provide a clear representation of various elements, making it easier to identify and troubleshoot issues. Mastering the art of interpreting these illustrations can significantly enhance your repair skills.

Key Elements to Note

When examining component illustrations, pay attention to several key aspects:

- Labels: Look for any markings or labels that indicate the names or functions of different elements.

- Numbering: Components are often numbered to correspond with a list of descriptions, aiding in identification.

- Orientation: Ensure you understand the orientation and positioning of each part within the assembly.

Tips for Effective Interpretation

Here are some helpful tips to make the process smoother:

- Familiarize yourself with common symbols and icons used in these illustrations.

- Consult the accompanying list for detailed descriptions of each item.

- Take your time to compare the visual representation with the actual components.

| Feature | Description |

|---|---|

| Labeling | Names or codes for easy identification. |

| Numbering | Corresponds with parts lists for reference. |

| Symbols | Indicates specific functions or characteristics. |

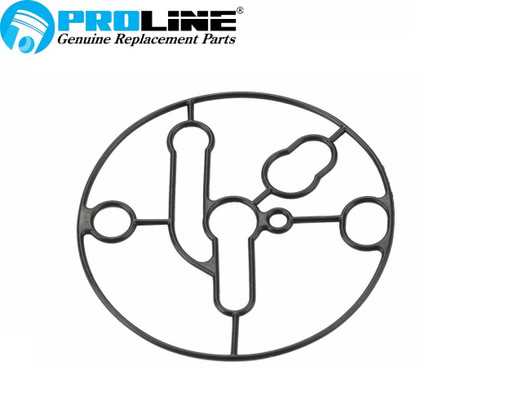

Replacement Parts and Maintenance Tips

Proper upkeep of your engine’s fuel delivery system is crucial for optimal performance and longevity. This section highlights essential components that may require replacement over time, along with practical suggestions to ensure smooth operation and prevent future issues.

Essential Components for Replacement

Regular inspections can help identify worn or damaged components that need to be replaced. Below is a table outlining some of the most commonly replaced elements along with their functions:

| Component | Function |

|---|---|

| Float | Regulates fuel level within the chamber. |

| Jet | Controls the fuel flow into the engine. |

| Gasket | Seals joints to prevent leaks. |

| Needle Valve | Manages fuel entry into the system. |

Maintenance Recommendations

To maintain efficient functioning, consider implementing the following practices:

- Conduct regular cleaning to remove debris and buildup.

- Replace filters as needed to ensure optimal fuel flow.

- Check for leaks and secure all connections.

- Inspect components periodically for wear and replace as necessary.

Troubleshooting Common Carburetor Problems

Understanding the typical issues that can arise in fuel delivery systems is essential for maintaining optimal engine performance. Various factors can contribute to irregular operation, often leading to decreased efficiency or functionality. This section outlines common challenges and their potential solutions, enabling users to identify and address these concerns effectively.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Clogged fuel passage | Inspect and clean the fuel line and inlet |

| Rough idling | Dirty or damaged components | Disassemble and clean all relevant parts |

| Excessive fuel consumption | Improper adjustments | Recalibrate the mixture settings |

| Engine stalls | Air leaks | Check gaskets and seals for wear |

| Black smoke from exhaust | Rich fuel mixture | Adjust the fuel-to-air ratio |

Importance of Accurate Parts Identification

Precise recognition of components is essential for ensuring optimal performance and longevity of mechanical systems. When individuals can accurately distinguish each element, it significantly reduces the risk of malfunction and enhances the overall efficiency of the equipment. Misidentifying any element can lead to improper assembly or replacement, resulting in costly repairs and prolonged downtimes.

Furthermore, thorough knowledge of each component contributes to effective maintenance practices. It allows users to perform timely inspections and replacements, minimizing wear and tear. Understanding the role of each segment in the assembly promotes a more informed approach to troubleshooting, enabling users to address issues swiftly and effectively.

In the realm of repairs, having an accurate grasp of components also fosters better communication between technicians and customers. When professionals can clearly identify and articulate the required elements, it instills confidence in clients, ensuring they receive the right solutions for their needs. Ultimately, the accuracy in identifying elements is crucial for achieving a seamless operation in any mechanical application.

Best Practices for Carburetor Cleaning

Ensuring optimal performance of fuel delivery systems requires regular maintenance and thorough cleaning. Adhering to effective techniques not only prolongs the lifespan of the components but also enhances the efficiency of the entire mechanism.

Here are some essential practices to follow during the cleaning process:

- Safety First: Always wear protective gear, such as gloves and goggles, to safeguard against harmful chemicals and debris.

- Use the Right Cleaner: Select a quality solvent specifically designed for cleaning fuel systems, ensuring it is compatible with the materials of the components.

- Disassemble with Care: Carefully take apart the assembly, noting the arrangement of each piece to avoid confusion during reassembly.

- Soak and Scrub: Soak the components in the cleaning solution for the recommended time, then gently scrub with a soft brush to remove any deposits.

- Inspect for Damage: While cleaning, check for any wear or damage to the parts, as these may require replacement to maintain functionality.

- Rinse Thoroughly: After scrubbing, rinse all pieces thoroughly to remove any remaining cleaner or debris.

- Dry Completely: Ensure all components are fully dry before reassembly to prevent moisture-related issues.

- Reassemble with Care: Follow your notes from the disassembly process to reassemble the system correctly, ensuring a proper fit of each piece.

By following these best practices, you can maintain the efficiency and longevity of your fuel delivery system, ensuring smooth operation for years to come.

Where to Find Nikki Parts

Locating components for your engine’s fuel delivery system can be straightforward with the right resources. Numerous suppliers and platforms specialize in offering various items essential for optimal performance. Whether you are looking for genuine replacements or compatible alternatives, there are several avenues to explore.

Start by checking online marketplaces, which often have extensive inventories. Websites dedicated to automotive or small engine supplies frequently carry a range of offerings. Additionally, local retailers that focus on outdoor equipment may have a selection of necessary items. Lastly, specialized forums and community groups can provide valuable recommendations on reliable sources.

| Source | Description |

|---|---|

| Online Marketplaces | Extensive selection with various options for all types of components. |

| Local Retailers | Convenient for immediate purchases, often with knowledgeable staff. |

| Specialized Forums | Community-driven advice and recommendations on reliable vendors. |

DIY Repair vs. Professional Services

When it comes to fixing mechanical issues, enthusiasts often face the choice between tackling the repairs themselves or seeking the expertise of professionals. Each approach has its own set of advantages and challenges, making it essential to evaluate your skills, the complexity of the problem, and your available resources.

Benefits of DIY Repairs

- Cost Savings: Performing repairs independently can significantly reduce expenses related to labor costs.

- Skill Development: Engaging in hands-on work enhances your mechanical knowledge and practical skills.

- Flexibility: DIY repairs allow you to work at your own pace and schedule, avoiding the need to fit into a professional’s timeline.

Advantages of Professional Assistance

- Expert Knowledge: Professionals bring specialized knowledge and experience, ensuring the repair is done correctly.

- Time Efficiency: Experts can often complete repairs more quickly, saving you valuable time.

- Warranty and Guarantees: Many professionals offer warranties on their work, providing peace of mind.