This section provides an overview of the essential elements that contribute to the effective functioning of a lawn maintenance machine. By examining the layout of the various components, users can gain a clearer understanding of how each piece interacts within the overall system.

Comprehending the arrangement of these components is crucial for both troubleshooting and maintenance tasks. Familiarity with the configuration allows operators to identify potential issues, ensuring the equipment operates smoothly and efficiently.

Furthermore, having a clear picture of the different sections aids in the selection of suitable replacements when necessary. This knowledge empowers users to perform upkeep tasks with confidence, ultimately enhancing the lifespan of their lawn care equipment.

This section provides a comprehensive overview of a specific component crucial for optimal performance in various landscaping and maintenance tasks. Understanding the assembly and functionality of this equipment can significantly enhance efficiency and longevity, ensuring it operates at peak capability.

| Component Name | Description | Function |

|---|---|---|

| Blade | Essential cutting tool that shapes grass. | Provides a clean cut for healthy lawn growth. |

| Spindle | Rotates the blade, enabling movement. | Transmits power to the cutting tool. |

| Lift Lever | Adjusts the height of the cutting apparatus. | Allows customization for different grass lengths. |

| Chassis | Framework supporting all components. | Ensures stability and alignment during operation. |

| Belt | Connects the engine to the cutting mechanism. | Transmits power from the engine to the spindle. |

Overview of Deck Components

This section provides a comprehensive look at the essential elements that contribute to the functionality of the cutting assembly. Understanding these components is crucial for effective maintenance and optimal performance of the equipment.

Key Elements of the Assembly

The main components include blades, spindles, and housing, each serving a specific purpose. Blades are designed to deliver a clean cut, while spindles facilitate smooth rotation. The housing protects these elements and ensures proper alignment during operation.

Maintenance Considerations

Regular inspection and maintenance of these components are vital for prolonging the lifespan of the equipment. Keeping blades sharp and ensuring spindles are well-lubricated can significantly enhance cutting efficiency.

