When it comes to maintaining a reliable lawn care machine, a clear understanding of its essential components is crucial. The intricate assembly of various elements ensures optimal performance, and knowing how they interact can significantly enhance maintenance efforts. This section delves into the various segments that make up the cutting apparatus, providing a comprehensive overview for enthusiasts and professionals alike.

Detailed visual representations of the individual components can serve as invaluable tools for repairs and replacements. Familiarity with these elements not only aids in troubleshooting but also fosters a deeper appreciation for the engineering behind effective lawn maintenance. Whether you are a seasoned technician or a novice user, grasping the layout of these key components will empower you to tackle any challenge.

In this discussion, we will explore the specific roles and configurations of each segment, ensuring you have the knowledge needed to make informed decisions. By examining how each part fits into the larger system, you can enhance your understanding and care of your mowing equipment, ultimately leading to improved functionality and longevity.

Understanding the LT180 Lawn Mower

The LT180 model represents a blend of innovation and reliability in the realm of lawn maintenance. Designed for efficiency, it caters to homeowners seeking a robust solution for maintaining their green spaces. This machine combines user-friendly features with powerful performance, making it an ideal choice for both small and medium-sized lawns.

Key Features

Equipped with a strong engine, this mower ensures consistent cutting power, allowing users to tackle diverse grass types with ease. Its cutting width is optimized for rapid lawn care, reducing the time spent on maintenance tasks. Additionally, the intuitive controls enhance the user experience, providing comfort during operation.

Maintenance Tips

Regular upkeep is crucial for longevity. Simple tasks like checking the oil, cleaning the blades, and inspecting the belts can greatly extend the life of this mower. Keeping the air filter clean also ensures optimal performance, allowing the engine to function efficiently.

Final Thoughts

Investing in this model not only simplifies lawn care but also enhances the overall aesthetics of outdoor spaces. By understanding its features and maintenance needs, users can maximize its potential, ensuring a well-kept lawn season after season.

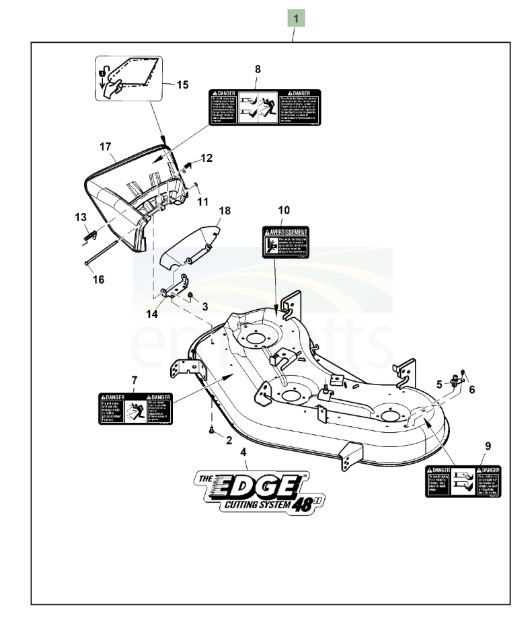

Essential Components of the Deck

The cutting mechanism of a lawn mower is crucial for achieving a well-manicured yard. Understanding the key elements involved in this assembly can greatly enhance maintenance and operational efficiency. Each component plays a specific role, ensuring that the equipment performs optimally while delivering a clean cut.

Cutting Blades

Blades are the heart of the cutting system. Their sharpness and design directly impact the quality of the cut. Regular inspection and timely replacement are vital for maintaining performance and preventing uneven trimming.

Spindle Assembly

The spindle assembly supports the blades and enables their rotation. This component must be kept well-lubricated to ensure smooth operation. Any signs of wear or damage should be addressed immediately to avoid further complications.

By familiarizing yourself with these essential elements, you can ensure that your lawn care equipment remains in excellent condition, providing the best results for your landscaping efforts.

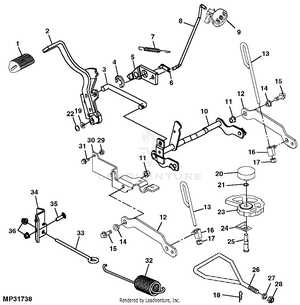

How to Read the Parts Diagram

Understanding an assembly illustration is essential for efficient maintenance and repairs. These visual representations simplify the identification of individual components and their relationships within the overall structure. Mastering this skill can lead to more effective troubleshooting and replacement of worn-out items.

