When working with machinery in the agricultural sector, having a clear view of how the different mechanisms interact can greatly enhance maintenance and operation efficiency. Whether you’re dealing with machinery for harvesting or planting, understanding the essential components is crucial for smooth functionality and performance.

In this section, we will explore the fundamental elements that contribute to the seamless operation of modern harvesting tools. By breaking down the technical structure into manageable pieces, you will gain a deeper insight into how these machines operate, ensuring better performance and longevity.

Familiarizing yourself with the individual sections of the machinery will also allow for timely repairs and adjustments, reducing downtime and ensuring that your equipment runs at peak efficiency throughout the farming season. Understanding these elements is key to optimizing your agricultural operations.

Understanding the Case IH 1063 Corn Head

The machinery in question plays a crucial role in efficient agricultural harvesting by streamlining the process of separating crops from the stalk. Its design focuses on improving productivity in the field, ensuring smooth operation across varying crop conditions. This equipment is engineered for durability and performance, allowing for a more effective harvest with reduced maintenance needs. By examining its structure and function, one can appreciate its importance in modern farming.

Key Features of the Equipment

Built with robust components, this harvester attachment is designed to handle tough harvesting tasks. Its operational efficiency is enhanced through precision-engineered mechanisms that work together to minimize crop loss while maximizing throughput. The streamlined setup simplifies adjustments, providing flexibility for different field conditions.

Maintenance Considerations

Regular inspection and upkeep are essential to maintaining optimal performance. Ensuring that all moving parts are well-lubricated and free from debris can significantly extend