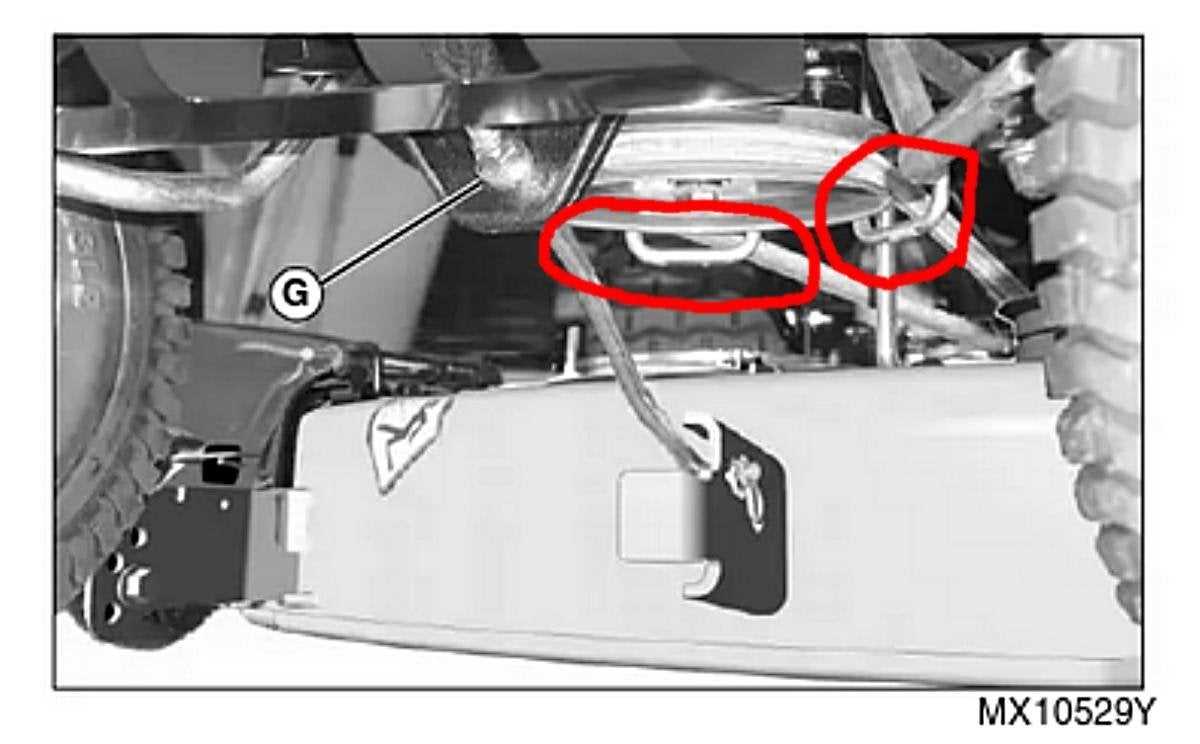

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in understanding complex machinery and components. They serve as visual aids that enhance comprehension, allowing users to navigate various elements effectively. This clarity is vital for both maintenance and repair tasks, as it minimizes errors and boosts efficiency.

Moreover, detailed representations facilitate better communication among technicians and users alike. When everyone involved has access to accurate visuals, it fosters a common understanding, reducing the likelihood of misunderstandings during service procedures. Investing time in creating and utilizing well-crafted illustrations ultimately leads to improved performance and longevity of equipment.

In addition, having reliable visual references can significantly shorten troubleshooting times. When individuals can quickly identify parts and their relationships, they can address issues more swiftly, leading to enhanced operational efficiency. In essence, the significance of well-designed visuals cannot be overstated, as they are fundamental to the successful upkeep of machinery.

Identifying Essential Parts

Understanding the fundamental components of your lawn equipment is crucial for effective maintenance and operation. By familiarizing yourself with these key elements, you can ensure optimal performance and longevity of the machine. This section will guide you through recognizing the primary sections and their functions.

| Component | Description |

|---|---|

| Frame | The sturdy structure that supports all other components and maintains stability during operation. |

| Cutting Blades | Sharp edges designed to efficiently trim grass, contributing to a clean and even lawn surface. |

| Drive Belt | A flexible band that transmits power from the engine to various moving parts, enabling functionality. |

| Wheels | Allow the equipment to maneuver across different terrains while providing support and balance. |

| Engine | The powerhouse that drives the entire machine, providing the necessary energy for operation. |

Common Issues with Deck Parts

When it comes to maintenance, certain challenges can frequently arise with various components. Understanding these typical problems can aid in early detection and prevent extensive damage. Below are some common concerns that users often face.

- Wear and Tear: Over time, components can experience significant deterioration due to regular use, leading to inefficiencies.

- Corrosion: Exposure to moisture and harsh conditions may result in rust, affecting functionality and longevity.

- Loose Connections: Vibration from operation can cause bolts and screws to loosen, leading to instability.

- Misalignment: Components may shift from their original positions, affecting performance and causing uneven operation.

- Build-Up of Debris: Grass clippings and dirt accumulation can hinder functionality, making regular cleaning essential.

Addressing these issues promptly can ensure optimal performance and prolong the lifespan of the machinery.

Replacement Parts and Compatibility

When it comes to maintaining your equipment, understanding the options for replacement components is essential. Ensuring that each element is suitable for your specific model enhances performance and longevity. Various alternatives exist, allowing for flexibility in sourcing the right items to meet your needs.

Finding Suitable Alternatives

Several manufacturers offer compatible components that match the specifications of your machinery. It is important to consider factors such as size, material quality, and functionality to ensure seamless integration. Checking compatibility can prevent potential issues and guarantee optimal performance.

Quality Assurance

Investing in high-quality alternatives is crucial for the overall health of your equipment. It is advisable to research reputable suppliers who provide reliable items. This practice not only safeguards your investment but also enhances the efficiency of your operations.