Key Elements to Focus On

- Labels: Each component is often marked with a reference number or code, which corresponds to a list of items.

- Connections: Pay attention to lines or arrows indicating how parts are interconnected, as this can help in reassembly.

- Scale: Note any scale indicators to understand the size of the components relative to one another.

Steps for Effective Interpretation

- Start by familiarizing yourself with the layout and structure of the illustration.

- Locate the reference numbers and cross-check them with the accompanying list for detailed descriptions.

- Identify any special notes or tips that may highlight important assembly information.

- Take time to review the orientation of each part to ensure correct installation.

Common LT180 Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your lawn care equipment. By adhering to a few key practices, you can keep your machine running smoothly and efficiently throughout its life cycle.

Routine Checks

- Inspect the oil levels frequently and change the oil as recommended by the manufacturer.

- Check air filters and replace them if they appear dirty or clogged.

- Examine the spark plug and clean or replace it if necessary for better ignition.

- Look for any loose or damaged belts and replace them to prevent operational issues.

Seasonal Maintenance

- Sharpen blades at the beginning of each mowing season to ensure a clean cut.

- Clean the underside of the cutting unit to remove grass buildup, which can affect performance.

- Store equipment in a dry place during off-seasons to prevent rust and deterioration.

- Test the battery and clean terminals to maintain proper electrical function.

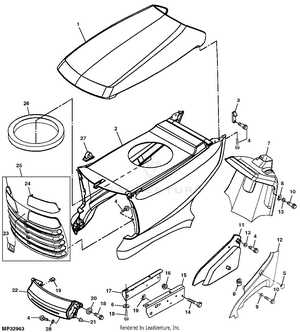

Identifying Worn Deck Parts

Recognizing components that have suffered from wear and tear is essential for maintaining optimal performance. Regular inspections can prevent larger issues and ensure that your equipment functions effectively. Understanding the signs of deterioration can save time and money in the long run.

Signs of Wear: Look for visible cracks, rust, or uneven surfaces. Components may show signs of excessive friction or misalignment. If you notice unusual noises during operation, it might indicate that certain elements need attention.

Routine Checks: Schedule regular assessments to identify problems early. Pay attention to the overall condition, including any loose connections or accumulated debris. Cleaning and maintaining your machinery can significantly extend its lifespan.

Replacement Considerations: When parts exhibit significant wear, consider replacing them promptly. Using high-quality replacements can enhance performance and reliability. Consult manufacturer guidelines for compatible options to ensure seamless integration.

Ordering Replacement Parts Online

When it comes to maintaining your machinery, sourcing new components online offers convenience and efficiency. This method allows users to easily find the necessary items without the hassle of visiting local retailers. With just a few clicks, you can compare prices, check availability, and ensure you are purchasing quality products tailored to your needs.

Finding Reliable Sources

To ensure a smooth purchasing experience, it’s essential to locate trustworthy websites that specialize in equipment supplies. Look for platforms with customer reviews and ratings, as these can provide insights into the reliability and quality of the items sold. Additionally, verify that the retailer offers secure payment options and a clear return policy, which adds an extra layer of confidence to your transaction.

Tips for Accurate Selection

Before placing an order, double-check the specifications of the components you need. Utilize available resources, such as manuals or online guides, to confirm compatibility with your machinery. This diligence will help prevent any costly mistakes and ensure that the replacement items function effectively. Don’t hesitate to reach out to customer support for clarification if needed.

Assembly Instructions for the Deck

Proper assembly of the mower’s cutting apparatus is essential for optimal performance and longevity. Follow these guidelines to ensure a smooth and efficient installation process.

- Gather all necessary components and tools before starting the assembly. This includes bolts, washers, and the required wrenches.

- Refer to the user manual for a comprehensive list of parts included in your set.

- Begin by positioning the frame on a stable surface, ensuring that it is clean and free of debris.

Next, follow these steps for assembly:

- Align the mounting brackets with the designated holes on the frame.

- Insert the bolts through the brackets and secure them with washers. Tighten them using the appropriate wrench, ensuring a snug fit without over-tightening.

- Attach the blades to the spindle assembly, making sure they are oriented correctly for effective cutting.

