Understanding the internal structure and how various elements work together is essential for anyone looking to maintain or repair machinery. Each component has its unique role, contributing to the overall performance and longevity of the equipment. By familiarizing yourself with the layout and connections, you can significantly enhance your ability to troubleshoot and resolve issues efficiently.

In this section, we will explore the different elements that make up the machinery. The aim is to provide a clear and organized breakdown, focusing on how individual pieces connect and operate. Whether you are dealing with mechanical adjustments or planning preventive maintenance, having a clear visual representation of the inner workings can greatly assist in the process.

By examining these components closely, you can gain deeper insights into their purpose and how they interact with one another. This detailed examination will empower you to handle repairs or adjustments with greater confidence, ensuring smooth operation for years to come.

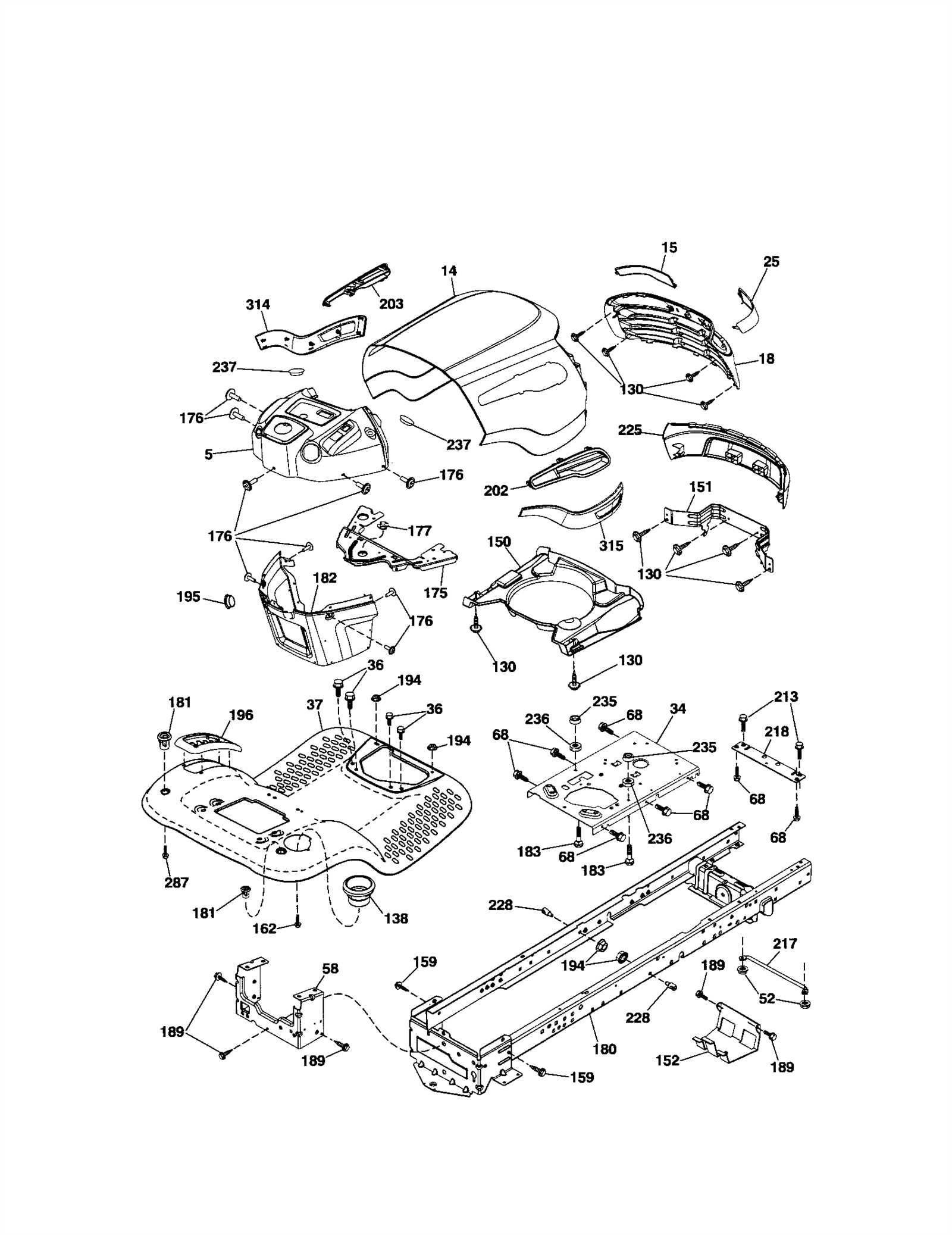

Yt3000 Craftsman: Key Components Overview

In this section, we will explore the essential elements that form the core of this equipment. These vital pieces ensure smooth functionality and efficient performance, contributing to the overall user experience. Understanding the roles and connections between these components is crucial for maintaining the machine in optimal working condition.

The structure includes several mechanical and electronic elements designed to work in harmony. From the propulsion system to the steering controls, each part plays a critical role in ensuring the equipment operates reliably and efficiently. Regular maintenance of these key pieces can prevent breakdowns and extend the lifespan of the machine.

