Maintaining a lush and healthy lawn requires a thorough understanding of the various components that contribute to the efficiency of your equipment. This section provides insights into the essential elements that ensure optimal performance in your gardening tasks.

By exploring the layout and functions of these crucial components, users can enhance their familiarity with the machinery. This knowledge not only aids in effective operation but also facilitates timely maintenance and repairs, ultimately leading to improved results in lawn care.

Whether you’re a novice or a seasoned gardener, grasping the intricacies of your equipment is vital. Equip yourself with the necessary understanding to tackle any challenges that may arise during your gardening endeavors.

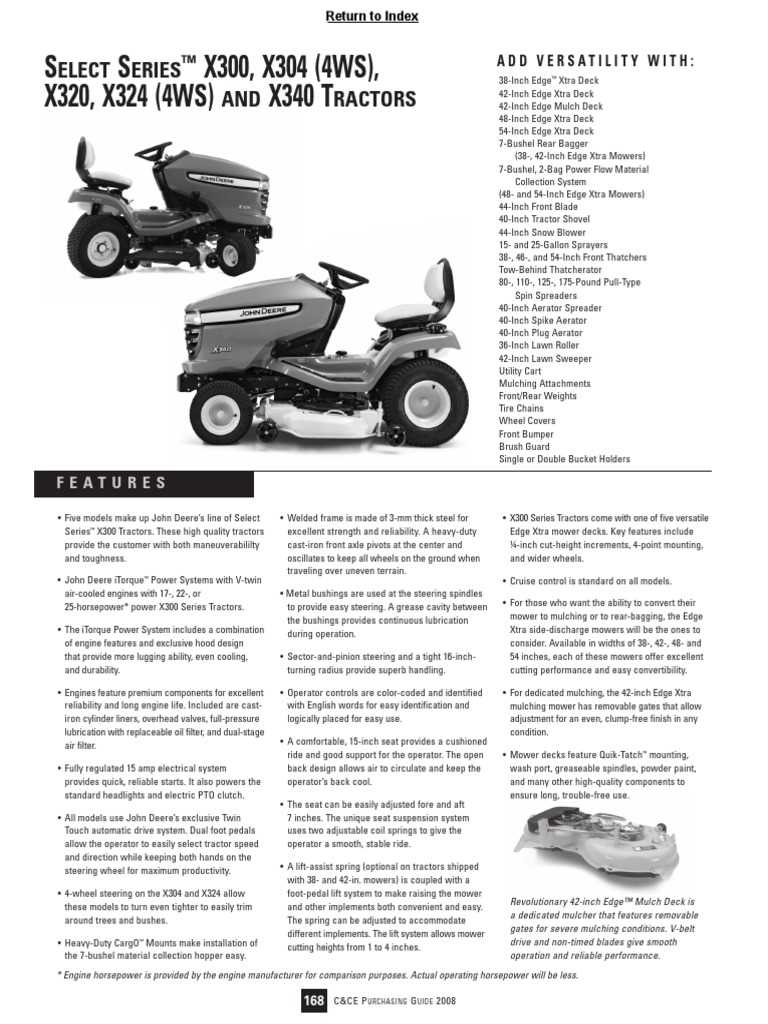

Understanding John Deere X320 Mower Deck

This section delves into the essential components and functionality of a specific cutting assembly utilized in lawn care machinery. It emphasizes the importance of understanding its construction and operational aspects for optimal performance and maintenance.

Key Components

- Blade assembly: Crucial for efficient cutting.

- Housing: Protects the internal mechanisms.

- Spindle: Facilitates blade rotation.

- Adjustment mechanisms: Allows for height modifications.

Maintenance Tips

- Regularly inspect blades for sharpness.

- Ensure proper lubrication of moving parts.

- Check for any debris accumulation.

- Adjust height settings according to grass type.

Components of the Mower Deck

The effectiveness of any cutting mechanism relies on its various elements, each playing a critical role in achieving optimal performance. Understanding these elements helps users maintain and troubleshoot the equipment efficiently.

Key Elements

Among the essential components are the cutting blades, which are responsible for achieving a clean cut. These blades must be sharp and properly aligned to ensure efficiency. Additionally, the housing structure provides support and stability during operation, preventing damage to the unit.