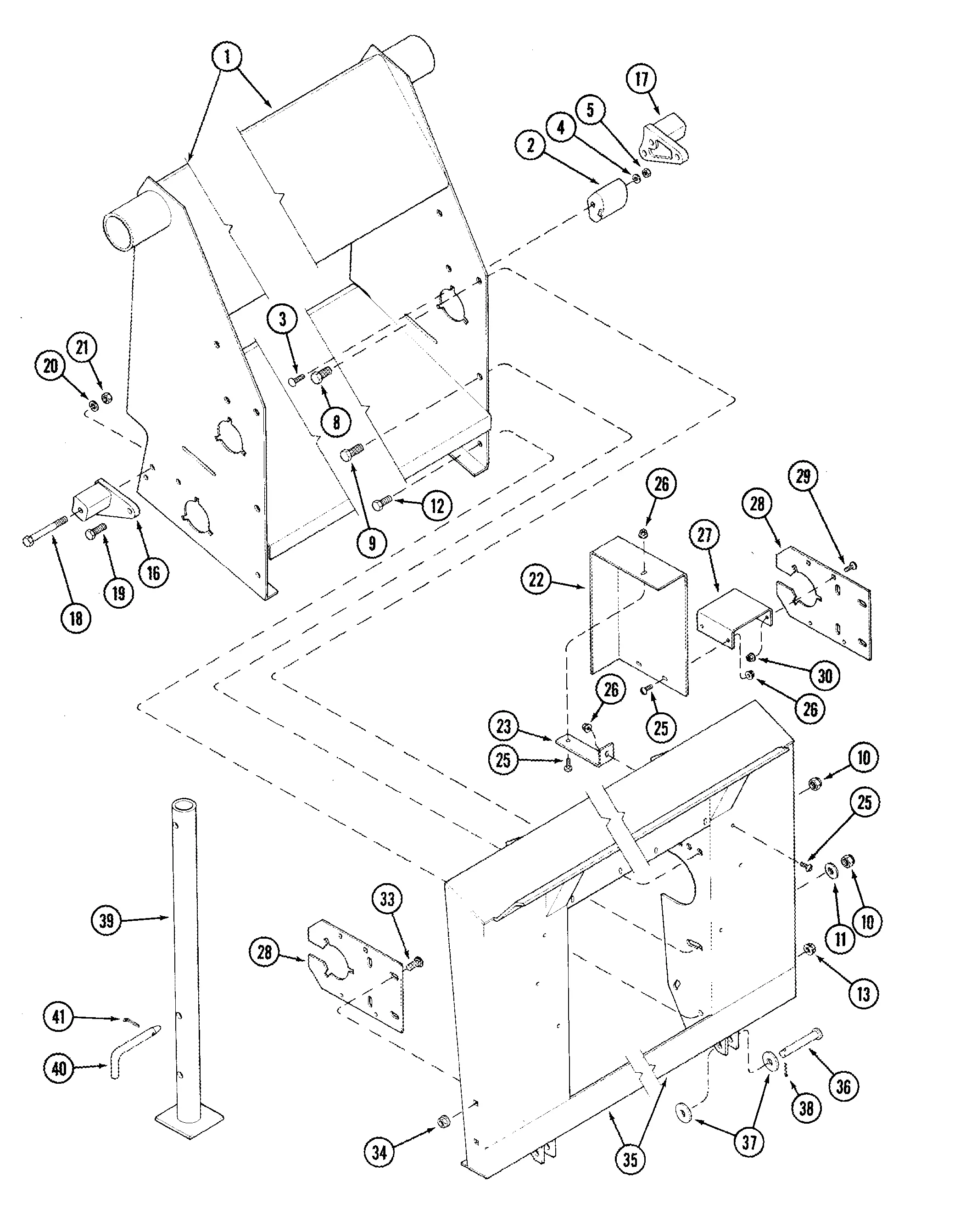

Key Components of the Case IH 1063

The structure of this agricultural attachment is designed to enhance efficiency in harvesting specific crops. It features several critical mechanical elements that work together to ensure optimal performance. Each piece plays a significant role in delivering reliable operation under challenging field conditions, making this equipment essential for high-yield results.

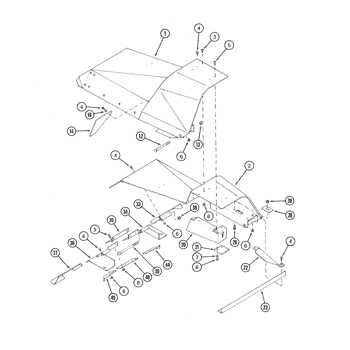

Cutting Blades: These sharp tools are essential for slicing through stalks, ensuring clean cuts while maintaining the integrity of the machinery. Their robust design ensures durability even under intense use.

Row Dividers: These guides help to separate and direct stalks into the machine’s mechanism, ensuring smooth and efficient intake. Their positioning and construction are crucial for seamless operation across varying field conditions.

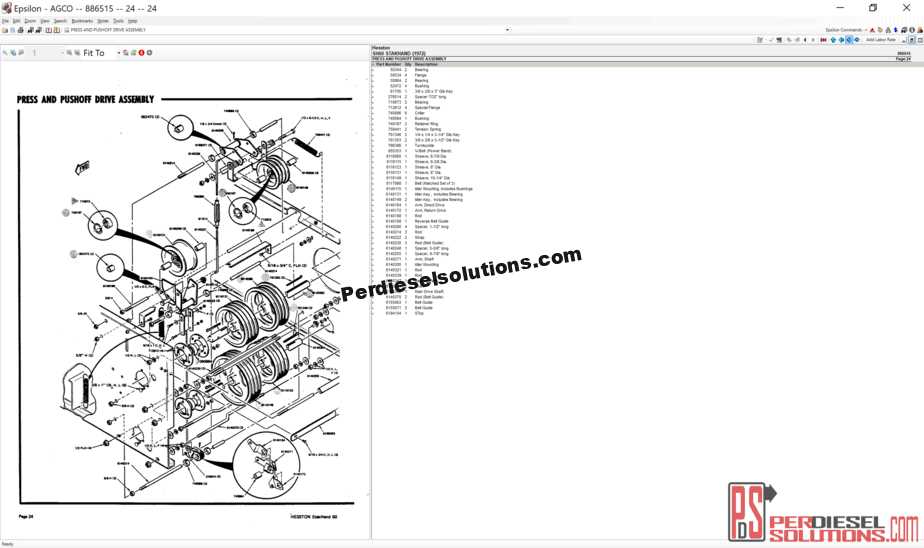

Drive System: This system powers the entire attachment, allowing synchronized movement of the various components. Its precise engineering ensures consistent and