Among the most important sections, attention should be paid to the engine assembly, which provides the necessary power, and the control mechanisms, which offer precision handling. These areas are interconnected with various support

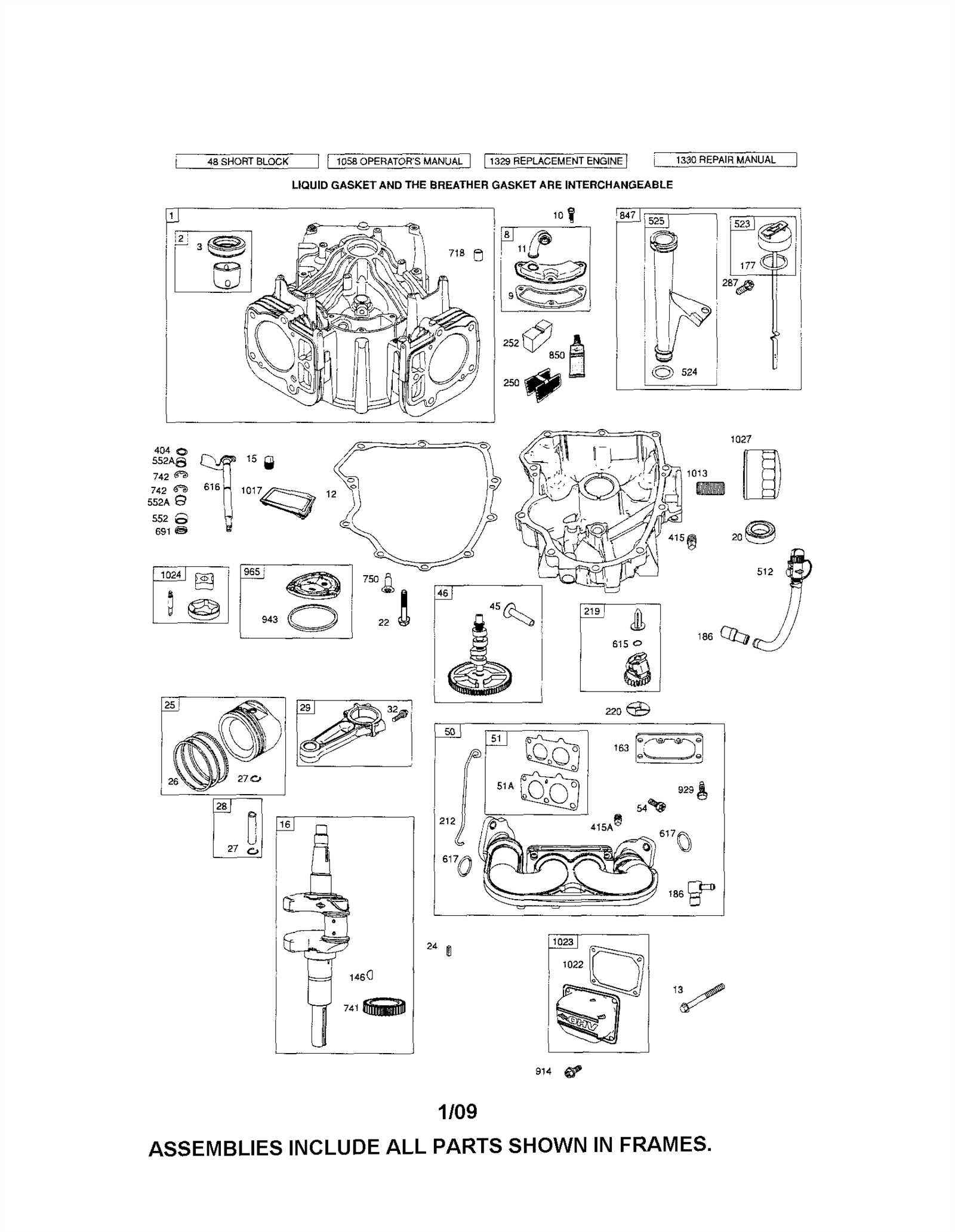

Engine System Breakdown for Yt3000

The motor system in this model is a complex yet efficient design, ensuring optimal performance and reliability. This section provides an overview of the key components that work together to power the machine, explaining their roles and how they contribute to the overall functionality. By understanding each part, one can better appreciate how the system operates and troubleshoot potential issues.

Main Components Overview

The engine is composed of various essential elements that collaborate to create a smooth-running system. Below is a list of the primary elements and their individual roles:

- Engine Block: The core structure that houses major parts, providing support and alignment.

- Carburetor:

