The inner workings of mechanical cutting tools rely on the seamless cooperation of various elements. Each individual component plays a vital role in ensuring efficient operation, durability, and safety during usage. Understanding the layout and interconnection of these elements helps maintain optimal performance.

In this article, we will delve into the structure of key mechanisms, exploring how various elements interact to keep the tool running smoothly. A proper grasp of this setup is essential for regular upkeep, quick troubleshooting, and extending the tool’s lifespan.

We will also highlight the importance of detailed schematics, which allow users to identify crucial elements effortlessly. With these insights, maintaining functionality becomes easier, whether you’re addressing wear and tear or replacing essential elements.

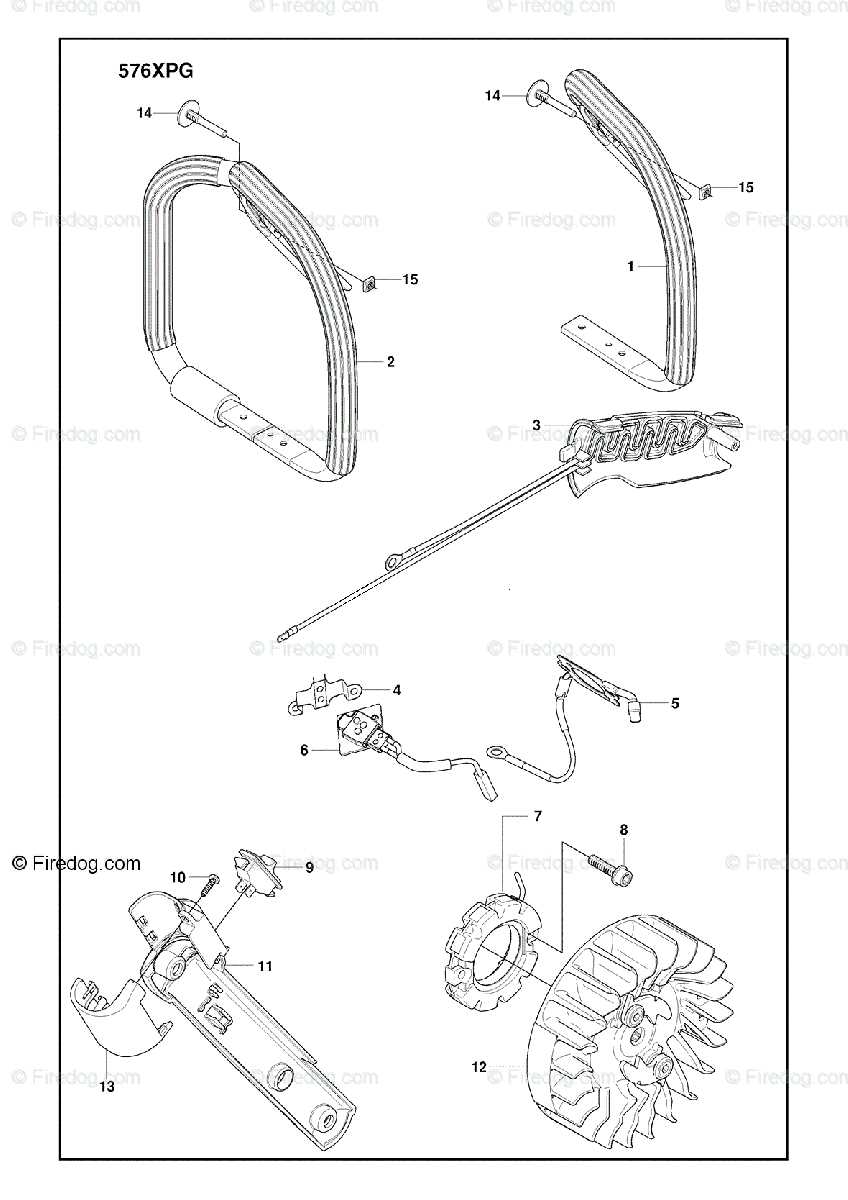

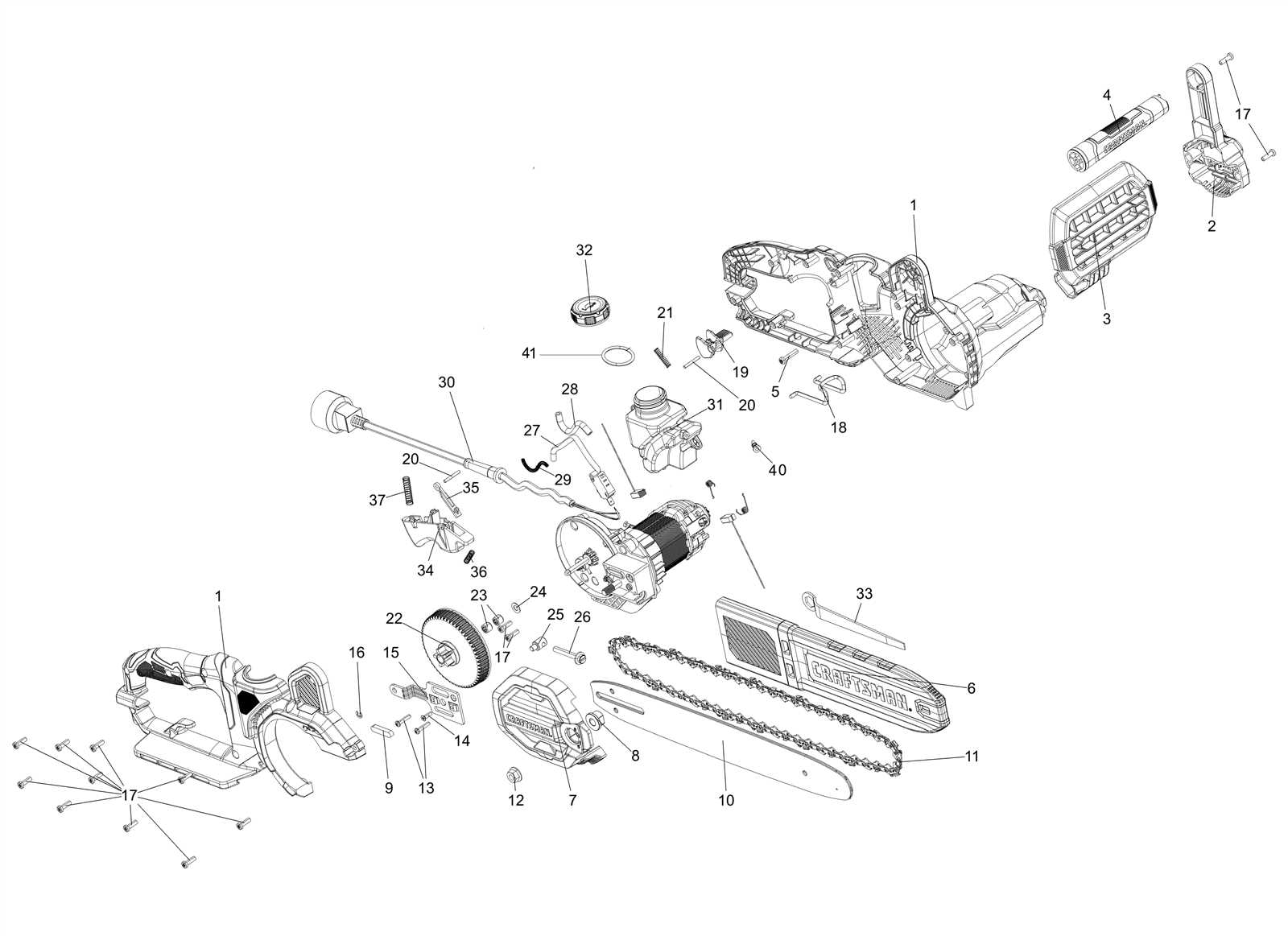

Craftsman Chainsaw Parts Diagram

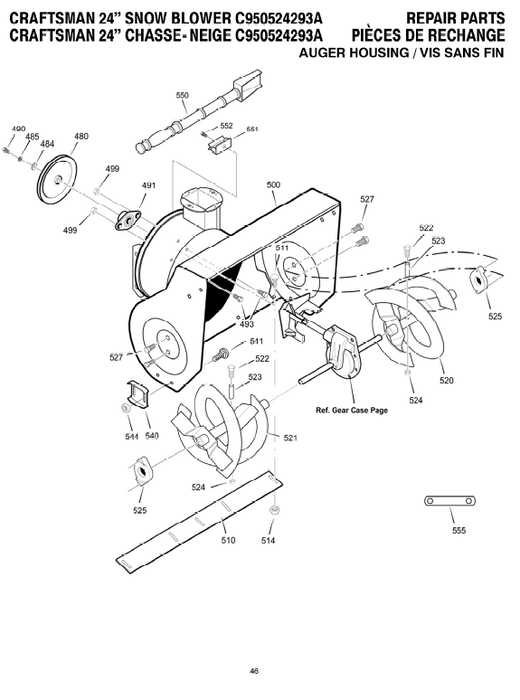

Understanding how individual components interact within a complex mechanical tool ensures smoother operation and easier maintenance. A visual representation allows users to quickly locate key elements, promoting efficient repairs and replacements.