Support and Adjustment Mechanisms

Another important aspect includes the adjustment mechanisms, which allow users to modify the height of the cut. This ensures versatility for different types of terrain. Bearings and spindles also contribute to the overall functionality, enabling smooth rotation and reducing friction.

Common Issues with Mower Parts

Regular maintenance and understanding potential challenges are essential for optimal performance of any cutting equipment. Various components may face wear and tear over time, leading to decreased efficiency and functionality.

One frequent issue is blades dulling, which can result in uneven cutting and strain on the engine. Ensuring blades are sharpened regularly can mitigate this problem.

Another common concern involves belt wear. Over time, belts can fray or stretch, affecting the power transmission to the cutting mechanism. Regular inspection and timely replacement are crucial to avoid performance drops.

Additionally, issues with bearings can arise, causing noise and instability. Lubrication and replacement of worn bearings can help maintain smooth operation.

Lastly, filter clogging is a typical problem that may hinder airflow and reduce engine performance. Regular cleaning and replacement of filters ensure proper function and longevity of the equipment.

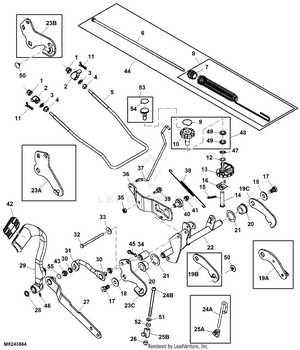

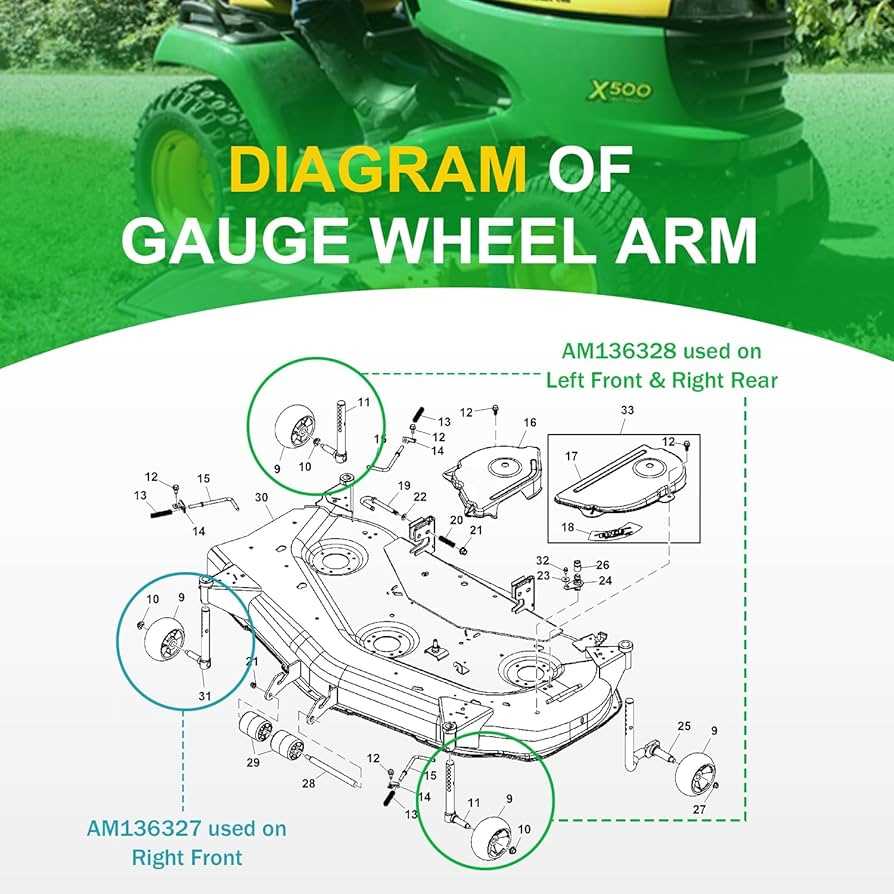

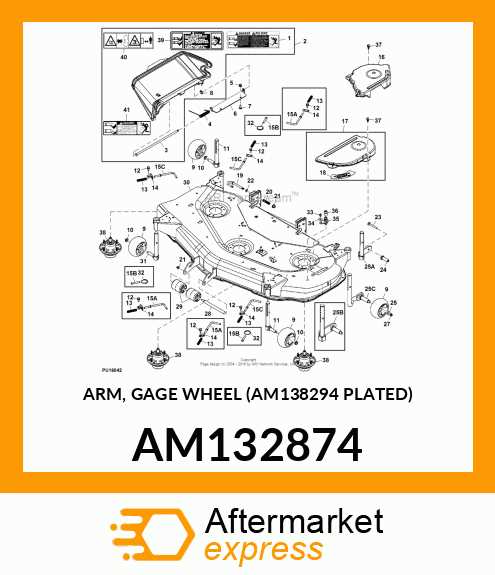

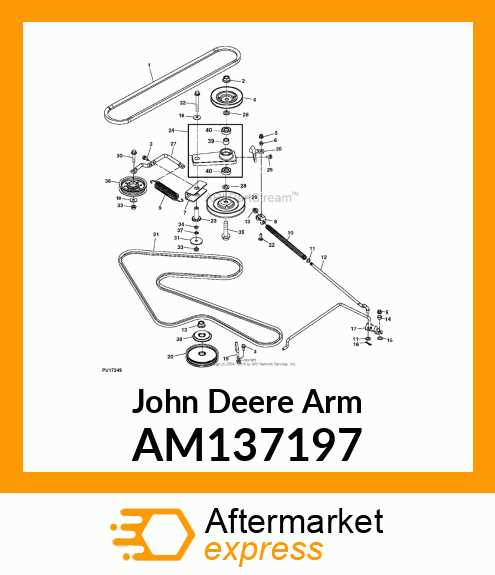

Identifying Replacement Parts

Understanding the various components of your equipment is crucial for efficient maintenance and operation. Recognizing when to replace specific elements can greatly enhance performance and longevity. This section aims to simplify the process of identifying necessary replacements.

Common Components to Check

Focus on frequently used elements such as blades, belts, and pulleys. Regular inspections of these items can prevent larger issues and ensure optimal functionality. Identifying wear and tear early on can save time and resources in the long run.

Utilizing Reference Guides

Consulting reference materials can provide detailed insights into each component’s specifications. Diagrams and charts can serve as valuable tools in matching the correct replacements to your machinery. By utilizing these resources, you can streamline the replacement process and maintain efficiency.