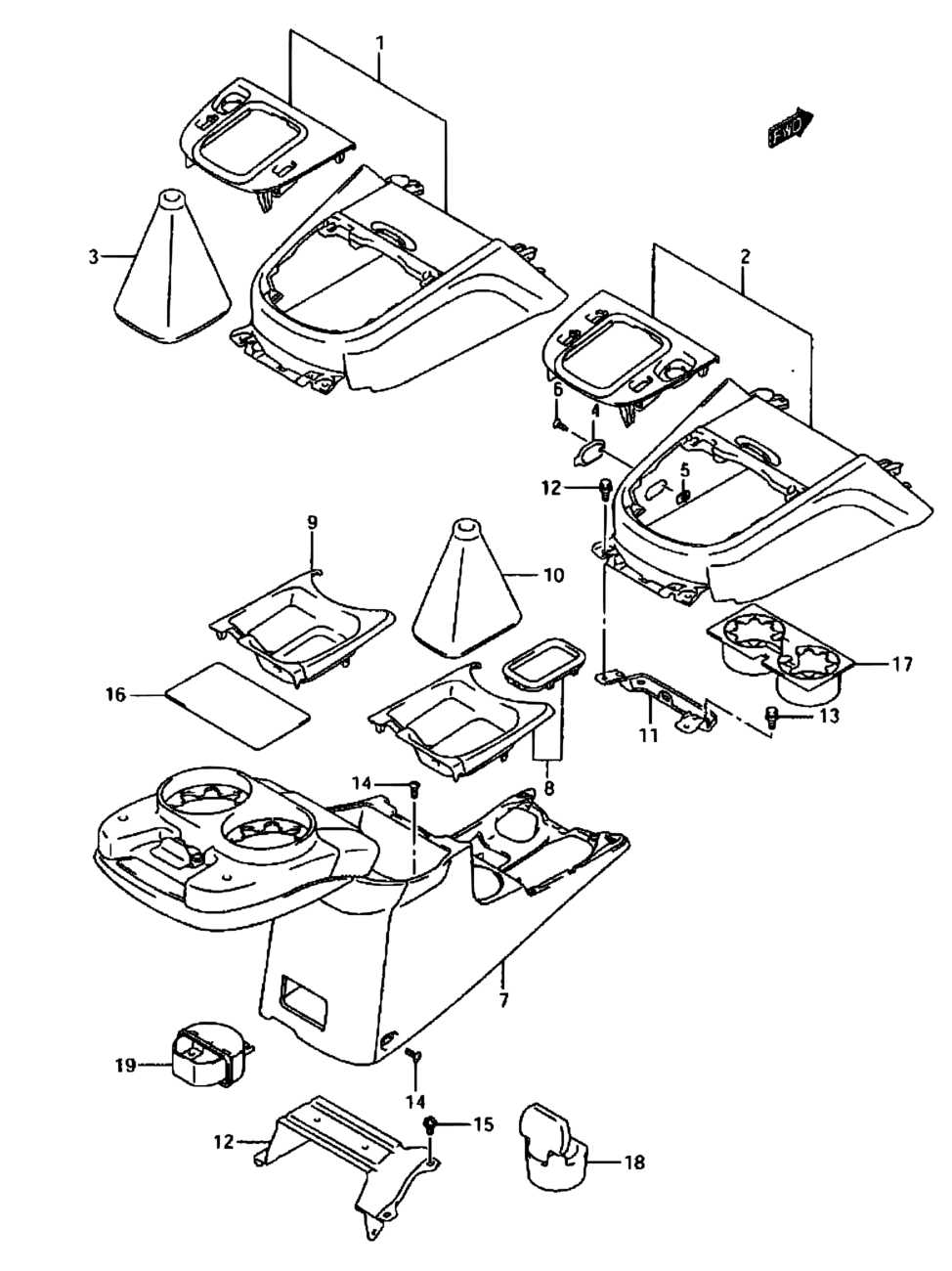

Transmission Assembly and Operation Guide

The transmission system plays a crucial role in ensuring smooth functionality by effectively transferring power from the engine to the wheels. Proper assembly and maintenance of this component are essential to guarantee optimal performance and longevity. This section provides an overview of how the system operates and the fundamental steps required to assemble it correctly.

Assembly Process: Start by carefully aligning the primary components of the system. It is important to ensure that each part is securely connected to prevent malfunctions during operation. Pay close attention to the alignment of gears and other moving elements to avoid unnecessary wear and tear.

Operation and Maintenance: Once assembled, regular checks and lubrication of the transmission are recommended. Routine inspections help in identifying potential issues early, allowing for timely adjustments or repairs. Keeping the system clean and well-lubricated will enhance its efficiency and reduce the

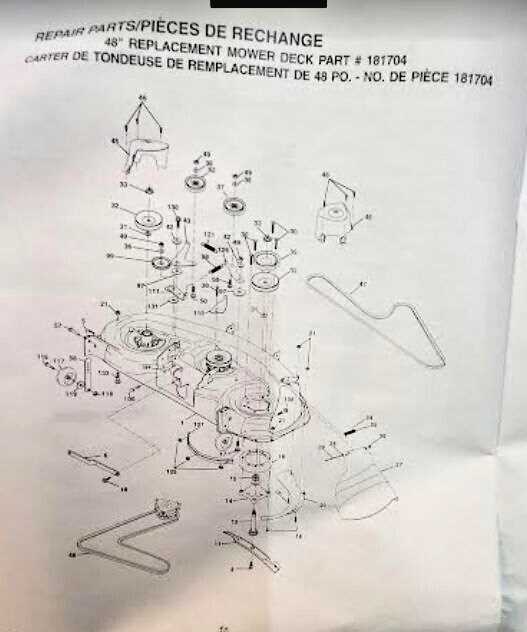

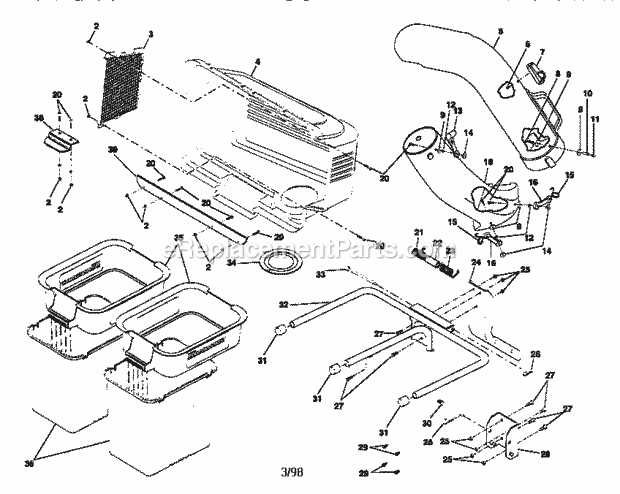

Deck and Blade Configuration Details

The layout and structure of the mowing deck, along with the arrangement of the cutting blades, play a crucial role in ensuring optimal grass trimming performance. Understanding how these components interact can help enhance the efficiency of the machine and extend its longevity.

Key Components of the Deck

- Deck Size: The width of the deck influences how much ground is covered in a single pass.

- Deck Material: Typically constructed from durable materials like steel, the deck must withstand regular wear and tear.

- Adjustable Height: A feature allowing for customization of cutting height to achieve desired grass length.