Maintenance Tips for Longevity

To ensure the lasting performance and efficiency of your equipment, regular upkeep is essential. Adopting effective maintenance practices can prevent potential issues and extend the lifespan of your machine.

Routine Inspections: Conduct periodic checks to identify wear and tear early. This includes examining belts, blades, and other critical components for signs of damage or deterioration.

Cleaning: Keep your machine free from debris and buildup. Regularly clean the exterior and interior parts to maintain optimal performance. Removing grass clippings and dirt prevents rust and promotes airflow.

Lubrication: Apply lubricant to moving parts as specified in the user manual. Proper lubrication reduces friction and minimizes wear, contributing to smoother operation.

Storage: When not in use, store your equipment in a dry, sheltered location. Protecting it from the elements will help prevent rust and damage, ensuring it remains in good working condition.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule outlined in the manufacturer’s manual. Regular servicing and timely part replacements are crucial for optimal functionality.

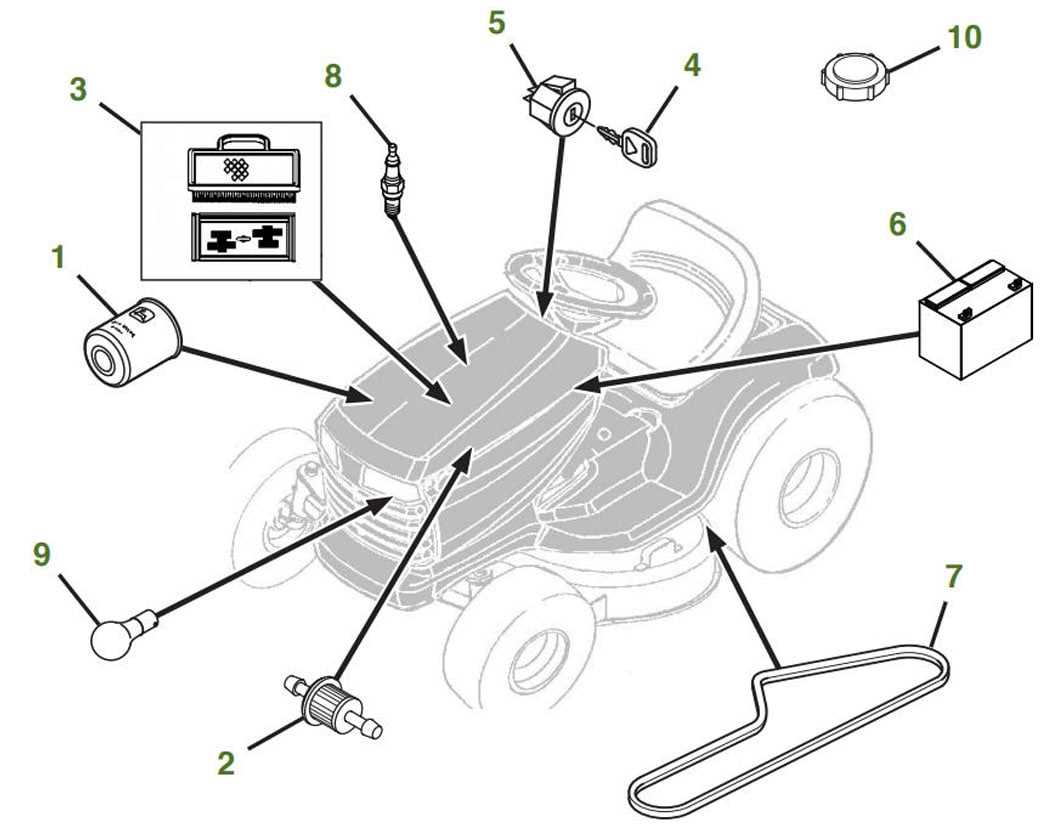

How to Read Parts Diagrams

Understanding visual representations of components can greatly assist in maintenance and repair tasks. These illustrations offer a simplified overview, allowing users to identify various elements quickly and efficiently. Familiarity with these visuals is essential for anyone looking to manage equipment effectively.