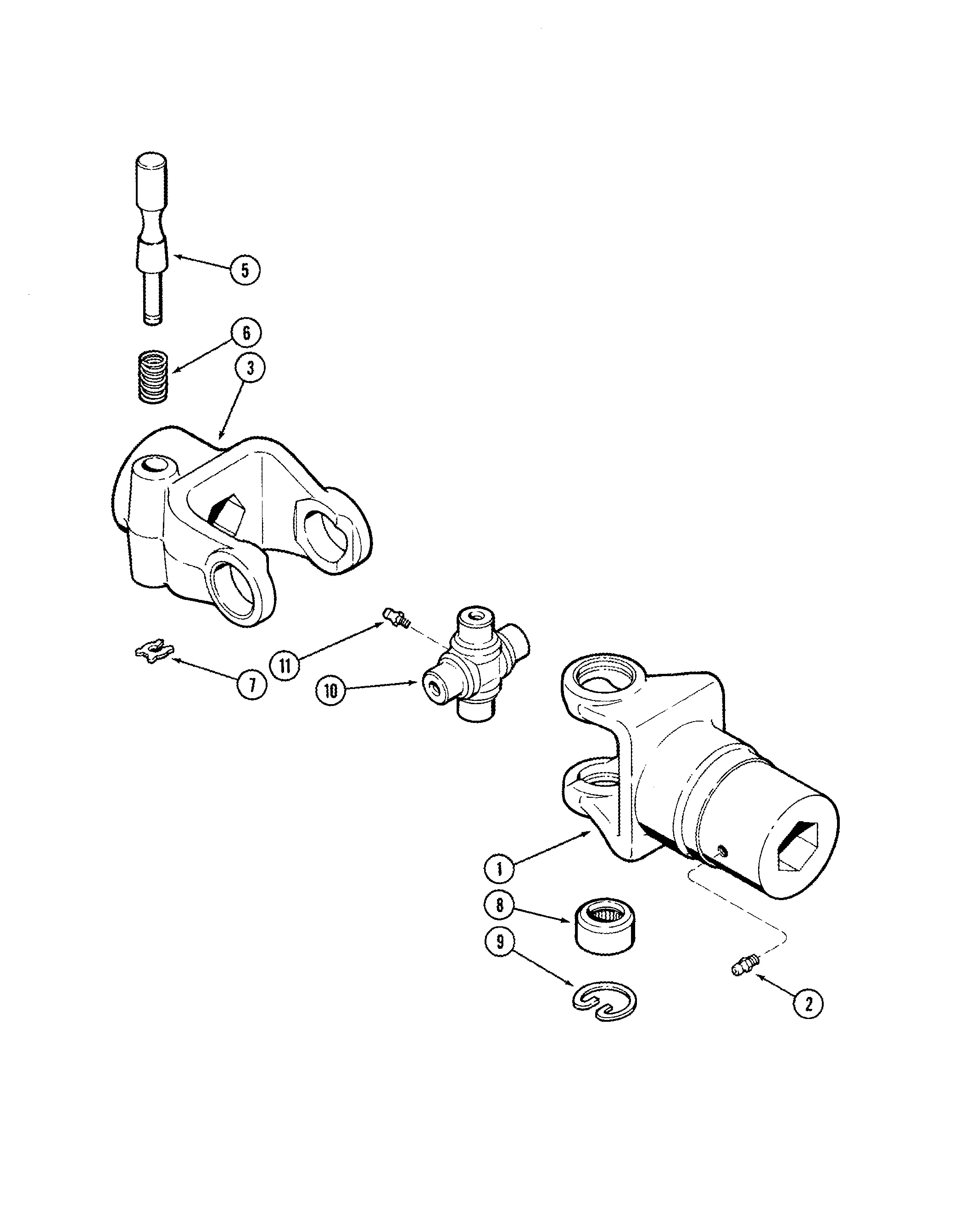

How the Corn Head Gearbox Operates

The gearbox plays a crucial role in the operation of agricultural harvesting machinery. Its main function is to manage the transfer of power from the engine to the components that are responsible for efficient crop collection. This section explains the basic mechanics of how the system works, highlighting the key processes involved in power transmission and control.