Blade Arrangement

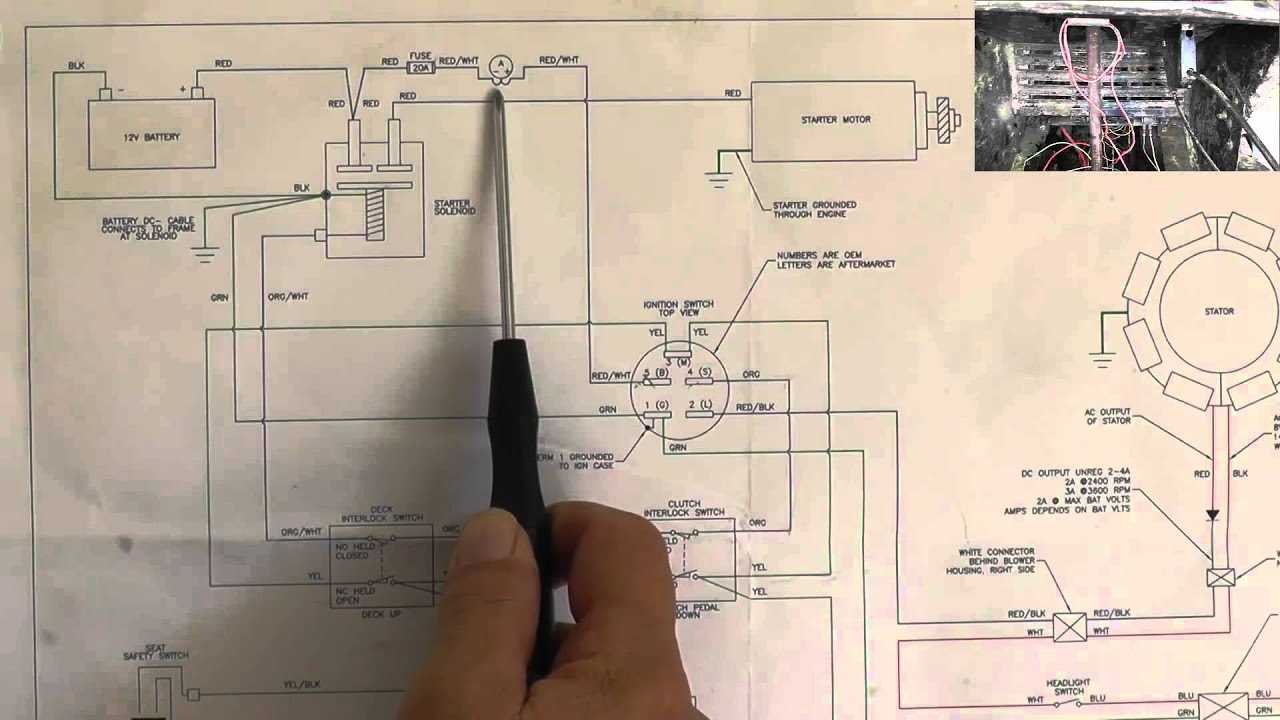

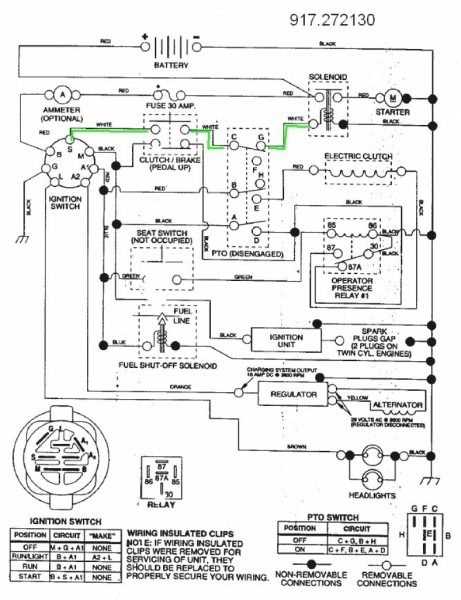

Electrical System Parts Explained

The electrical system in a machine is essential for ensuring proper functionality and efficiency. This section provides an overview of the key elements involved in managing and distributing electrical power, allowing various components to operate smoothly. Understanding these components is crucial for maintaining the system and troubleshooting potential issues.

Wiring and Connectors

The wiring serves as the backbone of the system, transmitting electrical signals between different units. Connectors, on the other hand, link these wires to the specific components, ensuring that the flow of current remains uninterrupted. Regular inspection of both wiring and connectors can help prevent disruptions or malfunctions.

Battery and Charging System

The battery supplies power to the entire setup, providing the necessary energy to start the machine and keep it running. The charging system replenishes the battery as the engine operates, ensuring that energy levels remain sufficient. Keeping the battery in good condition and ensuring the charging mechanism works efficiently are key to the longevity of th