Maintenance Tips for Mower Deck

Proper care and upkeep of your cutting apparatus are essential for ensuring optimal performance and longevity. Regular attention to maintenance tasks can prevent common issues and enhance efficiency during operation.

Regular Cleaning: Keeping the cutting surface free from debris, grass clippings, and dirt is crucial. After each use, take the time to clean the underside to prevent buildup that can hinder performance.

Blade Sharpening: Dull blades can lead to uneven cuts and stress the engine. Sharpen the blades regularly to ensure a clean cut, promoting healthier grass and reducing wear on the equipment.

Inspection of Components: Regularly check all moving parts for wear and tear. Look for signs of damage or corrosion that may affect functionality. Addressing these issues early can save time and costs down the road.

Lubrication: Keep all pivot points and bearings well-lubricated to ensure smooth operation. This practice helps to reduce friction and wear, extending the lifespan of mechanical components.

Seasonal Maintenance: At the start of each season, perform a comprehensive inspection and servicing of your cutting apparatus. This includes checking belts, pulleys, and all mechanical systems to ensure everything is in working order.

Tools Required for Repairs

Proper maintenance and repair of lawn equipment require specific instruments to ensure efficient and safe operation. Using the right tools not only simplifies the repair process but also helps in achieving a professional finish.

Essential Tools

To effectively tackle repairs, certain essential tools should be readily available. Here is a list of commonly used instruments:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts. |

| Screwdriver Set | For adjusting various screws and fasteners. |

| Socket Set | For accessing hard-to-reach nuts and bolts. |

| Pliers | For gripping and manipulating components. |

| Torque Wrench | For applying precise torque to fasteners. |

Additional Recommendations

In addition to the essential tools, having a few supplementary items can enhance your repair experience. Safety gear, such as gloves and goggles, is crucial to protect yourself during maintenance tasks. A tool organizer can also be beneficial for keeping everything in order.