Power Transmission and Distribution

The primary function of the gearbox is to transmit energy from the motor to various moving elements of the harvesting equipment. It uses gears to adjust speed and torque, ensuring that the machine can handle different harvesting conditions effectively. The arrangement of these gears allows for smooth operation even under heavy loads.

Speed Regulation and Control

Another important aspect of the gearbox is its ability to regulate the speed of the harvesting process. By modifying gear ratios, the operator can adjust the machine’s performance to suit the specific field conditions, ensuring optimal efficiency. This precise control over speed helps

Maintenance Tips for Corn Head Blades

Regular upkeep of cutting components is crucial for ensuring efficient and reliable harvesting. Proper care not only extends the lifespan of the equipment but also helps maintain performance in various field conditions. By following a few essential maintenance practices, operators can prevent unnecessary wear and tear, while also improving the overall efficiency of their machinery.

Inspecting Blade Condition

Frequent inspections of the blades can help identify any signs of damage or dullness. It’s important to check for cracks, chips, or bent edges, as these can reduce the effectiveness of the machine. Replacing or sharpening the blades when needed ensures smoother operations and reduces strain on the equipment.

Proper Lubrication

Keeping all moving parts well-lubricated is essential to minimize friction and prevent overheating. Regular application of high-quality lubricants, especially on

Identifying Wear on IH Augers

Regular inspection of augers is essential to ensure optimal performance during harvesting operations. Over time, signs of wear can develop, potentially impacting the efficiency of grain handling. Identifying these signs early helps maintain the longevity of your equipment and avoid costly repairs.

Key Signs of Wear

- Blade thinning: Auger blades may gradually become thinner due to constant friction with the harvested material, reducing their effectiveness.

- Uneven edges: The edges of the auger may show uneven wear, which can cause vibrations and decrease overall performance.

- Rust or corrosion: Prolonged exposure to moisture can lead to rust, weakening the structural integrity of the auger.

Preventative Measures

- Inspect the auger periodically for early signs of thinning or rust.

- Ensure the equipment is stored in

Importance of Proper Lubrication for Harvesting Equipment

Ensuring the correct lubrication of agricultural machinery is vital for optimal performance and longevity. Adequate lubrication minimizes friction between moving components, reducing wear and tear. This practice not only enhances efficiency but also plays a significant role in preventing breakdowns during crucial harvesting periods.

Effective lubrication contributes to smoother operation, allowing for improved productivity and reduced fuel consumption. When machinery operates under well-lubricated conditions, it experiences less strain, resulting in fewer maintenance requirements and longer service life.

Additionally, proper lubrication helps in maintaining consistent functionality, which is essential for achieving desired yields. Neglecting this aspect can lead to mechanical failures, resulting in costly repairs and downtime. Therefore, farmers should prioritize regular checks and maintenance to ensure their equipment operates at its best.

Troubleshooting Common Corn Head Issues

When working with harvesting equipment, various challenges can arise that may affect performance and efficiency. Identifying and resolving these issues is crucial to maintain optimal operation and minimize downtime. Below are some common problems encountered during the harvesting process and suggested solutions to help ensure a smooth operation.

Identifying Common Problems

- Inconsistent cutting performance

- Unusual noises during operation

- Blockages in the harvesting mechanism

- Poor crop flow

Suggested Solutions

- Inspect the Cutting Mechanism: Regularly check blades for wear and tear, ensuring they are sharp and aligned properly.

- Examine Drive Components: Look for any signs of wear in belts and chains, and replace them as needed to avoid slippage.

- Clear Blockages: Ensure that no debris is obstructing the flow of material through the equipment.

- Adjust Settings: Fine-tune the operational settings to better match the type of crop being harvested.

By taking proactive steps to troubleshoot these common issues, operators can enhance the efficiency of their harvesting equipment, leading to improved performance and reduced operational costs.