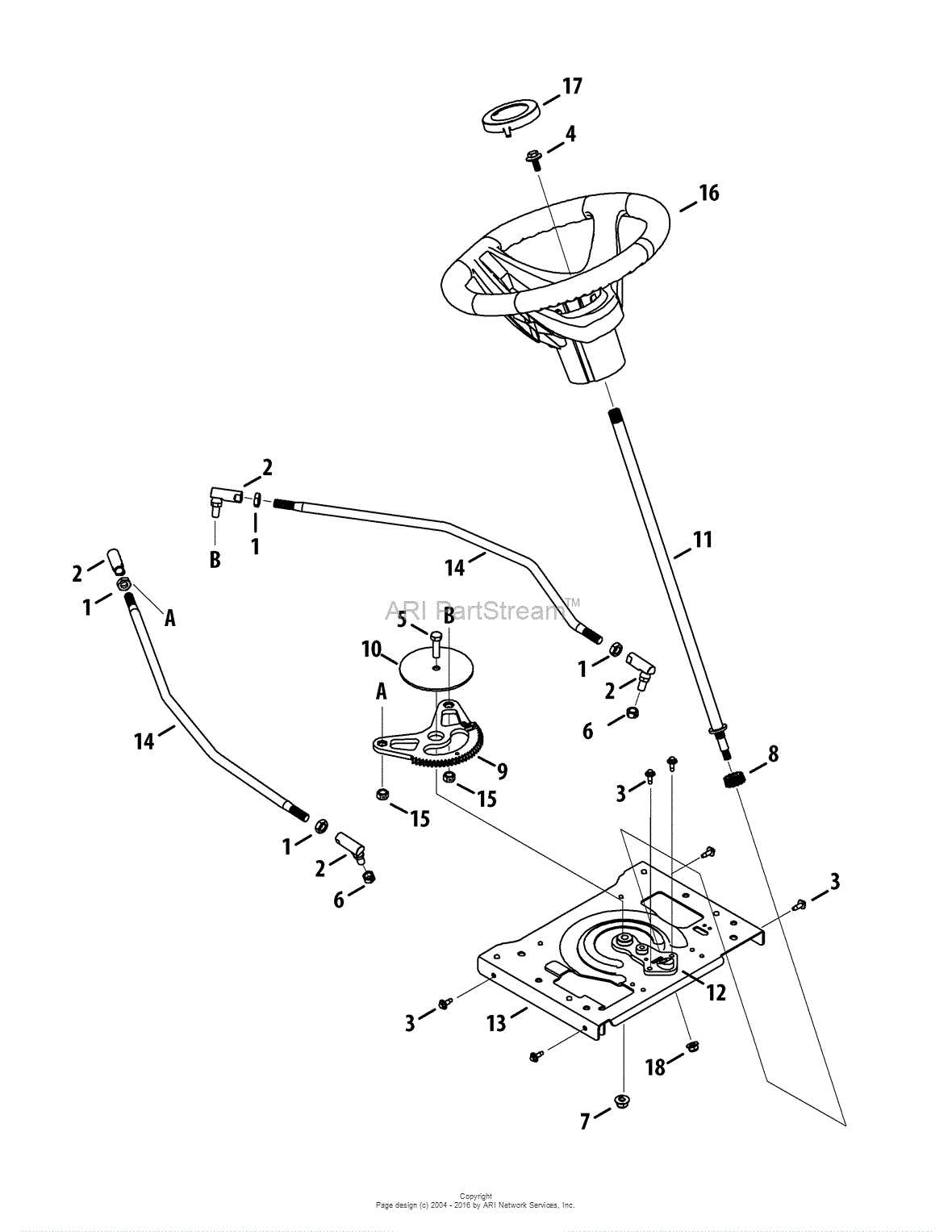

Steering Mechanism Layout for Yt3000

The steering system of a lawn tractor is crucial for ensuring smooth navigation and control during operation. This layout provides an overview of the key components and their arrangements, contributing to the effective steering performance. Understanding this configuration helps in identifying any potential issues and facilitates maintenance.

At the core of the steering assembly, you will find several essential elements that work in unison. Below is a breakdown of these components, their functions, and their relationships within the mechanism:

Component Description Steering Wheel The primary control device that allows the operator to guide the vehicle. Steering Shaft Connects the steering wheel to the gearbox, transmitting the operator’s input. Steering Gearbox Converts the rotational motion of the steering shaft into lateral movement for the wheels. Linkage System A series of rods and pivots that transfer motion from the gearbox to the wheel assembly. Wheels The final component that receives the steering input and changes direction accordingly. Each part plays a vital role in the overall functionality of the steering mechanism, ensuring that the user can navigate effortlessly across various terrains.