Each section of the machine plays a specific role, from energy transfer to safety mechanisms, working together to maintain optimal performance. Identifying these elements helps troubleshoot issues, reducing downtime and enhancing the tool’s lifespan.

Whether for professional tasks or personal projects, knowing how internal systems align and cooperate is crucial for both functionality and safety. A breakdown of these segments provides clarity, ensuring users make informed decisions when servicing or upgrading components.

Essential Components of a Chainsaw

Understanding the crucial elements of a cutting tool enhances its efficiency and functionality. Each component plays a specific role in ensuring that the equipment operates smoothly and effectively during use.

Main Parts of the Tool

- Engine: The powerhouse that drives the mechanism, available in various types, such as gas or electric.

- Guide Bar: A flat, elongated piece that supports the cutting chain, allowing it to rotate and cut through wood.

- Cutting Chain: A loop of linked sections equipped with sharp teeth designed to slice through materials effortlessly.

- Handle: The part that provides control, allowing the user to maneuver the tool with precision.

- Safety Features: Includes protective mechanisms like chain brakes and shields to minimize the risk of injury.

Additional Components

- Fuel System: Comprising a tank and lines that deliver energy to the engine.

- Air Filter: Prevents dust and debris from entering the engine, ensuring optimal performance.

- Clutch: Engages and disengages the chain from the engine to control cutting action.