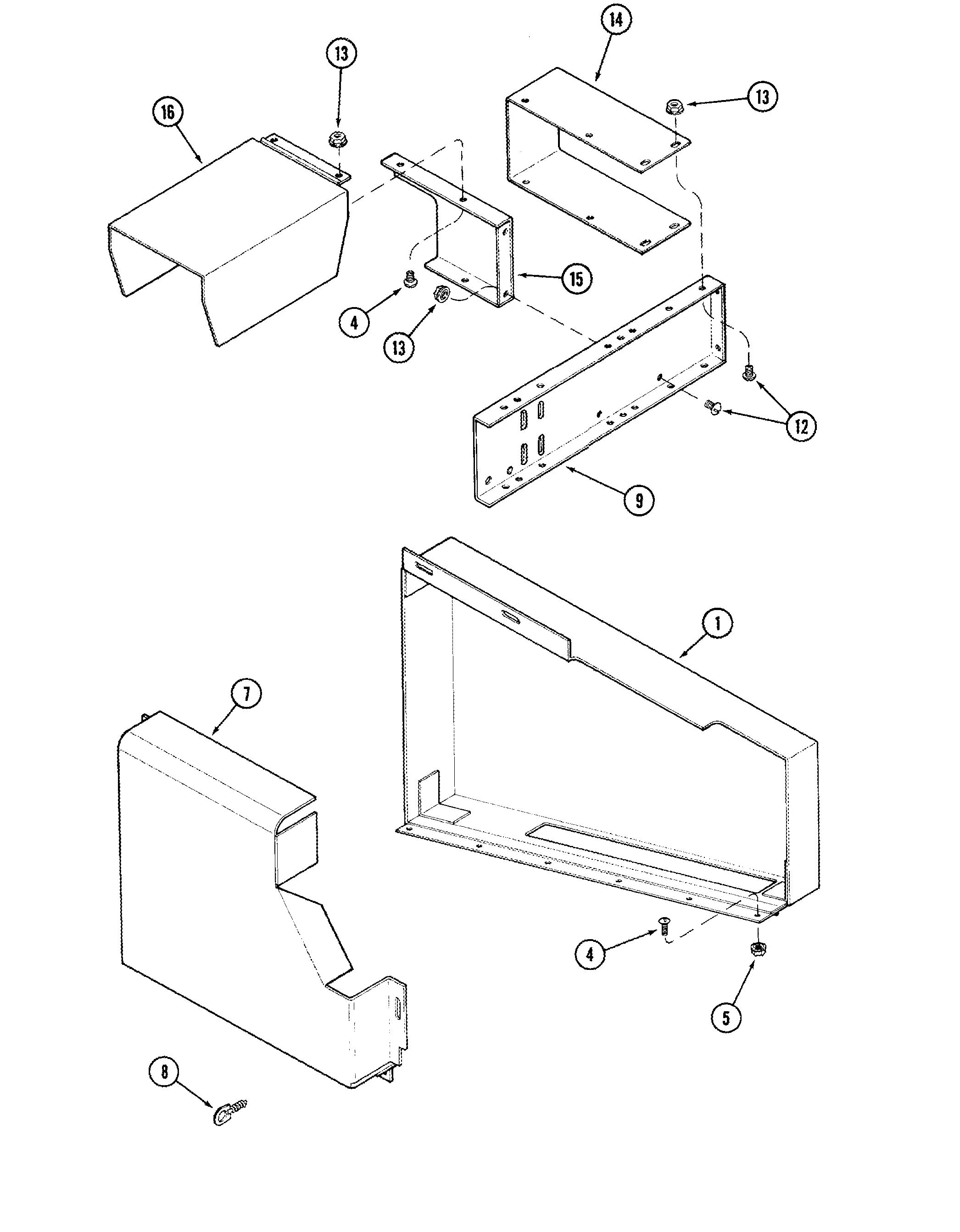

How to Replace Corn Head Chains

Replacing the chains in a harvesting attachment is crucial for maintaining optimal performance during the harvest season. This process can enhance efficiency and prolong the lifespan of your equipment. Below are the steps and considerations to ensure a successful replacement.