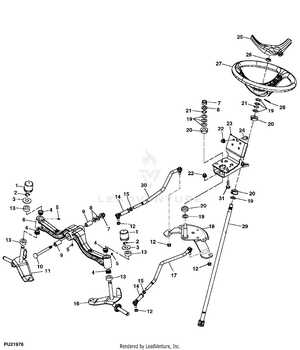

Assembly Instructions for Mower Parts

This section provides essential guidelines for putting together various components of your cutting machine. Proper assembly ensures optimal performance and longevity, allowing for a smoother operation during usage.

Preparation Steps

Before starting the assembly, gather all necessary tools and components. Ensure your workspace is clean and organized, allowing easy access to each item. Familiarize yourself with the individual elements to streamline the process.

Assembly Process

Begin by connecting the larger components, ensuring they fit securely together. Follow the manufacturer’s specifications for each connection to avoid future issues. Make sure to tighten all fasteners properly, as loose fittings can lead to malfunction. After completing the assembly, perform a thorough inspection to confirm everything is in place.

Safety Precautions During Maintenance

Ensuring a secure environment while conducting maintenance is crucial for preventing accidents and injuries. Adhering to safety guidelines not only protects the individual performing the tasks but also prolongs the lifespan of the equipment. Here are essential precautions to follow:

Personal Protective Equipment

- Wear sturdy footwear to avoid slips and falls.

- Use gloves to protect hands from sharp edges and moving parts.

- Ensure safety goggles are worn to shield eyes from debris.

Work Area Preparation

- Keep the workspace clean and free from clutter.

- Ensure adequate lighting to clearly see all components.

- Disconnect the power source before beginning any work.

By following these safety measures, individuals can effectively minimize risks during maintenance activities.