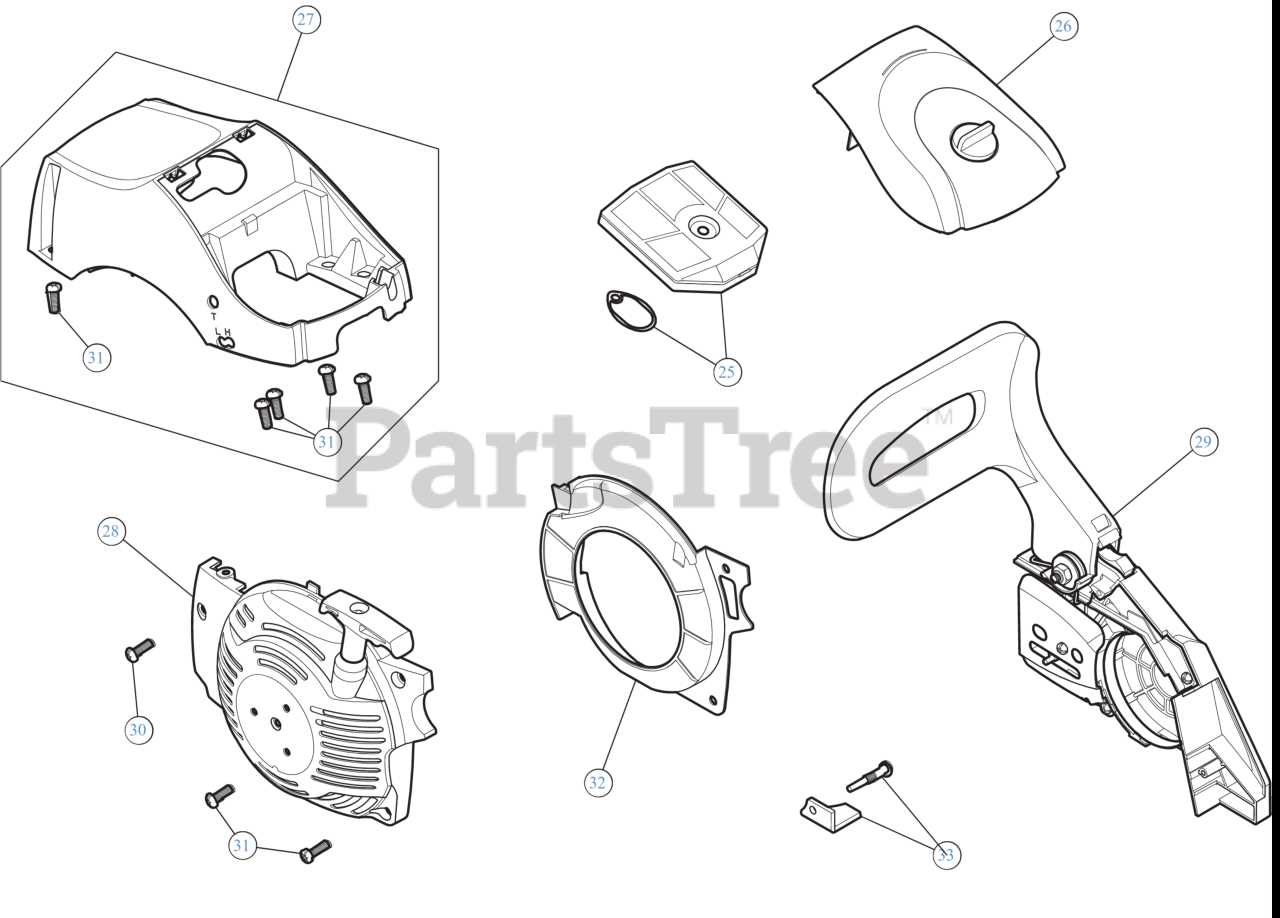

- Starter Mechanism: Facilitates the ignition of the engine, crucial for beginning operation.

- Lubrication System: Ensures that the cutting chain and guide bar are adequately oiled for smooth operation.

How to Identify Chainsaw Parts

Understanding the components of your equipment is essential for effective maintenance and repair. Familiarizing yourself with the various elements will help ensure optimal performance and longevity of your tool. Below are key strategies for recognizing and differentiating these essential elements.

Visual Inspection

Begin by closely examining the equipment. Look for the following features:

- Shape and Size: Different components vary in shape and dimensions, providing clues to their function.

- Color: Many elements are color-coded for easy identification, helping distinguish between them.

- Material: The material composition can indicate the purpose, such as metal for durability and plastic for lightweight designs.

Consulting Manuals and Resources

Utilize manuals and online resources for detailed descriptions. Here’s how:

- Refer to the user manual, which often contains labeled illustrations.

- Search online for guides and videos that provide visual aids and expert explanations.

- Join forums or communities focused on equipment maintenance for shared insights and tips.

Replacing Worn-Out Chainsaw Elements

Maintaining the efficiency and longevity of your cutting tool requires periodic replacement of its aging components. As time passes, certain elements may become less effective, leading to decreased performance and safety risks. Understanding how to identify and replace these worn-out elements can enhance the overall functionality of your equipment.

Identifying Worn Components

Recognizing which parts need replacement is crucial. Common signs of wear include:

- Decreased cutting efficiency

- Excessive vibration during operation

- Visible damage or cracks on the exterior

- Difficulty in starting the engine

Replacement Process

Follow these steps to replace the outdated elements effectively:

- Disconnect the power source to ensure safety.

- Remove the cover or casing to access the components.

- Carefully inspect each part for signs of wear.

- Replace any identified worn components with new, compatible alternatives.

- Reassemble the tool and check for proper functionality before use.

Maintenance Tips for Chainsaw Longevity

To ensure optimal performance and extend the lifespan of your outdoor power tool, regular upkeep is essential. Adopting effective maintenance practices can prevent unnecessary wear and tear, enhance efficiency, and reduce the risk of unexpected failures.

Regular Cleaning

Keeping your equipment clean is vital. Debris accumulation can affect its performance. Follow these steps:

- After each use, wipe down the exterior with a damp cloth.

- Remove any buildup around the cutting mechanism.

- Inspect and clean air filters regularly to ensure proper airflow.

Routine Inspections

Performing systematic checks helps identify potential issues before they escalate:

- Examine the chain for wear and sharpen as needed.

- Inspect the bar for damage or bending.

- Check all bolts and screws for tightness and secure them if loose.

Choosing the Right Chainsaw Chain

Selecting the appropriate cutting chain for your equipment is essential for optimal performance and safety. Various factors influence this decision, including compatibility, intended use, and the specific characteristics of the chain itself. Understanding these elements will help ensure efficient operation and prolong the life of your tool.