- Gather Required Tools:

- Wrench set

- Screwdriver

- Replacement chains

- Safety gloves

- Protective eyewear

- Prepare the Equipment:

Before beginning, ensure the machine is turned off and properly secured to prevent accidental operation. Disconnect the power source to enhance safety.

- Remove Old Chains:

Carefully locate the attachment points of the existing chains. Use the wrench to remove any fasteners holding the chains in place. Take note of the arrangement for easier installation of new chains.

- Install New Chains:

Position the new chains according to the notes taken during the removal. Secure them in place using the appropriate fasteners, ensuring they are tightly fitted to prevent slippage.

- Check Alignment and Tension:

After installation, verify that the chains are aligned correctly and have the proper tension. This step is vital to ensure smooth operation and to avoid premature wear.

- Test the Equipment:

Once everything is securely installed, reconnect the power source. Conduct a short test run to ensure everything is functioning smoothly. Observe for any unusual noises or misalignment.

By following these steps, you can effectively replace the chains on your harvesting equipment, ensuring it operates efficiently during the critical harvest period.

Optimizing Performance with Correct Adjustments

Ensuring the efficiency of agricultural machinery is vital for maximizing yield and reducing operational costs. Proper modifications and settings can significantly enhance the performance of your equipment. By understanding the essential components and their adjustments, you can achieve optimal functionality.

Here are some key aspects to consider for effective optimization:

- Understanding Equipment Features: Familiarize yourself with the main characteristics and capabilities of your machinery to make informed adjustments.

- Routine Maintenance: Regular inspections and servicing are crucial for preventing wear and tear, which can impact performance.

- Adjusting Settings: Fine-tuning the equipment settings based on the specific conditions can lead to improved efficiency.

- Monitoring Performance: Keep track of productivity metrics to identify areas needing adjustments or improvements.

By prioritizing these factors, you can significantly enhance the effectiveness of your machinery, ensuring it operates at peak performance throughout the season.

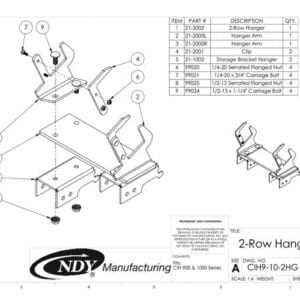

Where to Find Replacement Corn Head Parts

When it comes to maintaining agricultural machinery, sourcing components can be a crucial task. Whether you are looking to repair existing equipment or upgrade for better performance, understanding where to obtain these essential items is key to ensuring efficient operation.

There are several avenues to explore when searching for replacement components. Local dealerships often carry a variety of options and can provide expert advice tailored to your specific machinery. Online retailers also offer extensive inventories, frequently featuring user reviews and comparisons to aid in making informed decisions. Additionally, specialized forums and communities dedicated to farming equipment can be invaluable resources for finding rare or discontinued items.

Source Type Advantages Disadvantages Local Dealerships Personalized service, immediate availability Higher prices, limited stock Online Retailers Wider selection, competitive pricing Longer shipping times, potential for errors Online Forums Community support, tips for rare finds Variable reliability, lack of guarantees Upgrading the Case IH 1063 for Efficiency

Enhancing agricultural machinery can significantly improve productivity and reduce operational costs. By focusing on various components and their efficiency, farmers can achieve better performance in the field. This section explores key areas for improvement in a specific model to optimize its functionality.

Key Areas for Improvement

- Engine Performance: Upgrading the engine or optimizing its settings can lead to better fuel efficiency and increased power.

- Knife Quality: Replacing or sharpening the cutting knives can enhance the cutting efficiency, resulting in cleaner harvesting.

- Chain and Sprocket Maintenance: Regularly inspecting and replacing worn chains and sprockets ensures smooth operation and reduces wear on other components.

Benefits of Upgrades

- Improved Fuel Efficiency: Upgrades can lead to lower fuel consumption, saving money in the long run.

- Increased Yield Quality: Enhanced machinery results in better crop handling, leading to higher quality produce.

- Reduced Downtime: Investing in parts and maintenance reduces the likelihood of breakdowns, allowing for more consistent operation.