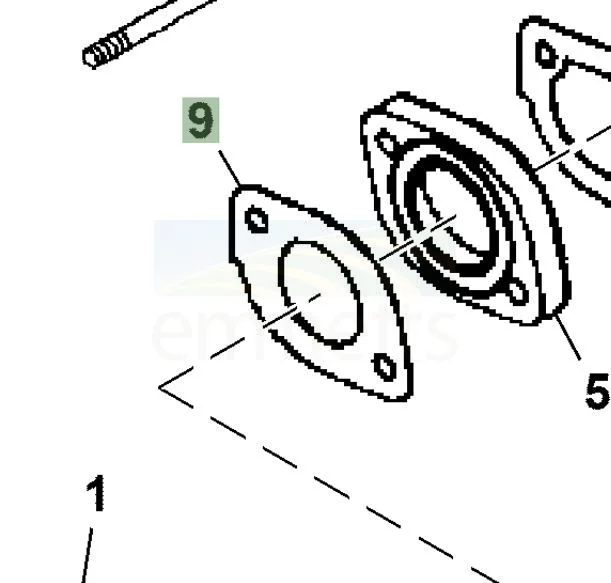

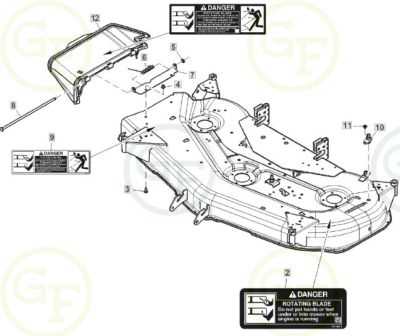

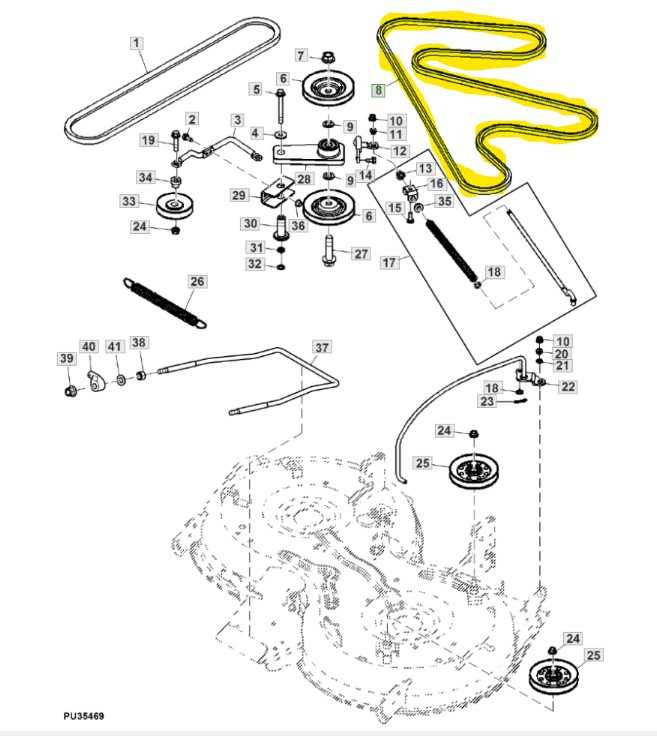

Diagram Overview of Mower Deck

This section provides a comprehensive look at the layout and components associated with the cutting mechanism of a lawn maintenance tool. Understanding the arrangement and functionality of each element is crucial for effective operation and maintenance.

Key Components Explained

Essential elements include the blade assembly, housing, and drive mechanisms. Each component plays a vital role in ensuring optimal performance and durability.

Maintenance Insights

Regular inspection and upkeep of these components can significantly enhance longevity. Identifying wear and tear early on is essential for maintaining efficiency.

Adjusting Mower Deck Height

Maintaining the appropriate cutting height is essential for achieving a healthy and visually appealing lawn. Proper adjustment ensures that grass is cut evenly and promotes robust growth. Here are key considerations for achieving the ideal height.

- Check the Manufacturer’s Recommendations: Refer to the guidelines provided by the equipment manufacturer for suggested cutting heights based on grass types.

- Measure Current Height: Use a ruler or measuring tape to determine the existing height of the grass before making adjustments.

- Adjusting Mechanism: Familiarize yourself with the height adjustment mechanism of your machine, which may include levers, pins, or knobs.

After understanding the current setup, follow these steps to modify the height effectively:

- Locate the adjustment mechanism, usually situated near the wheels.

- Loosen any necessary fasteners to enable height changes.

- Set the desired height using the adjustment features.

- Tighten all fasteners securely to maintain the new setting.

Finally, perform a test cut to verify that the grass is being trimmed to the desired height, making further adjustments as necessary.

Lubrication Guidelines for Mower Parts

Proper maintenance is essential for ensuring the longevity and efficiency of your cutting equipment. Regular lubrication of various components plays a crucial role in reducing wear and tear, preventing rust, and enhancing overall performance. Following appropriate guidelines helps in maintaining the optimal functionality of these machines.

Essential Lubrication Points

- Spindles: Regularly lubricate spindle bearings to ensure smooth rotation and minimize friction.

- Pivot Points: Apply grease to pivot areas to facilitate easy movement and prevent stiffness.

- Chain and Belt Drives: Lubricate chains and belts to reduce slippage and prolong their lifespan.

- Wheel Bearings: Ensure wheel bearings are adequately greased to support smooth operation and avoid overheating.

Recommended Lubrication Frequency

To maintain optimal performance, adhere to the following lubrication schedule:

- After every 25 hours of use, inspect and lubricate all critical components.

- Before seasonal storage, ensure that all moving parts are well-lubricated to prevent corrosion.

- Check lubrication levels monthly, especially during peak operational periods.

Finding OEM Parts for Replacement

Locating original equipment manufacturer components for your machinery is crucial for maintaining optimal performance and longevity. These authentic items ensure compatibility and reliability, making them the preferred choice for repairs.

When searching for these essential components, consider the following approaches:

- Check with authorized dealers who specialize in your equipment.

- Visit manufacturer websites to access official catalogs and listings.

- Explore trusted online marketplaces that focus on original parts.

- Consult forums and communities dedicated to equipment maintenance for recommendations.

Using OEM components not only guarantees a proper fit but also enhances the overall efficiency of your machinery, ultimately leading to better results in your tasks.

Customer Reviews of Mower Components

Feedback from users plays a crucial role in understanding the effectiveness of lawn care equipment. Reviews often highlight strengths and weaknesses, providing potential buyers with valuable insights.

Quality and Durability: Many users emphasize the longevity of these components, noting that well-made parts significantly enhance performance. Positive experiences often stem from robust materials that withstand heavy use.

Ease of Installation: Customers appreciate components that are straightforward to install. Clear instructions and compatibility with various models contribute to overall satisfaction, making maintenance tasks simpler.

Value for Money: Users frequently discuss the balance between cost and quality. Affordable options that do not compromise on efficiency receive high praise, demonstrating that quality components can be accessible.