When assessing different options, consider the following attributes:

| Attribute | Description |

|---|---|

| Pitch | The distance between the drive links, which affects the speed and power of the cutting tool. |

| Gauge | The thickness of the drive links, crucial for ensuring a snug fit within the guide bar. |

| Number of Links | Affects the overall length of the chain and should match the specifications of your equipment. |

| Tooth Design | The shape and sharpness of the teeth, influencing cutting efficiency and wood type suitability. |

By carefully evaluating these characteristics, you can choose a cutting chain that enhances your equipment’s capabilities while ensuring safety and effectiveness during operation.

Troubleshooting Common Chainsaw Issues

Understanding and addressing frequent problems with power cutting tools is essential for maintaining their efficiency and longevity. By identifying typical malfunctions, users can implement straightforward solutions that enhance performance and prevent further complications.

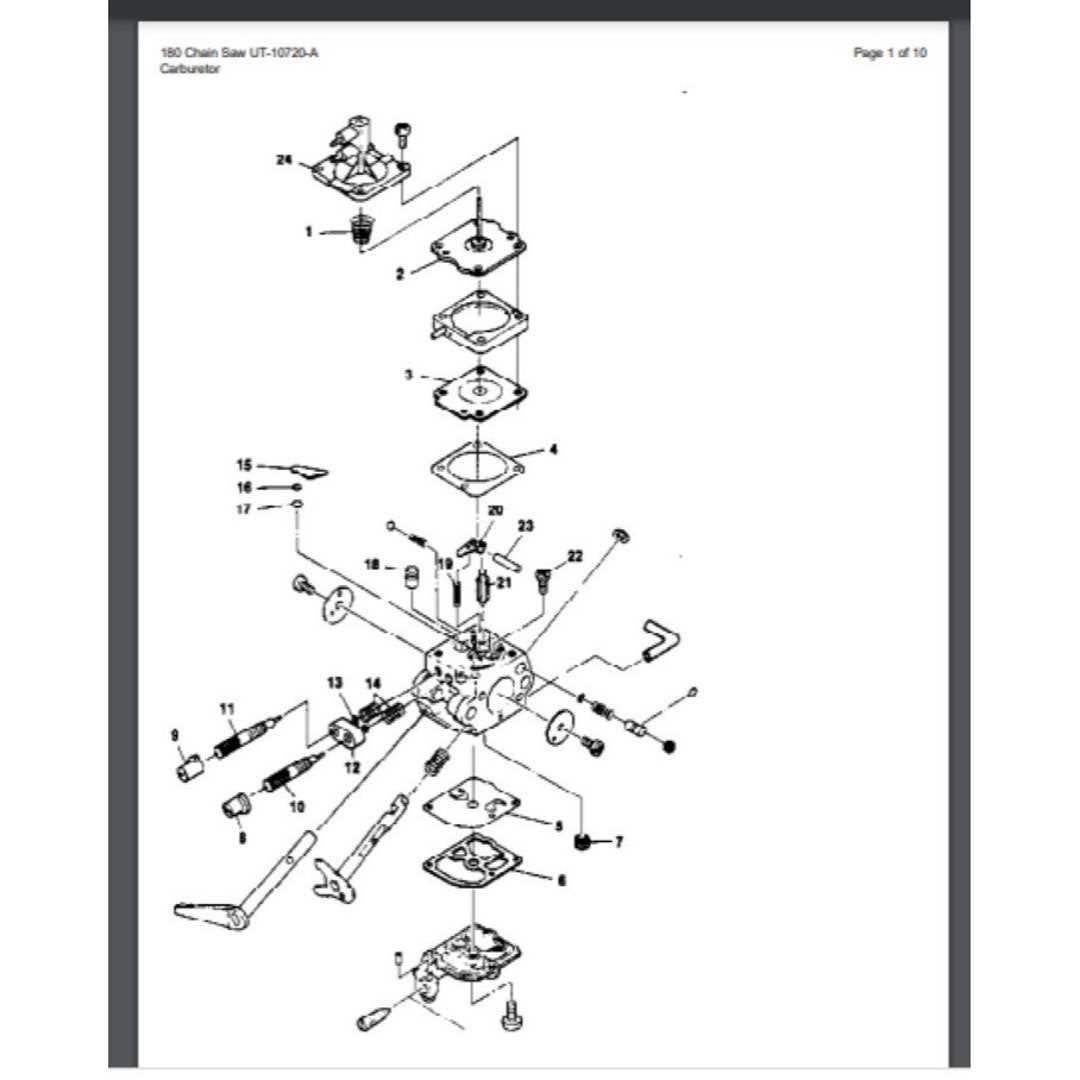

Engine Fails to Start

When the motor does not ignite, it can be due to several factors. First, ensure there is an adequate fuel supply. Stale fuel or incorrect fuel mixtures can also cause starting issues. Check the ignition system; a malfunctioning spark plug may need replacement. Additionally, inspect the air filter for blockages, as a clean air supply is crucial for proper combustion.