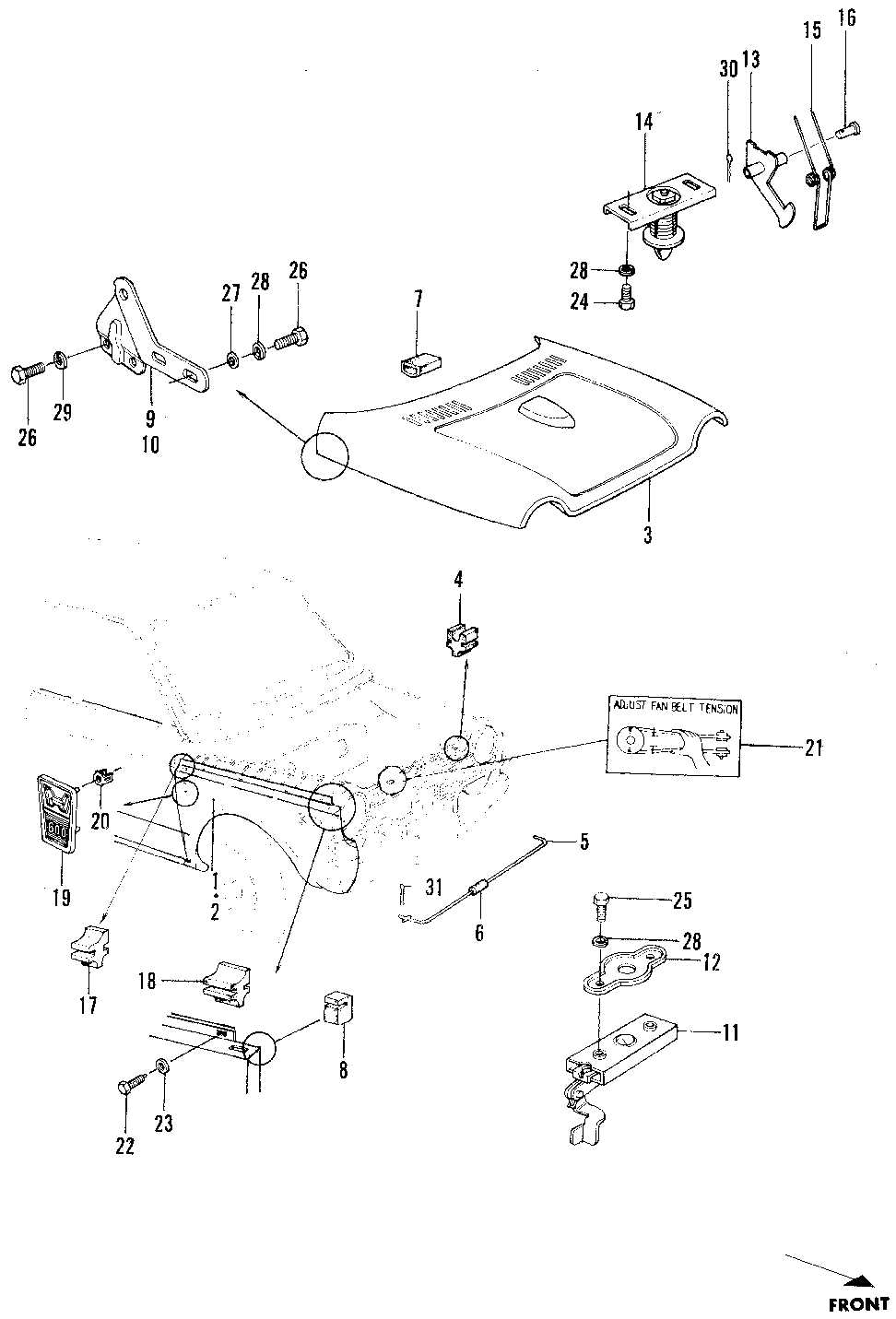

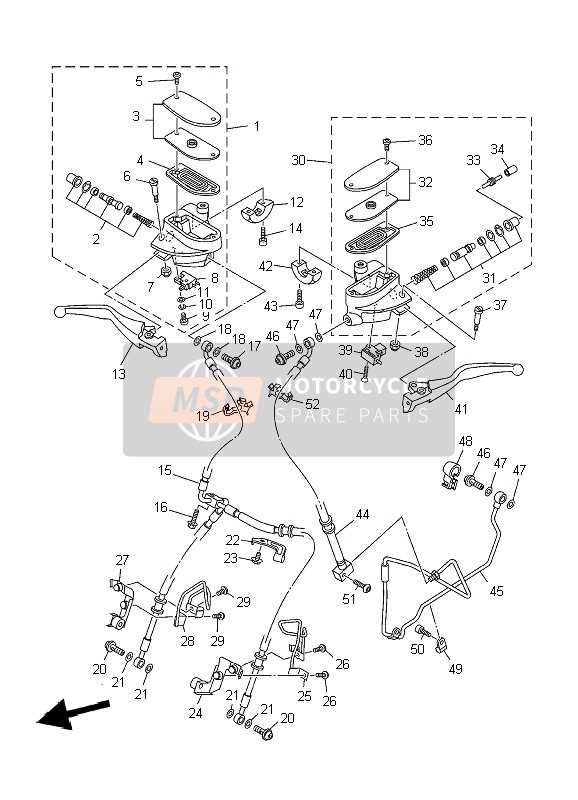

Understanding the Fuel System Design

The fuel system plays a crucial role in the overall functionality of small engines, ensuring the correct mixture of fuel and air is delivered for optimal performance. This section explores the fundamental components and workings of this essential system, shedding light on its significance in maintaining engine efficiency and reliability.

Key Components of the Fuel System

Several critical elements comprise the fuel delivery mechanism. Each component serves a specific purpose in managing fuel flow and maintaining the ideal mixture:

- Fuel Tank: Stores the fuel needed for operation.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Carburetor or Fuel Injector: Mixes fuel with air for combustion.

- Fuel Filter: Removes impurities to ensure clean fuel reaches the engine.

- Fuel Lines: Transport fuel between components.

Functionality and Importance

Understanding how these components interact is essential for diagnosing issues and performing maintenance. A well-designed fuel system ensures:

- Consistent fuel delivery for reliable engine start-up.

- Efficient combustion for improved power output.

- Minimized emissions for environmental compliance.

Regular inspection and maintenance of the fuel system are vital for the longevity and performance of the engine, highlighting the need for a comprehensive understanding of its design and operation.