| Key Elements | Description |

|---|---|

| Legend | Contains symbols and terms used throughout the illustration, providing clarity on what each element represents. |

| Labels | Text associated with each part, typically indicating the name or function, helping users to easily locate components. |

| Numbers | Sequential identifiers that correspond to parts, often referenced in accompanying documentation for ordering or replacement purposes. |

| Connections | Lines or arrows that illustrate how different elements interact or fit together, crucial for understanding assembly or disassembly. |

Tools Needed for Replacement

When it comes to replacing components on your equipment, having the right tools is essential for a smooth and efficient process. Proper preparation ensures that the task can be completed safely and effectively, minimizing the risk of damage to the machinery.

Essential Equipment

To successfully carry out the replacement, you’ll need a variety of tools. Some of the most important items include:

- Wrenches: Both adjustable and socket varieties are necessary for loosening and tightening fasteners.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help in removing various screws.

- Torque Wrench: This tool ensures that nuts and bolts are tightened to the manufacturer’s specifications.

Safety Gear

Safety should always be a priority when performing any maintenance. Recommended safety gear includes:

- Gloves: Protect your hands from sharp edges and hot surfaces.

- Goggles: Shield your eyes from debris that may be dislodged during the process.

- Steel-toed Boots: Ensure your feet are protected from heavy equipment.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to the assembly process for your equipment. Following these instructions will help ensure that all components are correctly fitted together, promoting optimal performance and longevity. Each step is designed to guide you through the necessary procedures, emphasizing clarity and ease of understanding.

Begin by gathering all necessary tools and components before you start. Having everything at hand will streamline the assembly process and minimize disruptions. Carefully inspect each item to ensure they are in good condition, free of any defects that could hinder performance.

Next, refer to the assembly instructions, which will outline each step in detail. Start by connecting the primary structure, ensuring all bolts are tightened securely. Progressively add other elements, making sure to follow the sequence provided. Pay attention to alignment to guarantee a stable final setup.

Once all components are assembled, conduct a thorough inspection. Check for any loose connections or misalignments. It is advisable to perform a test run to ensure everything operates smoothly. Address any issues before finalizing the setup, as this will contribute to the overall efficiency and safety of the equipment.

Where to Buy Replacement Parts

Finding quality components for your equipment is essential for maintaining its performance and longevity. There are various options available for sourcing these items, ensuring you have access to the right solutions for your needs. Below are some common avenues to explore when seeking reliable replacements.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Dealers specifically licensed to sell official components. | Genuine quality, expert advice, and warranty support. |

| Online Retailers | Various e-commerce platforms offering a wide range of components. | Convenience, competitive pricing, and home delivery options. |

| Local Hardware Stores | Community shops providing essential supplies and equipment. | Immediate access, local support, and potential for personalized service. |

| Aftermarket Suppliers | Companies producing alternative components that meet or exceed original specifications. | Potential cost savings and a variety of options to choose from. |

FAQs About D170 Deck Parts

This section addresses common inquiries regarding the components associated with the specific model mentioned. Understanding these elements can enhance maintenance and troubleshooting, ensuring optimal performance and longevity.

| Question | Answer |

|---|---|

| What should I check for regular maintenance? | Routine inspection of blades, belts, and connectors is essential to maintain efficiency and avoid breakdowns. |

| How do I identify worn components? | Look for signs of damage such as fraying, cracks, or rust, which may indicate the need for replacement. |

| Where can I find replacement components? | Authorized dealers and online retailers offer a variety of quality replacements suited for your machine. |

| Is there a warranty for replacement items? | Typically, most replacement items come with a manufacturer’s warranty; check specific terms at the point of purchase. |

| Can I install new components myself? | Many users can perform installation with basic tools; however, consulting the user manual for guidance is recommended. |