Finally, double-check all connections and ensure everything is secure. Regular maintenance checks will help prolong the lifespan of your equipment.

Deck Maintenance Tools You Need

Keeping your lawn care equipment in optimal condition requires the right tools for effective upkeep. A well-maintained apparatus not only enhances performance but also extends its lifespan. Understanding which implements are essential can make the process smoother and more efficient.

Essential Tools: Start with a reliable socket set to tackle any bolts or screws. A torque wrench ensures that everything is secured to the manufacturer’s specifications. Additionally, a comprehensive screwdriver set will assist in accessing hard-to-reach areas.

Cleaning Supplies: Regular cleaning is vital. Invest in a sturdy wire brush and a pressure washer for removing grass buildup. A good set of scrapers will help reach areas where debris tends to accumulate.

Lubricants and Fluids: Keep your equipment running smoothly with high-quality lubricants. Engine oil, grease, and other fluids are crucial for maintaining moving parts and preventing wear and tear.

Safety Gear: Don’t overlook the importance of personal safety. Use gloves, goggles, and sturdy footwear to protect yourself during maintenance tasks.

Equipped with these essential implements, you’ll ensure that your lawn care equipment remains in top shape, ready to tackle any task with ease.

Common Issues with LT180 Decks

When maintaining lawn equipment, various complications can arise, often affecting performance and efficiency. Identifying these common problems is essential for ensuring smooth operation and longevity of the machinery.

- Uneven Cutting: This issue is frequently encountered and can result from misalignment or worn-out components. Regular checks can help maintain proper height and balance.

- Clumping of Grass: Grass clumps can accumulate if the blades are dull or if the equipment operates under wet conditions. Keeping blades sharp and mowing in dry weather can mitigate this problem.

- Noise and Vibration: Unusual sounds or excessive vibration may indicate loose or damaged parts. Regular inspections and maintenance are crucial to address these concerns.

- Stalling: Frequent stalling can be attributed to fuel flow issues or blockages in the cutting system. Ensuring clean fuel lines and filters can prevent this disruption.

- Blade Wear: Over time, blades can become dull or chipped, leading to ineffective cutting. Routine sharpening and timely replacements are necessary to maintain performance.

By being aware of these common complications, users can take proactive measures to enhance the functionality and durability of their lawn care equipment.

Upgrading LT180 Deck Features

Enhancing the functionality of your mowing equipment can significantly improve its performance and user experience. By focusing on specific components, you can achieve a more efficient cutting process, leading to better results in lawn maintenance. This section explores various upgrades that can be implemented to elevate the capabilities of your machine.

Key Upgrades to Consider

- Improved Blades: Investing in high-quality, sharp blades can make a noticeable difference in cutting efficiency and grass health.

- Mulching Kit: Adding a mulching attachment allows for finer grass clippings, which can enhance lawn nutrition.

- Anti-Scalping Wheels: These help prevent uneven cuts, especially on uneven terrain, ensuring a consistent appearance.

- Height Adjustment System: A more precise height adjustment mechanism can offer greater control over cutting height, accommodating various grass types.

Maintenance Tips for Longevity

- Regularly inspect and sharpen blades to maintain cutting efficiency.

- Keep all moving parts well-lubricated to prevent wear and tear.

- Check for and replace worn components promptly to avoid further damage.

- Clean the area after each use to prevent grass buildup and rust.

By considering these enhancements and maintenance practices, you can ensure your mowing equipment remains in peak condition, providing a beautiful lawn and a satisfying mowing experience.

Resources for Further Learning

Expanding your knowledge about maintenance and repair for outdoor machinery can greatly enhance your understanding and skills. Whether you are a novice or a seasoned enthusiast, utilizing a variety of resources can help you troubleshoot and improve your equipment. Below are some valuable avenues for deepening your expertise in this area.

Online Communities and Forums

Engaging with online communities provides access to a wealth of shared experiences and advice. Websites and forums dedicated to outdoor equipment allow users to ask questions, share insights, and gain practical tips from fellow enthusiasts and professionals. These platforms often feature discussions on common issues, best practices, and innovative solutions.

Instructional Videos and Tutorials

Visual learning can be particularly effective when it comes to understanding machinery. Numerous platforms offer instructional videos that cover everything from basic maintenance to complex repairs. These tutorials often break down processes step by step, making it easier to follow along and apply what you learn directly to your own equipment.