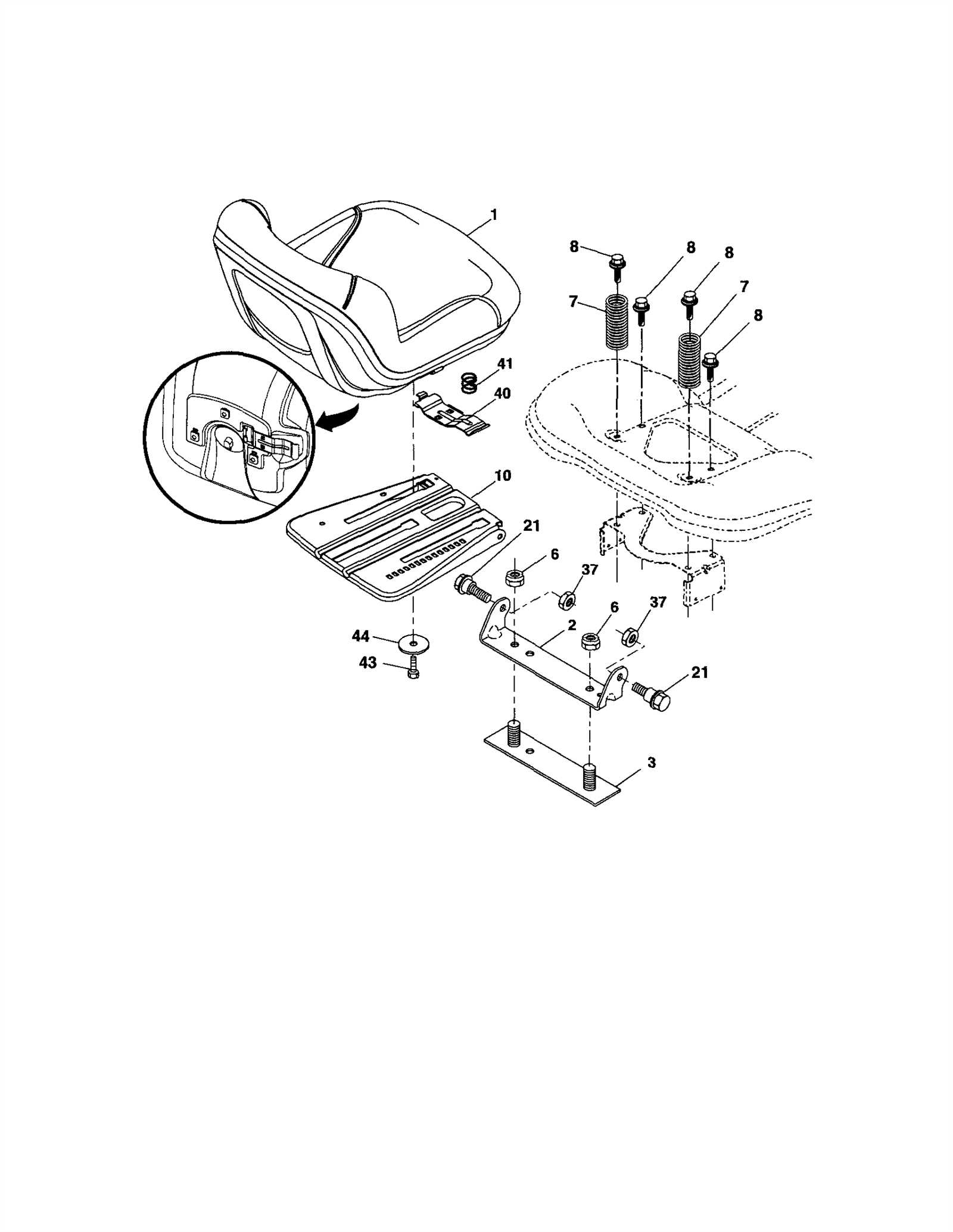

Seat and Comfort Features Breakdown

In modern machinery, the significance of seating arrangements and comfort-enhancing elements cannot be overstated. These features are designed not only to provide support during operation but also to ensure a pleasant user experience. Understanding the various components that contribute to seating comfort is essential for anyone looking to maximize their time spent using equipment.

Ergonomic Design

The ergonomic design of seating is paramount in reducing fatigue during prolonged use. Seats are often contoured to support the natural posture of the body, thereby minimizing strain on the back and hips. The inclusion of adjustable elements allows users to customize their seating position for optimal comfort.

Cushioning and Material Quality

High-quality cushioning materials play a crucial role in enhancing comfort levels. Foam padding, for example, absorbs vibrations and provides a softer sitting experience. Additionally, durable upholstery materials not only contribute to comfort but also ensure longevity and ease of maintenance, making the seating more user-friendly over time.