Poor Cutting Performance

If the tool struggles to cut effectively, the problem may lie in the cutting mechanism. Examine the blade for dullness or damage, as a sharp and intact blade is vital for optimal operation. Ensure that the tension on the chain is properly adjusted, as a loose or overly tight chain can hinder performance. Finally, check for any obstructions in the cutting path that could impede progress.

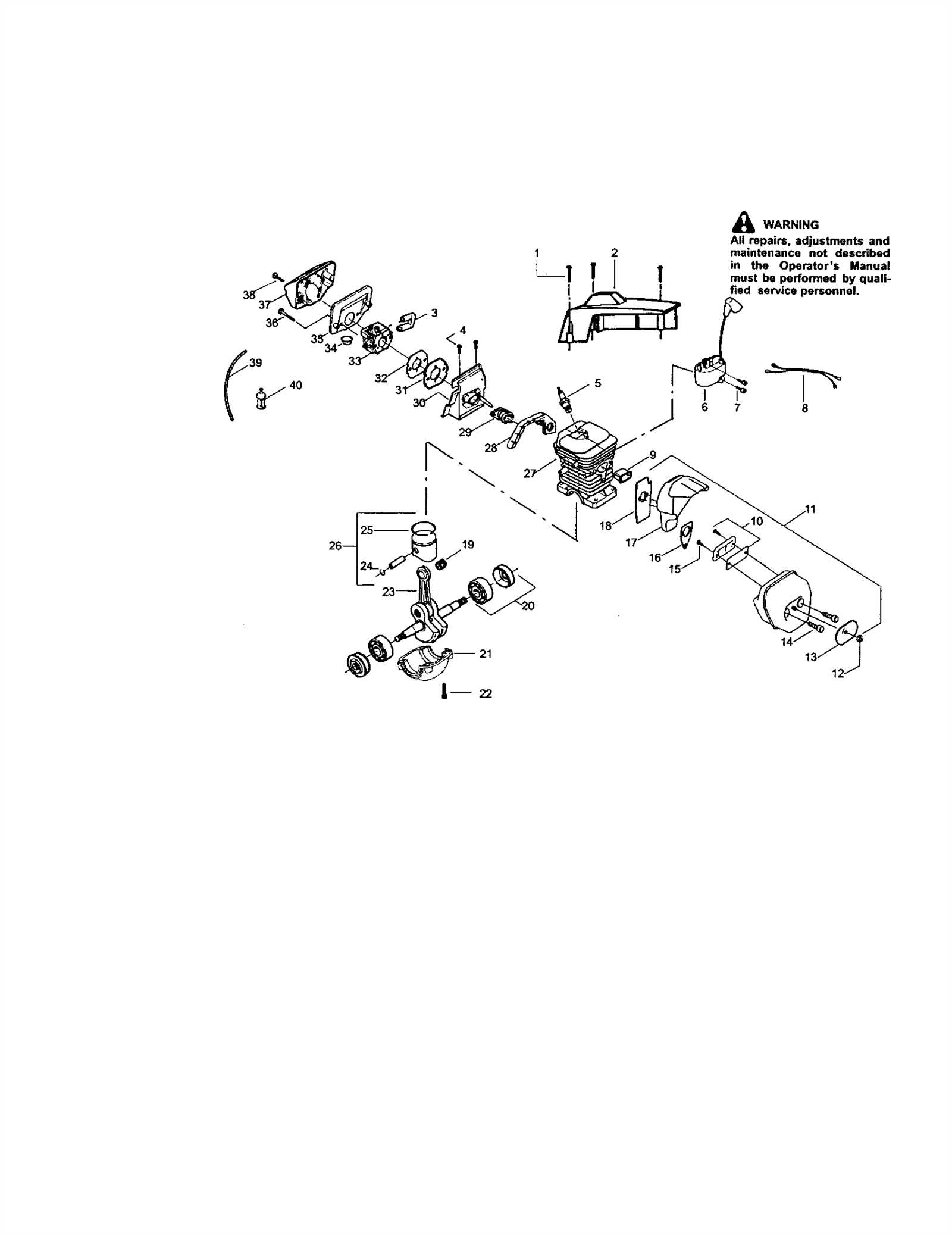

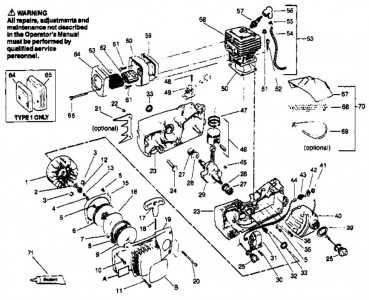

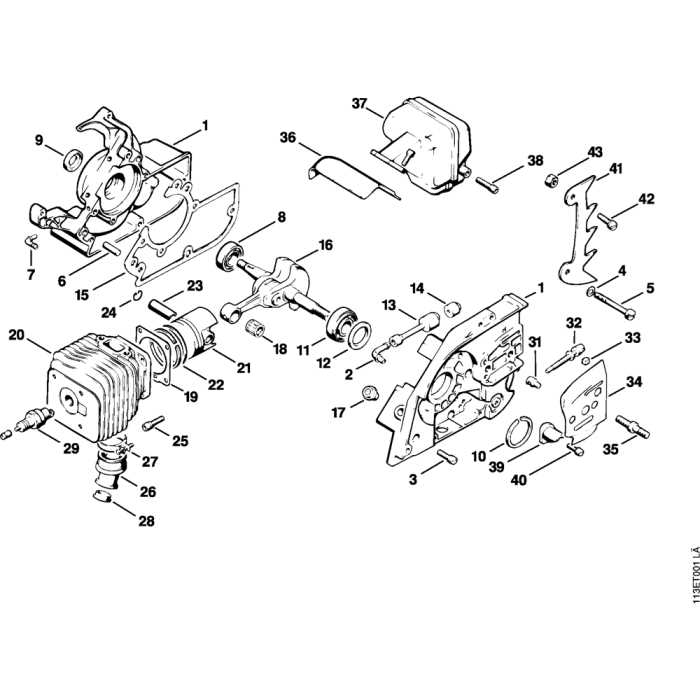

Guide to Chainsaw Engine Parts

This section provides an overview of the essential components that contribute to the functionality of a power saw’s motor. Understanding these elements is crucial for anyone looking to maintain or troubleshoot the equipment effectively.

The motor consists of various elements, each playing a vital role in its operation. Below are the primary components that make up the engine:

- Cylinder: This is where the combustion process occurs, driving the piston.

- Piston: A movable component that compresses the fuel-air mixture within the cylinder.

- Crankshaft: Converts the linear motion of the piston into rotational motion to power the cutting tool.

- Carburetor: Responsible for mixing air and fuel in the correct ratio for combustion.

- Ignition System: Initiates the combustion process through the spark plug.

- Fuel Tank: Stores the necessary fuel for the motor’s operation.

- Exhaust System: Channels the exhaust gases away from the engine, ensuring efficient operation.

Proper knowledge of these components can enhance performance and extend the life of the tool. Regular maintenance and inspections will ensure that each element functions optimally, contributing to overall efficiency.