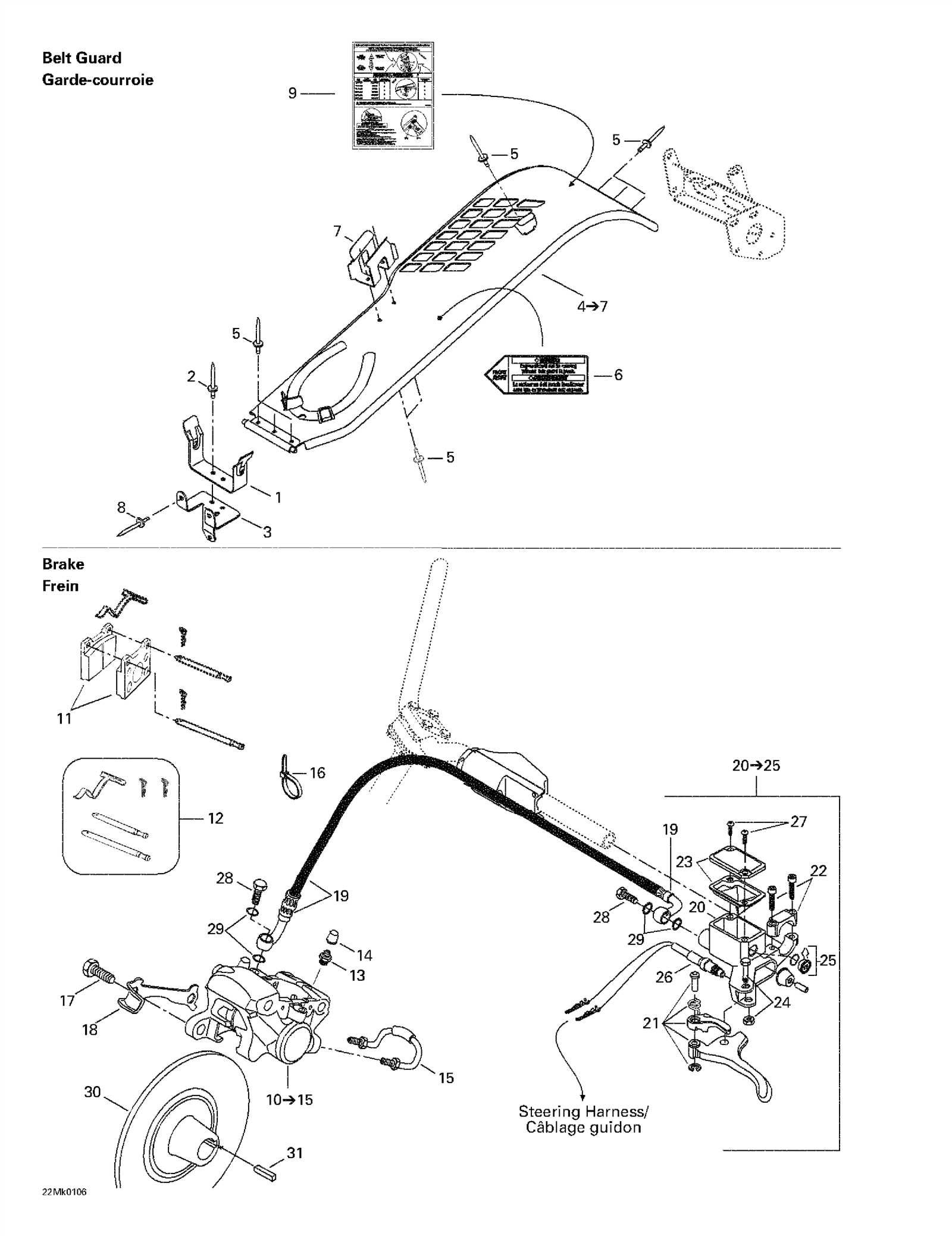

Exploring the Drive Belt Setup

The drive belt is a critical component in various machinery, facilitating power transmission between different elements. Understanding its arrangement is essential for ensuring optimal performance and longevity of the equipment. Proper installation and maintenance of the belt can prevent numerous operational issues.

When examining the configuration of the drive belt, consider the following aspects:

- Routing: The path the belt takes is crucial for effective operation. A clear route minimizes wear and enhances efficiency.

- Tension: Correct tensioning is vital. Too much slack can lead to slippage, while excessive tension may cause premature wear.

- Condition: Regular inspections for signs of wear, fraying, or damage help in maintaining functionality and avoiding breakdowns.

To ensure a successful setup, follow these guidelines:

- Consult the user manual for specific routing instructions.

- Check the tension using appropriate tools to ensure it meets specifications.

- Perform routine inspections to detect any potential issues early.

By adhering to these practices, you can enhance the efficiency and reliability of your equipment, ultimately leading to better performance and a longer lifespan.

Brake System Parts and Functions

The brake system is a critical component of any machinery, responsible for ensuring safety and control during operation. Understanding the various elements within this system can help users maintain and troubleshoot effectively. This section will explore the essential components, their roles, and how they contribute to the overall functionality of the braking mechanism.

Key Components of the Brake System

Each element of the braking mechanism plays a specific role, working together to provide effective stopping power. Here is an overview of the main components:

Component Function Brake Pads Friction material that presses against the rotor to slow down or stop movement. Brake Rotor The disc that the brake pads clamp down on to create friction and halt motion. Caliper Holds the brake pads and applies pressure to them against the rotor. Master Cylinder Converts force from the brake pedal into hydraulic pressure. Brake Lines Carry hydraulic fluid from the master cylinder to the calipers. Operational Overview

When the brake pedal is engaged, hydraulic fluid flows from the master cylinder through the brake lines to the calipers, causing them to press the brake pads against the rotor. This friction generates the necessary resistance to slow down or stop the equipment effectively. Regular inspection and maintenance of these components are essential for optimal performance and safety.

Maintenance Parts for Optimal Performance

Ensuring that your equipment operates efficiently requires attention to specific components that contribute to its overall functionality. Regular upkeep and the timely replacement of essential elements play a crucial role in maintaining peak performance and longevity.

Regular Inspection: Periodically examining critical components helps identify wear and tear before they lead to significant issues. Look for signs of deterioration, such as cracks or excessive rust, and address these concerns promptly.

Quality Replacements: When it comes time to replace any elements, opt for high-quality alternatives that meet or exceed manufacturer specifications. Utilizing superior substitutes not only enhances efficiency but also extends the lifespan of your equipment.

Proper Lubrication: Regularly applying suitable lubricants to moving parts minimizes friction, thereby reducing wear and improving operational smoothness. Ensure you use the recommended types of lubricants for optimal results.

Cleaning Practices: Keeping components clean from dirt and debris is essential for maintaining proper function. Develop a cleaning schedule to prevent buildup that can hinder performance and cause premature failure.

Storage Conditions: When your equipment is not in use, store it in a dry, climate-controlled environment. Proper storage protects against environmental factors that could damage sensitive elements.

By focusing on these maintenance strategies, you can ensure that your machinery continues to perform at its best for years to come.

Yt3000 Craftsman Model Diagram Interpretation

Understanding the visual representation of a machine can significantly enhance the maintenance and repair process. A well-structured illustration serves as a vital reference tool, allowing users to identify and locate components quickly. This section delves into the essentials of interpreting such a schematic, focusing on its various elements and their functions.

Key Components of the Visual Representation

- Labels: Each part is typically marked with labels that provide information about its function or specifications.

- Connections: Lines often illustrate how different parts are interconnected, indicating pathways for power or fluid flow.

- Grouping: Similar elements may be clustered together, which helps in understanding how they work collectively within the system.

Interpreting the Information

To effectively utilize the illustration, follow these steps:

- Begin by identifying the primary components, focusing on the core functionalities.

- Trace the connections between parts to grasp how they interact.

- Refer to the accompanying documentation for detailed explanations of each labeled item.

By mastering the interpretation of such visuals, users can streamline troubleshooting and enhance their overall efficiency.