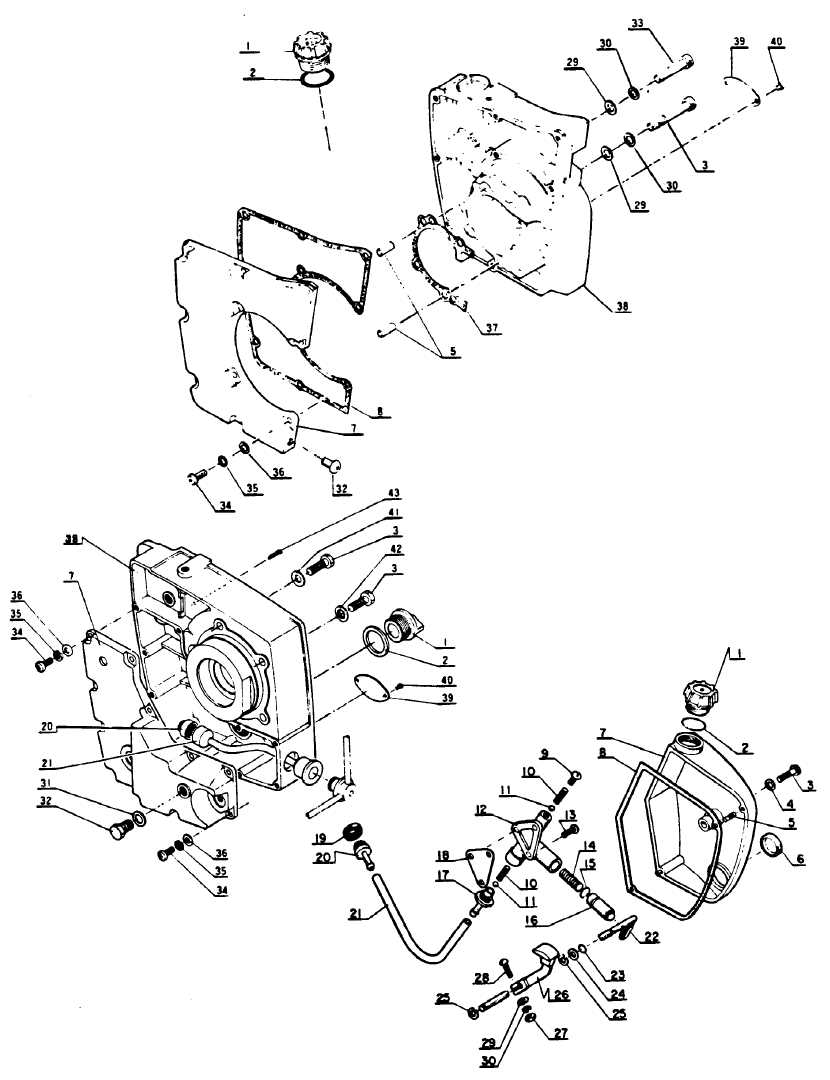

Lubrication System Overview

The lubrication mechanism plays a vital role in ensuring optimal performance and longevity of outdoor power equipment. It is designed to minimize friction between moving components, thereby enhancing efficiency and reducing wear and tear. A well-functioning lubrication system is essential for maintaining the effectiveness of various mechanical parts, ensuring smooth operation during use.

This system typically consists of several key elements that work together to deliver the necessary oil to critical areas. Understanding the components and their functions is crucial for proper maintenance and troubleshooting. Below is a summary of the primary components involved in the lubrication system:

| Component | Description |

|---|---|

| Oil Tank | Stores the lubricating fluid, providing a reservoir for the system. |

| Oil Pump | Distributes the oil from the tank to various moving parts as needed. |

| Oil Filter | Removes impurities from the lubricant to prevent damage to the components. |

| Delivery Lines | Transport the oil from the pump to the necessary locations throughout the machinery. |

| Lubrication Points | Specific areas where oil is applied to ensure smooth operation and reduce friction. |

Safety Features in Modern Chainsaws

Contemporary cutting tools incorporate a variety of innovative safety mechanisms designed to enhance user protection and minimize the risk of accidents. These advancements not only improve the overall experience for operators but also ensure a higher standard of safety in demanding environments.

Automatic Chain Brake

The automatic chain brake is a crucial feature that activates during kickback, instantly stopping the chain’s movement. This quick response significantly reduces the likelihood of injury, allowing users to maintain better control during operation. Operators are encouraged to familiarize themselves with this feature to enhance their safety practices.

Anti-Vibration Technology

Advanced anti-vibration systems are integrated into modern tools to reduce user fatigue and improve handling. By minimizing vibrations during use, these technologies not only increase comfort but also enhance precision, allowing for safer operation. Operators can work longer with less strain, resulting in better performance and reduced risk of mishaps.

Where to Find Chainsaw Replacement Parts

When your cutting tool requires new components, sourcing them effectively is essential for optimal performance. Fortunately, there are various avenues available to locate the necessary replacements, ensuring that your equipment remains in peak condition.

Online Retailers

One of the most convenient options is to explore online retailers. Websites specializing in outdoor equipment often offer a wide range of components for various brands. Using the search feature with model numbers can help streamline the process, allowing you to find the exact items needed for your specific model.

Local Hardware Stores

Another reliable resource is local hardware or home improvement stores. Many of these establishments carry a selection of components for outdoor machinery. Speaking with a knowledgeable staff member can provide insights into which components are compatible with your equipment. Additionally, they may assist in placing special orders if the desired items are not in stock.